EP0504311B1 - Verfahren zur herstellung von dickwandigen formstücken, insbesondere für verpackungszwecke - Google Patents

Verfahren zur herstellung von dickwandigen formstücken, insbesondere für verpackungszwecke Download PDFInfo

- Publication number

- EP0504311B1 EP0504311B1 EP91902425A EP91902425A EP0504311B1 EP 0504311 B1 EP0504311 B1 EP 0504311B1 EP 91902425 A EP91902425 A EP 91902425A EP 91902425 A EP91902425 A EP 91902425A EP 0504311 B1 EP0504311 B1 EP 0504311B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- suction

- type

- suction surface

- holes

- moulding tool

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title claims abstract description 20

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 6

- 238000004806 packaging method and process Methods 0.000 title abstract description 11

- 239000002994 raw material Substances 0.000 claims abstract description 10

- 238000000465 moulding Methods 0.000 claims description 36

- 239000000463 material Substances 0.000 claims description 7

- 239000010893 paper waste Substances 0.000 claims description 6

- 239000004744 fabric Substances 0.000 claims description 5

- 239000010897 cardboard waste Substances 0.000 claims description 4

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 3

- 230000001427 coherent effect Effects 0.000 claims description 2

- 239000011248 coating agent Substances 0.000 claims 6

- 238000000576 coating method Methods 0.000 claims 6

- 238000012856 packing Methods 0.000 claims 4

- 239000000725 suspension Substances 0.000 abstract description 12

- 239000002699 waste material Substances 0.000 abstract description 6

- 239000000123 paper Substances 0.000 abstract description 4

- 239000007900 aqueous suspension Substances 0.000 abstract 1

- 238000001914 filtration Methods 0.000 abstract 1

- 239000004793 Polystyrene Substances 0.000 description 6

- 239000007788 liquid Substances 0.000 description 6

- 229920002223 polystyrene Polymers 0.000 description 6

- 239000011230 binding agent Substances 0.000 description 4

- 229920005989 resin Polymers 0.000 description 4

- 239000011347 resin Substances 0.000 description 4

- HEMHJVSKTPXQMS-UHFFFAOYSA-M Sodium hydroxide Chemical compound [OH-].[Na+] HEMHJVSKTPXQMS-UHFFFAOYSA-M 0.000 description 3

- 230000015572 biosynthetic process Effects 0.000 description 3

- 238000005755 formation reaction Methods 0.000 description 3

- 238000002156 mixing Methods 0.000 description 3

- IANQTJSKSUMEQM-UHFFFAOYSA-N 1-benzofuran Chemical compound C1=CC=C2OC=CC2=C1 IANQTJSKSUMEQM-UHFFFAOYSA-N 0.000 description 2

- 238000001035 drying Methods 0.000 description 2

- 239000000835 fiber Substances 0.000 description 2

- 239000003292 glue Substances 0.000 description 2

- 239000004033 plastic Substances 0.000 description 2

- RSWGJHLUYNHPMX-UHFFFAOYSA-N Abietic-Saeure Natural products C12CCC(C(C)C)=CC2=CCC2C1(C)CCCC2(C)C(O)=O RSWGJHLUYNHPMX-UHFFFAOYSA-N 0.000 description 1

- 239000004677 Nylon Substances 0.000 description 1

- KHPCPRHQVVSZAH-HUOMCSJISA-N Rosin Natural products O(C/C=C/c1ccccc1)[C@H]1[C@H](O)[C@@H](O)[C@@H](O)[C@@H](CO)O1 KHPCPRHQVVSZAH-HUOMCSJISA-N 0.000 description 1

- CDBYLPFSWZWCQE-UHFFFAOYSA-L Sodium Carbonate Chemical compound [Na+].[Na+].[O-]C([O-])=O CDBYLPFSWZWCQE-UHFFFAOYSA-L 0.000 description 1

- 229920002472 Starch Polymers 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- 239000012876 carrier material Substances 0.000 description 1

- 239000005018 casein Substances 0.000 description 1

- BECPQYXYKAMYBN-UHFFFAOYSA-N casein, tech. Chemical compound NCCCCC(C(O)=O)N=C(O)C(CC(O)=O)N=C(O)C(CCC(O)=N)N=C(O)C(CC(C)C)N=C(O)C(CCC(O)=O)N=C(O)C(CC(O)=O)N=C(O)C(CCC(O)=O)N=C(O)C(C(C)O)N=C(O)C(CCC(O)=N)N=C(O)C(CCC(O)=N)N=C(O)C(CCC(O)=N)N=C(O)C(CCC(O)=O)N=C(O)C(CCC(O)=O)N=C(O)C(COP(O)(O)=O)N=C(O)C(CCC(O)=N)N=C(O)C(N)CC1=CC=CC=C1 BECPQYXYKAMYBN-UHFFFAOYSA-N 0.000 description 1

- 235000021240 caseins Nutrition 0.000 description 1

- 235000019993 champagne Nutrition 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 230000029087 digestion Effects 0.000 description 1

- 230000007613 environmental effect Effects 0.000 description 1

- 239000002657 fibrous material Substances 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 235000012055 fruits and vegetables Nutrition 0.000 description 1

- 229920001778 nylon Polymers 0.000 description 1

- 239000002245 particle Substances 0.000 description 1

- 239000005011 phenolic resin Substances 0.000 description 1

- 229920001568 phenolic resin Polymers 0.000 description 1

- 239000002985 plastic film Substances 0.000 description 1

- 229920006255 plastic film Polymers 0.000 description 1

- 235000019353 potassium silicate Nutrition 0.000 description 1

- 238000001556 precipitation Methods 0.000 description 1

- 238000002360 preparation method Methods 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 238000004513 sizing Methods 0.000 description 1

- 239000010802 sludge Substances 0.000 description 1

- 239000002002 slurry Substances 0.000 description 1

- NTHWMYGWWRZVTN-UHFFFAOYSA-N sodium silicate Chemical compound [Na+].[Na+].[O-][Si]([O-])=O NTHWMYGWWRZVTN-UHFFFAOYSA-N 0.000 description 1

- 235000019698 starch Nutrition 0.000 description 1

- 239000008107 starch Substances 0.000 description 1

- 239000004753 textile Substances 0.000 description 1

- KHPCPRHQVVSZAH-UHFFFAOYSA-N trans-cinnamyl beta-D-glucopyranoside Natural products OC1C(O)C(O)C(CO)OC1OCC=CC1=CC=CC=C1 KHPCPRHQVVSZAH-UHFFFAOYSA-N 0.000 description 1

- 235000014101 wine Nutrition 0.000 description 1

Images

Classifications

-

- D—TEXTILES; PAPER

- D21—PAPER-MAKING; PRODUCTION OF CELLULOSE

- D21J—FIBREBOARD; MANUFACTURE OF ARTICLES FROM CELLULOSIC FIBROUS SUSPENSIONS OR FROM PAPIER-MACHE

- D21J7/00—Manufacture of hollow articles from fibre suspensions or papier-mâché by deposition of fibres in or on a wire-net mould

Definitions

- the invention relates to a method and a suction mold for the production of thick-walled shaped pieces, in particular for packaging purposes.

- the invention is therefore based on the object to improve the known method of suction molding and the suction molds necessary for this in such a way that, in particular from waste paper and / or cardboard waste in shredded form, substantially more stable molded articles should be able to be produced.

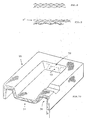

- the suction mold for carrying out the method, it consists of a suction box with a vacuum connection and with a suction surface corresponding to the desired shape of the packaging molding, the suction surface being made of a dimensionally stable support with holes distributed over the suction surface and spaced apart from one another, and that the support is suitable for molding with at least a fine-meshed layer, such as a mesh, grid or fabric layer is covered, the mesh size of which is kept smaller than the cross section of the holes.

- At least one further suction surface with a separate suction box is arranged on the suction side is associated with its area close to the other suction surface at a distance that corresponds to a maximum of twice the wall thickness of the packaging molding to be produced.

- the negative pressure is maintained for a certain period of time in order to at least roughly dewater the molding, which, however, due to its wall thickness and despite the residual water content that is still present, is already so stable that it can already be removed from the suction mold can while maintaining its specified shape.

- the larger wall thickness after drying of the shaped part also ensures that it has sufficient stability or rigidity to be able to serve as a replacement for the polystyrene shaped pieces.

- waste paper and / or cardboard waste can be used without further notice, which only requires comminution but does not require preparation for fiber digestion, that is to say the wastes comminuted into chips are merely added to the suspension liquid, softened and then the suspension enriched with chips can be used can be processed directly.

- plastic chips which are often found in paper and cardboard waste. It has been found that the presence of plastic chips in the finished shaped pieces is even advantageous, since these contribute to the increased strength of the shaped pieces, but more than 5% plastic chips should not be included.

- binders are still added to the suspension, then such binders are suitable as are customary in paper production, for example rosin saponified with boiling soda solution or sodium hydroxide solution, but also phenolic resins, coumarone resins, montan resins or resins from pulp liquor.

- resin glues casein, starch, animal glue, water glass or the like can also be used as additives for the sizing.

- the suction mold consists of a suction box 1 with a vacuum or vacuum connection 2 and a suction surface 3 adapted to the desired shape of the shaped piece VS. If the suction box 1 is provided with a cover 9, as shown in FIG. 4 is, this has a correspondingly large inflow connection 10 for the suspension, through which the suspension flows when the entire molding box 1 is exchanged for the suspension in the mold cavity.

- the suction surface 3 according to FIG.

- the suction surface 3 consists of a dimensionally stable support 4 with holes distributed over the suction surface and spaced apart from one another 5 (see also FIG. 3), the carrier 4 being covered on the side on which the shaped piece VS is to be formed with at least one fine-mesh layer 6 such as a mesh, grid or fabric layer (for example made of nylon), whose mesh size is kept substantially smaller than the cross section of the holes 5.

- the holes 5 have a diameter D of 1 to 2 mm, preferably 1.5 mm and a distance A from each other of 4 to 6 mm, preferably 5 mm.

- wire mesh is preferably used for the layer, which has a wire thickness of 0.2 to 0.4 mm, the wires 7 in the fabric having a distance A 1 of 0.3 to 0.5 mm. It has proven to be particularly advantageous and effective that the crossing wires 7 of the fine-meshed layer 6 extend in two planes E, as illustrated in FIG. 2.

- the mesh size of the individual layers may well be the same or approximately the same as the size of the holes 5, since this results in a staggering of the passages in the depth.

- one or more layers 6 can also take over the function of the carrier 4, ie replace it, the layer 6 ′ on the suction side imparting its fine surface structure to the shaped piece. With such a design it is of course a prerequisite that the material for the layers 6 is a dimensionally stable material, ie it must not be a soft textile fabric, for example.

- the material to be used for the formation of the layer 6 can be both dimensionally stable and, preferably, dimensionally stable material, in the latter case there being the possibility, for example, of the layer 6 by pressing in corresponding tools of the shape of Adjust carrier 4 and to fix them on the carrier 4 in a suitable manner.

- the top view (in the direction of arrow P according to FIG. 2) in FIG. 3 corresponds to the dimensions of an actual embodiment in which the holes 5 have a hole size of approximately 1 mm in diameter, the layer 6 having a mesh size two to four times smaller, and further comprising flat F and strip-shaped waste SA, as shown, in the supplied slurry.

- Flat wastes, i.e. chips have sizes of about 1 to 6 cm2, with which the best results could be achieved.

- Stiff-shaped that is, sauerkraut-like waste SA, such as is obtained when comminuting, for example, file papers, has dimensions of about 1 to 5 mm in width and about 10 to 30 cm in length.

- suction surfaces 3 in the mold boxes 1 according to FIGS. 4, 5 are shown there in the simplest form.

- Other and much more complicated shapes of the carrier 4 and the associated layer 6 are, however, readily possible, care being taken only to ensure that there are no areas in which the suction-effective areas shield one another, which prevents precipitation or suction of raw material particles.

- the suction mold F is to make these at least two parts and thus the moldings F1 and F2 movable apart .

- a suitable hinge 14 is sufficient for being able to swing open the upper mold parts 9.

- the shaped piece formed is in a position, owing to its larger wall thickness, to withstand the loads which occur when the shape is divided, ie not to tear. With the greater wall thickness that can be achieved, there is also the advantage of being able to be shaped using divisible molds.

- the covers 9 result in clean edges on the shaped pieces.

- FIG. 5 is that at least one further suction surface 3 'with a separate suction box 1' is arranged on the suction side F, this suction box 1 'having a separate suction nozzle 1' '.

- the further suction surface 3 ' is associated with its area 8 close to the other suction surface 3 at a distance D 1 which corresponds at most to approximately twice the wall thickness S of the molded part VS to be produced.

- FIG. 6 shows a view of a molded part VS produced from the non-smooth side and FIG. 7 shows a section through such a molded part, wherein, as also from FIG. 7 It can be seen that two such shaped pieces serve to fix an article G to be packaged in a cardboard box K.

- the web cavities 13, as indicated in FIG. 6, result from the suction surfaces 3 ′ additionally arranged in the form F according to FIG. 5.

- the spacing of the holes 5 in the carrier 4 from one another is concerned, it is important to note in this regard that on the one hand a sufficiently large suction cross section is created on the one hand and on the other hand the carrier 4 is sufficiently stable to withstand high vacuum (e.g. 120 mb ) not to deform in relation to its specified shape.

- the distance values are fluid, since they depend on the hole size, the carrier material, the wall thickness of the carrier and ultimately also on the material of the fine-meshed layer 6 applied directly to the carrier 4. So far, too the hole spacing (for example, corresponding to the diameter of the holes 5) is also a factor to be considered for the wall thickness of the shaped pieces to be achieved.

- FIG. 11 shows the flow diagram of the entire process.

- the paper waste 16 is brought to the desired shredder size in a suitable shredding machine 17 and is conveyed into the mixing tank 18, to which a sufficient quantity of suspension liquid is fed from a tank 19.

- This liquid with the chips contained therein and softened then passes into the actual work basin 20, into which the molding boxes 1 are immersed with a suitable lifting mechanism 21, these molding boxes 1 being connected on the suction side to a vacuum pump 24 via a vacuum line 22 and a pressure-tightly closed separating container 23 are.

- the aspirated liquid is returned from the container 23 to the tank 19 by a pump 25 and from there takes part in the cycle again.

- all tanks and containers are provided twice and are accordingly integrated into the system. This double arrangement serves, in particular, to have sufficient time in the mixing containers 18 for the continuous input of the softening of the batch of chips entered in each case.

- the chips produced from the paper waste 16 with the shredding machine 17 have a shape that cannot be defined geometrically, but a cut size of the order of 1 to 6 cm 2.

- Approx. 500 liters of liquid with a quantity of chips of 3 to 5 kg are prepared and mixed in the mixing container.

- the liquid temperature corresponds to the normal ambient or line temperature, but can be increased if this is required by the peculiarity of the schnitzel.

- the residual moisture in the molding produced depends on how long the suction pressure on molding box 1 remains when it comes from the suspension in the Working pool 20 is lifted out by means of the lifting mechanism 21. After removal from the molding box 1, the molding or the molding is dried in a dryer 26.

- the molded part VS that can be produced with the method and the device according to the invention is shown in perspective in FIG. 10, the illustrated shape being to be understood only as an example. It is important here that stiffening web designs 11 are present in the channel 30 on the raw side of the shaped piece VS, which is only indicated by dashed lines at one point, which limit the web cavities 13. Seen from the raw side (in the direction of arrow 31), these web cavity spaces 13 have smooth walls and have a bottom 32 which has twice the wall thickness S of the fitting VS. As can be seen from FIG. 6, a plurality of such web cavities 13 can be provided on the rear or raw side of the shaped piece, i.e. a corresponding number of additional, separate suction boxes 1 'are then arranged in the suction mold according to the invention according to FIG. These additional suction boxes 1 'are attached to the cover 9, which has correspondingly large mass inflow openings 33.

Landscapes

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Paper (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Processing And Handling Of Plastics And Other Materials For Molding In General (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

- Blow-Moulding Or Thermoforming Of Plastics Or The Like (AREA)

- Making Paper Articles (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE4001918 | 1990-01-24 | ||

| DE4001918A DE4001918C1 (da) | 1990-01-24 | 1990-01-24 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0504311A1 EP0504311A1 (de) | 1992-09-23 |

| EP0504311B1 true EP0504311B1 (de) | 1993-07-28 |

Family

ID=6398618

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP91902425A Expired - Lifetime EP0504311B1 (de) | 1990-01-24 | 1991-01-23 | Verfahren zur herstellung von dickwandigen formstücken, insbesondere für verpackungszwecke |

Country Status (7)

| Country | Link |

|---|---|

| EP (1) | EP0504311B1 (da) |

| AT (1) | ATE92125T1 (da) |

| CA (1) | CA2069295A1 (da) |

| DE (2) | DE4001918C1 (da) |

| DK (1) | DK0504311T3 (da) |

| ES (1) | ES2044722T3 (da) |

| WO (1) | WO1991011555A1 (da) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4106986A1 (de) * | 1991-03-05 | 1992-09-10 | Charles Ulbricht | Verpackungssystem daemm-, isolier- sowie traegerplatte |

| DE4332680A1 (de) * | 1993-09-25 | 1995-03-30 | Karl Schenk Inh Roland Schenk | Formen zum Gießen und/oder Handhaben von Formteilen |

| JPH09203423A (ja) * | 1996-01-25 | 1997-08-05 | Toyota Motor Corp | 防錆カバーの製造方法及びこれを用いた防錆カバー |

| WO2003018911A1 (es) * | 2001-08-16 | 2003-03-06 | Arnulfo Lopez Hernandez | Piñatas y figuras decorativas de papel y carton reciclado elaboradas con una camera de alto vacio |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3261740A (en) * | 1963-09-27 | 1966-07-19 | Diamond Int Corp | Method and mold for producing multilayer absorbent tray |

| US3325349A (en) * | 1964-03-18 | 1967-06-13 | Diamond Int Corp | Method and mold for controlling stock thickness in a pulp molding operation |

| US4014739A (en) * | 1974-05-09 | 1977-03-29 | International Paper Company | Mold construction having removable base member |

| US4034447A (en) * | 1975-10-02 | 1977-07-12 | Idra Ag | Papier-mache coffin |

| GB8403507D0 (en) * | 1984-02-10 | 1984-03-14 | Vernon & Co Pulp Prod | Moulding |

-

1990

- 1990-01-24 DE DE4001918A patent/DE4001918C1/de not_active Expired - Fee Related

-

1991

- 1991-01-23 AT AT91902425T patent/ATE92125T1/de not_active IP Right Cessation

- 1991-01-23 ES ES91902425T patent/ES2044722T3/es not_active Expired - Lifetime

- 1991-01-23 DE DE9191902425T patent/DE59100232D1/de not_active Expired - Fee Related

- 1991-01-23 DK DK91902425.7T patent/DK0504311T3/da active

- 1991-01-23 CA CA002069295A patent/CA2069295A1/en not_active Abandoned

- 1991-01-23 EP EP91902425A patent/EP0504311B1/de not_active Expired - Lifetime

- 1991-01-23 WO PCT/DE1991/000067 patent/WO1991011555A1/de active IP Right Grant

Also Published As

| Publication number | Publication date |

|---|---|

| CA2069295A1 (en) | 1991-07-25 |

| DK0504311T3 (da) | 1993-10-18 |

| EP0504311A1 (de) | 1992-09-23 |

| WO1991011555A1 (de) | 1991-08-08 |

| ATE92125T1 (de) | 1993-08-15 |

| DE4001918C1 (da) | 1991-04-04 |

| DE59100232D1 (de) | 1993-09-02 |

| ES2044722T3 (es) | 1994-01-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3903382C2 (da) | ||

| DE2848459C2 (de) | Vorrichtung zur Herstellung einer Faserbahn | |

| EP0706484B1 (de) | Palette zum transport von lasten | |

| DE69306440T2 (de) | Saugform für Faserbrei, Verfahren und Formvorrichtung zur Herstellung von Formteilen | |

| DE69429718T2 (de) | Verfahren und vorrichtung zur herstellung von formkörpern | |

| DE1586593A1 (de) | Eierschachtel | |

| DE2461308A1 (de) | Etikettvorratsband und vorrichtung zur herstellung desselben sowie verfahren zur herstellung von hierfuer benoetigten werkzeugen | |

| DE4042222A1 (de) | Verfahren zur wiederaufbereitung von thermoplastbeschichteten verpackungsmaterialien sowie thermoplastmaterial fuer weitere verarbeitung | |

| EP0504311B1 (de) | Verfahren zur herstellung von dickwandigen formstücken, insbesondere für verpackungszwecke | |

| DE3686244T2 (de) | Herstellungsverfahren geformter holzprodukte. | |

| DE8714602U1 (de) | Verpackungsformstück für die Schutzumhüllung von Gegenständen | |

| DE69307304T2 (de) | Einrichtung zur herstellung von formkörpern aus faserbrei | |

| DE102021211856B4 (de) | Stofflöser zum Erzeugen einer Stoffsuspension aus festen Partikeln und einem fließfähigen Medium | |

| DE1288498B (de) | Verfahren und Vorrichtung zum Skin-Verpacken von Gegenstaenden | |

| AT398093B (de) | Verfahren zur herstellung formbeständiger gegenstände | |

| EP0115552B1 (de) | Vorrichtung zur Herstellung von Formteilen | |

| DE202021103061U1 (de) | Behälter | |

| DE1177546B (de) | Behaelter aus Fasermasse, insbesondere zum Verpacken von Fleisch und Gefluegel | |

| AT398094B (de) | Verfahren zur herstellung tragender gegenstände, hierunter paletten | |

| DE3622598C2 (da) | ||

| DE1467719A1 (de) | Abquetschform und Formverfahren | |

| DE914711C (de) | Verfahren zum Herstellen einer Tuer, insbesondere fuer Kraftfahrzeuge, aus Kunstharzoder aehnlichen Stoffen | |

| DE319986C (de) | Presse zum Herstellen von Gegenstaenden aus Papiermasse | |

| DE4324261A1 (de) | Verpackungsformstück und Verfahren und Vorrichtung zu seiner Herstellung | |

| DE102024103543A1 (de) | Trommel für einen Trommelpulper und Trommelpulper |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| 17P | Request for examination filed |

Effective date: 19920214 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| 17Q | First examination report despatched |

Effective date: 19921221 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| REF | Corresponds to: |

Ref document number: 92125 Country of ref document: AT Date of ref document: 19930815 Kind code of ref document: T |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19930803 |

|

| REF | Corresponds to: |

Ref document number: 59100232 Country of ref document: DE Date of ref document: 19930902 |

|

| REG | Reference to a national code |

Ref country code: GR Ref legal event code: FG4A Free format text: 3008636 |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: T3 |

|

| ITF | It: translation for a ep patent filed | ||

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FG2A Ref document number: 2044722 Country of ref document: ES Kind code of ref document: T3 |

|

| EPTA | Lu: last paid annual fee | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| EAL | Se: european patent in force in sweden |

Ref document number: 91902425.7 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GR Payment date: 19971230 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: LU Payment date: 19980115 Year of fee payment: 8 Ref country code: BE Payment date: 19980115 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19980116 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19980121 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: ES Payment date: 19980122 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DK Payment date: 19980126 Year of fee payment: 8 Ref country code: CH Payment date: 19980126 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19980128 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19980130 Year of fee payment: 8 Ref country code: AT Payment date: 19980130 Year of fee payment: 8 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19980204 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990123 Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990123 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990123 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990124 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19990125 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990131 Ref country code: GR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990131 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990131 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DK Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990202 |

|

| BERE | Be: lapsed |

Owner name: VIESSMANN WERKE G.M.B.H. & CO. Effective date: 19990131 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990801 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19990123 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19991103 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: DK Ref legal event code: EBP |

|

| REG | Reference to a national code |

Ref country code: ES Ref legal event code: FD2A Effective date: 20010604 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050123 |