EP0290720B1 - Capuchon avec anneau d'inviolabilité - Google Patents

Capuchon avec anneau d'inviolabilité Download PDFInfo

- Publication number

- EP0290720B1 EP0290720B1 EP88101943A EP88101943A EP0290720B1 EP 0290720 B1 EP0290720 B1 EP 0290720B1 EP 88101943 A EP88101943 A EP 88101943A EP 88101943 A EP88101943 A EP 88101943A EP 0290720 B1 EP0290720 B1 EP 0290720B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- closure cap

- screw cap

- connecting webs

- cap according

- recess

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 229920003023 plastic Polymers 0.000 claims abstract description 3

- 239000004033 plastic Substances 0.000 claims abstract description 3

- 239000011324 bead Substances 0.000 claims description 3

- 239000000463 material Substances 0.000 claims description 2

- 239000012528 membrane Substances 0.000 claims 1

- 208000027418 Wounds and injury Diseases 0.000 abstract description 8

- 230000006378 damage Effects 0.000 abstract description 8

- 208000014674 injury Diseases 0.000 abstract description 8

- 230000007704 transition Effects 0.000 abstract description 2

- 238000012546 transfer Methods 0.000 description 8

- 239000003814 drug Substances 0.000 description 2

- 238000002347 injection Methods 0.000 description 2

- 239000007924 injection Substances 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 238000013461 design Methods 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 229940079593 drug Drugs 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000007789 sealing Methods 0.000 description 1

- 238000010008 shearing Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D41/00—Caps, e.g. crown caps or crown seals, i.e. members having parts arranged for engagement with the external periphery of a neck or wall defining a pouring opening or discharge aperture; Protective cap-like covers for closure members, e.g. decorative covers of metal foil or paper

- B65D41/32—Caps or cap-like covers with lines of weakness, tearing-strips, tags, or like opening or removal devices, e.g. to facilitate formation of pouring openings

- B65D41/34—Threaded or like caps or cap-like covers provided with tamper elements formed in, or attached to, the closure skirt

- B65D41/3442—Threaded or like caps or cap-like covers provided with tamper elements formed in, or attached to, the closure skirt with rigid bead or projections formed on the tamper element and coacting with bead or projections on the container

- B65D41/3447—Threaded or like caps or cap-like covers provided with tamper elements formed in, or attached to, the closure skirt with rigid bead or projections formed on the tamper element and coacting with bead or projections on the container the tamper element being integrally connected to the closure by means of bridges

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D41/00—Caps, e.g. crown caps or crown seals, i.e. members having parts arranged for engagement with the external periphery of a neck or wall defining a pouring opening or discharge aperture; Protective cap-like covers for closure members, e.g. decorative covers of metal foil or paper

- B65D41/02—Caps or cap-like covers without lines of weakness, tearing strips, tags, or like opening or removal devices

- B65D41/04—Threaded or like caps or cap-like covers secured by rotation

- B65D41/0407—Threaded or like caps or cap-like covers secured by rotation with integral sealing means

- B65D41/0414—Threaded or like caps or cap-like covers secured by rotation with integral sealing means formed by a plug, collar, flange, rib or the like contacting the internal surface of a container neck

- B65D41/0421—Threaded or like caps or cap-like covers secured by rotation with integral sealing means formed by a plug, collar, flange, rib or the like contacting the internal surface of a container neck and combined with integral sealing means contacting other surfaces of a container neck

Definitions

- the invention relates to a closure cap with tamper-evident locking ring according to the preamble of patent claim 1.

- a closure cap of a similar type is known for example from DE-PS 27 04 461.

- the connecting webs are arranged such that they run approximately radially in the transition from the outer circumference of the screw cap to the upper circumference of the locking ring, supporting segments being arranged on the upper circumference of the locking ring in the closing direction of rotation in front of the connecting webs.

- a support segment is preferably arranged in front of each connecting web in the closing direction of rotation.

- the screw cap is unscrewed further after the connecting webs have been torn, the retaining ring remains on the neck of the container, while the screw cap can be completely unscrewed and screwed back on as required.

- a closure cap of the generic type is known from DE-U-79 08 673.

- the risk of injury discussed above has already been reduced insofar as the connecting webs on the screw cap are injection molded in a recessed manner with respect to the lower edge thereof.

- This is realized in that the connection area formed by the connecting webs between the securing ring and the screw cap is covered on the outside by a collar which runs around the outside and which defines the lower edge of the screw cap with its lower edge.

- a collar which runs around the outside and which defines the lower edge of the screw cap with its lower edge.

- the present invention is therefore based on the object of further improving a closure cap with tamper-evident locking ring of the type described at the outset in such a way that the risk of injury when the closure cap is actuated can be completely ruled out.

- the connecting webs have gating ends lying radially inside the lower edge of the screw cap.

- the connecting webs have gating ends, which, with respect to the axis of rotation of the closure cap, are arranged axially between the upper circumference of the securing ring and the lower edge of the screw cap.

- the connecting webs are preferably provided with predetermined breaking points at their recessed injection ends.

- Essential to the invention is the idea of arranging the gating ends of the connecting webs sunk in relation to the lower edge of the screw cap in a recess or a recess within the lower edge of the screw cap.

- the container which can be, for example, a drug container

- the tearing ends of the connecting webs remain completely within the lower edge of the screw cap, in particular in the recesses or recesses on the lower edge of the screw cap, so that none axially over this lower edge or radially protruding tearing ends more, which could pose a risk of injury to the users of the screw cap.

- closure cap for pharmaceutical containers

- this represents a very significant advantage, since experience has shown that pharmaceuticals are taken in particular by older people and it has been scientifically proven that the skin of people over the age of 50 is increasingly thinning, so that in this group of people

- the risk of injury due to the actuation of closure caps of the type described at the outset is particularly high, in particular also in view of the fact that the screwing and screwing operations on pharmaceutical containers take place in relatively large numbers.

- the closure cap according to the invention allows it to be screwed onto a container both by hand and with the aid of sealing machines, the connecting webs being secured against mechanical stress when screwed on for the first time, but can be removed in a simple and easy manner when unscrewing the first time.

- the closure cap according to the invention can be used in commercially available containers, for example pharmaceutical bottles with a so-called transfer ring in the form of an annular bead on the container neck, and can also be injection-molded from plastic in one operation.

- a first embodiment of a closure cap 1 is shown, the right half a side view and the left half a section in the diameter plane shows.

- the cap 1 is provided with a tamper-evident locking ring 3, which is integrally formed with a screw cap 5 via connecting webs 4 (see FIGS. 2 and 3).

- the screw cap 5 has, in a known manner, an internal thread 2 for screwing the closure cap onto a container neck (not shown) with a corresponding screw thread, this container neck also having a mouth opening and a transfer ring in a known manner.

- the screw cap 5 On its outer circumference, the screw cap 5 is also provided with gripping ribs in a known manner.

- the securing ring 3 is 5 out of a larger diameter than the screw cap are, for example, six connecting bars 4 between the screw cap 5 and locking ring 3 is provided, said connecting webs are in each case distributed at an interval of 60 o uniformly over the outer circumference of the screw cap. 5

- the connecting webs 4 are now molded onto the screw cap 5 in a recessed manner with respect to the lower edge 15 thereof, such that in each case one connecting web 4 has a splash end 9 which is approximately radially inside the lower edge 15 of the screw cap 5 lies.

- niches or recesses 10 are formed in the region of the lower edge 15 of the screw cap 5 for receiving the gating ends 9 of the connecting webs 4, which thus are also equally spaced at 60 o over the outer circumference of the screw cap 5 are distributed.

- Each of the niches or recesses 10 is defined by a horizontal upper edge 7 and by two lateral, vertical flanks 11a and 11b delimited, these side flanks 11a and 11b each passing over rounded corners into the lower edge 15 of the screw cap 5.

- the upper edge 7 of the recess or recess 10 also forms a further lower edge of the screw cap 5 in this area.

- the upper edge 7 of the recess or recess 10 and the lower edge of the screw cap 5 initially merges into the gating end 9 of the connecting web 4 and then sits in the radial direction over the upper edge of the connecting web 4 in the upper circumference 8 of the Circlip 3 continues.

- the connecting web 4 is essentially triangular in profile, the side of the connecting web 4 opposite the gating end 9 being connected in one piece to the inside 12 of the securing ring 3.

- the gating ends 9 of the connecting webs 4, which are sunk in the recesses or recesses 10, are preferably provided with predetermined breaking points, which makes it easier for the connecting webs 4 to be torn off or sheared off during the first screwing-on process for the purpose of separating the screw cap 5 from the securing ring 3.

- the gating ends 9 of the connecting webs 4 are eccentrically in the niches or recesses 10, i.e. thus arranged off-center in the area between the lateral flanks 11a and 11b.

- support elements or support cams 6 are provided in front of the connecting webs, and in each case a support element or support cam 6 with an approximately triangular profile is arranged in front of each connecting web 4.

- the axial height of the support elements or support cams 6 is chosen to be greater than the axial height of the connecting webs 4, in particular the axial height of a support element or piece cam 6 being somewhat larger than the distance between the lower edge 15 of the screw cap 5 and the upper edge 7 of the recess or Recess 10.

- the support element or the piece cam 6 also projects partially into the recess or recess 10 and is likewise arranged off-center in relation to the lateral flanks 11a and 11b.

- the locking ring 3 also has on its lower edge 16 a number of mutually spaced, inwardly projecting gripping elements or gripping cams 13 (see FIGS. 1 and 4), in each case viewed in the axial direction below the arrangement of a niche or recess 10 within the lower edge 15 of the screw cap 5.

- the elastic, approximately bead-shaped gripping elements or gripping cams 13 are thus also equally spaced at a distance of 60 o each at the lower edge 16 of the locking ring 3 and serve to engage behind a transfer ring of a container in the closed position of the closure cap 1.

- a closed gripping ring or a gripping ring with expansion slots is provided be, which engages behind the transfer ring of the container in the closed position of the closure cap.

- the securing ring 3 When the cap 1 is first screwed onto the external thread of a neck of a container filled with any filling material, the securing ring 3 first runs with its lower edge 16 onto the transfer ring of the container neck, and during the further screwing-on process the elastic gripping elements or gripping cams 13 are stretched so that the Circlip 3 can be rotated downward via this transfer ring, the gripping elements or gripping cams 13 engaging behind the lower edge of the transfer ring with their corresponding surfaces.

- the retaining ring 3 is held in position by the transfer ring, causing the connecting webs 4 to expand until they tear, such that the connecting webs 4 tear off at the predetermined breaking points of the sprayer 9, which now act as tearing ends remain on the upper edge 7 of the associated niche or recess 10 and do not protrude beyond the outer circumference of the screw cap 5.

- the remaining part of the connecting webs 4 remains on the inside 12 of the retaining ring 3, which itself remains on the neck of the container, while the screw cap 5 can be unscrewed in a known manner and screwed on again as required.

- the support elements or support cams 6 arranged in the closing direction of rotation (arrow S) in front of the connecting webs 4 ensure that the first Closing the container, ie the first time the cap 1 is screwed onto the container neck, the connecting webs 4 can lie circumferentially against a support surface formed by the profile of the supporting elements or supporting cams 6, so that tearing off of the connecting webs 4 when screwing on is avoided with certainty.

- a variant compared to the embodiment according to FIGS. 1-3 is that the screw cap 5 extends on its inner side 5 'in an inner, axially downward to the lower edge 15 Boundary wall 14 continues, which thus delimits the recess or recess 10 towards the inside of the screw cap 5, such that a recess 10 is defined by the upper edge 7, the two side flanks 11a and 11b and the inside of the inner boundary wall 14.

- This inner boundary wall 14 is preferably skin-like or film-like and is used, for example, in certain applications to shield connecting webs 4 and support cams 6 towards the inside.

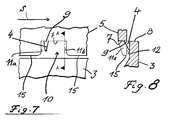

- FIGS. 7 and 8 a further embodiment of a closure cap with tamper-evident locking ring can be seen, which is compared to the in the 2 and 3 or 5 and 6 illustrated embodiments is modified in such a way that no special support elements or support cams 6 are now provided on the inside 12 of the locking ring 3 in front of the connecting webs 4. Rather, in the exemplary embodiment according to FIGS.

- a constructive modification is made in such a way that in each case a connecting web 4 is arranged within the associated niche or recess 10 in such a way that this connecting web 4 in the closing direction of rotation, ie in the direction of the arrow S seen, lies at a relatively short distance behind the vertical lateral flank 11a of the recess or recess 10.

- the side flanks 11a of the recesses or recesses 10 are thus practically immediately in front of the connecting webs 4 in the direction of the arrow S, which ensures that when the container is closed for the first time, i. when the cap 1 is screwed onto the container neck for the first time, the connecting webs 4 can lie against the supporting surfaces formed by these lateral flanks 11a in the circumferential direction, so that in this embodiment, the connecting webs 4 are also reliably avoided when screwing on.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Closures For Containers (AREA)

- Adornments (AREA)

- Burglar Alarm Systems (AREA)

Claims (16)

- Capuchon avec anneau d'inviolabilité en matière plastique, dans lequel une partie de bord est réalisée, sous la forme d'un anneau d'inviolabilité (3), par l'intermédiaire de pattes de liaison (4), d'une seule pièce avec un capuchon fileté (5) qui peut être vissé sur un goulot de récipient muni d'un filet et d'un bourrelet annulaire pour immobiliser axialement l'anneau d'inviolabilité (3) sur le goulot fileté, l'anneau d'inviolabilité (3) comportant, sur son bord inférieur, un anneau de préhension élastique ou une pluralité d'éléments de préhension élastiques disposés selon un écartement mutuel pour s'engager derrière le bourrelet annulaire lorsque le capuchon est en position fermée, et les pattes de liaison (4) étant moulées par injection sur le capuchon fileté (5), en retrait par rapport au bord inférieur (15) de ce dernier, caractérisé en ce que chaque extrémité moulée (9) des pattes de liaison (4) est disposée dans une niche ou un évidement (10) ménagé dans le bord inférieur (15) du capuchon fileté (5).

- Capuchon selon la revendication 1, caractérisé en ce que les pattes de liaison (4) comportent des extrémités moulées (9) disposées radialement à l'intérieur du bord inférieur (15) du capuchon fileté (5).

- Capuchon selon la revendication 1 ou 2, caractérisé en ce que les pattes de liaison (4) comportent des extrémités moulées (9) qui, par rapport à l'axe de rotation du capuchon (1), sont disposées axialement entre le pourtour supérieur (8) de l'anneau d'inviolabilité (3) et le bord inférieur (15) du capuchon fileté (5).

- Capuchon selon l'une des revendications 1 à 3, caractérisé en ce que les pattes de liaison (4) sont munies de points de rupture théorique à leurs extrémités moulées (9) disposées en retrait.

- Capuchon selon l'une des revendications 1 à 4, caractérisé en ce que la niche ou l'évidement (10) est limité par un bord supérieur horizontal (7) ainsi que par deux flancs latéraux verticaux (11a, 11b), le bord supérieur (7) ainsi que les flancs latéraux (11a, 11b) se trouvant à l'intérieur de la paroi dans la zone du bord inférieur (15) du capuchon fileté (5), et l'extrémité moulée respective (9) de la patte de liaison (4) formant un point de liaison avec ce bord supérieur (7) de la niche ou de l'évidement (10).

- Capuchon selon la revendication 5, caractérisé en ce que le côté intérieur (5') du capuchon fileté (5) se prolonge par une paroi intérieure de limitation (14) pour la niche ou l'évidement (10), ladite paroi s'étendant axialement vers le bas jusqu'au bord inférieur (15) du capuchon fileté (5).

- Capuchon selon la revendication 6, caractérisé en ce que la paroi intérieure de limitation (14) de la niche ou de l'évidement (10) est réalisés sous la forme d'une membrane ou d'une pellicule.

- Capuchon selon l'une des revendications 1 à 7, caractérisé en ce que chaque extrémité moulée (9) est disposée de manière excentrée dans les niches ou les évidements (10).

- Capuchon selon l'une des revendications 1 à 8, caractérisé en ce que chacune des extrémités des pattes de liaison opposée à l'extrémité moulée (9) des pattes de liaison (4) est solidarisée avec le côté intérieur (12) de l'anneau d'inviolabilité (3) opposé aux niches ou aux évidements (10).

- Capuchon selon la revendication 9, caractérisé en ce que, dans le sens de rotation de fermeture (S) devant les pattes de liaison (4) est disposé un élément d'appui ou un ergot d'appui (6) sur le côté intérieur (12), opposé à une niche ou à un évidement (10), de l'anneau d'inviolabilité (3).

- Capuchon selon la revendication 10, caractérisé en ce que chacun des éléments d'appui ou ergots d'appui (6) est disposé de manière excentrée par rapport aux niches ou aux évidements (10).

- Capuchon selon l'une des revendications 1 à 11, caractérisé en ce que les pattes de liaison (4) présentent sensiblement un profil triangulaire.

- Capuchon selon l'une des revendications 10 à 12, caractérisé en ce que les éléments d'appui ou ergots d'appui (6) présentent un profil sensiblement triangulaire et leur extrémité libre fait saillie, au moins en partie, du côté intérieur (12) de l'anneau d'inviolabilité (3) dans la niche ou l'évidement (10).

- Capuchon selon l'une des revendications 10 à 13, caractérisé en ce que, vue dans le sens axial, la hauteur de l'élément d'appui ou de l'ergot d'appui (6) est supérieure à la hauteur de la patte de liaison (4).

- Capuchon selon l'une des revendications 1 à 14, caractérisé en ce que les pattes de liaison (14) sont disposées de façon que chacune d'elles forme un prolongement radial du pourtour supérieur (8) de l'anneau d'inviolabilité (3) jusqu'à l'extrémité moulée (9) sur le bord supérieur (7) à l'intérieur de la niche ou de l'évidement (10).

- Capuchon selon l'une des revendications 1 à 10 et/ou 12 et/ou 15, caractérisé en ce que les pattes de liaison (4) sont disposées à l'intérieur des niches ou des évidements (10) de façon qu'une patte de liaison (4), vue dans le sens de rotation de fermeture (S), se trouve à une distance relativement réduite derrière le flanc latéral vertical correspondant (11a) de la niche ou de l'évidement (10), de sorte que ces flancs (11a) forment des surfaces d'appui pour les pattes de liaison (4) lors du premier vissage du capuchon (1).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT88101943T ATE84486T1 (de) | 1987-05-12 | 1988-02-10 | Verschlusskappe mit originalitaets-sicherungsring. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19873715862 DE3715862A1 (de) | 1987-05-12 | 1987-05-12 | Verschlusskappe mit originalitaets-sicherungsring |

| DE3715862 | 1987-05-12 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0290720A2 EP0290720A2 (fr) | 1988-11-17 |

| EP0290720A3 EP0290720A3 (en) | 1990-06-06 |

| EP0290720B1 true EP0290720B1 (fr) | 1993-01-13 |

Family

ID=6327382

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP88101943A Expired - Lifetime EP0290720B1 (fr) | 1987-05-12 | 1988-02-10 | Capuchon avec anneau d'inviolabilité |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP0290720B1 (fr) |

| AT (1) | ATE84486T1 (fr) |

| DE (2) | DE3715862A1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7621411B2 (en) | 2000-02-07 | 2009-11-24 | Locite (R&D) Limited | Applicator, applicator cap and a container having an applicator cap |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB2223748A (en) * | 1988-09-09 | 1990-04-18 | Metal Closures Group Ltd | Closures |

| FR3103470B1 (fr) | 2019-11-26 | 2021-12-24 | El Sakkaf Sherif | Bouchon de bouteille amélioré |

Family Cites Families (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2421119A1 (fr) * | 1978-03-28 | 1979-10-26 | Captocap Ltd | Bouchon inviolable en matiere plastique |

| DE3421820A1 (de) * | 1984-06-13 | 1985-12-19 | Zeller Plastik Koehn, Gräbner & Co, 5583 Zell | Originalitaetsverschluss |

| DE8434870U1 (de) * | 1984-11-28 | 1985-01-24 | Golde GmbH Spritzgußwerk, 8192 Geretsried | Originalitaetsgesicherter Kunststoff-Schraubverschluss |

-

1987

- 1987-05-12 DE DE19873715862 patent/DE3715862A1/de active Granted

-

1988

- 1988-02-10 AT AT88101943T patent/ATE84486T1/de active

- 1988-02-10 DE DE8888101943T patent/DE3877413D1/de not_active Expired - Fee Related

- 1988-02-10 EP EP88101943A patent/EP0290720B1/fr not_active Expired - Lifetime

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7621411B2 (en) | 2000-02-07 | 2009-11-24 | Locite (R&D) Limited | Applicator, applicator cap and a container having an applicator cap |

Also Published As

| Publication number | Publication date |

|---|---|

| DE3877413D1 (de) | 1993-02-25 |

| DE3715862C2 (fr) | 1990-04-19 |

| ATE84486T1 (de) | 1993-01-15 |

| EP0290720A3 (en) | 1990-06-06 |

| DE3715862A1 (de) | 1988-12-01 |

| EP0290720A2 (fr) | 1988-11-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3233805C2 (fr) | ||

| EP0137352A2 (fr) | Fermeture de garantie en matière plastique | |

| EP0049876A1 (fr) | Bouchon à vis inviolable | |

| DE2363054A1 (de) | Einrichtung zum verschliessen von flaschen und dgl. mittels schraubkapsel und zerreissbaren behaeltern fuer die anfaengliche getrennte aufbewahrung der komponenten des eingepackten erzeugnisses | |

| EP0593396A1 (fr) | Fermeture de garantie en matière plastique | |

| WO2007031162A1 (fr) | Fermeture a vis inviolable destinee a des recipients et des bouteilles, en particulier des bouteilles en plastique | |

| EP0254673A1 (fr) | Couvercle de récipient muni d'une bague de garantie | |

| DE2753080C2 (de) | Verschlußkappe mit Originalitätssicherung | |

| EP3934993A1 (fr) | Fermeture rotative en matière synthétique comprenant au moins un élément de liaison | |

| DE19617350A1 (de) | Kappenarretierung | |

| DE2638351C3 (de) | Garantieverschluß für Flaschen | |

| DE2130098A1 (de) | Flasche mit Steckkappenverschluss | |

| EP0290720B1 (fr) | Capuchon avec anneau d'inviolabilité | |

| CH715781A2 (de) | Schraubkappe und Kunststoffdrehverschluss mit einer Schraubkappe und einem Ausgussstutzen sowie einem Verbindungsmittel zur unverlierbaren Befestigung der Schraubkappe am Ausgussstutzen. | |

| EP0886606B1 (fr) | Orifice de contenant et bouchon de fermeture | |

| EP0589254A1 (fr) | Capuchon inviolable | |

| EP0387302B1 (fr) | Fermeture inviolable | |

| DE2755491C2 (fr) | ||

| DE4305138A1 (en) | Safety closure for bottles etc.with cap and safety ring with break line - has recesses between sectors formed around flanged lower edge of safety ring | |

| DE2349265C3 (de) | Vorrichtung zum Verschließen eines Behälters, insbesondere einer Flasche, mit einer Schraubkappe | |

| EP0060983B1 (fr) | Récipient avec fermeture de sécurité | |

| EP0344357B1 (fr) | Fermeture de récipient en forme de bouteille, en particulier pour liquide de rinçage | |

| DE2856433A1 (de) | Verschluss fuer behaelter | |

| DE10155578B4 (de) | Verschlussvorrichtung mit Originalitätsring | |

| DE4204977A1 (de) | Kindersicherheitsverschluss |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): AT DE FR GB IT |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT DE FR GB IT |

|

| 17P | Request for examination filed |

Effective date: 19900713 |

|

| 17Q | First examination report despatched |

Effective date: 19911009 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: HEINLEIN, PATRICIA |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT DE FR GB IT |

|

| REF | Corresponds to: |

Ref document number: 84486 Country of ref document: AT Date of ref document: 19930115 Kind code of ref document: T |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: HEINLEIN, HANS |

|

| ET | Fr: translation filed | ||

| ITF | It: translation for a ep patent filed | ||

| REF | Corresponds to: |

Ref document number: 3877413 Country of ref document: DE Date of ref document: 19930225 |

|

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) |

Effective date: 19930129 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19980126 Year of fee payment: 11 Ref country code: AT Payment date: 19980126 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19980216 Year of fee payment: 11 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19980424 Year of fee payment: 11 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990210 Ref country code: AT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19990210 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19990210 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19991029 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19991201 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: IT Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 20050210 |