EP0507294B1 - Arrangement pour nettoyage et dégraissage des pièces d'oeuvre - Google Patents

Arrangement pour nettoyage et dégraissage des pièces d'oeuvre Download PDFInfo

- Publication number

- EP0507294B1 EP0507294B1 EP92105674A EP92105674A EP0507294B1 EP 0507294 B1 EP0507294 B1 EP 0507294B1 EP 92105674 A EP92105674 A EP 92105674A EP 92105674 A EP92105674 A EP 92105674A EP 0507294 B1 EP0507294 B1 EP 0507294B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- installation according

- supply pipe

- pipes

- container

- cleaning

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23G—CLEANING OR DE-GREASING OF METALLIC MATERIAL BY CHEMICAL METHODS OTHER THAN ELECTROLYSIS

- C23G3/00—Apparatus for cleaning or pickling metallic material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B08—CLEANING

- B08B—CLEANING IN GENERAL; PREVENTION OF FOULING IN GENERAL

- B08B3/00—Cleaning by methods involving the use or presence of liquid or steam

- B08B3/02—Cleaning by the force of jets or sprays

Definitions

- the invention relates to a system for cleaning and degreasing workpieces of different types, preferably using an aqueous cleaning liquid.

- Such cleaning systems or apparatus are required for both manufacturing and service companies for cleaning workpieces from simple to very complex geometry.

- the workpieces can be present as individual parts or as bulk goods.

- a chamber cleaning machine in which the small components to be cleaned are introduced into a cleaning chamber by means of a basket trolley, in which, above the basket trolley, z. B. also in household machines known manner a circumferential nozzle tube with downward spray nozzles is arranged.

- Such a machine is not suitable for cleaning complicated workpieces and in particular for cleaning tightly packed bulk goods.

- the cleaning system known from US Pat. No. 4,370,992 is more suitable for this application, in which a drum is rotatably arranged in a closed chamber, into which the containers holding the bulk material can be inserted. Above the revolving drum, nozzle pipes are arranged, through whose nozzles directed towards the drum the cleaning liquid is sprayed for the purpose of spray cleaning.

- This cleaning system does not guarantee optimal cleaning, particularly in the case of workpieces of complex construction, in particular if an aqueous cleaning liquid is used while avoiding aggressive chemicals.

- the present invention proceeds in its construction a cleaning system of the type known from FR 2 597 767 A1, the features of which are common to the invention are specified in the preamble of claim 1.

- the parts loading unit according to claim 2 is proposed, which can advantageously be flooded with flood pipes according to claim 3.

- Such a system is universal for various cleaning tasks such as Spray, flood and immersion cleaning can be used.

- a workpiece carrier floor can be inserted into the parts loading unit, which is stationary in this case, while the spray cleaning unit performs a rotational movement around the parts loading unit while dispensing the cleaning liquid.

- shock-resistant individual parts can also be cleaned in the form of bulk goods, they can be placed in a container perforated walls and lid are introduced and this is inserted into the parts loading unit, which in turn is set in rotary motion.

- this parts loading unit is designed in the manner of a cage, so that the jets of the rotating spray cleaning unit strike the workpiece or the container to be cleaned at different angles.

- Claim 8 relates to an appropriate arrangement of the flood pipes.

- the invention proposes a very variable cleaning system which enables both spray cleaning in the permanently rotating system and flood cleaning, the workpieces to be cleaned being able to be present both in the form of individual parts and in batches. This creates all the prerequisites for the best possible cleaning results, even on a water chemical treatment basis achieve so that a consistently environmentally friendly concept can be realized with the system according to the invention. Despite the increasing variety of parts, almost all cleaning and degreasing problems can be solved in the industrial and craft sector.

- a particular advantage is that the usable space of the system according to the invention can be designed for workpiece carriers as well as for Euro standard containers with the dimensions 600 x 400 x 280 mm. Both closed and open-walled containers can be used depending on the drive of the parts loading unit.

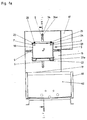

- FIGS. 1, 2, 3 and 4 A first exemplary embodiment shown in FIGS. 1, 2, 3 and 4 is explained in more detail below.

- the system for cleaning and degreasing workpieces according to the invention is, as illustrated with FIG. 1, housed in a closed chamber 10 which is placed on a base cabinet 60.

- the base cabinet 60 comprises a collecting container 62 with bath care devices for the cleaning liquid, which are not shown in detail.

- a control cabinet 61 accommodating the control is attached to the chamber 10.

- the cleaning liquid applied in the chamber 10 is essentially collected by the baffle plate 12 and passed through the outlet 19 into the collecting container 62.

- the workpieces or the like (not shown) to be cleaned are located in a container 50, which preferably has the size of a Euro standard container of 600 x 400 x 280 mm.

- the walls of the container 50 and its cover 51 inserted in a receptacle 24a are perforated so that cleaning fluid can penetrate into the interior of the container.

- the container 50 is part of a parts loading unit 20 which surrounds the container 50 in a cage-like manner and can be rotated about the central axis 0.

- the parts loading unit 20 is in turn surrounded by a spray cleaning unit 30, via whose nozzles 34a attached to nozzle tubes 34, cleaning liquid can be sprayed off in the direction of the container 50, as with the Rays S is indicated.

- This spray cleaning unit 30 can also be rotated about the central axis 0. By relative movement of the parts loading unit 20 and the spray cleaning unit 30, an optimal spray or spray cleaning can be realized.

- flood pipes 25 are arranged integrated with the guide rails 24 of the parts loading unit 20 above the opening of the container 50 above, through whose downward outlets 25 a cleaning liquid can be applied, as indicated by the arrows F. Closed-walled containers 50 or those with fine perforations are expediently used in the flood cleaning.

- both the parts loading unit 20 and the spray cleaning unit 30 can be set in rotation and both units have to be continuously supplied with cleaning liquid, special measures for the drive and the cleaning liquid supply are necessary, as is illustrated by the other figures.

- the container 50 with its cover 51 outside the chamber 10 is shown in FIG.

- the container 50 After filling with the workpieces to be cleaned, which can also be in the form of bulk material, it is to be moved into the parts loading unit 20 on the rails designed as roller conveyor 23 with rollers 23a in the direction of arrows a. If larger and / or shock-sensitive workpieces are to be cleaned, These can be fastened on the workpiece carrier base 52 with the aid of fastening means (not shown) and introduced into the parts loading unit 20 instead of the container 50.

- the lower rails designed as roller conveyor 23 and the upper rails 24, as can be seen in the view in FIG. 1, are arranged in the corner regions of the container 50 and are designed in such a way that the container is complete even when the parts loading unit 20 rotates through an angle of 360 ° is secured.

- the perforated container 50 can be closed at the top by an appropriately likewise perforated cover 51 which can be inserted into the cover receptacle 24a of the guide rails 24 and secured therein.

- the roller conveyors 23 and the guide rails 24 are connected on the drive side to a disk-shaped holder 21 and on the opposite side to a ring 22, through which the container 50 or the workpiece carrier base 52 is inserted. Since the parts loading unit 20 is thus cage-like, it is possible to apply cleaning fluid to the workpieces to be cleaned in almost any position, which is injected via the nozzle pipes 34 with their nozzles 34a.

- the cleaning liquid is supplied via the central connecting pipe 40, which, as will be explained with reference to the other figures, also serves as the drive shaft for the parts loading unit 20.

- the connecting pipe 40 At its end located inside the chamber 10, the connecting pipe 40 is connected in a rotationally fixed manner to the holder 21 by means of a connecting flange 27.

- Radially extending channels 26 are incorporated into the holder 21, which are connected at one end to outlet openings 47 of the connecting pipe 40 and at the other end to the flood pipes 25, which are arranged within the guide rails 24 and whose flood pipe outlets 25a are located above a container 50 to be inserted into the parts loading unit 20. This allows the container 50 to be flooded with cleaning fluid, provided that the connecting pipe 40 is closed at its end in the chamber with the shorter screw plug 42.

- the spray cleaning unit 30 is supplied with its nozzle pipes 34, the nozzles 34a of which are directed radially inwards, via the same connecting pipe 40.

- the connecting pipe has a number of outlet openings 41 distributed over the circumference of the pipe and via which the distributor pipes 32 of the spray cleaning unit 30 can be supplied with cleaning liquid.

- These distributor pipes in turn open into a distributor ring 33, in which the above-mentioned nozzle pipes 34 are inserted at an angle of 90 °.

- the distributor pipes 32 are inserted into bores 37 of a hub 31 rotatably mounted on the connecting pipe 40, the bores 41 of the connecting pipe 40 and the bores 37 of the hub 31 , in which the distribution pipes 32 are inserted, open into a common, internal annular groove 36.

- This annular groove 36 ensures a uniform supply of cleaning fluid even when the spray cleaning unit 30 is rotating.

- the device according to the invention is to be used for immersion cleaning, it is sufficient to place one in the parts loading unit To flood 20 inserted and in this case closed-walled containers via the flood pipes 25, while in this case the spray cleaning unit 30 does not have to be charged with cleaning liquid.

- the supply ducts and pipes for the flooding are dimensioned in such a way that they offer a lower flow resistance.

- the cross sections of the channels 26 and the flood pipes 25 and the diameters of the outlet openings 47 and the flood pipe outlets 25a are dimensioned much larger than the cross sections of the distributor pipes 32, the nozzle pipes 34 and the nozzles 34a and the bores 37. According to the principle of the smallest According to Le Chatelier, the hydraulic system pressure that occurs in this distribution system is reduced in the flood cleaning system, so that practically no cleaning liquid is released from the nozzles 34a of the spray cleaning unit.

- the direction of flow of the cleaning liquid is indicated in FIG. 4 by arrows b.

- the central supply of the cleaning liquid via the connecting tube 40 which also serves as the drive shaft, requires an exact and stable rotary mounting of the parts loading unit 20 and the spray cleaning unit 30 in view of the not inconsiderable torques.

- the hub 31 which is connected in a rotationally fixed manner to the spray cleaning unit 30, is slidably mounted in a slide bearing ring 14, which is attached to the chamber wall 13.

- support rollers 11 are provided within the cleaning chamber 10, on which the distributor ring 3 rests with its circumferential surface in a rolling manner.

- the connecting tube 40 which acts as the drive shaft for the parts loading unit 20, is mounted within the hub 31 with deep-groove ball bearings 38 arranged at an axial distance from one another. Further storage is provided on the distributor ring 33 of the spray cleaning unit 30, roller bearings 35, the rollers 35a of which bear against the circumferential surface of the holder 21 and are mounted on an axis 35b which are carried by carriers 35c fastened to the distributor ring 33. As the top view in FIG. 1 shows, three such roller bearings 35 are attached to the distributor ring 33 equidistantly from one another. In all roller bearings 35, the axis 35b is mounted eccentrically between the supports 35c, so that any radial play in the bearing during assembly or maintenance can be compensated for by rotating the axis.

- the rotary drive of the parts loading unit 20 is served by the electric motor 17 (see FIG. 2) attached to the chamber wall 13, the motor pinion 17a of which is via a transmission gearwheel 18 is in gear connection with the drive pinion 49, which is fixed on the connecting tube 40 with the aid of a hub shaft tensioning set 45, 46.

- the spray cleaning unit 30 is driven by the second electric motor 15 fastened to the upper part of the chamber wall 13, the motor pinion 15a of which is in transmission connection with the drive pinion 39, which is firmly connected to the hub 31, via the transmission gearwheel 16.

- the drive motors 15 and 17 as well as pumps (not shown in detail) and any devices for checking and maintenance of the cleaning liquid are controlled by control and regulation devices housed in the control cabinet 61 or monitored with suitable measuring devices.

- the supply of cleaning liquid, the z. B. is pumped out of the container 62 by means of circulating pumps, takes place via a line, not shown, which is fluid-tight but rotatably connected to the inlet pipe 44 of the connecting pipe 40.

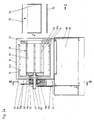

- FIGS. 1a, 2a, 3a, 4a A second exemplary embodiment shown in FIGS. 1a, 2a, 3a, 4a is explained in more detail below.

- the second embodiment corresponds to the first in terms of structure and mode of operation. For this reason, only the changes and the improvements achieved with them are described below.

- the parts that are the same as in the first exemplary embodiment have the same numbering.

- the baffle 12 is no longer present. It is through a whole spout 19 covering filter level not shown in the drawing replaced. The cleaning liquid applied in the chamber 10 is cleaned by this filter level and passes through this into the collecting container 62.

- the lid 51 can expediently be lowered into the container 50. This ensures that when the container 50 rotates, the loose workpieces within the component assembly unit 20 are largely fixed and are not damaged.

- the lid has a device, not shown in the drawing, which allows it to be secured within the container.

- the annular holder 21 is completely omitted.

- the spatial arrangement of the two flood pipes 25 with the guide rails 24 has remained the same.

- the supply of the cleaning liquid to the flood pipes 25 takes place via a radially extending feed pipe 121, which is attached above the outlet opening 47 of the connecting flange 127 and which branches at the other end in a T-shape and the two ends of the T-shaped branch with the flood pipes 25 connects.

- a further radially extending tube 121a is attached to the connecting flange 127, which also branches out in a T-shape and which serves as a holder for the roller conveyor 23.

- the connecting pipe 40 is closed at its end located in the chamber with two screw plugs 42 and 43, respectively.

- these two locking screws are replaced by a single selective locking screw 143.

- This selector lock screw 143 is milled in a semicircle in the middle. With the help of this selector screw 143, the outlet opening 47 can be either close or release so that the cleaning liquid reaches the radial feed line 121 and the flood pipes 25 via the connecting pipe 40.

- the distributor ring 33 is completely absent.

- the distributor pipes 32 are no longer connected to the distributor ring 33, but directly to the nozzle pipes 34 via a 90 ° elbow.

- This bearing hub 114 is designed as a roller bearing hub with the roller bearing 135 attached to the circumference and its associated roller axis 135a.

- the connecting tube which acts as the drive shaft for the parts loading unit 20, is mounted within the hub 131 with slide bearings 138 arranged at an axial distance from one another.

- the rotary drive of the parts loading unit 20 is provided by the electric motor 17 attached to the chamber wall 13 (cf. FIG. 2a), the motor pinion 17a of which is connected to the drive pinion 49 via a transmission element 118, which sits on the connecting pipe 40 and has a feather key connection.

- the second electric motor 15 attached to the upper part of the chamber wall 13 serves to drive the spray cleaning unit 30, which is in gear connection from the motor pinion 15a via the transmission element 116 to the drive pinion 39, which is fixedly connected to the hub 131.

- the power transmission from the two electric motors 15 and 17 to transmission elements 116 and 118 takes place via gear drive, chain drive or the like.

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Cleaning By Liquid Or Steam (AREA)

- Cleaning And De-Greasing Of Metallic Materials By Chemical Methods (AREA)

- Detergent Compositions (AREA)

Claims (20)

- Installation de nettoyage et de dégraissage de pièces, de préférence avec un liquide de nettoiement aqueux, consistant en une chambre fermée (10) un porte-pièces (20) disposé de façon à pouvoir tourner dans la chambre, une unité de nettoyage par projection (30) pouvant tourner autour de l'axe de rotation du porte-pièces, qui présente plusieurs tuyaux garnis de buse (34) à axes parallèles avec des buses de projection (34a) orientées sur les pièces, servant au nettoyage par projection, le liquide de nettoiement pouvant être amené par des tuyaux radiaux de distribution, qui sont reliés à un tuyau coaxial de raccordement (40), installation caractérisée en ce que le tuyau coaxial de raccordement (40) sert d'axe à l'unité de nettoyage par projection (30) et d'arbre d'entraînement au porte-pièces et en ce que le porte-pièces et l'unité de nettoyage par projection (30) peuvent être respectivement entraînés par des moteurs dans le même sens ou à contre-sens.

- Installation selon la revendication 1, caractérisée en ce que le porte-pièces est constitué sous la forme d'une unité d'alimentation en pièces (20), dans laquelle on peut insérer un récipient (50) le cas échéant perforé en partie ou totalement pour recevoir les différentes pièces séparées ou des produits en vrac.

- Installation selon la revendication 2, caractérisée en ce que l'unité d'alimentation en pièces (20) présente au-dessus du récipient (50) des tuyaux d'immersion qui sont reliés, par l'intermédiaire d'arrivées (26, 121) s'étendant à peu près radialement, au tuyau de raccordement (40).

- Installation selon la revendication 2 ou 3, caractérisée en ce que l'unité d'alimentation en pièces (20) présente à la manière d'une cage des barreaux (24, 23) s'étendant avec leurs axes parallèles, qui sont disposés au-dessus et en dessous ou sur le côté entre ces récipients, qui peuvent être introduits (50).

- Installation selon la revendication 4, caractérisée en ce que les barreaux (24, 23) sont fixés respectivement sur le côté d'entraînement de l'unité d'alimentation en pièces (20) sur un support (21, 212) et sont fixés du côté de l'alimentation sur un anneau (22).

- Installation selon la revendication 4 ou 5, caractérisée en ce que les barreaux qui soutiennent le récipient (50) par en dessous sont constitués comme des voies de roulement (23).

- Installation selon la revendication 4, 5 ou 6, caractérisée par des dispositifs servant à fixer le couvercle du récipient.

- Installation selon l'une des revendications 4 à 7, caractérisée en ce que les tuyaux d'immersion (25) sont intégrés dans les barreaux (24).

- Installation selon l'une ou plusieurs des revendications 2 à 8, caractérisée en ce que le tuyau de raccordement (40) présente un ajutage d'arrivée ouvert axialement (44) et des orifices de sortie radiaux (41, 47), qui sont disposés dans le sens axial les uns derrière les autres et débouchent dans les tuyaux de distribution (32) de l'unité de nettoyage par projection (30) ainsi que les entrées (26, 121) de l'unité d'alimentation en pièces (20).

- Installation selon la revendication 9, caractérisée en ce que la section transversale opérationnelle des tuyaux d'immersion (25) avec ses sorties (25a), les canaux (26) et les orifices de sortie des tuyaux de raccordement (47) associés à ceux-ci, est plus grande que celle des tuyaux garnis de buses (34) avec leurs buses (34a), des tuyaux de distribution (32) et des orifices de sortie des tuyaux de raccordement (41) associés à ceux-ci.

- Installation selon la revendication 10, caractérisée en ce que les orifices de sortie des tuyaux de raccordement (47) alimentant les tuyaux d'immersion (25) peuvent être raccordés de préférence au moyen d'une vis de fermeture (43, 142) pouvant être insérée dans le tuyau de raccordement (40).

- Installation selon l'une ou plusieurs des revendications 2 à 11, caractérisée en ce que le tuyau de raccordement (40), qui est relié de façon solidaire en rotation par son extrémité mise à l'intérieur de la chambre (10) à l'unité d'alimentation en pièces (20), présente en dehors de la chambre (10) un pignon d'entraînement (49) se trouvant en liaison motrice avec un moteur d'entraînement (17) et un ajutage d'arrivée (44) pouvant être relié, de façon à pouvoir tourner mais en étant étanche aux liquides, à un tuyau d'alimentation.

- Installation selon la revendication 12, caractérisée en ce que l'on dispose de façon coaxiale au tuyau de raccordement (40) un moyeu (31, 131) de façon à ce qu'il puisse tourner, moyeu qui présente à l'intérieur de la chambre (10) des perçages (37), situés en regard des orifices de sortie (41) du tuyau de raccordement (40), dans lesquels sont insérés les tuyaux de distribution (32) de l'unité de nettoyage par projection (30) et en ce qu'en dehors de la chambre (10) repose sur le moyeu (31) un pignon d'entraînement (39) qui est en liaison motrice avec un moteur d'entraînement (15).

- Installation selon la revendication 13, caractérisée en ce que le moyeu (31) présente sur la surface enveloppe tournée vers le tuyau de raccordement (40) une rainure annulaire (36), dans laquelle débouchent les ouvertures de sortie (41) du tuyau de raccordement (40) ainsi que les tuyaux de distribution (32) de l'unité de nettoyage par projection (30).

- Installation selon la revendication 13 ou 14, caractérisée en ce qu'entre le moyeu (31, 131) et le tuyau de raccordement (40) sont disposés au moins un palier, de préférence deux paliers (38, 138) à une certaine distance l'un de l'autre et en ce que le moyeu (31) est monté dans un palier (14, 114) prévu sur la paroi de la chambre (13).

- Installation selon la revendication 15, caractérisée en ce que le support (21) de l'unité d'alimentation en pièces (20) s'appuie en roulant par sa surface périphérique sur des roulements à rouleaux (35) répartis sur le pourtour, roulements qui sont placés sur l'anneau de distribution (33).

