EP0385151B1 - Betätigungsvorrichtung für einen Zapfhahn an einer Getränkeabfüllanlage - Google Patents

Betätigungsvorrichtung für einen Zapfhahn an einer Getränkeabfüllanlage Download PDFInfo

- Publication number

- EP0385151B1 EP0385151B1 EP90102458A EP90102458A EP0385151B1 EP 0385151 B1 EP0385151 B1 EP 0385151B1 EP 90102458 A EP90102458 A EP 90102458A EP 90102458 A EP90102458 A EP 90102458A EP 0385151 B1 EP0385151 B1 EP 0385151B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- valve

- chamber

- tap

- actuating

- connection

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67D—DISPENSING, DELIVERING OR TRANSFERRING LIQUIDS, NOT OTHERWISE PROVIDED FOR

- B67D1/00—Apparatus or devices for dispensing beverages on draught

- B67D1/08—Details

- B67D1/12—Flow or pressure control devices or systems, e.g. valves, gas pressure control, level control in storage containers

- B67D1/14—Reducing valves or control taps

- B67D1/1405—Control taps

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B67—OPENING, CLOSING OR CLEANING BOTTLES, JARS OR SIMILAR CONTAINERS; LIQUID HANDLING

- B67D—DISPENSING, DELIVERING OR TRANSFERRING LIQUIDS, NOT OTHERWISE PROVIDED FOR

- B67D1/00—Apparatus or devices for dispensing beverages on draught

- B67D1/08—Details

- B67D1/12—Flow or pressure control devices or systems, e.g. valves, gas pressure control, level control in storage containers

- B67D1/14—Reducing valves or control taps

- B67D2001/1488—Reducing valves or control taps pneumatically operated

Definitions

- the invention relates to an actuating device for a tap on a beverage filling system, in which the beverage in a storage container is under the pressure of a gas, in particular carbonic acid, and the tap can be transferred from the closed position into the open position by means of an actuator that can be adjusted against the pressure of a spring is.

- a gas in particular carbonic acid

- Such an actuator is known from German utility model 87 13 372. To ensure the function of the known actuating device, it is necessary to match the actuating member to the tap to be opened or closed by means of corresponding components. Due to the multi-part construction, assembly and disassembly efforts are often increased.

- the invention has for its object to provide an actuating device of the type mentioned, which is easy to assemble and disassemble from the tap and in which the actuator of the tap is actuated by means of servo actuation.

- a tap formed as a plug seat sits on the tap, which has a connectable to a gas pressure line and is equipped with a check valve, and that on the holder an actuating piston for the actuator of Tap and connecting channels or connecting chambers for the pressurized gas to be supplied from the connection to the actuating piston and a housing which is located in a connecting channel or connecting chamber and can be opened by a pivoted lever, can be plugged in such a way that the check valve is held in the open position and the inlet is in the plugged-in state the connecting channels are connected to the connection in a gastight manner.

- the connection to the compressed gas connection is established on the one hand by plugging the housing onto the holder and, on the other hand, the actuating piston is brought into its position suitable for actuating the actuating member.

- the actuating device can thus be brought into the operating position by a single handle.

- the valve located in the connecting channels or connecting spaces is opened and the actuating piston is supplied with the compressed gas, which in turn transfers the actuating member from its closed position into the open position, so that the pressurized beverage can flow out via the tap.

- the housing comprises a plurality of axially parallel, pot-shaped chambers which are closed on one side by an in particular common cover and of which a first chamber connected to the connection via a connecting channel directly or indirectly via a further chamber connects the valve body formed by the swing lever operated check valve and a second chamber connected to the first chamber via an orifice receives the actuating piston.

- a housing designed in this way is compact in construction, can be easily produced by injection molding and allows assembly from the open side.

- the connection between individual chambers can be achieved in a particularly simple manner by spraying in that a recess, which is provided on the edge of the partition wall of adjacent chambers facing the cover, forms the connection between the chambers and / or the diaphragm.

- the actuator can be actuated by the Relieve the actuating piston of the piston from the pressure acting on it in a simple manner in that a plunger is arranged in the connecting channel from the valve to the chamber of the actuating piston between the valve body of the valve which can be actuated by the pivoting lever and designed as a check valve and the pivoting lever and which is arranged over a

- the spring is supported on the valve body and forms a further valve seat of an inlet of a ventilation channel for the valve body.

- This embodiment of the invention can be achieved by dimensioning the spring acting on the check valve and the spring acting on the tappet, so that the check valve closes first and only then can the pressure via the tappet be reduced from the chamber with the actuating piston.

