EP0301217A2 - Dispositif pour séparer des particules de tabac d'un mélange gaz/tabac - Google Patents

Dispositif pour séparer des particules de tabac d'un mélange gaz/tabac Download PDFInfo

- Publication number

- EP0301217A2 EP0301217A2 EP88109550A EP88109550A EP0301217A2 EP 0301217 A2 EP0301217 A2 EP 0301217A2 EP 88109550 A EP88109550 A EP 88109550A EP 88109550 A EP88109550 A EP 88109550A EP 0301217 A2 EP0301217 A2 EP 0301217A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- hood

- separator according

- deflection space

- tobacco

- area

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B7/00—Selective separation of solid materials carried by, or dispersed in, gas currents

- B07B7/02—Selective separation of solid materials carried by, or dispersed in, gas currents by reversal of direction of flow

-

- A—HUMAN NECESSITIES

- A24—TOBACCO; CIGARS; CIGARETTES; SIMULATED SMOKING DEVICES; SMOKERS' REQUISITES

- A24B—MANUFACTURE OR PREPARATION OF TOBACCO FOR SMOKING OR CHEWING; TOBACCO; SNUFF

- A24B1/00—Preparation of tobacco on the plantation

- A24B1/04—Sifting, sorting, cleaning or removing impurities from tobacco

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B07—SEPARATING SOLIDS FROM SOLIDS; SORTING

- B07B—SEPARATING SOLIDS FROM SOLIDS BY SIEVING, SCREENING, SIFTING OR BY USING GAS CURRENTS; SEPARATING BY OTHER DRY METHODS APPLICABLE TO BULK MATERIAL, e.g. LOOSE ARTICLES FIT TO BE HANDLED LIKE BULK MATERIAL

- B07B7/00—Selective separation of solid materials carried by, or dispersed in, gas currents

- B07B7/08—Selective separation of solid materials carried by, or dispersed in, gas currents using centrifugal force

Definitions

- the invention relates to a separator for separating tobacco particles from a tobacco / gas mixture of the type specified in the preamble of claim 1.

- DE-OS 36 19 816 shows a device for expanding tobacco which, in addition to a cyclone dust separator, contains a separator with a mesh screen.

- the mesh screen allows the vapor / air mixture to pass to an outlet tube which it recirculates while the tobacco particles are directed down to an airlock.

- EP-OS 29 588 discloses a process for heating tobacco which is impregnated with an expansion agent, in which the gas containing expanded tobacco is separated from the tobacco particles by means of a tangential separator.

- a separator of the type specified for separating dust particles from a gas is apparent from DE-PS 639 871.

- an annular channel is connected to the inlet, from the underside of which several, wreath-like channels in helical windings lead in the same direction as the raw gas supply line downwards and open into a chamber below the annular channel in a continuous transition to the chamber wall; the radius of curvature of these channels is smaller than half the diameter of the hood.

- centrifugal separator in which the mixture flows have to be transported at a relatively high speed in order to produce the desired separation due to the change in movement when passing through the curved channels.

- the invention is therefore based on the object of providing a separator of the type specified, in which the disadvantages mentioned above do not occur.

- a separator which enables the gas / tobacco particles to be separated properly in a structurally simple manner with relatively low conveying speeds.

- the horizontal flow cross section of the hood must be chosen so large that the vertical flow rate of the gas phase is always lower than the sinking rate of the tobacco particles to be separated, i.e. the overall system must take into account the highest expected gas flow on the one hand and the lowest expected sinking rate of the On the other hand, tobacco particles can be designed.

- the size ratio of the area of the deflection space to the area of the inlet must be in the range from 5 to 30; at the same time the size ratio of the area of the hood to the area of the inlet must be greater than 50, in particular greater than 100.

- the usual speeds required for the pneumatic transport of the tobacco / gas mixture occur in the range of approximately 20 m / s, while the gas outlet speeds at the upper end of the hood range from approximately 0.1 to 0.2 m / s.

- the hood can be opened downwards, i.e. the separator can be operated without a discharge element which is susceptible to malfunction, in particular contamination.

- a discharge element generally a cellular wheel sluice or a discharge screw.

- the degree of separation improves with decreasing gas phase, since in this case the difference between the vertical flow rate of the gas phase and the sinking rate of the tobacco particles increases.

- a flow resistance is arranged in the upper area of the hood, which usually consists of a perforated plate with holes evenly distributed over the perforated plate surface.

- a sieve or filter can be arranged below the flow resistance; as an alternative to this, it is also possible to design the flow resistance itself as a sieve or filter.

- an opening which can be closed by a door and which allows access to the interior of the hood or the deflection space can be provided in the hood and / or the deflection space.

- the wall of the hood is provided with a heater in order to prevent condensation and the resulting contamination of the walls.

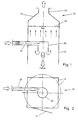

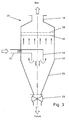

- the separator shown in FIGS. 1 and 2, generally indicated by reference number 10, has a vertically arranged hood 12 which is open at the bottom and has a regular cross section; As can be seen from FIG. 2, this cross section is generally rectangular, in particular square, or circular, as indicated by the dash-dotted lines.

- the door 24 is used for easy inspection and cleaning of the separator 10.

- the hood of the separator 10 is provided with an outlet funnel 14 with an outlet opening 16 which has a smaller cross section than the hood 12.

- a fan (not shown) is connected to the outlet opening 16.

- a transport pipe 22 generally a transport pipe, is fed, which is fed the two-phase mixture to be separated, ie the mixture of tobacco / gas.

- the direction of transport is indicated by the large arrow, while the flows of the two phases of the tobacco / gas mixture in line 12 are indicated by the two different arrows.

- the transport line 22 opens tangentially into the deflection space 20 has a circular cross section and is usually designed as a vertically arranged cylinder which is closed at the top and open at the bottom.

- the tobacco / gas mixture arriving from line 22 lies tangentially against the inner wall of the deflection space 20 and is supplied on a spiral path along the inner wall of the deflection space 20 while simultaneously braking the lower opening of the deflection space 20.

- the tobacco particles fall down, as indicated by the arrows, while the lighter phase, namely gas, is sucked up by the fan and exits from the outlet opening 16 of the hood 12.

- a flow resistance 18 is arranged in the upper area of the hood, i.e. somewhat below the funnel 14, but above the deflection space 20, which consists of a perforated plate with holes evenly distributed over its surface.

- the hood 12 can be open at the bottom, as can be seen from FIG. In this case, the separator 10 can be operated without a discharge element for the separated tobacco particles that is susceptible to malfunction, in particular contamination.

- this discharge element is formed by a cellular wheel sluice 28 which is located in the outlet opening in the funnel-shaped, lower region 26 of the hood 12.

- the embodiment according to FIG. 3 also differs from the embodiment according to FIGS. 1 and 2 by an additionally provided sieve 30; this sieve 30 is in the hood 12 between the Deflection chamber 20 and the flow resistance 18 arranged and prevents the entrainment of tobacco particles in the suction line connected to the outlet 16.

- the horizontal flow cross section of the hood 13 must be chosen so large that the vertical flow rate of the gas phase is always lower than the sinking rate of the tobacco particles to be separated, i.e. the separator 10 must be designed taking into account the highest expected gas flow on the one hand and the lowest expected sink rate of the tobacco particles on the other.

- FIG. 4 shows an embodiment of a separator 10 which can be used when the gas phase consists of steam or contains condensing components.

- the walls of the hood 12 should be provided with a heater in order to prevent condensation and the resulting contamination of the walls.

- the heating in the wall of the hood 12 is indicated by the zigzag line.

- the gas phase consisting of steam or containing condensing components is drawn off to the left as shown in FIG. 4 and fed to an outlet connection 32 which is inclined somewhat downward in relation to the horizontal in the outflow direction, so that the condensate formed there collects at the bottom of the outlet connection 32 and can be discharged via a line 34.

- this embodiment has the structure already described, so that it does not have to be described again.

- FIG. 5a shows different embodiments of the deflection space.

- the cylindrical deflection space 20 is provided with a closed, pointed roof 38, so that no tobacco particles or contaminants can be deposited on the deflection space.

- FIGS. 5b and 5c finally show embodiments of deflection spaces 20 which are open at the top.

- FIG. 5b shows an embodiment in which a funnel-shaped area 4 adjoins the cylindrical deflection space 20, which is provided with a cleaning opening at its upper end, so that the interior of the deflection space 20 is freely accessible, in particular for cleaning purposes.

- FIG. 5c shows an embodiment of the deflection space, which has side walls 42 which run obliquely inwards over its entire height and is likewise provided with a cleaning opening 44 at its upper end. The result is a smooth inner wall of the deflection space 42, so that the deposition of tobacco particles or impurities is largely excluded.

- FIGS. 6 and 7 show an embodiment of a separator which differs from the previously discussed embodiments in that two deflection spaces 20 are arranged vertically next to one another in the hood 12. Each deflection space 20 is provided with an associated transport line 22 for supplying the tobacco / gas mixture.

- FIG. 8 finally shows an embodiment of the separator 10 corresponding to FIGS. 1 and 2, but with a deflection space 20 corresponding to FIG. 5b.

- 1,500 kg of tobacco per hour were injected with a gas or steam mass flow of 500 kg / hour. processed.

- the inlet speed of the tobacco / gas mixture was of the order of magnitude of about 20 m / s required for the pneumatic transport.

- the speed of the gas drawn off was between 0.1 and 0.2 m / s, for which purpose a vacuum of 5 mbar was maintained in the upper, funnel-shaped end region of the hood 12.

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Agronomy & Crop Science (AREA)

- Cyclones (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DK377088A DK172024B1 (da) | 1987-07-29 | 1988-07-07 | Separator til adskillelse af små tobaksstykker fra en tobak/gasblanding |

| CA000572671A CA1300042C (fr) | 1987-07-29 | 1988-07-21 | Instrument permettant de separer les particules de tabac a partir d'un melangetabac-gaz |

| FI883548A FI90005C (fi) | 1987-07-29 | 1988-07-28 | Avskiljare foer avskiljande av tobaksbestaondsdelar fraon en tobaks/gasblandning |

| MYPI88000861A MY103137A (en) | 1987-07-29 | 1988-07-29 | Separator for separating tobacco particles from a tobacco/gas mixture |

| AU20185/88A AU600845B2 (en) | 1987-07-29 | 1988-07-29 | Separator for separating tobacco particles from a tobacco/gas mixture |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3725148 | 1987-07-29 | ||

| DE3725148 | 1987-07-29 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0301217A2 true EP0301217A2 (fr) | 1989-02-01 |

| EP0301217A3 EP0301217A3 (en) | 1989-12-06 |

| EP0301217B1 EP0301217B1 (fr) | 1993-02-03 |

Family

ID=6332642

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP88109550A Expired - Lifetime EP0301217B1 (fr) | 1987-07-29 | 1988-06-15 | Dispositif pour séparer des particules de tabac d'un mélange gaz/tabac |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US4938235A (fr) |

| EP (1) | EP0301217B1 (fr) |

| DE (1) | DE3878072D1 (fr) |

| HK (1) | HK25794A (fr) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0774213A1 (fr) | 1995-11-20 | 1997-05-21 | British-American Tobacco (Germany) GmbH | Procédé et dispositif pour le traitement de feuilles de tabac pour la fabrication de tabac coupé |

| AT403133B (de) * | 1996-03-14 | 1997-11-25 | Scheuch Alois Gmbh | Sichter |

| US5826590A (en) * | 1996-09-26 | 1998-10-27 | Brown & Williamson Tobacco Corp. | Method and plant for treating tobacco stems for the production of cut tobacco |

| EP2045199A1 (fr) * | 2007-10-02 | 2009-04-08 | Klaus Wilhelm | Appareil à air comprimé pour alimenter en poudre ou en matériaux granulaires |

| CN104705778A (zh) * | 2015-01-19 | 2015-06-17 | 河南中烟工业有限责任公司 | 一种烟草流动萃取装置 |

| CN111358034A (zh) * | 2020-03-31 | 2020-07-03 | 佛山市高明曦逻科技有限公司 | 一种烟叶烤房回收装置以及使用方法 |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH683226A5 (de) * | 1991-12-09 | 1994-02-15 | Egri Laszlo | Expandieren und Trocknen von Tabak. |

| US5582193A (en) * | 1994-08-24 | 1996-12-10 | Philip Morris Incorporated | Method and apparatus for expanding tobacco |

| US6371126B1 (en) * | 2000-03-03 | 2002-04-16 | Brown & Williamson Tobacco Corporation | Tobacco recovery system |

| CA2499853C (fr) * | 2004-03-15 | 2012-11-13 | Universal Leaf Tobacco Company, Inc. | Appareil et methode de balayage et de tri de feuilles de tabac |

| DE102005062090B4 (de) * | 2005-12-22 | 2010-01-14 | Hauni Maschinenbau Ag | Sichtvorrichtung und Verfahren zum Trennen von schweren und leichten Partikeln von Tabakmaterial |

| US8281931B2 (en) * | 2009-09-18 | 2012-10-09 | Key Technology, Inc. | Apparatus and method for post-threshing inspection and sorting of tobacco lamina |

| CN106617259A (zh) * | 2017-02-22 | 2017-05-10 | 广东中烟工业有限责任公司 | 一种负压管道除尘阻火装置 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3026002A1 (de) * | 1979-07-10 | 1981-02-05 | Rothmans Of Pall Mall | Verfahren zum verarbeiten von tabak und vorrichtung zur durchfuehrung dieses verfahrens |

| DE3416701A1 (de) * | 1983-05-19 | 1984-11-22 | Hauni-Werke Körber & Co KG, 2050 Hamburg | Einrichtung zum beschicken tabakverarbeitender strangmaschinen |

| DE3409814A1 (de) * | 1984-03-16 | 1985-09-19 | Waeschle Maschinenfabrik Gmbh, 7980 Ravensburg | Gegenstromsichter |

| DE3700684A1 (de) * | 1986-01-13 | 1987-07-23 | Sumitomo Chemical Co | Flockentrenn-vorrichtung und -verfahren |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE639871C (de) * | 1936-12-15 | Heinrich Junkmann Dipl Ing | Fliehkraftstaubabscheider | |

| US4366825A (en) * | 1979-11-21 | 1983-01-04 | Philip Morris Incorporated | Expansion of tobacco |

| US4407306A (en) * | 1981-12-17 | 1983-10-04 | American Brands, Inc. | Method for expanding tobacco with steam at high temperature and velocity |

| GB8515217D0 (en) * | 1985-06-15 | 1985-07-17 | British American Tobacco Co | Treatment of tobacco |

| DE3710677A1 (de) * | 1987-03-31 | 1988-10-13 | Bat Cigarettenfab Gmbh | Vorrichtung zum expandieren von zerkleinertem tabakmaterial |

-

1988

- 1988-06-15 EP EP88109550A patent/EP0301217B1/fr not_active Expired - Lifetime

- 1988-06-15 DE DE8888109550T patent/DE3878072D1/de not_active Expired - Fee Related

- 1988-07-29 US US07/226,025 patent/US4938235A/en not_active Expired - Fee Related

-

1994

- 1994-03-24 HK HK257/94A patent/HK25794A/xx not_active IP Right Cessation

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE3026002A1 (de) * | 1979-07-10 | 1981-02-05 | Rothmans Of Pall Mall | Verfahren zum verarbeiten von tabak und vorrichtung zur durchfuehrung dieses verfahrens |

| DE3416701A1 (de) * | 1983-05-19 | 1984-11-22 | Hauni-Werke Körber & Co KG, 2050 Hamburg | Einrichtung zum beschicken tabakverarbeitender strangmaschinen |

| DE3409814A1 (de) * | 1984-03-16 | 1985-09-19 | Waeschle Maschinenfabrik Gmbh, 7980 Ravensburg | Gegenstromsichter |

| DE3700684A1 (de) * | 1986-01-13 | 1987-07-23 | Sumitomo Chemical Co | Flockentrenn-vorrichtung und -verfahren |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0774213A1 (fr) | 1995-11-20 | 1997-05-21 | British-American Tobacco (Germany) GmbH | Procédé et dispositif pour le traitement de feuilles de tabac pour la fabrication de tabac coupé |

| AT403133B (de) * | 1996-03-14 | 1997-11-25 | Scheuch Alois Gmbh | Sichter |

| US5826590A (en) * | 1996-09-26 | 1998-10-27 | Brown & Williamson Tobacco Corp. | Method and plant for treating tobacco stems for the production of cut tobacco |

| EP2045199A1 (fr) * | 2007-10-02 | 2009-04-08 | Klaus Wilhelm | Appareil à air comprimé pour alimenter en poudre ou en matériaux granulaires |

| CN104705778A (zh) * | 2015-01-19 | 2015-06-17 | 河南中烟工业有限责任公司 | 一种烟草流动萃取装置 |

| CN111358034A (zh) * | 2020-03-31 | 2020-07-03 | 佛山市高明曦逻科技有限公司 | 一种烟叶烤房回收装置以及使用方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3878072D1 (de) | 1993-03-18 |

| US4938235A (en) | 1990-07-03 |

| HK25794A (en) | 1994-03-31 |

| EP0301217B1 (fr) | 1993-02-03 |

| EP0301217A3 (en) | 1989-12-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0301217B1 (fr) | Dispositif pour séparer des particules de tabac d'un mélange gaz/tabac | |

| DE2825273A1 (de) | Abscheider | |

| EP0182000B1 (fr) | Filtre à cyclone équipé de bougies filtrantes en métal disposées en tandem | |

| CH636533A5 (de) | Filtervorrichtung zum filtern von durch staub und faserabfaelle verunreinigter luft. | |

| WO2007073783A1 (fr) | Systeme d'epuration de gaz | |

| DE2719544C2 (de) | Einrichtung zum Reinigen eines Filterbetts aus körnigem Material | |

| EP2465617A1 (fr) | Procédé et dispositif de séparation de fines particules à partir de produits en vrac en forme de granulés dans une conduite tubulaire | |

| DE2251513A1 (de) | Verfahren und vorrichtung zum unterbinden des zusetzens von luftfoerderanlagen | |

| DE936488C (de) | Zyklon-Staubabscheider | |

| EP1364696B1 (fr) | Dispositif d'épuration d'un courant gazeux | |

| EP0392455B1 (fr) | Séparateur | |

| DE2224519B2 (de) | Ein- oder mehrstufiger Wäscher | |

| DE3626053C2 (fr) | ||

| DE2934590C2 (de) | Zyklonabscheider | |

| DE2038871B2 (de) | Filtriervorrichtung zum Abscheiden von Feststoffen aus gasförmigen Medien | |

| EP3453444A1 (fr) | Dispositif de séparation de matière solide des gaz | |

| EP0125620A1 (fr) | Système de filtrage d'air | |

| DE4307407C2 (de) | Vorrichtung zur Herstellung von Zigaretten mit Auftrennung der Tabakpartikel | |

| DE2254162B2 (de) | Vorrichtung zum Entstauben von Abgasen | |

| DE202011000826U1 (de) | Anlage zum Reinigen von industriellen Abgasen | |

| EP0264669B1 (fr) | Dispositif de logement de produits en vrac pouvant s'écouler | |

| DE2163735B2 (de) | Vorrichtung zum abscheiden von fluessigkeitstropfen aus einem stroemenden gasfoermigen medium | |

| DE2904830C2 (de) | Vorrichtung zum Abscheiden feiner Nebeltröpfchen | |

| DE19738912A1 (de) | Vorrichtung und Verfahren zum Abscheiden von Feststoffen aus einem Trägerstrom sowie deren Verwendung | |

| DE1407985A1 (de) | Abscheider fuer Absauganlagen,insbesondere fuer Raumluftabsauganlagen in Textilbetrieben |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): BE CH DE FR GB IT LI NL |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): BE CH DE FR GB IT LI NL |

|

| 17P | Request for examination filed |

Effective date: 19900309 |

|

| 17Q | First examination report despatched |

Effective date: 19910920 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): BE CH DE FR GB IT LI NL |

|

| ITF | It: translation for a ep patent filed |

Owner name: BARZANO' E ZANARDO MILANO S.P.A. |

|

| ET | Fr: translation filed | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19930215 |

|

| REF | Corresponds to: |

Ref document number: 3878072 Country of ref document: DE Date of ref document: 19930318 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Free format text: BRITISH-AMERICAN TOBACCO (GERMANY) GMBH |

|

| NLT1 | Nl: modifications of names registered in virtue of documents presented to the patent office pursuant to art. 16 a, paragraph 1 |

Owner name: BRITISH-AMERICAN TOBACCO (GERMANY) GMBH |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 20000512 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 20000515 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 20000524 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 20000529 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 20000605 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010615 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 20010616 Year of fee payment: 14 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010630 Ref country code: CH Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010630 Ref country code: BE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20010630 |

|

| BERE | Be: lapsed |

Owner name: BRITISH-AMERICAN TOBACCO (GERMANY) G.M.B.H. Effective date: 20010630 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020101 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 20010615 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20020228 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 20020101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 20030101 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050615 |