EP0148328A2 - Electrical switch with fixed contacts formed by parts of conductive tracks - Google Patents

Electrical switch with fixed contacts formed by parts of conductive tracks Download PDFInfo

- Publication number

- EP0148328A2 EP0148328A2 EP84111611A EP84111611A EP0148328A2 EP 0148328 A2 EP0148328 A2 EP 0148328A2 EP 84111611 A EP84111611 A EP 84111611A EP 84111611 A EP84111611 A EP 84111611A EP 0148328 A2 EP0148328 A2 EP 0148328A2

- Authority

- EP

- European Patent Office

- Prior art keywords

- contact

- fixed contacts

- tracks

- contacts

- conductor tracks

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H1/00—Contacts

- H01H1/12—Contacts characterised by the manner in which co-operating contacts engage

- H01H1/36—Contacts characterised by the manner in which co-operating contacts engage by sliding

- H01H1/40—Contact mounted so that its contact-making surface is flush with adjoining insulation

- H01H1/403—Contacts forming part of a printed circuit

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01H—ELECTRIC SWITCHES; RELAYS; SELECTORS; EMERGENCY PROTECTIVE DEVICES

- H01H19/00—Switches operated by an operating part which is rotatable about a longitudinal axis thereof and which is acted upon directly by a solid body external to the switch, e.g. by a hand

- H01H19/005—Electromechanical pulse generators

Definitions

- the invention relates to an electrical switch, the fixed contacts of which are covered with a metallic layer of parts of conductor tracks on a circuit board and the movable contacts are designed as sliding contacts that can be moved on predetermined contact tracks via the fixed contacts on the circuit board, and in the case of a contact track a plurality of electrically connected fixed contacts are provided.

- a copper layer that is laminated onto the printed circuit board is usually used as the material for the conductor tracks and from which the conductor tracks are etched, preferably using a photo-etching process.

- the copper conductor tracks are not suitable as contacts for a switch, since the copper easily oxidizes, which inadmissibly increases the contact resistance between the movable and the fixed contacts.

- Such fixed contacts formed from conductor tracks are usually covered with a noble metal layer, for example with a gold layer.

- This gold layer is usually applied by a galvanic process.

- all conductor tracks on the printed circuit board are covered with a gold layer.

- the gold plating has a very small thickness, for example a few ⁇ m, the gold layer, which is essential for the fixed contacts, makes up a considerable part of the price of the entire printed circuit board.

- the covering varnish remains on the printed circuit board after the free pieces of the conductive path have been glazed, since removing them would cause additional work steps and costs and, at the same time, as corrosion protection for them parts of the conductor tracks covered with an EdeLMetal layer.

- the covering lacquer for the fee may not be applied to the locations of the circuit boards that correspond to the contact paths of the movable contacts.

- the material of the lacquer layer would get on the movable and fixed contacts due to abrasion when the switch was actuated, thus giving rise to considerable contact faults. It has therefore been accepted that in the area of the contact tracks of the movable contacts, it is not possible to cover the conductor tracks before the charge.

- the object of the invention is to achieve a further saving in EdeLmetaLL with switches of the type mentioned.

- the invention is based on the knowledge that there are numerous switches of the specified type in which a plurality of fixed contacts arranged on a contact track are electrically connected to one another.

- An example of such switches are the so-called coding switches.

- Such electrically connected fixed contacts lying on a common contact path have so far only been used as one continuous contact, which of course runs the entire length with a layer of precious metal, e.g. B. a gold layer must be provided.

- the conductor tracks in the switches in question are obtained by etching out a copper layer originally completely covering the circuit board, the connecting lines and supply lines for the fixed contacts on the circuit board can be routed as desired and can also have any shape and length without the material consumption thereby being reduced or the manufacturing effort changes.

- the etching baths are consumed less quickly, even with longer conductor tracks, since less copper has to be dissolved. With the invention, it is therefore possible to achieve a considerable saving in basic metal in the switches of the type mentioned without additional expenditure on process steps or material.

- the connecting lines for the contacts arranged on a contact path could be located directly on the edge of the con tact course run.

- the lacquer cover is arranged at a short distance from the contact track. However, this means that the noble metal coating extends somewhat beyond the contact path. If the connecting lines now ran directly after the contact track, they would still cover a narrow edge with EdeLmetaLL.

- the connecting lines are therefore arranged at a distance from the contact tracks and connected to the contacts via connecting webs. Then only narrow strips of the connecting webs are covered with the EdeLmetaLL layer after the contacts.

- the conductor tracks used to connect the fixed contacts of a contact track run approximately parallel to the contact track and the connecting webs run approximately perpendicular to the contact track.

- a further saving on EdeLmetaLL can be achieved by routing the supply lines to the fixed contacts so that the supply lines are arranged as perpendicular as possible to the contact path when the contact paths cross inevitably. Since, as mentioned at the beginning, there is an application of covering lacquer on the contact track is not possible, it is inevitable that the conductor tracks forming the supply lines are also gold-plated at the intersection points with the contact tracks. A right-angled crossing results in the smallest area to be gilded.

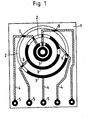

- a circuit pattern has been produced by etching on the circuit board 1 made of insulating material.

- the conductor tracks are shown partly black and partly hatched.

- the conductor tracks 3 drawn in black form the fixed contacts and the parts of the conductor tracks which are provided with an EdeLmetaLL harsh.

- the hatched conductor tracks 4 form the supply lines for the fixed contacts 3 and were covered during VergoLden.

- the ring-shaped connection contacts 5 are provided with a gold layer and serve to attach electrical supply lines for the switch.

- the contact tracks for the movable contacts are represented by the five circular tracks 2 which are concentric with one another.

- the parts of the contact tracks that are not filled in black are not per se visible on the circuit board. However, they are usually recognizable on the printed circuit board, since the ring-shaped zones between the contact tracks are printed with the covering varnish for the coating.

- the circuit board 1 is also printed with the covering varnish outside the contact track 2, with the exception of the connection contacts 5. Therefore, all conductor tracks present on the contact tracks are provided with a gold layer, that is to say not only the contact rings 5 but also the parts of the supply lines 4, which are one Cross the contact path. This is the case at the locations designated 6, 7, 8 and 9, where the supply lines 4 are inevitably covered with a gold layer.

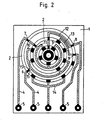

- FIG. 2 shows the same printed circuit board for a coding switch as FIG. 1, but here the printed conductors are arranged according to the invention, which leads to a considerable saving in GoLd.

- the individual contacts are present on each contact track in the embodiment according to FIG. 2, while the electrical connection of the individual interconnected contacts runs between the contact tracks.

- the connecting lines designated 10, 11, 12, 13 and 14 are arranged between the individual contacts. Since these can be covered between the contact tracks and outside of the contact tracks with a lacquer before the gold coating, there is a substantial saving in gold, since the areas to be gold-plated are considerably smaller, which is readily shown by a comparison with the black area parts in FIG. 1 .

- the connecting lines 10, 11, 12, 13 and 14 are arranged approximately parallel to and at a distance from the contact tracks 2 and are connected to the fixed contacts 3 by connecting webs 15 running approximately perpendicular to the contact tracks 2.

Landscapes

- Contacts (AREA)

- Rotary Switch, Piano Key Switch, And Lever Switch (AREA)

- Coupling Device And Connection With Printed Circuit (AREA)

- Manufacture Of Switches (AREA)

Abstract

Bei elektrischen Schaltern, deren Festkontakte (3) durch Leiterbahnen auf einer Leiterplatte (1) gebildet sind, die mit einer Edelmetallschicht überzogen sind, sind die Verbindungen zwischen den auf einer Kontaktbahn (2) liegenden und elektrisch untereinander verbundenen Festkontakten außerhalb der Kontaktbahnen (2) der beweglichen Kontakte verlegt. Dadurch ergibt sich die Möglichkeit des Abdeckens der Verbindungsleitungen beim Aufbringen der Edelmetallschicht und damit eine erhebliche Einsparung an Edelmetall.In the case of electrical switches, the fixed contacts (3) of which are formed by conductor tracks on a circuit board (1) which are coated with a noble metal layer, the connections between the fixed contacts lying on a contact track (2) and electrically interconnected are outside the contact tracks (2) the moving contacts. This results in the possibility of covering the connecting lines when the noble metal layer is applied and thus a considerable saving in noble metal.

Description

Die Erfindung bezieht sich auf einen elektrischen SchaLter, dessen Festkontakte mit einer EdeLmetaLLschicht überzogene TeiLe von Leiterbahnen auf einer SchaLtungspLatte sind und dessen bewegliche Kontakte aLs SchLeifkontakte ausgebildet sind, die auf vorgegebenen Kontaktbahnen über die Festkontakte auf der LeiterpLatte bewegbar sind, und bei dem auf einer Kontaktbahn mehrere, elektrisch miteinander verbundene Festkontakte vorgesehen sind.The invention relates to an electrical switch, the fixed contacts of which are covered with a metallic layer of parts of conductor tracks on a circuit board and the movable contacts are designed as sliding contacts that can be moved on predetermined contact tracks via the fixed contacts on the circuit board, and in the case of a contact track a plurality of electrically connected fixed contacts are provided.

Es sind bereits verschiedene Ausführungen von elektrischen SchaLtern bekannt, bei denen die Festkontakte durch TeiLe von Leiterbahnen gebildet sind, die auf einer SchaLtungsplatte angeordnet sind. Die beweglichen Kontakte von solchen SchaLtern sind als SchLeifkontakte ausgebildet, und zwar als Kontaktfedern oder auch aLs Kontaktstücke, die durch davon getrennte Federn auf die Kontakte auf der Leiterbahn gedrückt werden. Die SchLeifkontakte werden auf vorgegebenen Bahnen über die feststehenden Kontakte auf der LeiterpLatte geführt, und zwar bei DrehschaLtern auf kreisförmigen Bahnen und bei Schiebeschaltern auf geradLinigen Bahnen.Various designs of electrical switches are already known, in which the fixed contacts are formed by parts of conductor tracks which are arranged on a circuit board. The movable contacts of such switches are designed as sliding contacts, specifically as contact springs or as contact pieces, which are pressed onto the contacts on the conductor track by springs separate therefrom. The sliding contacts are guided on specified tracks over the fixed contacts on the printed circuit board, namely for rotary switches on circular tracks and for sliding switches on straight-line tracks.

ALs Material für die Leiterbahnen wird meist eine Kupferschicht verwendet, die auf die LeiterpLatte aufkaschiert ist und aus der die Leiterbahnen, vorzugsweise nach einem Fotoätzverfahren, ausgeätzt werden. Die KupferLeiterbahnen eignen sich aber nicht aLs Kontakte für einen SchaLter, da das Kupfer Leicht oxidiert, wodurch der übergangswiderstand zwischen den beweglichen und den festen Kontakten in unzulässiger Weise erhöht wird.A copper layer that is laminated onto the printed circuit board is usually used as the material for the conductor tracks and from which the conductor tracks are etched, preferably using a photo-etching process. However, the copper conductor tracks are not suitable as contacts for a switch, since the copper easily oxidizes, which inadmissibly increases the contact resistance between the movable and the fixed contacts.

DeshaLb werden solche aus Leiterbahnen gebildete Festkontakte in der RegeL mit einer Edelmetallschicht, beispielsweise mit einer GoLdschicht, überzogen. Diese GoLdschicht wird meist durch ein gaLvanisches Verfahren aufgebracht. Hierbei werden alle Leiterbahnen auf der LeiterpLatte mit einer GoLdschicht überzogen.Therefore, such fixed contacts formed from conductor tracks are usually covered with a noble metal layer, for example with a gold layer. This gold layer is usually applied by a galvanic process. Here, all conductor tracks on the printed circuit board are covered with a gold layer.

ObwohL die Goldauflage eine sehr geringe Dicke, beispielsweise von wenigen µm hat, macht die für die feststehenden Kontakte unverzichtbare GoLdschicht einen beträchtlichen TeiL des Preises der ganzen LeiterpLatte aus.Although the gold plating has a very small thickness, for example a few µm, the gold layer, which is essential for the fixed contacts, makes up a considerable part of the price of the entire printed circuit board.

Man ist daher dazu übergegangen, nur diejenigen TeiLe der Leiterbahnen der SchaLtungspLatte zu vergolden, die zur Kontaktgabe dienen. Dies geschieht in der Weise, daß ein Lackmuster aufgedruckt wird, welches die LeiterbahnenteiLe abdeckt, die nicht vergoldet werden solten. Man kann auf diese Weise einen beträchtlichen TeiL der Kosten für die GoLdschicht einsparen.It has therefore started to gold-plate only those parts of the conductor tracks of the circuit board that are used to make contact. This is done in such a way that a varnish pattern is printed, which covers the conductor parts, which should not be gold-plated. In this way, a considerable part of the costs for the gold layer can be saved.

Der AbdeckLack verbleibt nach dem VergoLden der freien Leiterbahnenstücke auf der Leiterplatte, da ein Entfernen zusätzliche Arbeitsgänge und -kosten verursachen würde und er auch gleichzeitig aLs Korrosionsschutz für die nicht mit einer EdeLmetaLLschicht überzogenen TeiLe der Leiterbahnen dient.The covering varnish remains on the printed circuit board after the free pieces of the conductive path have been glazed, since removing them would cause additional work steps and costs and, at the same time, as corrosion protection for them parts of the conductor tracks covered with an EdeLMetal layer.

Der AbdeckLack für die VergoLdung darf aber keinesfalls auf die SteLLen der Schaltungsplatten aufgebracht werden, welche den Kontaktbahnen der bewegLichen Kontakte entsprechen. Durch Abrieb bei der Betätigung des SchaLters würde das MateriaL der Lackschicht auf die beweglichen und die festen Kontakte geraten und so zu erheblichen Kontaktstörungen AnLaß geben. Man hat es daher hingenommen, daß im Bereich der Kontaktbahnen der beweglichen Kontakte ein Abdecken der Leiterbahnen vor der VergoLdung nicht möglich ist.The covering lacquer for the fee may not be applied to the locations of the circuit boards that correspond to the contact paths of the movable contacts. The material of the lacquer layer would get on the movable and fixed contacts due to abrasion when the switch was actuated, thus giving rise to considerable contact faults. It has therefore been accepted that in the area of the contact tracks of the movable contacts, it is not possible to cover the conductor tracks before the charge.

Aufgabe der Erfindung ist es, eine weitere Einsparung an EdeLmetaLL bei SchaLtern der eingangs genannten Art zu erzielen.The object of the invention is to achieve a further saving in EdeLmetaLL with switches of the type mentioned.

Diese Aufgabe wird durch die im Kennzeichen des Anspruchs 1 gegebenen Maßnahmen gelöst.This object is achieved by the measures given in the characterizing part of claim 1.

VorteiLhafte WeiterbiLdungen der Erfindung können den Unteransprüchen entnommen werden.Advantageous further developments of the invention can be found in the subclaims.

Die Erfindung geht von der Erkenntnis aus, daß es zahlreiche SchaLter der angegebenen Art gibt, bei denen mehrere auf einer Kontaktbahn angeordnete Festkontakte elektrisch miteinander verbunden sind. Ein Beispiel für solche Schalter sind die sogenannten CodierschaLter..SoLche elektrisch miteinander verbundenen, auf einer gemeinsamen Kontaktbahn Liegenden Festkontakte hat man bisher als einen einzigen durchgehenden Kontakt ausgeführt, der natürlich auf der ganzen Länge mit einer Edelmetallschicht, z. B. einer GoLdschicht, versehen sein muß.The invention is based on the knowledge that there are numerous switches of the specified type in which a plurality of fixed contacts arranged on a contact track are electrically connected to one another. An example of such switches are the so-called coding switches. Such electrically connected fixed contacts lying on a common contact path have so far only been used as one continuous contact, which of course runs the entire length with a layer of precious metal, e.g. B. a gold layer must be provided.

Bei solchen SchaLtern kann eine nicht unerhebliche Menge an EdeLmetaLL dadurch eingespart werden, daß die zur Verbindung der einzelnen Festkontakte dienenden Leiterbahnen außerhalb der Kontaktbahnen der beweglichen Kontakte angeordnet werden. Es ist dann möglich, diese Verbindungen vor der VergoLdung mit einem AbdeckLack abzudecken, so daß nur die eigentlichen Kontakte vergoLdet werden. Hierdurch ist eine weitere erhebliche Reduzierung des EdeLmetaLLbedarfs solcher SchaLter und damit der Kosten für solche SchaLter möglich.With such switches, a not inconsiderable amount of EdeLmetaLL can be saved by arranging the conductor tracks used to connect the individual fixed contacts outside the contact tracks of the movable contacts. It is then possible to cover these connections with a covering varnish before the coating, so that only the actual contacts are coated. This enables a further substantial reduction in the basic metal requirement of such switches and thus the costs for such switches.

Da die Leiterbahnen bei den in Frage stehenden SchaLtern durch Ausätzen einer die SchaLtungspLatte ursprünglich vollständig bedeckenden Kupferschicht erhalten werden, können die VerbindungsLeitungen und ZuLeitungen für die Festkontakte auf der SchaLtungspLatte beliebig geführt werden und auch eine beliebige Form und Länge haben, ohne daß sich dadurch der Materialverbrauch oder der HersteLLungsaufwand ändert. Es werden sogar bei Längeren Leiterbahnen die Ätzbäder weniger schneLL verbraucht, da weniger Kupfer aufgelöst werden muß.-Durch die Erfindung ist es daher möglich, ohne zusätzLichen Aufwand an Verfahrensschritten oder Material eine erhebliche Einsparung an EdeLmetaLL bei den SchaLtern der genannten Art zu erzieLen.Since the conductor tracks in the switches in question are obtained by etching out a copper layer originally completely covering the circuit board, the connecting lines and supply lines for the fixed contacts on the circuit board can be routed as desired and can also have any shape and length without the material consumption thereby being reduced or the manufacturing effort changes. The etching baths are consumed less quickly, even with longer conductor tracks, since less copper has to be dissolved. With the invention, it is therefore possible to achieve a considerable saving in basic metal in the switches of the type mentioned without additional expenditure on process steps or material.

An sich könnten die VerbindungsLeitungen für die auf einer Kontaktbahn angeordneten Kontakte direkt am Rand der Kontaktbahn verlaufen. Dies würde jedoch bedeuten, daß die Lackabdeckung für die Edelmetallbeschichtung sehr präzise aufgedruckt werden muß. Es wäre hierzu ein sehr hoher Aufwand beim Lackdruck erforderlich. Um einen solchen Aufwand zu vermeiden und trotzdem sicherzusteLLen, daß die Kontakte mit Sicherheit voLLständig überzogen werden, wird die Lackabdeckung mit geringem Abstand von der Kontaktbahn angeordnet. Dies bedeutet aber, daß der Edelmetallüberzug sich noch etwas über die Kontaktbahn hinaus erstreckt. Würden nun die VerbindungsLeitungen direkt anschließend an die Kontaktbahn verlaufen, so würde noch ein schmaler Rand von ihnen mit EdeLmetaLL überzogen werden.As such, the connecting lines for the contacts arranged on a contact path could be located directly on the edge of the con tact course run. However, this would mean that the lacquer cover for the precious metal coating must be printed very precisely. This would require a very high outlay in coating printing. In order to avoid such effort and still ensure that the contacts are completely covered with security, the lacquer cover is arranged at a short distance from the contact track. However, this means that the noble metal coating extends somewhat beyond the contact path. If the connecting lines now ran directly after the contact track, they would still cover a narrow edge with EdeLmetaLL.

Gemäß der weiteren AusbiLdung der Erfindung werden daher die VerbindungsLeitungen in Abstand von den Kontaktbahnen angeordnet und über Verbindungsstege mit den Kontakten verbunden. Es werden dann LedigLich schmale Streifen der Verbindungsstege anschließend an die Kontakte noch mit der EdeLmetaLLschicht überzogen.According to the further embodiment of the invention, the connecting lines are therefore arranged at a distance from the contact tracks and connected to the contacts via connecting webs. Then only narrow strips of the connecting webs are covered with the EdeLmetaLL layer after the contacts.

Besonders vorteilhaft ist es, wenn die zur Verbindung der Festkontakte einer Kontaktbahn dienenden Leiterbahnen in etwa parallel zur Kontaktbahn und die Verbindungsstege etwa senkrecht zur Kontaktbahn verlaufen.It is particularly advantageous if the conductor tracks used to connect the fixed contacts of a contact track run approximately parallel to the contact track and the connecting webs run approximately perpendicular to the contact track.

Eine weitere Einsparung an EdeLmetaLL kann dadurch erreicht werden, daß die ZuLeitungen zu den Festkontakten so geführt werden, daß bei den unvermeidlichen überkreuzungen von Kontaktbahnen die ZuLeitungen möglichst rechtwinkelig zur Kontaktbahn angeordnet werden. Da, wie dies eingangs erwähnt wurde, ein Aufbringen von AbdeckLack auf die Kontaktbahn nicht möglich ist, ist es unvermeidlich, daß die die ZuLeitungen bildenden Leiterbahnen an den KreuzungssteLLen mit den Kontaktbahnen mit vergoldet werden. Durch eine rechtwinkeLige Kreuzung ergibt sich aber die kleinste zu vergoldende FLäche.A further saving on EdeLmetaLL can be achieved by routing the supply lines to the fixed contacts so that the supply lines are arranged as perpendicular as possible to the contact path when the contact paths cross inevitably. Since, as mentioned at the beginning, there is an application of covering lacquer on the contact track is not possible, it is inevitable that the conductor tracks forming the supply lines are also gold-plated at the intersection points with the contact tracks. A right-angled crossing results in the smallest area to be gilded.

Die Erfindung soLL anhand der Figuren näher erläutert werden.

- Fig. 1 zeigt eine SchaLtungspLatte für einen elektrischen CodierschaLter nach dem Stand der Technik und

- Fig. 2 zeigt die gleiche SchaLtungspLatte wie in Fig. 1, jedoch mit einer Führung der Leiterbahnen gemäß der Erfindung.

- Fig. 1 shows a circuit board for an electrical coding switch according to the prior art and

- Fig. 2 shows the same circuit board as in Fig. 1, but with a guide of the conductor tracks according to the invention.

Auf der aus IsoLierstoff bestehenden SchaLtungspLatte 1 ist ein Leiterbahnmuster durch Ausätzen erzeugt worden. Die Leiterbahnen sind teilweise schwarz und teilweise schraffiert dargestellt. Die schwarz gezeichneten Leiterbahnen 3 bilden die Festkontakte und die TeiLe der Leiterbahnen, die mit einer EdeLmetaLLschicht versehen sind. Die schraffiert dargestellten Leiterbahnen 4 bilden die Zuleitungen für die Festkontakte 3 und wurden beim VergoLden abgedeckt. Mit einer GoLdschicht versehen sind außer den Festkontakten 3 die ringförmigen AnschLußkontakte 5, die zum Anbringen von elektrischen ZuLeitungen für den SchaLter dienen.A circuit pattern has been produced by etching on the circuit board 1 made of insulating material. The conductor tracks are shown partly black and partly hatched. The

Die Kontaktbahnen für die beweglichen Kontakte sind durch die fünf zueinander konzentrischen Kreisbahnen 2 dargestellt. Die nicht schwarz ausgefüLLten TeiLe der Kontaktbahnen sind auf der SchaLtungspLatte an sich nicht sichtbar. Sie sind jedoch in der RegeL insofern auf der LeiterpLatte erkennbar, da die ringförmigen Zonen zwischen den Kontaktbahnen mit dem AbdeckLack für die VergoLdung bedruckt sind. Mit dem AbdeckLack ist auch die SchaLtungspLatte 1 außerhalb der Kontaktbahn 2 bedruckt, mit Ausnahme der AnschLußkontakte 5. Mit einer GoLdschicht werden deshalb alle auf den Kontaktbahnen vorhandenen Leiterbahnen versehen, also nicht nur die Kontaktringe 5, sondern auch die TeiLe der ZuLeitungen 4, welche eine Kontaktbahn überkreuzen. Dies ist der FaLL an den mit 6, 7, 8 und 9 bezeichneten SteLLen, wo die ZuLeitungen 4 zwangsläufig mit einer Goldschicht überzogen werden.The contact tracks for the movable contacts are represented by the five

Fig. 2 zeigt die gleiche LeiterpLatte für einen Codierschalter wie Fig. 1, jedoch sind hier die Leiterbahnen gemäß der Erfindung angeordnet, was zu einer erheblichen Einsparung an GoLd führt. Wie ersichtlich, sind bei der Ausführungsform nach Fig. 2 auf jeder Kontaktbahn nur die einzelnen Kontakte vorhanden, während die elektrische Verbindung der einzelnen miteinander verbundenen Kontakte zwischen den Kontaktbahnen verläuft. AußerhaLb der Kontaktbahnen 2 sind die mit 10, 11, 12, 13 und 14 bezeichneten VerbindungsLeitungen zwischen den einzelnen Kontakten angeordnet. Da diese zwischen den Kontaktbahnen und außerhalb der Kontaktbahnen mit einem Lack vor der VergoLdung abgedeckt werden können, ergibt sich eine wesentliche Einsparung an Gold, da die zu vergoldenden FLächen erheblich kleiner sind, was ein VergLeich mit den schwarzen FLächenteilen von Fig. 1 ohne weiteres zeigt.FIG. 2 shows the same printed circuit board for a coding switch as FIG. 1, but here the printed conductors are arranged according to the invention, which leads to a considerable saving in GoLd. As can be seen, only the individual contacts are present on each contact track in the embodiment according to FIG. 2, while the electrical connection of the individual interconnected contacts runs between the contact tracks. Apart from the

Die VerbindungsLeitungen 10, 11, 12, 13 und 14 sind etwa parallel zu den Kontaktbahnen 2 und in Abstand von diesen angeordnet und durch etwa senkrecht zu den Kontaktbahnen 2 verlaufende Verbindungsstege 15 mit den Festkontakten 3 verbunden.The connecting

GLeichzeitig wurden an den SteLLen, wo die ZuLeitungen zu den Festkontakten die Schleifbahnen überkreuzen, die ZuLeitungen so angeordnet, daß sie die Kontaktbahnen senkrecht kreuzen. So wurde aus den schrägen überkreuzungen 7, 8 und 9 von Fig. 1 eine rechtwinkelige überkreuzung bei den gleichen KreuzungssteLLen von Fig. 2. Auf diese Weise konnte die zu vergoldende FLäche noch vermindert werden.At the same time, at the points where the leads to the fixed contacts cross the slideways, the leads were arranged so that they cross the contact paths vertically. Thus, the

Claims (4)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE19833336130 DE3336130A1 (en) | 1983-10-05 | 1983-10-05 | ELECTRIC SWITCH |

| DE3336130 | 1983-10-05 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0148328A2 true EP0148328A2 (en) | 1985-07-17 |

| EP0148328A3 EP0148328A3 (en) | 1988-03-23 |

Family

ID=6210999

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP84111611A Withdrawn EP0148328A3 (en) | 1983-10-05 | 1984-09-28 | Electrical switch with fixed contacts formed by parts of conductive tracks |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US4578547A (en) |

| EP (1) | EP0148328A3 (en) |

| JP (1) | JPS6097518A (en) |

| DE (1) | DE3336130A1 (en) |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5315077A (en) * | 1993-04-05 | 1994-05-24 | Bourns, Inc. | Rotary switch including cam operated flexible contacts |

| DE19919395A1 (en) * | 1998-04-29 | 1999-11-04 | Capax B V | Hybrid printed circuit carrier for switch with integrated contacts which is assembled using pick-and-place apparatus |

| US6288653B1 (en) * | 1998-12-22 | 2001-09-11 | Yun Ning Shih | Curved surface signal pick-up device |

| DE69918727T2 (en) * | 1998-12-24 | 2005-07-21 | Teikoku Tsushin Kogyo Co. Ltd., Kawasaki | Method for producing a switch pattern on a switch substrate |

| DE102009012145B4 (en) * | 2009-03-06 | 2014-02-20 | Abb Technology Ag | Process for the production of components, as well as components themselves |

| JP4622879B2 (en) * | 2006-02-17 | 2011-02-02 | パナソニック株式会社 | Rotary operation type encoder |

| CN102306582A (en) * | 2011-07-11 | 2012-01-04 | 浙江正泰机床电气制造有限公司 | Rotary universal switch |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2314277A1 (en) * | 1973-03-22 | 1974-10-03 | Reck Dieter | CODE SWITCH |

| EP0050804A2 (en) * | 1980-10-28 | 1982-05-05 | Siemens Aktiengesellschaft | Code switch |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2896033A (en) * | 1955-01-27 | 1959-07-21 | Daystrom Inc | Printed circuit assembly |

| JPS5242003B2 (en) * | 1971-12-06 | 1977-10-21 | ||

| US3794784A (en) * | 1973-05-07 | 1974-02-26 | Atlantic Richfield Co | Rotary wafer switch having rotor mounted, spiral arranged axial bridging contacts |

| DE2441469C3 (en) * | 1974-08-29 | 1980-12-04 | Hartmann & Braun Ag, 6000 Frankfurt | Electric rotary switch in closed design |

| JPS5147271A (en) * | 1974-10-18 | 1976-04-22 | Matsushita Electric Ind Co Ltd | INSATSUSUITSUCHIPURINTOKIBAN |

| US4038504A (en) * | 1975-11-19 | 1977-07-26 | A.C. Nielsen Company | Rotary, printed circuit wafer switch and method for adjusting |

| FR2336782A1 (en) * | 1975-12-22 | 1977-07-22 | Radiotechnique Compelec | ROTARY ENCODER SWITCHES |

| US4246453A (en) * | 1979-07-12 | 1981-01-20 | Electro Audio Dynamics, Inc. | Switch |

-

1983

- 1983-10-05 DE DE19833336130 patent/DE3336130A1/en not_active Withdrawn

-

1984

- 1984-09-28 EP EP84111611A patent/EP0148328A3/en not_active Withdrawn

- 1984-10-01 US US06/656,700 patent/US4578547A/en not_active Expired - Fee Related

- 1984-10-04 JP JP59207248A patent/JPS6097518A/en active Pending

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2314277A1 (en) * | 1973-03-22 | 1974-10-03 | Reck Dieter | CODE SWITCH |

| EP0050804A2 (en) * | 1980-10-28 | 1982-05-05 | Siemens Aktiengesellschaft | Code switch |

Non-Patent Citations (1)

| Title |

|---|

| 31ST ELECTRONIC COMPONENTS CONFERENCE, Atlanta, Georgia, 11.-13. Mai 1981, Seiten 424-433, IEEE, New York, US; W. REYES et al.: "Factors influencing thin gold performance for separable connectors" * |

Also Published As

| Publication number | Publication date |

|---|---|

| JPS6097518A (en) | 1985-05-31 |

| EP0148328A3 (en) | 1988-03-23 |

| US4578547A (en) | 1986-03-25 |

| DE3336130A1 (en) | 1985-04-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE3610821C2 (en) | ||

| DE112006002516B4 (en) | Chip resistor and mounting structure for a chip resistor | |

| DE2911620C2 (en) | Method of making conductive through holes in circuit boards | |

| EP0374648B1 (en) | Device for the connexion of an electric cable | |

| EP0762817A1 (en) | Shielding for flat assemblies | |

| DE2247902A1 (en) | Printed circuit board and process for making same | |

| DE2539925A1 (en) | METHOD OF MANUFACTURING A MULTI-LAYER PRINTED CIRCUIT BOARD | |

| DE19638681C2 (en) | Method of manufacturing an electrical junction box | |

| DE3502744C2 (en) | ||

| DE2103064A1 (en) | Device for the production of modular elements | |

| DE19511300A1 (en) | Method of forming antenna structure for inserting into chip-card | |

| EP0017979B1 (en) | Electrical network and method of manufacturing same | |

| DE2604111A1 (en) | STRIPBAND TRANSMISSION LINE | |

| DE60128537T2 (en) | ASSEMBLY TO CONNECT AT LEAST TWO PRINTED CIRCUITS | |

| DE8912914U1 (en) | Conductor arrangement made of punched conductor tracks | |

| EP0148328A2 (en) | Electrical switch with fixed contacts formed by parts of conductive tracks | |

| DE1085209B (en) | Printed electrical circuit board | |

| DE2364520A1 (en) | METHOD OF MANUFACTURING AN ELECTRICAL PRINTED CIRCUIT | |

| DE102015115819A1 (en) | Conductor bridge element and mounting belt and circuit boards with such | |

| DE1930642A1 (en) | Circuit board for receiving and connecting electrical components | |

| DE3704498C2 (en) | ||

| WO1985000085A1 (en) | Printed board for the surface soldering of integrated miniature circuits and manufacturing method of such printed boards | |

| EP0278485B1 (en) | Process for making a digitalization board | |

| DE2611871A1 (en) | ELECTRICAL CIRCUIT ASSEMBLY IN MULTI-LAYER CONSTRUCTION AND PROCESS FOR THEIR PRODUCTION | |

| DE4405919A1 (en) | Electric component |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): BE CH DE FR GB IT LI |

|

| RAP1 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: STANDARD ELEKTRIK LORENZ AKTIENGESELLSCHAFT Owner name: ALCATEL N.V. |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Kind code of ref document: A3 Designated state(s): BE CH DE FR GB IT LI |

|

| RAP3 | Party data changed (applicant data changed or rights of an application transferred) |

Owner name: ALCATEL N.V. Owner name: STANDARD ELEKTRIK LORENZ AKTIENGESELLSCHAFT |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: THE APPLICATION IS DEEMED TO BE WITHDRAWN |

|

| 18D | Application deemed to be withdrawn |

Effective date: 19880926 |

|

| RIN1 | Information on inventor provided before grant (corrected) |

Inventor name: OESTERLE, HERMANN FRIEDRICH Inventor name: GUENTHER, HORST HERMANN |