- Installation selon la revendication 16, caractérisée par trois roulements à rouleaux (35) disposés sensiblement équidistants l'un de l'autre, qui sont réglables axialement par rapport à l'axe de rotation.

- Installation selon l'une ou plusieurs des revendications 1 à 17, caractérisée en ce que les tuyaux de distribution (32) de l'unité de nettoyage par projection (30) sont reliés aux tuyaux garnis de buses (34) par un anneau de distribution (33), qui s'appuie à l'intérieur de la chambre (10) par sa surface périphérique sur des rouleaux d'appui (11).

- Installation selon l'une ou plusieurs des revendications 1 à 18, caractérisée en ce que l'on dispose un plan de filtration sur un réservoir collecteur (62) pour le liquide de nettoiement.

- Installation selon l'une ou plusieurs des revendications 2 à 19, caractérisée en ce que l'on peut enfoncer et fixer un couvercle (51) dans le récipient (50).

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4111099A DE4111099C1 (fr) | 1991-04-05 | 1991-04-05 | |

| DE4111099 | 1991-04-05 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0507294A1 EP0507294A1 (fr) | 1992-10-07 |

| EP0507294B1 true EP0507294B1 (fr) | 1994-08-17 |

Family

ID=6428909

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP92105674A Expired - Lifetime EP0507294B1 (fr) | 1991-04-05 | 1992-04-02 | Arrangement pour nettoyage et dégraissage des pièces d'oeuvre |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0507294B1 (fr) |

| AT (1) | ATE110012T1 (fr) |

| DE (2) | DE4111099C1 (fr) |

Cited By (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1640077A2 (fr) | 2004-09-27 | 2006-03-29 | MAFAC ERNST SCHWARZ GmbH & Co. KG MASCHINENFABRIK | Dispositif et méthode pour le traitement par nettoyage et/ou sèchage d'articles |

| EP2130614A1 (fr) | 2008-06-05 | 2009-12-09 | MAFAC ERNST SCHWARZ GmbH & Co. KG MASCHINENFABRIK | Dispositif de traitement pour pièces |

| EP2156905A1 (fr) | 2008-08-22 | 2010-02-24 | MAFAC ERNST SCHWARZ GmbH & Co. KG MASCHINENFABRIK | Dispositif de traitement pour pièces d'usinage |

| DE102014107063A1 (de) | 2014-05-19 | 2015-11-19 | Mafac Ernst Schwarz Gmbh & Co. Kg Maschinenfabrik | Behandlungsvorrichtung für Werkteile mit einer elektrischen Behandlungseinheit |

| EP3718652A1 (fr) | 2019-04-04 | 2020-10-07 | MAFAC ERNST SCHWARZ GmbH & Co. KG | Procédé de nettoyage et dispositif de nettoyage |

Families Citing this family (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4342555A1 (de) * | 1993-12-14 | 1995-06-22 | Guenther Zippel Maschf | Einrichtung zum Reinigen von industriellen Teilen |

| DE9416129U1 (de) * | 1994-10-06 | 1994-12-22 | Eduard Schedel GmbH, 88486 Kirchberg | Reinigungsvorrichtung für Werkzeuge, Werkstücke und ähnliche Kleinteile |

| DE19714603C1 (de) * | 1997-04-09 | 1998-10-29 | Schwarz Ernst Mafac Gmbh | Verfahren und Vorrichtung zur Reinigung von Werkstücken |

| DE10212604B3 (de) * | 2002-03-21 | 2004-01-22 | Mafac Ernst Schwarz Gmbh & Co. Kg | Vorrichtung zur Aufnahme eines Werkstückträgers und zur Zuführung eines ersten und zweiten Mediums und Reinigungsbehälter mit einer solchen Vorrichtung |

| DE10216285B4 (de) * | 2002-04-12 | 2012-03-29 | Mafac Ernst Schwarz Gmbh & Co. Kg Maschinenfabrik | Reinigungsvorrichtung zur Reinigung von Werkstücken |

| DE102010011738B4 (de) * | 2010-03-17 | 2017-09-14 | Piller Entgrattechnik Gmbh | Waschanlage zum Waschen von Werkstücken |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2639453A1 (de) * | 1976-09-02 | 1978-03-09 | Franz Josef Loecke | Rotations-reinigungsvorrichtung |

| DE3429369A1 (de) * | 1984-08-09 | 1986-02-20 | Stohrer-Doduco GmbH & Co, 7250 Leonberg | Fluessigreinigungsanlage |

| DE3436865A1 (de) * | 1984-10-08 | 1986-06-12 | Ulrich 8402 Neutraubling Klotzki | Vorrichtung zum reinigen von flaschenkaesten o.dgl. |

| DE3519757C2 (de) * | 1985-06-01 | 1994-06-01 | Guenther Zippel Maschf | Kammerreinigungsmaschine |

| FR2597767A1 (fr) * | 1986-04-24 | 1987-10-30 | Bertagna Hugo | Procede de nettoyage par aspersion de solutions aqueuses ou autres d'elements ou pieces mecaniques a la sortie des machines de fabrication |

| US5022419A (en) * | 1987-04-27 | 1991-06-11 | Semitool, Inc. | Rinser dryer system |

-

1991

- 1991-04-05 DE DE4111099A patent/DE4111099C1/de not_active Expired - Fee Related

-

1992

- 1992-04-02 AT AT92105674T patent/ATE110012T1/de active

- 1992-04-02 DE DE59200380T patent/DE59200380D1/de not_active Expired - Lifetime

- 1992-04-02 EP EP92105674A patent/EP0507294B1/fr not_active Expired - Lifetime

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP1640077A2 (fr) | 2004-09-27 | 2006-03-29 | MAFAC ERNST SCHWARZ GmbH & Co. KG MASCHINENFABRIK | Dispositif et méthode pour le traitement par nettoyage et/ou sèchage d'articles |

| DE102004046802B3 (de) * | 2004-09-27 | 2006-04-27 | Mafac Ernst Schwarz Gmbh & Co. Kg Maschinenfabrik | Behandlungsvorrichtung und Verfahren zur reinigenden und/oder trocknenden Behandlung von Werkstücken |

| EP2130614A1 (fr) | 2008-06-05 | 2009-12-09 | MAFAC ERNST SCHWARZ GmbH & Co. KG MASCHINENFABRIK | Dispositif de traitement pour pièces |

| EP2130615A1 (fr) | 2008-06-05 | 2009-12-09 | MAFAC ERNST SCHWARZ GmbH & Co. KG MASCHINENFABRIK | Dispositif de traitement pour pièces |

| EP2156905A1 (fr) | 2008-08-22 | 2010-02-24 | MAFAC ERNST SCHWARZ GmbH & Co. KG MASCHINENFABRIK | Dispositif de traitement pour pièces d'usinage |

| DE102014107063A1 (de) | 2014-05-19 | 2015-11-19 | Mafac Ernst Schwarz Gmbh & Co. Kg Maschinenfabrik | Behandlungsvorrichtung für Werkteile mit einer elektrischen Behandlungseinheit |

| WO2015176954A1 (fr) | 2014-05-19 | 2015-11-26 | Mafac Ernst Schwarz Gmbh & Co. Kg Maschinenfabrik | Dispositif de traitement de pièces équipé d'une unité de traitement électrique |

| DE102014107063B4 (de) * | 2014-05-19 | 2017-02-16 | Mafac Ernst Schwarz Gmbh & Co. Kg Maschinenfabrik | Behandlungsvorrichtung für Werkteile mit einer elektrischen Behandlungseinheit |

| US10583470B2 (en) | 2014-05-19 | 2020-03-10 | Mafac Ernst Schwarz Gmbh & Co. Kg Maschinenfabrik | Treatment device for workpieces, comprising an electric treatment unit |

| EP3718652A1 (fr) | 2019-04-04 | 2020-10-07 | MAFAC ERNST SCHWARZ GmbH & Co. KG | Procédé de nettoyage et dispositif de nettoyage |

| DE102019108913A1 (de) * | 2019-04-04 | 2020-10-08 | MAFAC - E. Schwarz GmbH & Co. KG | Reinigungsverfahren und reinigungsvorrichtung |

| US11638936B2 (en) | 2019-04-04 | 2023-05-02 | Mafac—E. Schwarz Gmbh & Co. | Cleaning device |

Also Published As

| Publication number | Publication date |

|---|---|

| DE59200380D1 (de) | 1994-09-22 |

| ATE110012T1 (de) | 1994-09-15 |

| DE4111099C1 (fr) | 1992-10-15 |

| EP0507294A1 (fr) | 1992-10-07 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0749395B1 (fr) | Dispositif de traitement de la surface de carrosseries de vehicules | |

| DE69027536T2 (de) | Vorrichtung zum kontinuierlich in kontaktbringen von festen und flüssigen stoffen | |

| EP2246129B1 (fr) | Installation de nettoyage | |

| DE2361732C2 (de) | Schneckenwellen-Extruder zum Fixieren radioaktiver und/oder toxischer Abfallstoffe | |

| EP0507294B1 (fr) | Arrangement pour nettoyage et dégraissage des pièces d'oeuvre | |

| CH676208A5 (fr) | ||

| EP0146833B1 (fr) | Dispositif pour le polissage électrolytique des surfaces intérieures d'objets cylindriques creux | |

| DE102009036503A1 (de) | Spannvorrichtung für Rotationseinheiten in Reinigungskammer bzw. Reinigungsmaschine | |

| DE8003873U1 (de) | Vorrichtung zum reinigen von farbverschmutzten rollwerkzeugen, wie lammfell- oder kunstfaserfellrollen, zur rationellen flaechenbeschichtung durch schnelle verteilung von leim-, dispersions-, oel- oder lackfarben | |

| WO2011123878A1 (fr) | Dispositif pour transporter un objet à traiter | |

| EP2130615B1 (fr) | Dispositif de traitement pour pièces | |

| DE19950202C2 (de) | Rollenbahn für Skidrahmen | |

| EP0990521B1 (fr) | Dispositif et procédé de nettoyage des éléments des machines à imprimer | |

| EP2072154A2 (fr) | Procédé et dispositif de nettoyage de pièces à usiner | |

| DE29909258U1 (de) | Waschvorrichtung für Autofußmatten aus vorzugsweise gummiartigem Material | |

| DE4116421C1 (en) | Dispersing, milling and mixing device - has cage-like cylindrical housing with perforated sidewalls fastened to drive shaft which runs in hollow cylinder mounted with mixing tool | |

| DE3406296A1 (de) | Fluessigreinigungsanlage | |

| DE19950199B4 (de) | Reinigungsstation zum Besprühen und/oder Spülen von Fahrzeugkarosserien und Verfahren zum Reinigen von Fahrzeugkarosserien | |

| DE3429369A1 (de) | Fluessigreinigungsanlage | |

| EP4359332A1 (fr) | Système de traitement, procédé de traitement de pièces, et procédé de conversion d'un système de traitement | |

| DE2646892A1 (de) | Vorrichtung zum transportieren von werkstuecken | |

| DE19950197B4 (de) | Reinigungsstation zum Besprühen und/oder Spülen von Fahrzeugkarosserien und Verfahren zum Reinigen von Fahrzeugkarosserien | |

| EP4366883A1 (fr) | Installation de traitement et procédé de traitement de pièces | |

| DE2821192A1 (de) | Verfahren und anlage zum konservieren von teilen durch auftragen einer beschichtung im tauchverfahren | |

| DE19607937A1 (de) | Anlage zur Hohlraumkonservierung von Werkstücken, insbesondere Fahrzeugkarossen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT CH DE FR LI |

|

| 17P | Request for examination filed |

Effective date: 19920911 |

|

| 17Q | First examination report despatched |

Effective date: 19940111 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT CH DE FR LI |

|

| REF | Corresponds to: |

Ref document number: 110012 Country of ref document: AT Date of ref document: 19940915 Kind code of ref document: T |

|

| ET | Fr: translation filed | ||

| REF | Corresponds to: |

Ref document number: 59200380 Country of ref document: DE Date of ref document: 19940922 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20110427 Year of fee payment: 20 Ref country code: CH Payment date: 20110421 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 20110418 Year of fee payment: 20 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20110525 Year of fee payment: 20 |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59200380 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: DE Ref legal event code: R071 Ref document number: 59200380 Country of ref document: DE |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF EXPIRATION OF PROTECTION Effective date: 20120403 |

|

| REG | Reference to a national code |

Ref country code: AT Ref legal event code: MK07 Ref document number: 110012 Country of ref document: AT Kind code of ref document: T Effective date: 20120402 |