EP0086013B1 - Werkstoff, welcher mindestens teilweise aus einer einen Einweg-Gedächtniseffekt zeigenden Komponenten aufgebaut ist und Verfahren zu dessen Herstellung - Google Patents

Werkstoff, welcher mindestens teilweise aus einer einen Einweg-Gedächtniseffekt zeigenden Komponenten aufgebaut ist und Verfahren zu dessen Herstellung Download PDFInfo

- Publication number

- EP0086013B1 EP0086013B1 EP83200129A EP83200129A EP0086013B1 EP 0086013 B1 EP0086013 B1 EP 0086013B1 EP 83200129 A EP83200129 A EP 83200129A EP 83200129 A EP83200129 A EP 83200129A EP 0086013 B1 EP0086013 B1 EP 0086013B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- memory effect

- weight

- way memory

- way

- component

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 239000000463 material Substances 0.000 title claims abstract description 23

- 230000003446 memory effect Effects 0.000 title claims abstract description 20

- 238000000034 method Methods 0.000 title claims abstract description 11

- 238000004519 manufacturing process Methods 0.000 title abstract description 10

- 239000000843 powder Substances 0.000 claims abstract description 6

- 239000002131 composite material Substances 0.000 claims description 7

- 238000001125 extrusion Methods 0.000 claims description 6

- 239000000203 mixture Substances 0.000 claims description 6

- 229910000881 Cu alloy Inorganic materials 0.000 claims description 4

- 229910000831 Steel Inorganic materials 0.000 claims description 4

- 229910052759 nickel Inorganic materials 0.000 claims description 4

- 239000011265 semifinished product Substances 0.000 claims description 4

- 239000010959 steel Substances 0.000 claims description 4

- 229910052802 copper Inorganic materials 0.000 claims description 3

- 238000005245 sintering Methods 0.000 claims description 3

- 229910000640 Fe alloy Inorganic materials 0.000 claims description 2

- 229910001069 Ti alloy Inorganic materials 0.000 claims description 2

- 238000004663 powder metallurgy Methods 0.000 claims description 2

- 238000002360 preparation method Methods 0.000 claims 3

- 229910000990 Ni alloy Inorganic materials 0.000 claims 2

- 229910001257 Nb alloy Inorganic materials 0.000 claims 1

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 claims 1

- 238000007731 hot pressing Methods 0.000 claims 1

- 229910045601 alloy Inorganic materials 0.000 abstract description 9

- 239000000956 alloy Substances 0.000 abstract description 9

- 230000000694 effects Effects 0.000 abstract description 9

- 238000001513 hot isostatic pressing Methods 0.000 abstract description 3

- 238000004026 adhesive bonding Methods 0.000 abstract description 2

- 238000000576 coating method Methods 0.000 abstract description 2

- 239000011162 core material Substances 0.000 abstract description 2

- 238000009792 diffusion process Methods 0.000 abstract description 2

- 238000003466 welding Methods 0.000 abstract description 2

- 239000000470 constituent Substances 0.000 abstract 4

- 229910017535 Cu-Al-Ni Inorganic materials 0.000 abstract 1

- 229910017767 Cu—Al Inorganic materials 0.000 abstract 1

- 229910004353 Ti-Cu Inorganic materials 0.000 abstract 1

- 238000005219 brazing Methods 0.000 abstract 1

- KHYBPSFKEHXSLX-UHFFFAOYSA-N iminotitanium Chemical compound [Ti]=N KHYBPSFKEHXSLX-UHFFFAOYSA-N 0.000 abstract 1

- 229910001000 nickel titanium Inorganic materials 0.000 abstract 1

- 239000002344 surface layer Substances 0.000 abstract 1

- 229910052751 metal Inorganic materials 0.000 description 5

- 239000002184 metal Substances 0.000 description 5

- 229910000730 Beta brass Inorganic materials 0.000 description 3

- 239000002775 capsule Substances 0.000 description 3

- 229910001285 shape-memory alloy Inorganic materials 0.000 description 3

- 239000007858 starting material Substances 0.000 description 3

- 229910000838 Al alloy Inorganic materials 0.000 description 2

- 230000002349 favourable effect Effects 0.000 description 2

- 239000000047 product Substances 0.000 description 2

- 230000009466 transformation Effects 0.000 description 2

- 229910001369 Brass Inorganic materials 0.000 description 1

- 229910001209 Low-carbon steel Inorganic materials 0.000 description 1

- 238000000137 annealing Methods 0.000 description 1

- 239000010951 brass Substances 0.000 description 1

- 229910052804 chromium Inorganic materials 0.000 description 1

- 238000005253 cladding Methods 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000007906 compression Methods 0.000 description 1

- 230000006835 compression Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000007797 corrosion Effects 0.000 description 1

- 238000005260 corrosion Methods 0.000 description 1

- 238000010586 diagram Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 229910000734 martensite Inorganic materials 0.000 description 1

- 238000010310 metallurgical process Methods 0.000 description 1

- 230000000704 physical effect Effects 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 230000002787 reinforcement Effects 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 238000005476 soldering Methods 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 230000007704 transition Effects 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22F—CHANGING THE PHYSICAL STRUCTURE OF NON-FERROUS METALS AND NON-FERROUS ALLOYS

- C22F1/00—Changing the physical structure of non-ferrous metals or alloys by heat treatment or by hot or cold working

- C22F1/006—Resulting in heat recoverable alloys with a memory effect

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/12—All metal or with adjacent metals

- Y10T428/12014—All metal or with adjacent metals having metal particles

- Y10T428/12028—Composite; i.e., plural, adjacent, spatially distinct metal components [e.g., layers, etc.]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/12—All metal or with adjacent metals

- Y10T428/12493—Composite; i.e., plural, adjacent, spatially distinct metal components [e.g., layers, joint, etc.]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/12—All metal or with adjacent metals

- Y10T428/12493—Composite; i.e., plural, adjacent, spatially distinct metal components [e.g., layers, joint, etc.]

- Y10T428/125—Deflectable by temperature change [e.g., thermostat element]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/12—All metal or with adjacent metals

- Y10T428/12493—Composite; i.e., plural, adjacent, spatially distinct metal components [e.g., layers, joint, etc.]

- Y10T428/125—Deflectable by temperature change [e.g., thermostat element]

- Y10T428/12507—More than two components

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/12—All metal or with adjacent metals

- Y10T428/12493—Composite; i.e., plural, adjacent, spatially distinct metal components [e.g., layers, joint, etc.]

- Y10T428/125—Deflectable by temperature change [e.g., thermostat element]

- Y10T428/12514—One component Cu-based

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/12—All metal or with adjacent metals

- Y10T428/12493—Composite; i.e., plural, adjacent, spatially distinct metal components [e.g., layers, joint, etc.]

- Y10T428/12535—Composite; i.e., plural, adjacent, spatially distinct metal components [e.g., layers, joint, etc.] with additional, spatially distinct nonmetal component

- Y10T428/12556—Organic component

- Y10T428/12562—Elastomer

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/12—All metal or with adjacent metals

- Y10T428/12493—Composite; i.e., plural, adjacent, spatially distinct metal components [e.g., layers, joint, etc.]

- Y10T428/12535—Composite; i.e., plural, adjacent, spatially distinct metal components [e.g., layers, joint, etc.] with additional, spatially distinct nonmetal component

- Y10T428/12556—Organic component

- Y10T428/12569—Synthetic resin

Definitions

- the invention is based on a method for producing a material having a two-way memory effect according to the preamble of claims 1, 2 and 5.

- the invention has for its object to provide a method for producing a technically usable reversible two-way memory effect material based on Cu / Al / Ni and Cu / Al alloys, which can be used both for the production of semi-finished products in rod, Profile and sheet shape as suitable for components that can be used in practice.

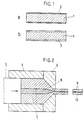

- Fig. 1 the longitudinal section through an embodiment of the material as a semi-finished product is shown in rod form. 1a relates to the state after the first method step, FIG. 1 to the finished product. 1 is the component that shows the one-way memory effect (core material), 2 is a metallic coating. The final result is that the additional component 3 is formed as an edge zone (inactive zone) of the material in the form of a rod by diffusion annealing.

- core material the component that shows the one-way memory effect

- 2 is a metallic coating.

- the additional component 3 is formed as an edge zone (inactive zone) of the material in the form of a rod by diffusion annealing.

- Fig. 2 shows the process flow and the means in the manufacture of the material in rod or strip form as a tri-metal.

- 4 is the press cylinder of an extrusion press, 5 the corresponding press plunger (punch), 6 the die.

- the latter advantageously has a relatively narrow tightening angle (corresponding to the cone angle in the case of round cross sections) in the tapered part.

- 7 are the outer layers of a component of the compact which shows the one-way memory effect.

- 8 represents the inner layer of the further (no memory effect) component of the pressed body.

- 9 are the outer layers of the component of the finished material showing the one-way memory effect in cross-section (flat bar).

- 10 is the inner layer consisting of the further (inactive) component of the finished material in cross section.

- Prismatic bodies were cut out of this material and assembled with a flat rod made of corrosion-resistant steel (18 Cr / 8 Ni) in such a way that a laminated body (sandwich) according to FIGS. 7 and 8 of FIG. 2 was formed.

- This pressing body of rectangular cross-section was inserted into an extrusion press and pressed at a temperature of 800 ° C. to form a composite material in the form of a flat bar.

- This type of tri-metal can be produced in practically any cross-section and commercially available lengths. A well-known two-way memory effect was measured on him.

- the starting materials for the two components had the same alloy composition as in Example I (Cu / Al / Ni and Cr / Ni steel).

- a capsule made of soft, low-carbon steel (St 35) with a height of 200 mm, an outer diameter of 80 mm and a wall thickness of 2 mm a round rod made of 5 mm diameter Cr / Ni steel was placed coaxially in the middle. Then the free space of the capsule was filled with Cu / Al / NI powder and the capsule was evacuated, welded and hot-isostatically pressed at 950 ° C. for 3 hours under a pressure of 140 MPa. After the hot-isostatic pressing, the casing made of soft steel was removed by mechanical processing and the pressed body made of composite material was hammered at a temperature of 850 ° C in several steps to the desired finished size (rod shape).

- the following alloy was selected as the starting material for a composite material for the first component (one-way memory effect):

- a sintered round rod of 20 mm diameter was first produced from the first component using powder metallurgical methods by pre-compressing and sintering the powder mixture.

- a tube with an inner diameter of 20 mm and a wall thickness of 2 mm was made from the Ti / Ni / Cu / Fe alloy, into which the round bar just fit. The latter was inserted into the pipe in such a way that it was just stuck.

- the composite material prepared in this way was then heated to a temperature of 850 ° C. and, at this temperature, reduced to a diameter of 10 mm in several passes by rotary hammering. The cross-sectional decrease per stitch was approx. 20%.

- Round hammering produced a solid, compact composite material that had a significant two-way memory effect. It should be emphasized that only the highly elastic properties of the second, inactive component forming the edge zone were used, but not the memory effects that are also inherently present (they are not in the temperature range of interest).

- soldering, welding, roll cladding, extrusion or other metallurgical processes as well as gluing can be used as the manufacturing process for connecting the components with different physical properties.

- u. a. Two-layer (bimetal) or three-layer (trimetal) materials can be produced.

- the material can be produced from the individual components using powder metallurgy and further processed into semi-finished bimetallic or trimetal products. This can be done by cold compression, sintering and extrusion, or by hot isostatic pressing with possibly subsequent rotary hammering.

- an additional corrosion protection layer e.g. B. 5 to 100 microns thickness applied or generated in the edge zone. The latter of course also applies to all other manufacturing processes.

- the composite material does not necessarily have to consist only of metallic components.

- the inactive second component can be a high-strength, highly elastic, heat-resistant plastic, which in turn can be made up of various components (including reinforcement materials). The condition is that the plastic can withstand the elastic movements without damage and tolerates the temperatures that occur during operation.

- the new material and the corresponding manufacturing process give the person skilled in the art a means of considerably expanding the area of application of the two-way memory effect, in particular in the temperature range between approximately 100 ° C. and 200 ° C. This applies above all to the construction of switches, relays and temperature triggers.

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Crystallography & Structural Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Laminated Bodies (AREA)

- Powder Metallurgy (AREA)

- Pressure Welding/Diffusion-Bonding (AREA)

- Package Frames And Binding Bands (AREA)

- Forging (AREA)

- Extrusion Of Metal (AREA)

- Heat Treatment Of Nonferrous Metals Or Alloys (AREA)

- Electroplating And Plating Baths Therefor (AREA)

- Solid-Phase Diffusion Into Metallic Material Surfaces (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT83200129T ATE23569T1 (de) | 1982-02-05 | 1983-01-26 | Werkstoff, welcher mindestens teilweise aus einer einen einweg-gedaechtniseffekt zeigenden komponenten aufgebaut ist und verfahren zu dessen herstellung. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CH706/82 | 1982-02-05 | ||

| CH706/82A CH660882A5 (de) | 1982-02-05 | 1982-02-05 | Werkstoff mit zweiweg-gedaechtniseffekt und verfahren zu dessen herstellung. |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0086013A2 EP0086013A2 (de) | 1983-08-17 |

| EP0086013A3 EP0086013A3 (en) | 1983-09-21 |

| EP0086013B1 true EP0086013B1 (de) | 1986-11-12 |

Family

ID=4193271

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP83200129A Expired EP0086013B1 (de) | 1982-02-05 | 1983-01-26 | Werkstoff, welcher mindestens teilweise aus einer einen Einweg-Gedächtniseffekt zeigenden Komponenten aufgebaut ist und Verfahren zu dessen Herstellung |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US4518444A (OSRAM) |

| EP (1) | EP0086013B1 (OSRAM) |

| JP (1) | JPS58151242A (OSRAM) |

| AT (1) | ATE23569T1 (OSRAM) |

| CH (1) | CH660882A5 (OSRAM) |

| DE (1) | DE3367625D1 (OSRAM) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106984794A (zh) * | 2017-03-31 | 2017-07-28 | 福州大学 | 异种双金属复合板的共挤压制备设备及使用方法 |

Families Citing this family (54)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH653369A5 (de) * | 1983-03-14 | 1985-12-31 | Bbc Brown Boveri & Cie | Verbundwerkstoff in stab-, rohr-, band-, blech- oder plattenform mit reversiblen thermo-mechanischen eigenschaften und verfahren zu dessen herstellung. |

| JPS59230741A (ja) * | 1983-06-15 | 1984-12-25 | 株式会社日立製作所 | 形状記憶複合材料 |

| DE3501650C2 (de) * | 1985-01-19 | 1987-04-02 | Diehl GmbH & Co, 8500 Nürnberg | Sicherungseinrichtung, insbesondere für Minen |

| DE4006076C1 (OSRAM) * | 1989-08-12 | 1990-12-13 | Fried. Krupp Gmbh, 4300 Essen, De | |

| JPH083133B2 (ja) * | 1990-07-12 | 1996-01-17 | 日立粉末冶金株式会社 | 船外機用バルブシート材およびその製造方法 |

| DE4023404C2 (de) * | 1990-07-23 | 1996-05-15 | Castolin Sa | Verwendung einer abschmelzbaren Elektrode |

| US6682608B2 (en) * | 1990-12-18 | 2004-01-27 | Advanced Cardiovascular Systems, Inc. | Superelastic guiding member |

| ATE140647T1 (de) * | 1991-04-09 | 1996-08-15 | Furukawa Electric Co Ltd | Verbundene teile von ni-ti-legierugen mit verschiedenen metallen und verbindungsverfahren dafür |

| US6497709B1 (en) | 1992-03-31 | 2002-12-24 | Boston Scientific Corporation | Metal medical device |

| US7101392B2 (en) * | 1992-03-31 | 2006-09-05 | Boston Scientific Corporation | Tubular medical endoprostheses |

| DE69332950T2 (de) * | 1992-03-31 | 2004-05-13 | Boston Scientific Corp., Natick | Blutgefässfilter |

| US5226979A (en) * | 1992-04-06 | 1993-07-13 | Johnson Service Company | Apparatus including a shape memory actuating element made from tubing and a means of heating |

| US20050059889A1 (en) * | 1996-10-16 | 2005-03-17 | Schneider (Usa) Inc., A Minnesota Corporation | Clad composite stent |

| US5630840A (en) | 1993-01-19 | 1997-05-20 | Schneider (Usa) Inc | Clad composite stent |

| DE69414765T2 (de) * | 1993-06-30 | 1999-05-06 | Hitachi, Ltd., Tokio/Tokyo | Formgedächnis-Rohrkupplung für Unterwasserrohre |

| US5842312A (en) * | 1995-03-01 | 1998-12-01 | E*Sorb Systems | Hysteretic damping apparati and methods |

| JP3045460B2 (ja) * | 1995-04-19 | 2000-05-29 | 株式会社小松製作所 | 焼結接合方法およびその方法を用いる焼結複合部材 |

| US6329069B1 (en) | 1995-07-26 | 2001-12-11 | Surface Genesis, Inc. | Composite structure and devices made from same and method |

| US5611874A (en) * | 1995-07-26 | 1997-03-18 | Surface Genesis, Inc. | Clad shape memory alloy composite structure and method |

| US5836066A (en) * | 1996-07-22 | 1998-11-17 | Innovative Dynamics, Inc. | Process for the production of two-way shape memory alloys |

| US20060047223A1 (en) * | 2004-08-31 | 2006-03-02 | Ryan Grandfield | Apparatus and method for joining stainless steel guide wire portion to nitinol portion, without a hypotube |

| US6149742A (en) * | 1998-05-26 | 2000-11-21 | Lockheed Martin Corporation | Process for conditioning shape memory alloys |

| US6238496B1 (en) * | 1998-07-01 | 2001-05-29 | Jeffrey W. Akers | Method for precision modification and enhancement of shape memory alloy properties |

| US7018401B1 (en) | 1999-02-01 | 2006-03-28 | Board Of Regents, The University Of Texas System | Woven intravascular devices and methods for making the same and apparatus for delivery of the same |

| JP3300684B2 (ja) * | 1999-07-08 | 2002-07-08 | 清仁 石田 | 形状記憶特性及び超弾性を有する銅系合金、それからなる部材ならびにそれらの製造方法 |

| AU3441001A (en) * | 1999-12-01 | 2001-06-12 | Advanced Cardiovascular Systems Inc. | Nitinol alloy design and composition for vascular stents |

| US6790218B2 (en) * | 1999-12-23 | 2004-09-14 | Swaminathan Jayaraman | Occlusive coil manufacture and delivery |

| US20040191556A1 (en) * | 2000-02-29 | 2004-09-30 | Jardine Peter A. | Shape memory device having two-way cyclical shape memory effect due to compositional gradient and method of manufacture |

| US6602272B2 (en) * | 2000-11-02 | 2003-08-05 | Advanced Cardiovascular Systems, Inc. | Devices configured from heat shaped, strain hardened nickel-titanium |

| US7976648B1 (en) | 2000-11-02 | 2011-07-12 | Abbott Cardiovascular Systems Inc. | Heat treatment for cold worked nitinol to impart a shape setting capability without eventually developing stress-induced martensite |

| US6622558B2 (en) | 2000-11-30 | 2003-09-23 | Orbital Research Inc. | Method and sensor for detecting strain using shape memory alloys |

| US6855161B2 (en) | 2000-12-27 | 2005-02-15 | Advanced Cardiovascular Systems, Inc. | Radiopaque nitinol alloys for medical devices |

| US7082868B2 (en) * | 2001-03-15 | 2006-08-01 | Ati Properties, Inc. | Lightweight armor with repeat hit and high energy absorption capabilities |

| WO2003018853A2 (en) * | 2001-08-24 | 2003-03-06 | University Of Virginia Patent Foundation | Reversible shape memory multifunctional structural designs and method of using and making the same |

| DE10162296C1 (de) * | 2001-12-19 | 2003-04-03 | Karlsruhe Forschzent | Superelastisches Bauelement und Verfahren zum Einprägen und Konservieren einer Krümmung vorgegebener Geometrie |

| CA2487934A1 (en) * | 2002-05-30 | 2003-12-11 | University Of Virginia Patent Foundation | Active energy absorbing cellular metals and method of manufacturing and using the same |

| US7497943B2 (en) | 2002-08-30 | 2009-03-03 | Baker Hughes Incorporated | Additives to enhance metal and amine removal in refinery desalting processes |

| US7942892B2 (en) * | 2003-05-01 | 2011-05-17 | Abbott Cardiovascular Systems Inc. | Radiopaque nitinol embolic protection frame |

| WO2004110740A1 (en) * | 2003-05-28 | 2004-12-23 | University Of Virginia Patent Foundation | Re- entrant cellular multifunctional structure for energy absorption and method of manufacturing and using the same |

| US20050099261A1 (en) * | 2003-11-06 | 2005-05-12 | Steven Walak | Two way composite nitinol actuation |

| US7998090B2 (en) * | 2004-08-31 | 2011-08-16 | Abbott Cardiovascular Systems Inc. | Guide wire with core having welded wire segments |

| CN1330781C (zh) * | 2005-01-13 | 2007-08-08 | 四川大学 | 冷轧超薄叠层合金化制备CuAlNiMn形状记忆合金薄膜 |

| JP4203051B2 (ja) * | 2005-06-28 | 2008-12-24 | 本田技研工業株式会社 | 力覚センサ |

| US7296453B1 (en) * | 2005-11-22 | 2007-11-20 | General Electric Company | Method of forming a structural component having a nano sized/sub-micron homogeneous grain structure |

| US8360361B2 (en) | 2006-05-23 | 2013-01-29 | University Of Virginia Patent Foundation | Method and apparatus for jet blast deflection |

| KR101297009B1 (ko) | 2006-10-22 | 2013-08-14 | 이데브 테크놀로지스, 아이엔씨. | 스트랜드 단부를 고정하기 위한 방법 및 이의 장치 |

| US20090226338A1 (en) * | 2006-11-13 | 2009-09-10 | Igor Troitski | Method and system for manufacturing of complex shape parts from powder materials by hot isostatic pressing with controlled pressure inside the tooling and providing the shape of the part by multi-layer inserts |

| JP5157864B2 (ja) * | 2008-01-23 | 2013-03-06 | 日立電線株式会社 | ろう付け用クラッド材及びろう付け製品 |

| RU2381903C2 (ru) * | 2008-03-19 | 2010-02-20 | Институт радиотехники и электроники Российской Академии Наук | Композитный функциональный материал |

| US8220843B2 (en) * | 2008-07-30 | 2012-07-17 | Parker-Hannifin Corporation | Sealing joint for connecting adjoining duct pieces in an engine exhaust system |

| US9790438B2 (en) | 2009-09-21 | 2017-10-17 | Ecolab Usa Inc. | Method for removing metals and amines from crude oil |

| US9061088B2 (en) | 2012-02-02 | 2015-06-23 | Abbott Cardiovascular Systems, Inc. | Guide wire core wire made from a substantially titanium-free alloy for enhanced guide wire steering response |

| US10661885B2 (en) * | 2012-05-16 | 2020-05-26 | The Boeing Company | Shape memory alloy active spars for blade twist |

| US9636485B2 (en) | 2013-01-17 | 2017-05-02 | Abbott Cardiovascular Systems, Inc. | Methods for counteracting rebounding effects during solid state resistance welding of dissimilar materials |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| NL295669A (OSRAM) * | 1962-07-23 | |||

| DE2004546B2 (de) * | 1970-02-02 | 1973-05-10 | Dannöhl, Waiter, Dr.phil., 6233 Kelkheim | Zwei- und mehrphasige silberbasiswerkstoffe |

| US3748108A (en) * | 1970-04-07 | 1973-07-24 | Us Army | Thermally activated spring with improved thermal properties |

| GB1478962A (en) * | 1973-06-06 | 1977-07-06 | Yorkshire Imperial Metals Ltd | Composite metal elongate product |

| US3872573A (en) * | 1973-12-19 | 1975-03-25 | Raychem Corp | Process and apparatus for making heat recoverable composite couplings |

| FR2309786A1 (fr) * | 1975-04-29 | 1976-11-26 | Air Liquide | Recipient pour fluides sous pression |

| US4025997A (en) * | 1975-12-23 | 1977-05-31 | International Telephone & Telegraph Corporation | Ceramic mounting and heat sink device |

| GB1594573A (en) * | 1976-11-05 | 1981-07-30 | Raychem Sa Nv | Sealing and insulating heat-recoverable article and method |

| CH630289A5 (de) * | 1977-05-09 | 1982-06-15 | Bbc Brown Boveri & Cie | Hochdaempfender verbundwerkstoff. |

| SE7908244L (sv) * | 1978-10-06 | 1980-04-07 | Raychem Corp | Relshjul |

| US4310354A (en) * | 1980-01-10 | 1982-01-12 | Special Metals Corporation | Process for producing a shape memory effect alloy having a desired transition temperature |

-

1982

- 1982-02-05 CH CH706/82A patent/CH660882A5/de not_active IP Right Cessation

- 1982-07-27 US US06/402,274 patent/US4518444A/en not_active Expired - Fee Related

-

1983

- 1983-01-26 DE DE8383200129T patent/DE3367625D1/de not_active Expired

- 1983-01-26 EP EP83200129A patent/EP0086013B1/de not_active Expired

- 1983-01-26 AT AT83200129T patent/ATE23569T1/de not_active IP Right Cessation

- 1983-02-04 JP JP58016314A patent/JPS58151242A/ja active Granted

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106984794A (zh) * | 2017-03-31 | 2017-07-28 | 福州大学 | 异种双金属复合板的共挤压制备设备及使用方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| JPS58151242A (ja) | 1983-09-08 |

| EP0086013A2 (de) | 1983-08-17 |

| ATE23569T1 (de) | 1986-11-15 |

| EP0086013A3 (en) | 1983-09-21 |

| DE3367625D1 (en) | 1987-01-02 |

| US4518444A (en) | 1985-05-21 |

| CH660882A5 (de) | 1987-05-29 |

| JPH0129144B2 (OSRAM) | 1989-06-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0086013B1 (de) | Werkstoff, welcher mindestens teilweise aus einer einen Einweg-Gedächtniseffekt zeigenden Komponenten aufgebaut ist und Verfahren zu dessen Herstellung | |

| EP0122429B1 (de) | Verbundwerkstoff in Stab-, Rohr-, Band-, Blech- oder Plattenform mit reversiblen thermo-mechanischen Eigenschaften und Verfahren zu dessen Herstellung | |

| EP0192105B1 (de) | Verfahren zum Warmumformen mindestens eines Bleches aus einem schwer verformbaren Werkstoff | |

| DE60111420T2 (de) | Verfahren zur herstellung eines verbundblechs aus aluminium | |

| EP0035601B1 (de) | Verfahren zur Herstellung einer Gedächtnislegierung | |

| DE1758162A1 (de) | Verfahren zum Herstellen von mit einer korrosionsbestaendigen Plattierung versehenen Gegenstaenden aus unedlen Metallen | |

| DE2156440A1 (de) | Verfahren zur Herstellung von Werkstücken aus Werkstoffen mit verschiedenen Eigenschaften | |

| EP0129691B1 (de) | Formstück aus einem Verbundwerkstoff und Herstellungsverfahren hierzu | |

| EP0045985B1 (de) | Verfahren zur Herstellung einer Kupferbasis-Gedächtnislegierung | |

| EP0356718B1 (de) | Verfahren zur Formgebung und Verbesserung der mechanischen Eigenschaften von pulvermetallurgisch hergestellten Rohlingen aus einer Legierung mit erhöhter Warmfestigkeit durch Strangpressen | |

| EP0545145B1 (de) | Herstellung eines Poren enthaltenden Kupferwerkstoffes als Halbzeug das einer Zerspanungsbehandlung unterworfen wird | |

| DE102020000913A1 (de) | Bleifreie Lötfolie | |

| DE1951140C3 (de) | Verfahren zum Herstellen eines metallischen Mehrschichtkörpers | |

| DE3601707A1 (de) | Verfahren zur herstellung von koerpern hoher dichte und hoher zugfestigkeit | |

| DE4201065C2 (de) | Anwendung des Sprühkompaktier-Verfahrens zur Verbesserung der Biegewechselfestigkeit von Halbzeug aus Kupferlegierungen | |

| AT390031B (de) | Mehrschichtmaterial | |

| EP2906386B1 (de) | Schichtverbund | |

| DE2504032C2 (OSRAM) | ||

| DE1558883A1 (de) | Titan-hartloetlegierung | |

| DE19511089A1 (de) | Bauteil mit aufgelöteten Folien aus ODS-Sintereisen-Legierungen | |

| EP1457616A1 (de) | Verbundplatte aus Leichtmetall | |

| DE2458739C3 (de) | Verfahren zum Herstellen eines Verbundwerkstoffs mittels Explosivschweißens, der neben einer Tantalschicht weitere Metallschichten aufweist | |

| DE2418686C2 (de) | Verfahren zur Herstellung von Halbzeug aus dispersionsgehärteten Kupferlegierungen | |

| DE2112370C2 (de) | Verfahren zur Herstellung superplastisch verformbarer kupferhaltiger Zink- oder Zink-Aluminium-Legierungen | |

| AT4683U1 (de) | Verwendung einer wolfram-schwermetalllegierung |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB LI SE |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH DE FR GB LI SE |

|

| 17P | Request for examination filed |

Effective date: 19840119 |

|

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Kind code of ref document: B1 Designated state(s): AT BE CH DE FR GB LI SE |

|

| REF | Corresponds to: |

Ref document number: 23569 Country of ref document: AT Date of ref document: 19861115 Kind code of ref document: T |

|

| BECN | Be: change of holder's name |

Effective date: 19861112 |

|

| REF | Corresponds to: |

Ref document number: 3367625 Country of ref document: DE Date of ref document: 19870102 |

|

| ET | Fr: translation filed | ||

| RAP2 | Party data changed (patent owner data changed or rights of a patent transferred) |

Owner name: BBC BROWN BOVERI AG |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19901217 Year of fee payment: 9 Ref country code: GB Payment date: 19901217 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19901221 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: SE Payment date: 19901227 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19901228 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19910321 Year of fee payment: 9 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19910422 Year of fee payment: 9 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19920126 Ref country code: AT Effective date: 19920126 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19920127 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: CH Effective date: 19920131 Ref country code: LI Effective date: 19920131 Ref country code: BE Effective date: 19920131 |

|

| BERE | Be: lapsed |

Owner name: BBC BROWN BOVERI A.G. Effective date: 19920131 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19920930 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19921001 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| EUG | Se: european patent has lapsed |

Ref document number: 83200129.1 Effective date: 19920806 |