EP0148328A2 - Interrupteur électrique avec des contacts fixes formés par des parties de pistes conductrices - Google Patents

Interrupteur électrique avec des contacts fixes formés par des parties de pistes conductrices Download PDFInfo

- Publication number

- EP0148328A2 EP0148328A2 EP84111611A EP84111611A EP0148328A2 EP 0148328 A2 EP0148328 A2 EP 0148328A2 EP 84111611 A EP84111611 A EP 84111611A EP 84111611 A EP84111611 A EP 84111611A EP 0148328 A2 EP0148328 A2 EP 0148328A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- contact

- fixed contacts

- tracks

- contacts

- conductor tracks

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H1/00—Contacts

- H01H1/12—Contacts characterised by the manner in which co-operating contacts engage

- H01H1/36—Contacts characterised by the manner in which co-operating contacts engage by sliding

- H01H1/40—Contact mounted so that its contact-making surface is flush with adjoining insulation

- H01H1/403—Contacts forming part of a printed circuit

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H19/00—Switches operated by an operating part which is rotatable about a longitudinal axis thereof and which is acted upon directly by a solid body external to the switch, e.g. by a hand

- H01H19/005—Electromechanical pulse generators

Definitions

- the invention relates to an electrical switch, the fixed contacts of which are covered with a metallic layer of parts of conductor tracks on a circuit board and the movable contacts are designed as sliding contacts that can be moved on predetermined contact tracks via the fixed contacts on the circuit board, and in the case of a contact track a plurality of electrically connected fixed contacts are provided.

- a copper layer that is laminated onto the printed circuit board is usually used as the material for the conductor tracks and from which the conductor tracks are etched, preferably using a photo-etching process.

- the copper conductor tracks are not suitable as contacts for a switch, since the copper easily oxidizes, which inadmissibly increases the contact resistance between the movable and the fixed contacts.

- Such fixed contacts formed from conductor tracks are usually covered with a noble metal layer, for example with a gold layer.

- This gold layer is usually applied by a galvanic process.

- all conductor tracks on the printed circuit board are covered with a gold layer.

- the gold plating has a very small thickness, for example a few ⁇ m, the gold layer, which is essential for the fixed contacts, makes up a considerable part of the price of the entire printed circuit board.

- the covering varnish remains on the printed circuit board after the free pieces of the conductive path have been glazed, since removing them would cause additional work steps and costs and, at the same time, as corrosion protection for them parts of the conductor tracks covered with an EdeLMetal layer.

- the covering lacquer for the fee may not be applied to the locations of the circuit boards that correspond to the contact paths of the movable contacts.

- the material of the lacquer layer would get on the movable and fixed contacts due to abrasion when the switch was actuated, thus giving rise to considerable contact faults. It has therefore been accepted that in the area of the contact tracks of the movable contacts, it is not possible to cover the conductor tracks before the charge.

- the object of the invention is to achieve a further saving in EdeLmetaLL with switches of the type mentioned.

- the invention is based on the knowledge that there are numerous switches of the specified type in which a plurality of fixed contacts arranged on a contact track are electrically connected to one another.

- An example of such switches are the so-called coding switches.

- Such electrically connected fixed contacts lying on a common contact path have so far only been used as one continuous contact, which of course runs the entire length with a layer of precious metal, e.g. B. a gold layer must be provided.

- the conductor tracks in the switches in question are obtained by etching out a copper layer originally completely covering the circuit board, the connecting lines and supply lines for the fixed contacts on the circuit board can be routed as desired and can also have any shape and length without the material consumption thereby being reduced or the manufacturing effort changes.

- the etching baths are consumed less quickly, even with longer conductor tracks, since less copper has to be dissolved. With the invention, it is therefore possible to achieve a considerable saving in basic metal in the switches of the type mentioned without additional expenditure on process steps or material.

- the connecting lines for the contacts arranged on a contact path could be located directly on the edge of the con tact course run.

- the lacquer cover is arranged at a short distance from the contact track. However, this means that the noble metal coating extends somewhat beyond the contact path. If the connecting lines now ran directly after the contact track, they would still cover a narrow edge with EdeLmetaLL.

- the connecting lines are therefore arranged at a distance from the contact tracks and connected to the contacts via connecting webs. Then only narrow strips of the connecting webs are covered with the EdeLmetaLL layer after the contacts.

- the conductor tracks used to connect the fixed contacts of a contact track run approximately parallel to the contact track and the connecting webs run approximately perpendicular to the contact track.

- a further saving on EdeLmetaLL can be achieved by routing the supply lines to the fixed contacts so that the supply lines are arranged as perpendicular as possible to the contact path when the contact paths cross inevitably. Since, as mentioned at the beginning, there is an application of covering lacquer on the contact track is not possible, it is inevitable that the conductor tracks forming the supply lines are also gold-plated at the intersection points with the contact tracks. A right-angled crossing results in the smallest area to be gilded.

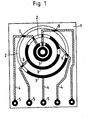

- a circuit pattern has been produced by etching on the circuit board 1 made of insulating material.

- the conductor tracks are shown partly black and partly hatched.

- the conductor tracks 3 drawn in black form the fixed contacts and the parts of the conductor tracks which are provided with an EdeLmetaLL harsh.

- the hatched conductor tracks 4 form the supply lines for the fixed contacts 3 and were covered during VergoLden.

- the ring-shaped connection contacts 5 are provided with a gold layer and serve to attach electrical supply lines for the switch.

- the contact tracks for the movable contacts are represented by the five circular tracks 2 which are concentric with one another.

- the parts of the contact tracks that are not filled in black are not per se visible on the circuit board. However, they are usually recognizable on the printed circuit board, since the ring-shaped zones between the contact tracks are printed with the covering varnish for the coating.

- the circuit board 1 is also printed with the covering varnish outside the contact track 2, with the exception of the connection contacts 5. Therefore, all conductor tracks present on the contact tracks are provided with a gold layer, that is to say not only the contact rings 5 but also the parts of the supply lines 4, which are one Cross the contact path. This is the case at the locations designated 6, 7, 8 and 9, where the supply lines 4 are inevitably covered with a gold layer.

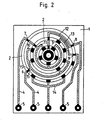

- FIG. 2 shows the same printed circuit board for a coding switch as FIG. 1, but here the printed conductors are arranged according to the invention, which leads to a considerable saving in GoLd.

- the individual contacts are present on each contact track in the embodiment according to FIG. 2, while the electrical connection of the individual interconnected contacts runs between the contact tracks.

- the connecting lines designated 10, 11, 12, 13 and 14 are arranged between the individual contacts. Since these can be covered between the contact tracks and outside of the contact tracks with a lacquer before the gold coating, there is a substantial saving in gold, since the areas to be gold-plated are considerably smaller, which is readily shown by a comparison with the black area parts in FIG. 1 .

- the connecting lines 10, 11, 12, 13 and 14 are arranged approximately parallel to and at a distance from the contact tracks 2 and are connected to the fixed contacts 3 by connecting webs 15 running approximately perpendicular to the contact tracks 2.

Landscapes

- Contacts (AREA)

- Coupling Device And Connection With Printed Circuit (AREA)

- Manufacture Of Switches (AREA)

- Rotary Switch, Piano Key Switch, And Lever Switch (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3336130 | 1983-10-05 | ||

| DE19833336130 DE3336130A1 (de) | 1983-10-05 | 1983-10-05 | Elektrischer schalter |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0148328A2 true EP0148328A2 (fr) | 1985-07-17 |

| EP0148328A3 EP0148328A3 (fr) | 1988-03-23 |

Family

ID=6210999

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84111611A Withdrawn EP0148328A3 (fr) | 1983-10-05 | 1984-09-28 | Interrupteur électrique avec des contacts fixes formés par des parties de pistes conductrices |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US4578547A (fr) |

| EP (1) | EP0148328A3 (fr) |

| JP (1) | JPS6097518A (fr) |

| DE (1) | DE3336130A1 (fr) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5315077A (en) * | 1993-04-05 | 1994-05-24 | Bourns, Inc. | Rotary switch including cam operated flexible contacts |

| DE19919395A1 (de) * | 1998-04-29 | 1999-11-04 | Capax B V | Schalter für elektrische Werkzeuge mit integrierten Schaltkontakten |

| US6288653B1 (en) * | 1998-12-22 | 2001-09-11 | Yun Ning Shih | Curved surface signal pick-up device |

| EP1013391B1 (fr) * | 1998-12-24 | 2003-04-09 | Teikoku Tsushin Kogyo Co. Ltd. | Procédé pour mouler une résine de moulage sur un substrat pourvu de trous et substrat de commutateur pourvu d'une résine de moulage |

| DE102009012145B4 (de) * | 2009-03-06 | 2014-02-20 | Abb Technology Ag | Verfahren zur Herstellung von Bauteilen, sowie Bauteile selbst |

| JP4622879B2 (ja) * | 2006-02-17 | 2011-02-02 | パナソニック株式会社 | 回転操作形エンコーダ |

| CN102306582A (zh) * | 2011-07-11 | 2012-01-04 | 浙江正泰机床电气制造有限公司 | 一种旋转型万能开关 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2314277A1 (de) * | 1973-03-22 | 1974-10-03 | Reck Dieter | Codierschalter |

| EP0050804A2 (fr) * | 1980-10-28 | 1982-05-05 | Siemens Aktiengesellschaft | Commutateur de codage |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2896033A (en) * | 1955-01-27 | 1959-07-21 | Daystrom Inc | Printed circuit assembly |

| JPS5242003B2 (fr) * | 1971-12-06 | 1977-10-21 | ||

| US3794784A (en) * | 1973-05-07 | 1974-02-26 | Atlantic Richfield Co | Rotary wafer switch having rotor mounted, spiral arranged axial bridging contacts |

| DE2441469C3 (de) * | 1974-08-29 | 1980-12-04 | Hartmann & Braun Ag, 6000 Frankfurt | Elektrischer Drehschalter in geschlossener Bauweise |

| JPS5147271A (ja) * | 1974-10-18 | 1976-04-22 | Matsushita Electric Ind Co Ltd | Insatsusuitsuchipurintokiban |

| US4038504A (en) * | 1975-11-19 | 1977-07-26 | A.C. Nielsen Company | Rotary, printed circuit wafer switch and method for adjusting |

| FR2336782A1 (fr) * | 1975-12-22 | 1977-07-22 | Radiotechnique Compelec | Commutateurs rotatifs codeurs |

| US4246453A (en) * | 1979-07-12 | 1981-01-20 | Electro Audio Dynamics, Inc. | Switch |

-

1983

- 1983-10-05 DE DE19833336130 patent/DE3336130A1/de not_active Withdrawn

-

1984

- 1984-09-28 EP EP84111611A patent/EP0148328A3/fr not_active Withdrawn

- 1984-10-01 US US06/656,700 patent/US4578547A/en not_active Expired - Fee Related

- 1984-10-04 JP JP59207248A patent/JPS6097518A/ja active Pending

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2314277A1 (de) * | 1973-03-22 | 1974-10-03 | Reck Dieter | Codierschalter |

| EP0050804A2 (fr) * | 1980-10-28 | 1982-05-05 | Siemens Aktiengesellschaft | Commutateur de codage |

Non-Patent Citations (1)

| Title |

|---|

| 31ST ELECTRONIC COMPONENTS CONFERENCE, Atlanta, Georgia, 11.-13. Mai 1981, Seiten 424-433, IEEE, New York, US; W. REYES et al.: "Factors influencing thin gold performance for separable connectors" * |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0148328A3 (fr) | 1988-03-23 |

| JPS6097518A (ja) | 1985-05-31 |

| DE3336130A1 (de) | 1985-04-18 |

| US4578547A (en) | 1986-03-25 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3610821C2 (fr) | ||

| DE112006002516B4 (de) | Chip-Widertand und Befestigungsstruktur für einen Chip-Widerstand | |

| DE2911620C2 (de) | Verfahren zum Herstellen von leitenden durchgehenden Bohrungen in Schaltungsplatten | |

| EP0374648B1 (fr) | Dispositif de connexion d'un câble électrique | |

| EP0762817A1 (fr) | Blindage pour des plaquettes de circuit | |

| DE2247902A1 (de) | Gedruckte schaltungsplatte und verfahren zu deren herstellung | |

| DE2539925A1 (de) | Verfahren zur herstellung einer mehrschichtigen gedruckten schaltungsplatte | |

| DE19638681C2 (de) | Verfahren zur Fertigung eines elektrischen Verteilerkastens | |

| DE3502744C2 (fr) | ||

| DE19511300A1 (de) | Antennenstruktur | |

| EP0017979B1 (fr) | Réseau électrique et procédé pour sa fabrication | |

| DE60128537T2 (de) | Zusammenbau zur verbindung von mindestens zwei gedruckten schaltungen | |

| DE2604111A1 (de) | Streifenband-uebertragungsleitung | |

| DE8912914U1 (de) | Leiteranordnung aus gestanzten Leiterbahnen | |

| EP0148328A2 (fr) | Interrupteur électrique avec des contacts fixes formés par des parties de pistes conductrices | |

| DE1085209B (de) | Gedruckte elektrische Leiterplatte | |

| DE2364520A1 (de) | Verfahren zur herstellung einer elektrischen, gedruckten schaltung | |

| DE102015115819A1 (de) | Leiterbrückenelement sowie Bestückungsgurt und Leiterplatten mit einem solchen | |

| DE1930642A1 (de) | Leiterplatte zum Aufnehmen und Verbinden elektrischer Bauelemente | |

| DE3704498C2 (fr) | ||

| WO1985000085A1 (fr) | Carte imprimee pour le montage en surface de circuits integres miniature et procede de fabrication de telles cartes imprimees | |

| EP0278485B1 (fr) | Méthode de fabrication d'une plaquette utilisable pour la digitalisation | |

| DE2611871A1 (de) | Elektrische schaltungsbaugruppe in mehrschichtbauweise und verfahren zu deren herstellung | |

| DE4405919A1 (de) | Mit galvanisierten , untereinander über Stanzgitter verbundenen Anschlüssen versehene elektrische Baugruppe sowie Herstellungsverfahren hierzu | |

| DE69400391T2 (de) | Versorgungsverteilung-Busschiene für Komponentenunterlage, die Komponentenunterlage und Verteilungsbrücken zum Verbinden der Busschiene mit der Unterlage |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE CH DE FR GB IT LI |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: STANDARD ELEKTRIK LORENZ AKTIENGESELLSCHAFT Owner name: ALCATEL N.V. |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): BE CH DE FR GB IT LI |

|

| RAP3 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ALCATEL N.V. Owner name: STANDARD ELEKTRIK LORENZ AKTIENGESELLSCHAFT |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19880926 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: OESTERLE, HERMANN FRIEDRICH Inventor name: GUENTHER, HORST HERMANN |