EP0190608B1 - Fixation de talon - Google Patents

Fixation de talon Download PDFInfo

- Publication number

- EP0190608B1 EP0190608B1 EP86100820A EP86100820A EP0190608B1 EP 0190608 B1 EP0190608 B1 EP 0190608B1 EP 86100820 A EP86100820 A EP 86100820A EP 86100820 A EP86100820 A EP 86100820A EP 0190608 B1 EP0190608 B1 EP 0190608B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- heel clamp

- protective sheet

- detent member

- guide rail

- ski

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A63—SPORTS; GAMES; AMUSEMENTS

- A63C—SKATES; SKIS; ROLLER SKATES; DESIGN OR LAYOUT OF COURTS, RINKS OR THE LIKE

- A63C9/00—Ski bindings

- A63C9/005—Ski bindings with means for adjusting the position of a shoe holder or of the complete binding relative to the ski

Definitions

- the invention relates to a heel holder according to the first part of patent claim 1.

- AT-B-374 692 describes a device for the longitudinal adjustment of ski binding parts with a guide rail to be fastened to the ski, which is provided with two lateral guide strips and with two toothed strips arranged between them and extending in the longitudinal direction of the device, to which a locking element is assigned, which is under the influence of at least one with its other end on a guided on the guide rail, the heel holder carrying guide plate supported helical compression spring and which - seen from the side - has an approximately open U-shaped cross-section, the the web connecting the two legs carries the locking teeth.

- one leg of the locking member bears under the influence of the helical compression spring on a downwardly projecting shoulder of the guide plate, and the other leg can be locked in the raised position of the locking member, that is to say when the locking teeth are out of engagement with the toothed strips.

- the guide rail is provided with two rows of holes, in each of which two projections of a locking member, which is pressed under the influence of a helical spring against the guide rail, engage in the locked position of the device.

- the latching element is supported on a wall of the housing of the heel holder that projects downward. It is constantly coupled with an approximately U-shaped wire bracket, the web of which runs in the transverse direction to the guide rail is accommodated in a recess in the remote holder.

- a special tool in the form of a screwdriver with two grooves in the narrow side surfaces of the blade, directed towards the axis of the screwdriver, of the wire bracket and thus the locking element are raised by pivoting the screwdriver by 90 ° becomes.

- the heel holder can then be moved along the guide rail.

- the invention has for its object to provide a heel holder of the type mentioned, in which no damage to the toothed strips of the guide rail can take place even after prolonged use and repeated adjustment, wherein only a commercially available screwdriver is required for the adjustment process itself.

- the measure of claim 2 ensures a full support of the mudguard on the guide rail and prevents the same from bending by the screwdriver even when the latching element is pivoted up.

- the angular range specified in claim 3 has proven to be particularly advantageous.

- the subject of claim 4 has the advantage that a certain saving in the weight of the heel holder is achieved.

- the feature of claim 5 prevents the screwdriver from sliding off the mudguard in the direction of the teeth.

- the measure of claim 6 facilitates the approach of the screwdriver to the mudguard and at the same time prevents it from sliding backwards.

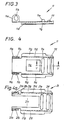

- Fig. 1 is a vertical longitudinal central section through an adjustment device provided on a heel holder, which is in the locked state

- Fig. 2 is a part of an analog section through the adjustment device in the unlocked state

- the mudguard is shown in side view and in plan view

- Fig. 5 shows a detail of the fender on a larger scale in section along the line VV in Fig. 4.

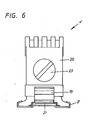

- Figs. 4a, 6 and 7 a second embodiment of a heel holder according to the invention is shown.

- Fig. 6 is a view of the same in the direction of arrow VI in Fig. 7, and Fig. 7 shows on a larger scale a partial section through the heel holder in the driving position, which partial section is taken through the vertical longitudinal median plane.

- 4a is a section similar to FIG. 4.

- the device shown in FIGS. 1 and 2 for the longitudinal adjustment of heel holders or the like is designated by 1 in its entirety. It consists of a guide rail 2 to be fastened to the ski, which is provided with two lateral guide strips and a recess extending centrally to its vertical longitudinal center plane. The latter is delimited on both sides by toothed bars 2a.

- a guide plate 3 is guided on the guide rail 2, on which a heel holder 4 is fastened.

- a web 5 is formed from the guide plate 3 and serves to support the transverse part of a guide element 6, which is U-shaped in plan view, for two helical compression springs 7.

- the guide plate 3 carries on its underside two lugs 8, which are intended to rest one leg 9a of the approximately U-shaped locking member 9.

- the leg 9a of the locking member 9 is plate-shaped and is penetrated by the ends of the legs 6a of the guide element 6 with play, so that it is pressed against the lugs 8 under the influence of the two helical compression springs 7, but against the guide element 6 within one certain area can pivot.

- a displacement of the legs 6a of the guide element 6 relative to the legs 9a is quite possible due to the game mentioned.

- the web 9b of the locking member 9 carries teeth which are intended for engagement in the toothed strips 2a of the guide rail 2.

- the leg 9c of the latching member 9 opposite the leg 9a is provided with an outwardly directed extension 9d which is used to raise the end of the latching member 9 by means of a screwdriver 10.

- a mudguard 11 which is intended to protect the two toothed strips 2a of the guide rail 2 against damage from the screwdriver 10 and therefore covers the toothed strips 2a in this area.

- the mudguard 11 has a rectangular recess 11c in its central region, which serves for the passage of the web 9b of the locking member 9 in the locked position thereof.

- the mudguard 11 has two bends 11a in one end region of its two long sides, in which elongated holes 11b b are left out (see FIG. 3). In these elongated holes 11b, horizontally arranged, transverse axles 9e engage, which project laterally from the locking member 9.

- the mudguard 11 carries two transverse ribs 11e and 11f, between which the end of the blade of the screwdriver 10 can be attached, as can be seen from FIGS. 1 and 2.

- the mudguard 11 which is approximately U-shaped in cross section, has two flanges 11g, which adjoin the ends of the two legs 11d and project with them, with which it rests on the regions of the guide rail 2 which adjoin the two toothed strips 2a in the transverse direction.

- the fender 11 is guided and stiffened by these flanges 11g, so that even with a very rough treatment of the adjusting device during the adjustment process, the mudguard 11 cannot bulge.

- the locking member 9 In the driving position of the heel holder 4, the locking member 9 is in the position shown in FIG. 1, in which it is pressed into the toothed strips 2a of the guide rail 2 by the two helical compression springs 7 with its web 9b supporting the teeth.

- the screwdriver 10 is inserted between the two ribs 11e and 11f and pivoted counterclockwise in the direction of the arrow 10a (see FIGS. 1 and 2).

- the locking member 9 is lifted out of the two toothed strips 2a, and the heel holder 4 can be adjusted along the guide rail 2.

- the two semiaxes 9e slide upwards along the two elongated holes 11b of the mudguard 11 until the locking member 9 has reached its upper position (see FIG. 2).

- the locking member 9 is pivoted back into the position shown in FIG. 1 under the influence of the two helical compression springs 7.

- the heel holder according to FIGS. 6 and 7 is designated in its entirety by 4 '. It is mounted on a guide rail 2 'which, in contrast to the guide rail 2 of the first exemplary embodiment, is provided with a row of holes 2'a.

- the heel holder 4 ' has a bearing block 20, in which a detent spring 22 is accommodated, which can be adjusted in its pretension by means of a screw 23, which acts on a spring plate 24.

- a locking member 19 is pivotally mounted at its left end in FIG. 7 in a manner not shown.

- the locking member 19 is acted upon by a spring 17, which strives to press the locking member into the locked position.

- the locking member 19 carries on its underside three locking teeth 19a, which are intended to engage in the holes in the row of holes 2'a.

- the end 19d of the locking member 19 protrudes beyond the rear boundary wall of the bearing block 20 and is used to engage a screwdriver with which the locking member 19 can be pivoted from the locked position into the unlocked position.

- a mudguard 21 which, in contrast to the mudguard 11 according to the first embodiment, as can be seen in connection with FIG Both legs 21c have bearing eyes 21a at their ends, in the elongated holes 21b of which semi-axes 19e engage, which are fastened to the locking member 19.

- the mudguard 21 also has two transverse ribs 21e and 21f on its section protruding beyond the rear boundary wall of the bearing bracket 20, which prevent the screwdriver from sliding off the mudguard.

- only the area of the perforated guide rail 2 ′ opposite the free end 19d of the locking member 19 is covered by the mudguard 21.

- the handling of the locking member 19 corresponds to that of the locking member 9, so that a more detailed explanation of the handling is unnecessary.

- the invention is by no means bound to the exemplary embodiments shown in the drawing and described above. Rather, various modifications of the same are conceivable without leaving the scope of the invention.

- the mudguard according to the invention can be used in versions in which the locking member can be locked in the pivoted-up position on the heel holder.

Landscapes

- Fittings On The Vehicle Exterior For Carrying Loads, And Devices For Holding Or Mounting Articles (AREA)

- Footwear And Its Accessory, Manufacturing Method And Apparatuses (AREA)

Claims (6)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT0027985A AT381456B (de) | 1985-02-01 | 1985-02-01 | Fersenhalter, insbesondere fuer leihski |

| AT279/85 | 1985-02-01 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0190608A2 EP0190608A2 (fr) | 1986-08-13 |

| EP0190608A3 EP0190608A3 (en) | 1987-08-05 |

| EP0190608B1 true EP0190608B1 (fr) | 1990-05-02 |

Family

ID=3486318

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP86100820A Expired - Lifetime EP0190608B1 (fr) | 1985-02-01 | 1986-01-22 | Fixation de talon |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4690424A (fr) |

| EP (1) | EP0190608B1 (fr) |

| JP (2) | JPS61181478A (fr) |

| CN (1) | CN86100094B (fr) |

| AT (1) | AT381456B (fr) |

| DE (1) | DE3670771D1 (fr) |

Families Citing this family (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR2614545B1 (fr) * | 1987-04-30 | 1989-06-16 | Salomon Sa | Fixation de securite pour ski |

| FR2614540B1 (fr) * | 1987-04-30 | 1989-06-09 | Salomon Sa | Outil de reglage d'une fixation de ski |

| FR2638654B1 (fr) * | 1988-11-08 | 1991-02-08 | Salomon Sa | Fixation de securite pour ski |

| EP0394513B1 (fr) * | 1989-04-25 | 1993-04-28 | Look S.A. | Fixation de sécurité de ski |

| FR2656226B1 (fr) * | 1989-12-27 | 1992-04-24 | Salomon Sa | Fixation de securite pour ski. |

| AT395538B (de) * | 1990-10-12 | 1993-01-25 | Tyrolia Freizeitgeraete | Vorrichtung zur laengsverstellung von fersenhaltern |

| FR2684889B1 (fr) * | 1991-12-13 | 1994-02-04 | Salomon Sa | Piece d'interface pour la glissiere d'un element de fixation, notamment de fixation alpine. |

| FR2899121B1 (fr) * | 2006-03-29 | 2008-07-04 | Salomon Sa | Ensemble ski de fond et dispositif de fixation de ski de fond |

| FR2912317B1 (fr) * | 2007-02-13 | 2009-05-08 | Salomon Sa | Ensemble comprenant un dispositif de solidarisation amovilble d'une embase a une platine. |

| NO20170891A1 (no) * | 2017-05-30 | 2018-09-03 | Rottefella As | Festemekanisme for et låseorgan som skal festes til en monteringsplate på en langrennsski |

| RU178628U1 (ru) * | 2017-07-12 | 2018-04-13 | Станислав Викторович Мозговой | Крепление для беговых лыж с упрощенной установкой на лыжу с помощью шурупов |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT276180B (de) * | 1965-12-20 | 1969-11-10 | Smolka & Co Wiener Metall | Skibindungselement |

| FR2451756A1 (fr) * | 1979-03-19 | 1980-10-17 | Salomon & Fils F | Fixation de securite pour ski |

| AT371348B (de) * | 1981-06-12 | 1983-06-27 | Tyrolia Freizeitgeraete | Vorrichtung zur laengsverstellung von skibindungs- teilen |

| DE3214585C3 (de) * | 1982-04-20 | 1996-06-13 | Rohrmoser Alois Skifabrik | Skibindung |

| AT374692B (de) * | 1982-07-05 | 1984-05-25 | Tyrolia Freizeitgeraete | Vorrichtung zur laengsverstellung von skibindungsteilen |

| AT377701B (de) * | 1983-03-04 | 1985-04-25 | Tyrolia Freizeitgeraete | Vorrichtung zur laengsverstellung |

-

1985

- 1985-02-01 AT AT0027985A patent/AT381456B/de not_active IP Right Cessation

-

1986

- 1986-01-14 CN CN86100094A patent/CN86100094B/zh not_active Expired

- 1986-01-22 EP EP86100820A patent/EP0190608B1/fr not_active Expired - Lifetime

- 1986-01-22 DE DE8686100820T patent/DE3670771D1/de not_active Expired - Fee Related

- 1986-01-29 US US06/823,552 patent/US4690424A/en not_active Expired - Fee Related

- 1986-01-31 JP JP61018256A patent/JPS61181478A/ja active Pending

-

1991

- 1991-08-19 JP JP1991065251U patent/JPH0630220Y2/ja not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| EP0190608A2 (fr) | 1986-08-13 |

| DE3670771D1 (de) | 1990-06-07 |

| AT381456B (de) | 1986-10-27 |

| CN86100094A (zh) | 1986-10-22 |

| ATA27985A (de) | 1986-03-15 |

| US4690424A (en) | 1987-09-01 |

| JPH0488979U (fr) | 1992-08-03 |

| CN86100094B (zh) | 1988-05-18 |

| JPH0630220Y2 (ja) | 1994-08-17 |

| EP0190608A3 (en) | 1987-08-05 |

| JPS61181478A (ja) | 1986-08-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2624429B2 (de) | Klemmittel | |

| EP0190608B1 (fr) | Fixation de talon | |

| DE3020346C2 (fr) | ||

| DE2830676C2 (de) | Skihaltevorrichtung | |

| DE19603657B4 (de) | Sicherheitszubehör für Fahrzeuge | |

| DE2945330A1 (de) | Verbinder zwischen einem wischblatthalter und einem wischarm | |

| DE3151964A1 (de) | Vorrichtung zur loesbaren befestigung | |

| DE69500498T2 (de) | Mehrzweck-Gepäckträger für Kraftfahrzeuge, insbesondere zum Transportieren von Skiern, Surfbrettern oder ähnlichem | |

| DE69311074T2 (de) | Vorrichtung zum Positionieren und Festhalten von optischen Fasern in einer Ebene | |

| EP0831001A1 (fr) | Rancher pour une bache | |

| DE3717108C2 (de) | Sicherheitsskibindung sowie aus Ski und Sicherheitsbindung bestehende Gesamtheit | |

| DE3881804T2 (de) | Transportwagen. | |

| DE2947121C2 (de) | Halterungsvorrichtung für Skipaare | |

| DE69502842T2 (de) | Vorrichtung, die einen Dachgepäckträger eines Kraftfahrzeuges bildet | |

| EP0051051B1 (fr) | Galerie pour véhicules | |

| AT264178B (de) | Eggenbalken | |

| DE19860213B4 (de) | Hordenwagen | |

| DE3021098A1 (de) | Regalwagen als putz- und arbeitswagen, insbesondere fuer krankenhaeuser und hotels | |

| DE2729726C2 (de) | Griffbefestigung an einem Geschirr | |

| DE2816952C2 (de) | Gelenkverbindung zur lösbaren Lagerung von Wendetafeln in Halteschienen | |

| DE2630451C3 (fr) | ||

| DE2928871C2 (fr) | ||

| DE2936404A1 (de) | Dreipunktaufhaengevorrichtung fuer schlepper | |

| DE3003420C2 (fr) | ||

| DE3007608C2 (de) | Vorrichtung zum Halten von Gegenständen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Kind code of ref document: A2 Designated state(s): CH DE FR LI |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): CH DE FR LI |

|

| 17P | Request for examination filed |

Effective date: 19870808 |

|

| 17Q | First examination report despatched |

Effective date: 19881207 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): CH DE FR LI |

|

| REF | Corresponds to: |

Ref document number: 3670771 Country of ref document: DE Date of ref document: 19900607 |

|

| ET | Fr: translation filed | ||

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PUE Owner name: AMF CORPORATION TRANSFER- HTM SPORTS CORP. Ref country code: CH Ref legal event code: PFA Free format text: TMC CORPORATION |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP Ref country code: FR Ref legal event code: CD |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Free format text: HTM SPORT- UND FREIZEITGERAETE AKTIENGESELLSCHAFT |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: TP |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19950104 Year of fee payment: 10 Ref country code: DE Payment date: 19950104 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19950127 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19960131 Ref country code: CH Effective date: 19960131 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19960930 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19961001 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |