EP0406575A1 - Füllvorrichtung für flüssiges Füllgut - Google Patents

Füllvorrichtung für flüssiges Füllgut Download PDFInfo

- Publication number

- EP0406575A1 EP0406575A1 EP90110753A EP90110753A EP0406575A1 EP 0406575 A1 EP0406575 A1 EP 0406575A1 EP 90110753 A EP90110753 A EP 90110753A EP 90110753 A EP90110753 A EP 90110753A EP 0406575 A1 EP0406575 A1 EP 0406575A1

- Authority

- EP

- European Patent Office

- Prior art keywords

- filling

- chamber

- closure

- annular

- filling device

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65B—MACHINES, APPARATUS OR DEVICES FOR, OR METHODS OF, PACKAGING ARTICLES OR MATERIALS; UNPACKING

- B65B39/00—Nozzles, funnels or guides for introducing articles or materials into containers or wrappers

- B65B39/001—Nozzles, funnels or guides for introducing articles or materials into containers or wrappers with flow cut-off means, e.g. valves

Definitions

- the invention relates to a filling device for liquid contents according to the preamble of the main claim.

- Such filling devices are known and are used in particular for filling liquids, such as coffee cream or the like, into correspondingly small, deep-drawn containers.

- liquids such as coffee cream or the like

- capillary-active filling tubes are used for one filling point in order to prevent such dripping of liquid after the filling process has ended.

- These small-diameter filling tubes are sealed by means of a membrane that can be pressurized, which is simply pressed onto the mouths of all filling tubes.

- the liquid to be metered is fed into the filling chamber from below, ie centrally from the filling tube side with a filling material supply connection in the form of a correspondingly large and curved filling tube which leads to a storage container arranged above the filling point.

- This known principle works perfectly, but has several disadvantages.

- the main disadvantage is that the curved filling tube acts like a siphon, ie if the filling process is interrupted, the liquid filling material remains in the pipe bend, is therefore at risk of contamination and requires special measures to empty it for downtimes.

- filling tube Since the filling tube has to be brought from below to the filling chamber between the actual filling tubes, this requires a corresponding appropriate distancing of the device and thus a corresponding length of the filling tubes, if these are to be as close as possible with their mouths above the opening level of the small containers to be filled.

- These filling tubes which are guided upwards as an arc and can be assigned to each filling point, also prevent the most compact possible arrangement of a plurality of filling points, so that generally only two rows of filling points can be arranged directly next to one another.

- the object of the invention is to improve it so that when the filling process is interrupted, no more liquid can remain in the filling supply and a simple cleaning option and a compact arrangement of a large number of filling points also in more than two rows should be possible.

- the idea is therefore abandoned that filling material has to be introduced into the chamber from below with a self-contained membrane that spans the entire filling material chamber.

- the membrane is designed in the form of an annular sealing sleeve with which a central access is created from above, but the sealing or sealing sleeve can be pressurized in the same way from above in order to be able to close the mouths of the filling tubes . Due to the central supply of filling material from the top to each filling point, there are practically no limits to the compact arrangement of a large number of filling points, since there is no longer any need to have filling pipe connections to the bottom of each filling point.

- Annular closure sleeves are also already known, but they do not have a radially extending membrane part, but merely represent a piece of tubing which is surrounded by a pressure chamber from which the piece of tubing can be radially pressurized on all sides and thus closed in an anus-like manner, ie , A flat membrane, which essentially only lies sealingly perpendicular to the tube mouths, is not present in this known closing device.

- the membrane effect with its much more favorable loading as in the filling device of the type mentioned at the outset, from which the filling device according to the invention starts.

- the ring part of the cuff and the contact surface of the chamber closure are expediently and advantageously designed in the shape of a truncated cone, that is to say that the ring part of the sealing or sealing collar lies against the truncated cone-shaped contact surface when no pressure is applied at opposite ends of the filling tube.

- the chamber closure is formed from an upper and a lower part, with an annular recess open towards the upper part being arranged in the lower part and a radial annular collar extending from a neck piece of the cuff.

- the upper edge or the collar is firmly clamped in the device.

- the inner edge of the recess can expediently be designed to protrude with respect to its bottom surface in order to improve the sealing effect even further.

- edge region of the ring part which extends outside the mouths of the filling tubes is clamped between the carrier and the chamber closure, and at least one annular pressure extension formed on the closure or on the carrier can also be provided in the clamping region, whereby this edge region of the sealing or closure collar is also provided is firmly clamped in the device when pressurized.

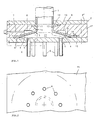

- the filling device consists of a carrier 15 for a plurality of filling tubes 6, starting from a filling chamber 17 provided with a filling material supply connection, the openings 5 on the filling chamber side of which can be closed with an elastic membrane that can be pressurized by the chamber closure 2.

- the filling device is only shown for one filling point, although a corresponding packaging and filling machine in the area of the actual filling station contains a large number of such filling points, combined in one block. It is now essential that the filling supply connection 1 to the chamber closure 2 connected and in this concentric to the connection 1, the elastic membrane in the form of an annular sealing or sealing collar 3 is formed.

- the radially oriented ring part 4 of the sealing collar 3 is arranged between the mouths 5 of the filling tubes 6 and an annular pressure chamber 8, which is open towards the ring part 4 and is provided with a pressure supply connection 7.

- the pressure chambers 8 of several filling points of a block can be connected to a central pressure connection by appropriate bores.

- the ring part 4 of the sleeve 3 and the contact surface 9 of the chamber closure 2 are frustoconical, i.e., as shown, the sealing sleeve lies against the contact surface 9 without pressure.

- dashed lines it is also possible to lay the frustoconical contact surface in the case of a corresponding cross-sectional dimension of the carrier 15 for the filling tubes 6 and to let the ring part 4 run in a radial plane to the neck piece 11. It is only important that the ring part 4 closes the orifices 5 of the filling tubes when pressure is applied.

- the chamber closure 2 is formed from an upper and a lower part 2 ', 2 ⁇ , wherein in the lower part 2 ⁇ an open to the upper part 2' towards the annular recess 10 and in this a radial, starting from the neck piece 11 of the sleeve 3 Ring collar 12 are arranged.

- the inner edge 13 of the recess 10 is designed to protrude with respect to its bottom surface 14. This can be achieved, for example, by an annular, small bead in the region of the inner edge 13, or, as shown, by a frustoconical design of the bottom surface 14 of the recess 10.

- the other edge region 4 ′ which extends outside the orifices 5 of the filling tubes 6 ′ of the ring part 4, this is between the carrier 15 and the chamber Closure 2 or, as shown, the lower part 2 'of the chamber closure 2 clamped, wherein in the clamping area in the illustrated embodiment, both in the carrier 15 and on the lower part 2' ring-shaped pressing extensions 16 are arranged, the sealing or sealing collar 3 when the device is clamped together hold securely when pressurized from the annular pressure chamber 8.

- the filling tubes can, in comparison to the view according to FIG. 2, be arranged in larger numbers and closer to one another and also shorter, which is not the case when the liquid is supplied from below would be possible since there must be a correspondingly wide gap between two filling tubes 6 for the passage of the liquid supply connection.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Supply Of Fluid Materials To The Packaging Location (AREA)

- Basic Packing Technique (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19893921791 DE3921791C1 (ru) | 1989-07-03 | 1989-07-03 | |

| DE3921791 | 1989-07-03 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| EP0406575A1 true EP0406575A1 (de) | 1991-01-09 |

Family

ID=6384171

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90110753A Withdrawn EP0406575A1 (de) | 1989-07-03 | 1990-06-07 | Füllvorrichtung für flüssiges Füllgut |

Country Status (2)

| Country | Link |

|---|---|

| EP (1) | EP0406575A1 (ru) |

| DE (1) | DE3921791C1 (ru) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2323081A (en) * | 1998-05-29 | 1998-09-16 | Unilever Plc | Nozzle for a filling machine |

| RU2503597C2 (ru) * | 2008-06-17 | 2014-01-10 | Бернд ХАНСЕН | Устройство для заполнения контейнеров |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4100619C2 (de) * | 1991-01-11 | 1996-10-31 | Tetra Pak Gmbh | Vorrichtung zum Einfüllen eines Fließmittels in Behälter und Verwendung der Vorrichtung zum Befüllen von Fließmittelpackungen |

| ES2128651T3 (es) * | 1995-10-24 | 1999-05-16 | Nestle Sa | Conjunto inyector dosificador y procedimiento para dosificar liquidos. |

| IT1290699B1 (it) * | 1997-02-25 | 1998-12-10 | Azionaria Costruzioni Automati | Dispositivo erogatore di liquidi. |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1413152A (fr) * | 1964-08-13 | 1965-10-08 | Perfectionnements aux procédés et appareils pour distribuer dans des emballages des doses déterminées de produits fluides |

-

1989

- 1989-07-03 DE DE19893921791 patent/DE3921791C1/de not_active Expired - Fee Related

-

1990

- 1990-06-07 EP EP90110753A patent/EP0406575A1/de not_active Withdrawn

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1413152A (fr) * | 1964-08-13 | 1965-10-08 | Perfectionnements aux procédés et appareils pour distribuer dans des emballages des doses déterminées de produits fluides |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2323081A (en) * | 1998-05-29 | 1998-09-16 | Unilever Plc | Nozzle for a filling machine |

| RU2503597C2 (ru) * | 2008-06-17 | 2014-01-10 | Бернд ХАНСЕН | Устройство для заполнения контейнеров |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3921791C1 (ru) | 1990-05-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3050957C2 (ru) | ||

| EP2194951B1 (de) | Vorrichtung zum einführen eines medikaments in einen infusionsbehälter | |

| DE2356397A1 (de) | Fluiduebertragungseinrichtung | |

| DE2351762A1 (de) | Rohr- oder tubenhalter | |

| DE2503626A1 (de) | Ventil fuer druckgaspackungen | |

| EP0560403B1 (de) | Verschliesselement für eine Verschliessmaschine | |

| DE102013110774A1 (de) | Vorrichtung zur Veränderung der Strahlform von fließfähigen Produkten | |

| DE102015110073B4 (de) | Faltenbalgdichtung sowie Arbeitskopf einer Vorrichtung oder Maschine zum Herstellen und/oder Behandeln von Behältern mit einer solchen Faltenbalgdichtung | |

| EP3071867B1 (de) | Abfüllventil für flüssigkeiten | |

| EP0406575A1 (de) | Füllvorrichtung für flüssiges Füllgut | |

| DE3426130A1 (de) | Ventilaufbau fuer behaelter fuer unter druck stehende fluessigkeit | |

| DE2310611B2 (de) | Fülleinrichtung für einen Aerosolbehalter | |

| DE102019118627A1 (de) | Kartusche mit Kolben und Entlüftungseinrichtung | |

| DE2632078C2 (de) | Dialysevorrichtung, vorzugsweise zur Reingigung von Blut | |

| DE2851886C2 (de) | Vorrichtung zur dosierten Abgabe von Flüssigkeiten | |

| DE19732593C2 (de) | Düse zum Herstellen eines Verzehrgutes | |

| DE1962438C3 (de) | Verfahren zum Füllen und dichten Verschließen von Druckmittelbehältern, insbesondere Flüssiggasbehältern, und Ventilverschluß | |

| EP0521475B1 (de) | Füllelement | |

| DE3405365C2 (ru) | ||

| DE29820062U1 (de) | Zweikomponenten-Behältnis | |

| EP0942874A1 (de) | Mehrkammer-spendersystem | |

| DE2550126A1 (de) | Verfahren und vorrichtung zum abfuellen einer oxydationsempfindlichen fluessigkeit, etwa wein, in flaschen | |

| EP0200164B1 (de) | Vorrichtung zum Mischen und Versprühen einer aus wenigstens zwei Komponenten, zum Beispiel Flüssigkeiten, und einem Treibgas bestehenden Mischung | |

| DE2035650C3 (de) | Aerosolventil | |

| DE2029179C3 (de) | Injektionsvorrichtung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): CH DE FR GB IT LI |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19910710 |