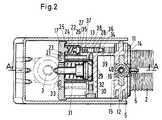

- a tap 1 shown in broken lines in the drawing has a connecting piece 2, with which it can be connected to a fitting of a beverage filling system.

- the tap 1 also has an actuator 3 which can be pivoted against spring pressure and by means of which the valve can be moved from the closed position into the open position.

- connection piece 2 sits with a ring 4 rotatably a plug receptacle 5, which has a connection for a gas pressure line.

- the connection consists of a connecting tube 6, on which a gas pressure line can be plugged, a channel 7 formed in the interior of the plug-in receptacle 5 and a check valve, which in turn consists of a valve body 9 acted upon by a spring 8 and a valve seat 10.

- the plug receptacle 5 has lateral guide webs 11, 12, onto which a housing 13 with guide grooves 14, 15 can be attached.

- a connecting channel 16 designed as a tappet penetrates into the plug-in receptacle 5 and lifts the valve body 9 from its valve seat 10, so that the compressed gas reaches the connecting channel 16 via the tube 6, the line 7, the check valve 8, 9, 10 can.

- the housing 13 is divided into a plurality of pot-shaped chambers lying axially parallel to one another, which are sealed on the side facing the actuating member 3 by means of a common cover 17 which can be fastened with screws.

- the connecting channel 18 lying in the vertical central plane leads to a chamber 19 likewise lying in the central vertical plane, which is connected to the adjacent chamber 21 via a recess 20a formed on the edge of the partition wall 20 facing the cover 17.

- the chamber 21 is in turn connected to a further chamber 22 via a small edge recess 23 acting as a diaphragm in the partition 24 between these chambers 21, 22.

- a check valve is accommodated, which consists of a valve body 26 supported on a spring 25 and its valve seat 27.

- a connection channel 28 extends from the chamber 22 and leads to a chamber 30 via a connection channel 29 arranged transversely thereto.

- an actuating piston 32 which is supported on a spring 31, is arranged, which acts on the actuating member 3 by means of a plunger 33 guided out of the housing 13.

- a plunger 34 is slidably disposed in the connecting channel 28.

- a return spring 35 is arranged between the valve body 26 and the tappet 34, the spring force of which is less than that of the spring 25.

- the plunger 34 is sealed between the connecting channel 29 and its end led out of the housing 13 by an annular seal 36 against the inner wall of the connecting channel 28.

- the tappet 34 At its end facing the valve body 26 and abutting the inner wall, the tappet 34 has axially extending flats 37 on its circumference, so that the space facing the valve body 26 and the space of the connecting channel 28 in the region of the connecting channel 29 are connected to one another.

- an axial channel 38 extends through the tappet 34. The inlet of this channel 38 facing the valve body 26 forms a further valve seat for the valve body 26.

- the axial channel 38 opens into a transverse bore 39, which forms an outlet, outside the housing 13.

- an arm 40a of a two-armed pivot lever which is pivotably mounted in a bearing block 41 of the housing acts on the end of the plunger 34 which is led out of the housing 13. whose other lever arm 40b can be pivoted by hand, in particular from a mug or the like, into which a drink is to be filled.

- the tap 1, including the housing 13, is enclosed by a box-like, attachable cover 42.

- the check valve 8-10 is opened, so that the pressure of the compressed gas is present in the chamber 22, because the connecting channel 18 is connected to the chamber 22 via the chambers 19, 21, the connection between the chambers 21 and 22 is realized via the aperture 23. If the plunger 34 is now moved in the direction of the valve body 26 by pivoting the lever 40, then the weak spring 35 is first compressed, so that the valve seat formed on the end face of the plunger 34 seals against the end face of the valve body 26. Upon further displacement, the valve body 26 is lifted from its valve seat 27 so that the compressed gas can flow into the connecting channel 28 and via the connecting channel 29 into the chamber 30.

- the compressed gas flow is throttled so that the piston 32 is not moved suddenly, but gently against the actuator 3.

- An outflow of the compressed gas via the axial channel 38 in the tappet 34 is not possible because the tappet 34 abuts the valve body 26 on the end face.

- the spring 25 moves the valve body 26 and the plunger 34 supported thereon. In the first phase of this movement, however, the end face of the tappet 34 still abuts the valve body 26. Only when the valve body 26 has reached its valve seat 27 and no further compressed gas passes, does the weaker spring 35 cause the tappet 34 to be lifted off the valve body 26, as a result of which the inlet of the axial channel 38 is opened.

- the compressed gas contained in the chamber 30 can then via the connecting channel 29 in the connecting channel 28 and between the flats 37 and the inner wall of the connecting channel 28 in the valve body 26 facing space of the plunger 34 and from here via its axial channel 38 to its outlet in emanate the atmosphere. Because of this pressure relief, the spring 31 can the piston 32nd return with the plunger 33 to the starting position so that the tap is closed again.

Landscapes

- Devices For Dispensing Beverages (AREA)

- Filling Of Jars Or Cans And Processes For Cleaning And Sealing Jars (AREA)

- Mechanically-Actuated Valves (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT90102458T ATE89236T1 (de) | 1989-03-03 | 1990-02-08 | Betaetigungsvorrichtung fuer einen zapfhahn an einer getraenkeabfuellanlage. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3906836 | 1989-03-03 | ||

| DE3906836A DE3906836C1 (zh) | 1989-03-03 | 1989-03-03 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0385151A1 EP0385151A1 (de) | 1990-09-05 |

| EP0385151B1 true EP0385151B1 (de) | 1993-05-12 |

Family

ID=6375470

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP90102458A Expired - Lifetime EP0385151B1 (de) | 1989-03-03 | 1990-02-08 | Betätigungsvorrichtung für einen Zapfhahn an einer Getränkeabfüllanlage |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US5044528A (zh) |

| EP (1) | EP0385151B1 (zh) |

| AT (1) | ATE89236T1 (zh) |

| DE (2) | DE3906836C1 (zh) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5363989A (en) * | 1993-07-09 | 1994-11-15 | Dec International, Inc. | Automatic control apparatus for a beverage tap |

| JP3662853B2 (ja) * | 2000-02-01 | 2005-06-22 | ホシザキ電機株式会社 | 飲料ディスペンサ |

| JP4250314B2 (ja) * | 2000-07-19 | 2009-04-08 | ホシザキ電機株式会社 | 飲料ディスペンサにおけるコック駆動装置の補正方法および装置 |

| US11124406B1 (en) * | 2014-07-13 | 2021-09-21 | Sestra Systems, Inc. | System and method for piston detection in a metering mechanism for use with beverage dispensing system |

| IT201700037089A1 (it) | 2017-04-04 | 2018-10-04 | Illycaffe Spa | Assieme di erogazione di una bevanda fredda |

Family Cites Families (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE479943C (de) * | 1925-07-31 | 1929-07-24 | Werner Sack Dipl Ing | Kupplung fuer Leitungen von Fluessigkeiten oder Gasen mit beiderseitigen Abschlussventilen, welche bei geschlossener Kupplung sich gegenseitig geoeffnet halten, und mit Vordichtung vor vollstaendigem Schluss der Kupplung |

| FR789951A (fr) * | 1935-05-13 | 1935-11-09 | Cocard Jules Sa | Distributeur pour appareil à commande par fluide sous pression |

| US3221936A (en) * | 1963-04-03 | 1965-12-07 | Samuel C Battaglia | Draught beer controlling and dispensing system |

| US3380629A (en) * | 1964-11-04 | 1968-04-30 | Gerald F Crate | Beverage dispensing apparatus |

| DE1532651A1 (de) * | 1966-05-21 | 1970-02-05 | Wilhelm Ricken | Getraenkeausgeber mit selbsttaetiger Dosierung der abgezapften Getraenkemenge |

| US3399809A (en) * | 1967-04-14 | 1968-09-03 | Simonich Mario | Operating device for a closing member of an ice-cream dispensing nozzle in an ice-cream continuously producing apparatus |

| DE6813103U (de) * | 1968-12-24 | 1969-06-19 | Kaufmann Heinz Herenz | Geraet zum abfuellen von fluessigkeiten |

| US3524383A (en) * | 1969-08-06 | 1970-08-18 | Charles H Locke | Pneumatic actuator |

| US4226343A (en) * | 1978-08-28 | 1980-10-07 | Custom Systems Associates, Inc. | Valving apparatus |

| JPS55501063A (zh) * | 1978-12-20 | 1980-12-04 | ||

| US4316557A (en) * | 1979-12-17 | 1982-02-23 | Sunkist Growers, Inc. | Beverage dispenser with removable tank connection means |

| US4496079A (en) * | 1982-01-15 | 1985-01-29 | Mccann's Engineering And Manufacturing Company | Combination lock for multiple faucets |

| US4549675A (en) * | 1982-09-07 | 1985-10-29 | The Cornelius Co. | Beverage dispensing valve |

| US4708155A (en) * | 1985-09-03 | 1987-11-24 | The Cornelius Company | Beverage dispensing valve with easy opening |

| DE8713372U1 (de) * | 1987-10-05 | 1987-11-19 | Feller, Friedrich, 8050 Freising | Zapfhahn zum Ausschenken von schäumenden Getränken |

| US4898308A (en) * | 1988-08-17 | 1990-02-06 | The Coca-Cola Company | Removable syrup package |

-

1989

- 1989-03-03 DE DE3906836A patent/DE3906836C1/de not_active Expired - Lifetime

-

1990

- 1990-02-08 EP EP90102458A patent/EP0385151B1/de not_active Expired - Lifetime

- 1990-02-08 AT AT90102458T patent/ATE89236T1/de not_active IP Right Cessation

- 1990-02-08 DE DE9090102458T patent/DE59001387D1/de not_active Expired - Fee Related

- 1990-02-21 US US07/482,559 patent/US5044528A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| ATE89236T1 (de) | 1993-05-15 |

| EP0385151A1 (de) | 1990-09-05 |

| US5044528A (en) | 1991-09-03 |

| DE59001387D1 (de) | 1993-06-17 |

| DE3906836C1 (zh) | 1990-09-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3122747A1 (de) | Elektromagnet-ventil | |

| DE2730287A1 (de) | Ventilblock | |

| DE2448510A1 (de) | Fahrzeug-druckluftbremsanlage | |

| DE3739337A1 (de) | Ventilanordnung | |

| EP0385151B1 (de) | Betätigungsvorrichtung für einen Zapfhahn an einer Getränkeabfüllanlage | |

| DE2944053C2 (zh) | ||

| DE19847311A1 (de) | Ventileinrichtung | |

| DE2619901A1 (de) | Luftverteilungsventil | |

| EP0289712A2 (de) | Druckregelventil | |

| DE3005280A1 (de) | Selbsttaetig schliessende armatur fuer duschalagen o.dgl. | |

| EP0058741A1 (de) | Kombinationsventil | |

| EP0398009B1 (de) | Eingangsseitig über eine Steuerleitung mit einem Niveauregelventil verbindbares sowie auch elektrisch ansteuerbares Schaltventil | |

| DE69505476T2 (de) | Dreiwegeschaltregler | |

| DE10158065A1 (de) | Redundanzdruck-Umschaltventil für elektronisch-pneumatische Bremsanlage | |

| EP0758063B1 (de) | Startventil für pneumatische Anlagen | |

| EP0008747B1 (de) | Steuerorgan für ein Reifenfüllgerät | |

| DE2245419C2 (zh) | ||

| EP0000794A1 (de) | Zweikreis-Steuerventil | |

| DE2045873A1 (de) | Ventil | |

| DE10120320B4 (de) | Vorgesteuertes Ventil mit einem Backupventil | |

| CH657675A5 (de) | Druckmediumbetaetigte stellmotoranordnung. | |

| DE3209247A1 (de) | Lastabhaengiger bremskraftregler fuer nutzfahrzeuge | |

| DE1284230B (de) | Selbsttaetiges Ventil zum Fuellen und Entleeren eines Arbeitszylinders | |

| DE146652C (zh) | ||

| DE1103704B (de) | Steuer- oder Mehrwegeventil |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19901218 |

|

| 17Q | First examination report despatched |

Effective date: 19921029 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE DK ES FR GB GR IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19930512 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRE;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED.SCRIBED TIME-LIMIT Effective date: 19930512 Ref country code: DK Effective date: 19930512 Ref country code: BE Effective date: 19930512 Ref country code: FR Effective date: 19930512 Ref country code: GB Effective date: 19930512 Ref country code: ES Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19930512 Ref country code: GR Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT Effective date: 19930512 Ref country code: NL Effective date: 19930512 |

|

| REF | Corresponds to: |

Ref document number: 89236 Country of ref document: AT Date of ref document: 19930515 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 59001387 Country of ref document: DE Date of ref document: 19930617 |

|

| EN | Fr: translation not filed | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBV | Gb: ep patent (uk) treated as always having been void in accordance with gb section 77(7)/1977 [no translation filed] |

Effective date: 19930512 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19940208 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Effective date: 19940228 Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19940228 Ref country code: LI Effective date: 19940228 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19941101 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |