EP0148495B1 - Radiateur multivalent pour le chauffage de locaux - Google Patents

Radiateur multivalent pour le chauffage de locaux Download PDFInfo

- Publication number

- EP0148495B1 EP0148495B1 EP84116177A EP84116177A EP0148495B1 EP 0148495 B1 EP0148495 B1 EP 0148495B1 EP 84116177 A EP84116177 A EP 84116177A EP 84116177 A EP84116177 A EP 84116177A EP 0148495 B1 EP0148495 B1 EP 0148495B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- convector

- radiator

- lamellae

- convectors

- operated

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28F—DETAILS OF HEAT-EXCHANGE AND HEAT-TRANSFER APPARATUS, OF GENERAL APPLICATION

- F28F13/00—Arrangements for modifying heat-transfer, e.g. increasing, decreasing

- F28F13/14—Arrangements for modifying heat-transfer, e.g. increasing, decreasing by endowing the walls of conduits with zones of different degrees of conduction of heat

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F28—HEAT EXCHANGE IN GENERAL

- F28D—HEAT-EXCHANGE APPARATUS, NOT PROVIDED FOR IN ANOTHER SUBCLASS, IN WHICH THE HEAT-EXCHANGE MEDIA DO NOT COME INTO DIRECT CONTACT

- F28D1/00—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators

- F28D1/02—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid

- F28D1/04—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with tubular conduits

- F28D1/053—Heat-exchange apparatus having stationary conduit assemblies for one heat-exchange medium only, the media being in contact with different sides of the conduit wall, in which the other heat-exchange medium is a large body of fluid, e.g. domestic or motor car radiators with heat-exchange conduits immersed in the body of fluid with tubular conduits the conduits being straight

Definitions

- the invention relates to a radiator for room air heating with convectors acted upon by heating media from different energy sources and at different temperature levels, which carry heat-conducting fins, which, according to their temperature level with thermal insulation distance between them, divide an air duct in the direction of flow into many rising, open at the top and bottom .

- Such multivalent radiators are used, for example, to a conventional convector by connecting a z. B. to support with solar energy or flue gas operated convector.

- the known multivalent heating system according to DE-A-2 945 071 has the disadvantage that the overall efficiency is impaired by thermal feedback, be it by turbulence in the air flow or by conduction of heat from the convector system to the convector system at a lower temperature and the efficiency remains below 50%.

- the invention is therefore based on the object of suppressing the thermal feedback from the convector system to the convector system of low temperature in the multivalent radiator system of the type described in DE-A-2 945 071.

- This object is achieved in that the slats of the convector of higher temperature with the slats of the convector of low temperature are connected with each other by keeping the open cables by thermal bridges made of a poorly conductive material. This results in a multivalent heating system with undisturbed laminar air flow and practically non-reactive heat exchange in several, spatially and thermally superimposed stages. This creates a so-called mode of operation between the upper convector with a higher working temperature and the lower convector with a lower working temperature.

- the fins are arranged at a heat-insulating distance from one another.

- the invention is primarily concerned with excluding feedback via the shaft wall.

- the arrangement of heat-insulating zones made of heat-insulating solid material is particularly important in the area of the adjacent lamella edges in order to avoid air vortices in this area.

- it is even more important to exclude the heat conduction from the convector to the convector of lower temperature, which is present in the known radiator according to DE-A-2 945 071 via the shaft wall.

- this heat conduction is suppressed in the invention in that the heat feedback is also suppressed via the path of indirect heat conduction via the shaft wall through thermal insulation zones.

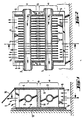

- the examples of a multivalent radiator shown in the drawing are used for room air heating with convectors acted on from different energy sources, a lower convector 1 and an upper convector 2.

- the convectors 1 are arranged in a common air duct. They are operated by heating media M 1 and M 2 from different heating sources, the upper convector 2 from a conventional heating source, the lower convector 1 from an auxiliary heating source, in particular for the use of solar energy.

- the tubular convectors 1 and 2 are covered with rectangular slats 3 and 4. Between the convector zone a of the lower temperature and the convector zone c of the higher temperature there is a transition zone b in which the lamellae 3 and 4 forming vertical trains 14 are separated from each other, either by a separation gap 8 or by insulating bridges 11 poorly heat-conducting material, for example plastic (see FIGS. 6 and 7).

- the shaft 5 is formed by a metallic one running from top to bottom Shaft wall 5 limited.

- a heat insulation zone is switched on in the heat conduction path from the convector zone c to the convector zone a in order to prevent thermal feedback via heat conduction paths.

- the outer metallic shaft wall 5 is lined overall by an inner insulating wall 6 made of plastic or other, poorly heat-conducting material to form the thermal insulation zone. 3, this lining can be interrupted in the transition zone b.

- FIG. 4 the lining is replaced by insulation strips 7 with which the slats 3, 4 are connected to the metal shaft wall 5.

- the lining can also, as FIG. 9 shows, be designed as an insulation collar, which adjoin one another from lamella 3 to lamella 4 and likewise form a continuous lining.

- FIGS. 6 and 7 show lamellae 3, 4 with a solid body connection by means of insulating bridges 11.

- This embodiment is distinguished in particular by that continuous, that is, uninterrupted trains 14 are formed via the convector systems, which ensure an undisturbed ascending laminar air flow which is only subjected to the thermals. This prevents feedback from both heat conduction and air flow due to eddy formation.

- FIG. 5 shows an embodiment in which the slats 4 of the upper convector 2 are connected directly to the metal shaft wall 5.

- the feedback by heat conduction to the lower convector 1 is avoided by switching on an insulation barrier 9 between the metallic wall above and below. If heat radiation is to take place in the area of the upper convector 2, the slats 4 of this convector 2 can be connected in a heat-conducting manner to the upper shaft wall 5 ′′, while the slats 3 of the lower convector 1 against the lower metal shaft wall 5 ′ through an insulating wall or through Insulation strips 7 are thermally insulated, which means that the thermal energy of the lower convector 1 is largely used to support the upper convector 2.

- a flap 15 can be provided on the upper exit side of the shaft, through which a baffle surface for deflecting the warm air, This flap 15 can also be arranged so that it can be deflected so that, if necessary, the warm air flow is deflected away from the window front into the room.

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT84116177T ATE41226T1 (de) | 1983-12-29 | 1984-12-22 | Multivalenter heizkoerper zur raumluftbeheizung. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3347438A DE3347438A1 (de) | 1983-12-29 | 1983-12-29 | Multivalenter heizkoerper zur raumluftbeheizung |

| DE3347438 | 1983-12-29 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0148495A2 EP0148495A2 (fr) | 1985-07-17 |

| EP0148495A3 EP0148495A3 (en) | 1986-07-23 |

| EP0148495B1 true EP0148495B1 (fr) | 1989-03-08 |

Family

ID=6218374

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84116177A Expired EP0148495B1 (fr) | 1983-12-29 | 1984-12-22 | Radiateur multivalent pour le chauffage de locaux |

Country Status (4)

| Country | Link |

|---|---|

| EP (1) | EP0148495B1 (fr) |

| JP (1) | JPH0689934B2 (fr) |

| AT (1) | ATE41226T1 (fr) |

| DE (2) | DE3347438A1 (fr) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101245971B (zh) * | 2007-04-10 | 2010-12-08 | 马永锡 | 密闭腔式换热器 |

| JP5006122B2 (ja) | 2007-06-29 | 2012-08-22 | 株式会社Sokudo | 基板処理装置 |

| JP5128918B2 (ja) | 2007-11-30 | 2013-01-23 | 株式会社Sokudo | 基板処理装置 |

| JP5179170B2 (ja) | 2007-12-28 | 2013-04-10 | 株式会社Sokudo | 基板処理装置 |

| JP5001828B2 (ja) | 2007-12-28 | 2012-08-15 | 株式会社Sokudo | 基板処理装置 |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE840252C (de) * | 1942-06-06 | 1952-05-29 | Basf Ag | Gasbeheizter Kreuzstromwaermeaustauscher |

| FR1217649A (fr) * | 1958-05-17 | 1960-05-04 | Radiateur pour chauffages centraux à eau chaude ou à vapeur à basse pression | |

| FR1389311A (fr) * | 1964-04-13 | 1965-02-12 | Système de tubes à ailettes, notamment pour préchauffeurs d'eau d'alimentation de chaudières à vapeur | |

| DE2747344A1 (de) * | 1977-10-21 | 1979-04-26 | Gerhard Dipl Ing Pruefling | Heizkoerper |

| DE7928453U1 (de) * | 1979-10-06 | 1980-02-28 | Skapargiotis, Georg, 7850 Loerrach | Heizkoerper insbesondere fuer eine zentralheizungsanlage |

| DE2945071A1 (de) * | 1979-11-08 | 1981-05-21 | Ulrich 2814 Bruchhausen-Vilsen Grigat | Multivalenter-thermik-tauscher-heizkoerper |

-

1983

- 1983-12-29 DE DE3347438A patent/DE3347438A1/de active Granted

-

1984

- 1984-12-22 EP EP84116177A patent/EP0148495B1/fr not_active Expired

- 1984-12-22 DE DE8484116177T patent/DE3477049D1/de not_active Expired

- 1984-12-22 AT AT84116177T patent/ATE41226T1/de not_active IP Right Cessation

- 1984-12-27 JP JP59274242A patent/JPH0689934B2/ja not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| EP0148495A3 (en) | 1986-07-23 |

| JPH0689934B2 (ja) | 1994-11-14 |

| EP0148495A2 (fr) | 1985-07-17 |

| DE3347438A1 (de) | 1985-07-18 |

| DE3347438C2 (fr) | 1987-06-04 |

| JPS60228896A (ja) | 1985-11-14 |

| DE3477049D1 (en) | 1989-04-13 |

| ATE41226T1 (de) | 1989-03-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE2725239A1 (de) | Waermeaustauschsystem und metalltafel fuer ein waermeaustauschsystem | |

| EP0186756A1 (fr) | Combustion en lit fluidisé avec des surfaces de chauffe immergées | |

| EP0148495B1 (fr) | Radiateur multivalent pour le chauffage de locaux | |

| EP0449124B1 (fr) | Echangeur de chaleur à espace annulaire | |

| DE2126226C3 (de) | Wärmeaustauscher | |

| EP1108963A2 (fr) | Echangeur de chaleur pour gaz de combustion | |

| EP0045491B1 (fr) | Poêle pour chauffer des petits locaux | |

| DE3421746A1 (de) | Waermeaustauscher | |

| EP0473946B1 (fr) | Chaudière sectionnée | |

| EP0254760A1 (fr) | Appareil de chauffage de local pour petits locaux | |

| DE2239086C2 (de) | Wärmetauscher, insbesondere für Durchlauferhitzer | |

| DE3320012A1 (de) | Waermetauscher, insbesondere fuer lueftungs- und klimaanlagen | |

| DE1613759C3 (de) | Kühlvorrichtung für Transformatoren | |

| DE3232794A1 (de) | Brennkammerboden zu einer wirbelschichtfeuerung | |

| DE1933688A1 (de) | Lamellenheizkoerper | |

| EP1072846A2 (fr) | Convecteur pour plafond | |

| DE3327094A1 (de) | Anordnung zur rueckgewinnung der in verbrennungsabgasen, insbesondere feuerungsabgasen, enthaltenen waermeenergie | |

| DE3313296A1 (de) | Heizflaechenausbildung | |

| DE3431343A1 (de) | Tauchheizflaechen fuer eine wirbelschichtfeuerung | |

| DE2217065C3 (de) | Herdplatte | |

| DE3105230A1 (de) | Raumheizofen | |

| DE3010773A1 (de) | Waermetauscher | |

| DE3624394A1 (de) | Heizkoerper | |

| DE8128210U1 (de) | Vorrichtung zur erhoehung der waermeausbeute bei einem zimmerkamin oder herdfeuer | |

| DE2947432A1 (de) | Waermetauscher, deren ausbildung und anordnung in einer einrichtung zur waermerueckgewinnung durch luftaustausch, insbesondere fuer wohnhaeuser und vergleichbare anlagen |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| 17P | Request for examination filed |

Effective date: 19860805 |

|

| 17Q | First examination report despatched |

Effective date: 19861107 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB IT LI LU NL SE |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19890308 Ref country code: IT Free format text: LAPSE BECAUSE OF FAILURE TO SUBMIT A TRANSLATION OF THE DESCRIPTION OR TO PAY THE FEE WITHIN THE PRESCRIBED TIME-LIMIT;WARNING: LAPSES OF ITALIAN PATENTS WITH EFFECTIVE DATE BEFORE 2007 MAY HAVE OCCURRED AT ANY TIME BEFORE 2007. THE CORRECT EFFECTIVE DATE MAY BE DIFFERENT FROM THE ONE RECORDED. Effective date: 19890308 |

|

| REF | Corresponds to: |

Ref document number: 41226 Country of ref document: AT Date of ref document: 19890315 Kind code of ref document: T |

|

| REF | Corresponds to: |

Ref document number: 3477049 Country of ref document: DE Date of ref document: 19890413 |

|

| ET | Fr: translation filed | ||

| NLV1 | Nl: lapsed or annulled due to failure to fulfill the requirements of art. 29p and 29m of the patents act | ||

| GBT | Gb: translation of ep patent filed (gb section 77(6)(a)/1977) | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: AT Effective date: 19891222 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LU Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19891231 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19900131 Year of fee payment: 6 |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19901222 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19940622 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19940623 Year of fee payment: 10 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19940628 Year of fee payment: 10 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19941223 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19941231 Ref country code: CH Effective date: 19941231 Ref country code: BE Effective date: 19941231 |

|

| EAL | Se: european patent in force in sweden |

Ref document number: 84116177.1 |

|

| BERE | Be: lapsed |

Owner name: GRIGAT ULRICH Effective date: 19941231 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| EUG | Se: european patent has lapsed |

Ref document number: 84116177.1 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: RN |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19970630 Year of fee payment: 13 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: FC |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19971031 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Free format text: THE PATENT HAS BEEN ANNULLED BY A DECISION OF A NATIONAL AUTHORITY Effective date: 19971231 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Free format text: LAPSE BECAUSE OF NON-PAYMENT OF DUE FEES Effective date: 19980901 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |