EP0365964B1 - Tuyau à jet - Google Patents

Tuyau à jet Download PDFInfo

- Publication number

- EP0365964B1 EP0365964B1 EP89119169A EP89119169A EP0365964B1 EP 0365964 B1 EP0365964 B1 EP 0365964B1 EP 89119169 A EP89119169 A EP 89119169A EP 89119169 A EP89119169 A EP 89119169A EP 0365964 B1 EP0365964 B1 EP 0365964B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- blast tube

- section

- tube according

- input

- blast

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 claims description 9

- 239000000203 mixture Substances 0.000 claims description 3

- 238000011144 upstream manufacturing Methods 0.000 claims 1

- 239000000463 material Substances 0.000 description 2

- 239000004576 sand Substances 0.000 description 2

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- 239000012530 fluid Substances 0.000 description 1

- 238000012423 maintenance Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04F—PUMPING OF FLUID BY DIRECT CONTACT OF ANOTHER FLUID OR BY USING INERTIA OF FLUID TO BE PUMPED; SIPHONS

- F04F5/00—Jet pumps, i.e. devices in which flow is induced by pressure drop caused by velocity of another fluid flow

- F04F5/02—Jet pumps, i.e. devices in which flow is induced by pressure drop caused by velocity of another fluid flow the inducing fluid being liquid

- F04F5/10—Jet pumps, i.e. devices in which flow is induced by pressure drop caused by velocity of another fluid flow the inducing fluid being liquid displacing liquids, e.g. containing solids, or liquids and elastic fluids

- F04F5/12—Jet pumps, i.e. devices in which flow is induced by pressure drop caused by velocity of another fluid flow the inducing fluid being liquid displacing liquids, e.g. containing solids, or liquids and elastic fluids of multi-stage type

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04F—PUMPING OF FLUID BY DIRECT CONTACT OF ANOTHER FLUID OR BY USING INERTIA OF FLUID TO BE PUMPED; SIPHONS

- F04F5/00—Jet pumps, i.e. devices in which flow is induced by pressure drop caused by velocity of another fluid flow

- F04F5/02—Jet pumps, i.e. devices in which flow is induced by pressure drop caused by velocity of another fluid flow the inducing fluid being liquid

- F04F5/10—Jet pumps, i.e. devices in which flow is induced by pressure drop caused by velocity of another fluid flow the inducing fluid being liquid displacing liquids, e.g. containing solids, or liquids and elastic fluids

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04F—PUMPING OF FLUID BY DIRECT CONTACT OF ANOTHER FLUID OR BY USING INERTIA OF FLUID TO BE PUMPED; SIPHONS

- F04F5/00—Jet pumps, i.e. devices in which flow is induced by pressure drop caused by velocity of another fluid flow

- F04F5/44—Component parts, details, or accessories not provided for in, or of interest apart from, groups F04F5/02 - F04F5/42

- F04F5/46—Arrangements of nozzles

- F04F5/466—Arrangements of nozzles with a plurality of nozzles arranged in parallel

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04F—PUMPING OF FLUID BY DIRECT CONTACT OF ANOTHER FLUID OR BY USING INERTIA OF FLUID TO BE PUMPED; SIPHONS

- F04F5/00—Jet pumps, i.e. devices in which flow is induced by pressure drop caused by velocity of another fluid flow

- F04F5/44—Component parts, details, or accessories not provided for in, or of interest apart from, groups F04F5/02 - F04F5/42

- F04F5/46—Arrangements of nozzles

- F04F5/467—Arrangements of nozzles with a plurality of nozzles arranged in series

Definitions

- the invention relates to a jet pipe for singing a sand or end water mixture according to the preamble of patent claim 1.

- Such a jet pipe is known from DE-PS 21 50 711.

- the section adjoining the entrance and the conical pipe section are connected to one another by screws.

- water under high pressure is fed in via the feed pipe and enters the pipe interior via the outlet openings in the direction of a conical jacket.

- a sand or earth-water mixture is sucked in on the inlet side and passed through the water cone jacket.

- a turbulence occurs, which leads to the conical section and the area having the outlet openings being subject to severe wear; Particularly when two such jet pipes are to be cascaded in series, an exchange of worn parts leads to considerable downtimes.

- a multi-stage jet pump is known from DD 153 905, in which, however, the section following a diffuser is cylindrical or divergent. The individual steps can be connected to each other by screws.

- a multi-stage jet pump is known from US Pat. No. 2,396,290, in which the sections adjoining the diffuser are designed to be divergent or cylindrical. Individual sections of the device can be connected to one another by screwing.

- the object of the invention is to design such a jet pipe, in which the wearing parts are easy to replace.

- the jet pipe should be designed so that the wear is additionally reduced.

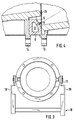

- the jet pipe 1 has a section 3 which can be connected to a supply line 2 for supplying a medium to be sucked in, a jet pipe housing 4 and a conical pipe section 5 which runs inside the latter.

- the section 3 is designed as a ring 6. It has a feed connection 7 which can be connected to a line which supplies a pressurized fluid medium and in particular water. Furthermore, outlet nozzles 9 are provided on a surface 8 extending into the interior of the tube and inclined against the tube axis in the circumferential direction, the axes of which are oriented such that water emerging from them to a common axial point 10 flows inside the tube and thus forms a conical water jacket 11. The outlet nozzles and the supply nozzle are connected to one another via a channel 12 which extends in the ring in the circumferential direction.

- the jet pipe housing 4 has a first connection 13 on the input side and an output connection 14 on the output side. Inside, the two nozzles are designed so that the conical tube section 5 can be inserted into the jet pipe housing 4 and is held coaxially by the two nozzles.

- the ring 6 On the input side, the ring 6 is flanged coaxially by means of screws via a second annular flange 15 to be fitted on the outside.

- the feed line is connected to section 3 via a further flange 16.

- the outlet-side flange 14 of the jet pipe section 16 arranged in front of it serves to mount the ring 6 belonging to the jet pipe section 17.

- the conical tube section 5 is designed such that its end 24 on the outlet side extends so far into section 3 of the subsequent jet tube section that the outlet nozzles 9 are covered as seen in a radial projection. This prevents the nozzles from being ground down and destroyed by the material passed through them.

- a corresponding ring insert not shown, corresponding in shape to the end of the conical pipe section, is used, which covers the nozzles there. It is also possible instead to have the end of the feed line 2 protruding into the interior so far that the material sucked in does not swirl directly past the nozzles.

- the jet pipe comprises a guide frame 18 with two side rails.

- the jet pipe housing and the ring 6 have pairs of wheels 21, 22; 23 on. With the help of these pairs of wheels, it is possible, in order to replace a conical tube section 5, to simply move the ring 6 away after loosening flange screws and to remove and replace the tube section 5. In the same way, maintenance work can optionally be carried out on the outlet nozzles 9 in a simple manner.

- water was supplied in each case via the supply nozzle 7.

- steam via one of the supply ports, if desired, for better solution of certain components.

- a ring 25 forming the free lip 24 can also be provided on the inlet side between the feed line 2 and the ring 6, which like the inwardly extended feed line 2 ensures that the nozzles 9 are not damaged .

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Jet Pumps And Other Pumps (AREA)

- Surgical Instruments (AREA)

- Percussion Or Vibration Massage (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Cleaning In General (AREA)

- Load-Engaging Elements For Cranes (AREA)

- Rigid Pipes And Flexible Pipes (AREA)

Claims (11)

caractérisé en ce que le segment de tube conique (5) et le segment annulaire (6) sont constitués par des éléments rapportés interchangeables montés dans ou sur un carter (4) de l'éjecteur.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT89119169T ATE79163T1 (de) | 1988-10-27 | 1989-10-16 | Strahlrohr. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3836661 | 1988-10-27 | ||

| DE3836661A DE3836661C1 (fr) | 1988-10-27 | 1988-10-27 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0365964A1 EP0365964A1 (fr) | 1990-05-02 |

| EP0365964B1 true EP0365964B1 (fr) | 1992-08-05 |

Family

ID=6366052

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP89119169A Expired - Lifetime EP0365964B1 (fr) | 1988-10-27 | 1989-10-16 | Tuyau à jet |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP0365964B1 (fr) |

| JP (1) | JPH02173400A (fr) |

| AT (1) | ATE79163T1 (fr) |

| DD (1) | DD284948A5 (fr) |

| DE (2) | DE3836661C1 (fr) |

| DK (1) | DK534189A (fr) |

Families Citing this family (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3636235A1 (de) * | 1985-10-24 | 1987-04-30 | Erich Sterzel | Duesenanordnung zur erzeugung einer gerichteten stroemung |

| JP2772500B2 (ja) * | 1991-10-01 | 1998-07-02 | 孝 山本 | 流体吐出ノズル装置 |

| DE4338425A1 (de) * | 1993-11-10 | 1995-05-11 | Huber Ges Fuer Versorgungs Und | Verfahren und Vorrichtung zur Hochdruckreinigung kontaminierter Böden |

| DE4446935C2 (de) * | 1994-12-28 | 1996-12-12 | Edmund Prof Dr Wax | Mehrstufiges Hochdruck-Strahlrohr |

| DE19500346C2 (de) * | 1995-01-07 | 1997-04-10 | Hubert Wax Gmbh & Co Kg | Vorrichtung zur naßmechanischen Behandlung kontaminierter, körniger Materialien und deren Aufschlämmungen |

| AUPO150996A0 (en) * | 1996-08-09 | 1996-08-29 | Melbourne, John Stanley | Hydro/pneumatic mixer |

| BE1016743A5 (nl) * | 2005-09-01 | 2007-05-08 | Packo Inox Nv | Inrichting en werkwijze voor het transporteren van vaste producten in een fluidumstroom. |

| DE102010014580A1 (de) * | 2010-04-09 | 2011-10-13 | Dieter Wurz | Mehrstoffdüse mit Primärgaskernstrahl |

| DE102014221203A1 (de) | 2014-10-20 | 2016-05-04 | Ksb Aktiengesellschaft | Strahlpumpe |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH101872A (fr) * | 1921-12-12 | 1923-11-01 | Eugene Caron Virgile | Procédé et appareil pour l'aspiration et la compression d'un fluide gazeux. |

| US2396290A (en) * | 1945-03-01 | 1946-03-12 | Schwarz Sigmund | Sludge pump |

| DE2150711C3 (de) * | 1971-10-12 | 1978-08-24 | Woma Apparatebau Wolfgang Maasberg & Co Gmbh, 4100 Duisburg | Verwendung einer Wasserstrahlpumpe als Tiefsauger |

| DE2321492A1 (de) * | 1973-04-27 | 1974-10-31 | Fritz Beckschulte | Vorrichtung zum mischen und foerdern von staub- oder granulatfoermigem gut mit wasser |

| PL130954B1 (en) * | 1979-10-31 | 1984-09-29 | Inst Przemyslu Wiazacych | Multi-stage jet pump |

| US4400138A (en) * | 1981-10-19 | 1983-08-23 | Baer William F | Multiple jet eductor |

| US4487553A (en) * | 1983-01-03 | 1984-12-11 | Fumio Nagata | Jet pump |

-

1988

- 1988-10-27 DE DE3836661A patent/DE3836661C1/de not_active Expired - Fee Related

-

1989

- 1989-10-16 DE DE8989119169T patent/DE58901988D1/de not_active Expired - Fee Related

- 1989-10-16 AT AT89119169T patent/ATE79163T1/de not_active IP Right Cessation

- 1989-10-16 EP EP89119169A patent/EP0365964B1/fr not_active Expired - Lifetime

- 1989-10-18 DD DD89333703A patent/DD284948A5/de not_active IP Right Cessation

- 1989-10-26 DK DK534189A patent/DK534189A/da not_active Application Discontinuation

- 1989-10-26 JP JP1281579A patent/JPH02173400A/ja active Pending

Also Published As

| Publication number | Publication date |

|---|---|

| DE58901988D1 (de) | 1992-09-10 |

| DK534189A (da) | 1990-04-28 |

| DK534189D0 (da) | 1989-10-26 |

| ATE79163T1 (de) | 1992-08-15 |

| JPH02173400A (ja) | 1990-07-04 |

| DD284948A5 (de) | 1990-11-28 |

| DE3836661C1 (fr) | 1990-04-19 |

| EP0365964A1 (fr) | 1990-05-02 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69118390T2 (de) | Einrichtung zum reinigen von rohrleitungen | |

| DE68905728T2 (de) | Reinigungsapparat. | |

| DE2243635B2 (de) | Verfahren und Vorrichtung zum Abfuhren des Bohrstaubes beim Gesteinsbohren mit Spulluft | |

| DE1913713A1 (de) | Spritzduese | |

| EP0077562A2 (fr) | Appareil de nettoyage de conduites pour égouts | |

| EP0365964B1 (fr) | Tuyau à jet | |

| DE3877721T2 (de) | Strahlduese zum vorwaertstreiben eines apparats entlang eines rohres und apparat, versehen mit einer solchen strahlduese. | |

| DE3344586A1 (de) | Filtervorrichtung | |

| EP3107689B1 (fr) | Tête de gicleur | |

| DE69102769T2 (de) | Rohrleitungsreinigungsverfahren und -vorrichtung. | |

| EP1356868B1 (fr) | Buse binaire avec un insert changeables | |

| DE1471630B2 (de) | Zweistufennaßwäscher zur Reinigung von Gasen | |

| EP0760259A1 (fr) | Dispositif d'injection pour le revêtement par pulvérisateur de poudre | |

| DE2005972B2 (de) | Verfahren und vorrichtung zur zerstaeubung einer fluessigkeit, suspension oder paste | |

| DE2500858A1 (de) | Belueftungs- und staubniederschlagsvorrichtung fuer den schneidkopf einer gewinnungsmaschine | |

| EP1167621B1 (fr) | Système d' hydrocyclones | |

| DE4446935C2 (de) | Mehrstufiges Hochdruck-Strahlrohr | |

| EP0105047A1 (fr) | Tête de coupe pour machine de traçages en veine | |

| EP0205739A1 (fr) | Dispositif et procédé d'alimentation de boue | |

| EP0720694A1 (fr) | Procede d'extraction et dispositifs appropries | |

| DE4312994C2 (de) | Vorrichtung zur Verspritzung von Suspensionen, insbesondere Mörteln | |

| DE3710450A1 (de) | Verfahren und einrichtung zur abkuehlung von walzgut in wasserkuehlstrecken | |

| DE2807121A1 (de) | Verfahren und vorrichtung zur hochdruck-stroemungsmittel-reinigung von stroemungswegen in rohren o.dgl. | |

| DE9107845U1 (de) | Strahlvorrichtung | |

| DE727848C (de) | Strahlrohrkraftschalter |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A1 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19900327 |

|

| 17Q | First examination report despatched |

Effective date: 19910426 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19920805 |

|

| REF | Corresponds to: |

Ref document number: 79163 Country of ref document: AT Date of ref document: 19920815 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 58901988 Country of ref document: DE Date of ref document: 19920910 |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19921031 |

|

| ITF | It: translation for a ep patent filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Free format text: KLOECKNER OECOTEC GMBH TRANSFER- THYSSEN ALTWERT UMWELTSERVICE GMBH |

|

| NLT1 | Nl: modifications of names registered in virtue of documents presented to the patent office pursuant to art. 16 a, paragraph 1 |

Owner name: THYSSEN ALTWERT UMWELTSERVICE GMBH;ALTWERT OECOTEC |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: THYSSEN ALTWERT UMWELTSERVICE GMBH TRANSFER- NORDA |

|

| NLS | Nl: assignments of ep-patents |

Owner name: NORDAC NORDDEUTSCHES ALTLASTENSANIERUNGSCENTRUM GM |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| REG | Reference to a national code |

Ref country code: GB Ref legal event code: 732E |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19971006 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19971016 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19971021 Year of fee payment: 9 Ref country code: AT Payment date: 19971021 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19971022 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19971029 Year of fee payment: 9 |

|

| BECA | Be: change of holder's address |

Free format text: 970407 *NORDAC NORDDEUTSCHES ALTLASTENSANIERUNGSCENTRUM G.M.B.H. & CO. K.G.:OBERWERDER DAMM 1-5, D-20539 HAMBURG |

|

| BECH | Be: change of holder |

Free format text: 970407 *NORDAC NORDDEUTSCHES ALTLASTENSANIERUNGSCENTRUM G.M.B.H. & CO. K.G. |

|

| BECN | Be: change of holder's name |

Effective date: 19970407 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19981016 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19981016 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19981031 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19981031 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19981031 |

|

| BERE | Be: lapsed |

Owner name: NORDAC NORDDEUTSCHES ALTLASTENSANIERUNGSCENTRUM G Effective date: 19981031 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990501 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19981016 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990630 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19990501 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20001229 Year of fee payment: 12 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020702 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20051016 |