EP0075064B1 - Abschleifvorrichtung für Bremsscheibe - Google Patents

Abschleifvorrichtung für Bremsscheibe Download PDFInfo

- Publication number

- EP0075064B1 EP0075064B1 EP82102824A EP82102824A EP0075064B1 EP 0075064 B1 EP0075064 B1 EP 0075064B1 EP 82102824 A EP82102824 A EP 82102824A EP 82102824 A EP82102824 A EP 82102824A EP 0075064 B1 EP0075064 B1 EP 0075064B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- brake disc

- bracket

- abrading device

- pair

- abrading

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B7/00—Machines or devices designed for grinding plane surfaces on work, including polishing plane glass surfaces; Accessories therefor

- B24B7/10—Single-purpose machines or devices

- B24B7/16—Single-purpose machines or devices for grinding end-faces, e.g. of gauges, rollers, nuts, piston rings

- B24B7/17—Single-purpose machines or devices for grinding end-faces, e.g. of gauges, rollers, nuts, piston rings for simultaneously grinding opposite and parallel end faces, e.g. double disc grinders

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

- B24B23/00—Portable grinding machines, e.g. hand-guided; Accessories therefor

- B24B23/08—Portable grinding machines designed for fastening on workpieces or other parts of particular section, e.g. for grinding commutators

Definitions

- This invention relates to an abrading device (or an abrader), and more particularly, it is concerned with a device for abrading the frictional surface of a brake disc of an automobile provided with a disc-type brake on its wheels, when the brake disc gets rusted or stained with oil on its surface.

- the invention also relates to a device for improving working precision in the abrading device for the automobile brake disc.

- an abrading device which, for avoiding trouble and complicacy in removing the brake disc from the axle at every time the brake disc is to be abraded, performs abrasion by urging a grinding stone to the frictional surface of the brake disc with its being mounted on the axle, and rotating the brake disc by an appropriate power source such as automobile engine, while the grinding stone is also being rotated so as not to cause scratches due to cutting by the grinding stone to appear on the frictional surface of the brake disc.

- the abovementioned conventional abrading device for the brake disc provides a fitting member for equipping the abrading device on the caliper supporting member and the supporting member for the grinder with respect to the fitting member being of a cantilever type, with the consequence that the grinding surface of the grinding stone cannot be maintained in a mutually parallel manner with the frictional surface of the brake disc so as to bring about unilateral contact between them, which thereby gives rise to scratches on the frictional surface of the brake disc.

- EP-A-0 006 764 describes an abrading device for vehicle brake discs having a bracket being substantially parallel to said disc mounted on an axle and being provided for the mounting of brake calipers.

- a pair of bearing frames are slidably mounted on a guide rod parallel to said axle.

- a pair of grinding stones one each held on said bearing frames hold said brake disc from its both surfaces. Grinding stone urging means hold the grinding stones in frictional contact with the brake disc.

- an improved abrading device for a brake disc of an automobile is capable of automatically performing cutting of the grinding stone to a predetermined degree.

- Such an improved abrading device for a brake disc of an automobile should make it possible for an operator of the device to know the termination of the cutting work by an electrical signal.

- an improve abrading device for a brake disc is provided with means aiming at increasing precision in the abrasion work by permitting horizontal deflection of the grinding stone following the surface of the brake disc within a certain predetermined limit through appropriate setting of a sliding resistance between the supporting cylinder of a bracket and a guide rod, thereby attempting to maintain uniform wear of the grinding stone on both sides of the brake disc.

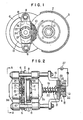

- the abrading device of the present invention is constructed with an axle 1 of the automobile, a brake disc 2 (hereinafter simply called “disc"), a disc cover 3, a caliper supporting member 4, a knuckle 5, and a substantially horse-shoe-shaped bracket 6 being fitted by bolts 7, 7 in a manner to be substantially parallel with the disc 2 and to protrude toward the outer periphery of the disc 2 by utilizing bolt holes remaining free after removal of the caliper from the caliper supporting member 4.

- the abovementioned guide rods 8, 8 support thereon bearing frames 9a, 9b at both the left and the right side of the substantially horse-shoe-shaped bracket 6 (vide Figure 2).

- the guide rods 8, 8 pass through both end parts of the bearing frame 9a, 9b, one of the bearing frames (9a) being fixed at one end of the guide rods 8, 8, and the other of the bearing frames (9b) being slidable along the guide rods 8, 8.

- Grinding stones 10, 10 are rotatably mounted on the opposing surfaces of the abovementioned bearing frames 9a, 9b through the shafts 11, 11.

- the rear surface of each grinding stone 10 is received on and held by a flange 12 having substantially the same diameter as the grinding stone.

- reference numeral 13 designates a cover for the grinding stone

- numeral 14 refers to a stopper flange for the grinding stone

- 15 designates a fixing bolt for the grinding stone.

- the end parts of the guide rods 8, 8 at the side of supporting the movable bearing frame 9b are joined with a fixed frame 16. Between the fixed frame 16 and the movable bearing frame 9b, there is provided a grinding stone urging device A for the cutting (abrading) operation.

- the urging device A may be either a manually operating means provided only with a tightening screw mechanism (i.e., a screw 17 and a pushing rod 18) as shown in Figure 4, or an automatic urging means as shown in Figure 2 utilizing a compression coil spring 19 or a tensile force of a dish spring.

- the automatic urging device A in Figure 2 is provided with means B for setting an abrading quantity, i.e., a moving quantity of the grinding stone.

- a supporting rod 20 for the coil spring 19 compressed between the movable bearing frame 9b and the fixed frame 16 extends outwardly through the fixed frame 16.

- the base part of the nut 21 is loosely fitted around the fixed frame 16.

- Electrical contacts 25, 26 are provided on the opposite surfaces of the fixed frame 16 and the nut 21, both of which are connected to a signalling apparatus 27 such as a pilot lamp, buzzer, bell, and so on.

- a brake caliper (not shown in the drawing) is removed from the caliper supporting member 4 and the nut 21 is turned to the left (vide: the embodiments shown in Figures 1 and 2) to thereby cause the bearing part 9b to retreat against force of a spring 19 and widen the space gap between the grinding stones 10, 10 and the brake disc 2.

- a screw rod 17 is turned to the left to directly pull the bearing frame 9b backward, thereby widening the gap between the grinding stones and the brake disc.

- the screw rod 17 is turned to the right so as to tighten it while continuing to urge the frictional surface of the brake disc with the grinding stones 10, 10, the abrading quantity of which is verified by monitoring with eyes. As soon as the required quantity of abrasion has been attained, the screw rod 17 is reversely turned to separate the grinding stones 10, 10 from the brake disc 2.

- each of the bearing frames 9a, 9b by fixing together the guide rods 8, 8 and the substantially horse-shoe-shaped bracket 6, and then slidably supporting the bearing frames 9a, 9b on the guide rods 8, 8.

- the abrading device for the brake disc is of such a construction that the substantially horse-shoe-shaped bracket 6 mounted on the caliper supporting member 4 of the automobile in a manner to be interchangeable with the caliper is protruded toward the outer periphery of the brake disc 2 substantially in parallel with the brake disc on the axle 1; then, at the outer periphery of the brake disc 2, there are provided a pair of bearing frames 9a, 9b, which are supported on the above- mentioned horse-shoe-shaped bracket 6, at least one of which is slidably supported on the above- mentioned substantially horse-shoe shaped bracket 6; the grinding stones 10, 10 are rotatably supported on the abovementioned bearing frame 9a, 9b in a manner to hold the brake disc 2 at both surfaces; and the grinding stone urging means A to the brake disc 2 is provided between the bearing frame 9b and the guide rod 8.

- the caliper supporting member 4to hold the grinding stones 10, 10 on both surfaces of the brake disc 2 in a manner to contact thereto, the substantially horse-shoe-shaped bracket 6, the guide rods 8, 8, the bearing frames 9a, 9b, and so forth are mutually supported at two points.

- a reference numeral 12 designates the grinding stone receiving and holding member integral with the shaft 11

- numeral 14 refers to the stopper for the grinding stone

- numeral 15 indicates a stopper screw.

- the grinding stone urging means A is constructed as an automatically operable means utilizing the force of the spring, to which there is additionally provided means B for presetting an abrading quantity, so that, if only the means B is manipulated beforehand, there follows automatic abrasion for the quantity set.

- the device is so constructed that, as soon as the abovementioned abrasion completes, a notifying signal may be emitted, hence there is no necessity for watching the abrading quantity of the brake disc 2 with eyes, which effectively contributes to improving the working efficiency.

- the fixed frame 16 is fitted between the pair of the guide rods 8, 8, to which the pushing screw rod 18 to be gradually advanced by the manually operated knob 17a through the screw 17 is supported, then one of the bearing frames 9b is pushed in the axial direction of the grinding stone, and, at the same time, the other bearing frame 9a is pulled toward the bearing frame 9b, thereby performing the cutting of the brake disc 2 by the grinding stones 10, 10.

- the embodiment illustrated in Figure 6 is of such a construction that the feeder 30 is rotatably fitted in the hole of the fixed frame 16, that the above- mentioned knob 17a is fixed to the feeder 30 with the pushing screw 17b, and that the screw 17 of the pushing guide rod 18 is screwed in the hole of the feeder.

- Reference numeral 32 designates a metal

- numeral 34 refers to a thrust bearing.

- rust does not uniformly develop on the brake disc 2 over its entire surface. In most cases, it develops in local places, and, in particular, as shown in the side view of Figure 2, it sometimes develops and adheres onto its surface in a wavy shape. In such case, when the sliding resistance of the guide rod 8 to the guide rod holding cylinder of the bracket 6 is too small, both grinding stones 10, 10 deflect to the left and right following the wavy surface of the disc brake 2, and its abrading efficiency is low. Although the deflection depends on the magnitude of the sliding resistance, it is governed by the weight of the movable part as a whole.

- stepwise or cascaded holes 36, 38, 40 are formed inside the push rod 18 in its longitudinal direction, through which holes a spring receiving and holding rod 42 is inserted in such a manner that it may move forward and backward in and along the long hole 44 and without rotation avoided by a rotation stopping pin 46.

- a pushing knob 48 is fixed on the outer end part of the spring receiving and holding rod 42, and a coil spring 50 is accommodated in a space defined between the inner end of the pushing knob 48 and a stage 38a of the hole 38.

- Numeral 52 refers to graduations inscribed in the outer periphery of the pushing knob 48.

- a sleeve 54 is interposed between the holding cylinder 6a and a guide rod 8, and a degree of pressure contact to the guide rod 8 of the sleeve 54 is adjusted to regulate the sliding resistance between the guide rod 8 and the holding cylinder 6a.

- a rotation stopper is provided between the supporting cylinder 6a and the sleeve 54.

- a reference numeral 58 designates an 0-ring

- numeral 60 refers to a snap ring

- numeral 62 denotes a ring to stop a flange 18a at the forward end part of the pushing rod 18

- 64 designates a fitting bolt for the stopper ring 62.

- the sliding resistance of the sleeve 54 to the guide rod 8 is established by the pushing screw 56, through reading of a numerical value from the graduations 52 inscribed on the outer periphery of the pushing knob 48 at the start of its moving, in such a manner that the value as read out may substantially coincide with a value previously found by a test machine.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Braking Arrangements (AREA)

- Grinding Of Cylindrical And Plane Surfaces (AREA)

Claims (9)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| AT82102824T ATE15003T1 (de) | 1981-09-18 | 1982-04-02 | Abschleifvorrichtung fuer bremsscheibe. |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP56147328A JPS6017661B2 (ja) | 1981-09-18 | 1981-09-18 | 自動車のブレ−キデイスク研削機の研削精度向上装置 |

| JP147328/81 | 1981-09-18 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| EP0075064A1 EP0075064A1 (de) | 1983-03-30 |

| EP0075064B1 true EP0075064B1 (de) | 1985-08-21 |

Family

ID=15427692

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82102824A Expired EP0075064B1 (de) | 1981-09-18 | 1982-04-02 | Abschleifvorrichtung für Bremsscheibe |

Country Status (6)

| Country | Link |

|---|---|

| EP (1) | EP0075064B1 (de) |

| JP (1) | JPS6017661B2 (de) |

| AT (1) | ATE15003T1 (de) |

| CA (1) | CA1191348A (de) |

| DE (1) | DE3212443C2 (de) |

| FR (1) | FR2513163A1 (de) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| IT1186873B (it) * | 1985-05-14 | 1987-12-16 | Galeazzo Maccaferri | Macchina per la rettifica dei dischi dei freni delle autovetture e degli automezzi in genere |

| US5152104A (en) * | 1989-09-12 | 1992-10-06 | Accu Industries, Inc. | Rotor finisher |

| DE9414699U1 (de) * | 1994-09-10 | 1994-11-03 | Trumpf GmbH & Co., 71254 Ditzingen | Vorrichtung zum Einspannen von Werkstücken o.dgl. |

| JPH09174399A (ja) * | 1995-12-22 | 1997-07-08 | Speedfam Co Ltd | 研磨装置及び該研磨装置を使用した研磨方法 |

| SE522123C2 (sv) * | 2001-04-10 | 2004-01-13 | Volvo Lastvagnar Ab | Metod för rekonditionering av ett friktionspar i en färdbroms samt fordon innefattande en anordning för rekonditionering av ett friktionspar i en färdbroms anordnad i nämnda fordon |

| GB2445361A (en) * | 2007-01-02 | 2008-07-09 | Simon Dockwray | Centrifugal clutch shoe pre-bedding and dynamic balancing machine |

| CN103506904B (zh) * | 2013-09-17 | 2016-02-03 | 洛阳轴研科技股份有限公司 | 一种薄壁轴承套圈两端面研磨机的使用方法 |

| WO2018051124A2 (en) * | 2016-09-16 | 2018-03-22 | Kenneth Edwards | Removal of glaze from vehicle brakes |

| CN107336097B (zh) * | 2017-07-17 | 2019-02-22 | 奇瑞汽车股份有限公司 | 一种制动盘dtv修复机 |

| US20200276965A1 (en) * | 2017-09-15 | 2020-09-03 | Kenneth Edwards | Vehicle Brake Health Monitoring |

| CN110193771B (zh) * | 2019-05-24 | 2021-06-04 | 贵州乌江水电开发有限责任公司沙沱发电厂 | 一种升船机安全卷筒制动盘自动除锈装置 |

| CN112621432B (zh) * | 2020-12-08 | 2022-04-19 | 北京金隅天坛家具股份有限公司 | 一种家具加工用木材打磨装置 |

| CN112846974B (zh) * | 2021-01-11 | 2022-03-29 | 黄山菲英汽车零部件有限公司 | 一种汽车刹车盘表面精细化处理机器人 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR1352248A (fr) * | 1964-05-15 | Machine à rectifier les disques de freins | ||

| DE1480125A1 (de) * | 1964-06-09 | 1969-07-03 | Teves Gmbh Alfred | Vorrichtung zum Polieren der Reibflaechen von Scheibenbremsen,insbesondere fuer Kraftfahrzeuge |

| ES334507A1 (es) * | 1966-05-21 | 1968-03-16 | Teves Kg Alfred | Un procedimiento para la limpieza de discos de freno oxida-dos y sucios, montados en instalaciones de freno. |

| US3573002A (en) * | 1968-02-12 | 1971-03-30 | Battelle Development Corp | Hydrator for lime and the like |

| DE2204955B2 (de) * | 1972-02-03 | 1974-10-03 | Maschinenfabrik Ernst Thielenhaus, 5600 Wuppertal | Planschleifmaschine zur Herstellung eines ebenen Werkstückes bestimmter Dicke, insbesondere Bremsscheiben von Kraftfahrzeugscheibenbremsen |

| DE2316672A1 (de) * | 1972-09-06 | 1974-03-28 | Hans Gramlich | Schleifen von scheibenbremsen |

| AU532016B2 (en) * | 1978-06-29 | 1983-09-15 | Hans Gramlich | Brake disc grinding method |

-

1981

- 1981-09-18 JP JP56147328A patent/JPS6017661B2/ja not_active Expired

-

1982

- 1982-04-02 EP EP82102824A patent/EP0075064B1/de not_active Expired

- 1982-04-02 CA CA000400414A patent/CA1191348A/en not_active Expired

- 1982-04-02 AT AT82102824T patent/ATE15003T1/de not_active IP Right Cessation

- 1982-04-02 DE DE3212443A patent/DE3212443C2/de not_active Expired

- 1982-04-02 FR FR8205743A patent/FR2513163A1/fr active Granted

Also Published As

| Publication number | Publication date |

|---|---|

| JPS5851059A (ja) | 1983-03-25 |

| DE3212443C2 (de) | 1984-10-25 |

| CA1191348A (en) | 1985-08-06 |

| DE3212443A1 (de) | 1983-04-14 |

| FR2513163B1 (de) | 1985-02-01 |

| FR2513163A1 (fr) | 1983-03-25 |

| ATE15003T1 (de) | 1985-09-15 |

| EP0075064A1 (de) | 1983-03-30 |

| JPS6017661B2 (ja) | 1985-05-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP0075064B1 (de) | Abschleifvorrichtung für Bremsscheibe | |

| US3830343A (en) | Disc brake with adjustable cam operator and thrust distributer | |

| US4480412A (en) | In-process grinding gage | |

| CA1108657A (en) | Workpiece clamping device | |

| US5213056A (en) | Slack adjustment tester | |

| JP7171891B2 (ja) | 研削盤用のクランプシステム | |

| US4168627A (en) | Wheel mounting apparatus | |

| US4520597A (en) | Grinding unit for industrial robot and automatic machines | |

| US2734319A (en) | billeter | |

| US1919545A (en) | Brake shoe grinder | |

| GB2063117A (en) | Apparatus for producing convex and/or concave spherical surfaces | |

| US3934378A (en) | Mechanism for making roller-hub grooves | |

| US2005870A (en) | Brake gauging device | |

| US1949070A (en) | Grinder attachment for brake relining machines | |

| US4468892A (en) | Grinding machine | |

| US7905165B1 (en) | Adapter assembly for hubbed rotor | |

| US2787095A (en) | Wheel truing device | |

| US2905476A (en) | Controlled centering chuck | |

| US2295061A (en) | Brake shoe grinding machine and gauge | |

| GB2029263A (en) | Improvements in or relating to rollermills | |

| US3538903A (en) | Cutting tool holder | |

| US3060649A (en) | Means for grinding automotive brake shoes | |

| US2187962A (en) | Combination precision grinder and caliper | |

| US1996252A (en) | Brake truing device | |

| CN116810424B (zh) | 一种摆杆轴承内圈车加工夹具及方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH GB LI NL |

|

| 17P | Request for examination filed |

Effective date: 19830531 |

|

| TCAT | At: translation of patent claims filed | ||

| TCNL | Nl: translation of patent claims filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): AT BE CH GB LI NL |

|

| REF | Corresponds to: |

Ref document number: 15003 Country of ref document: AT Date of ref document: 19850915 Kind code of ref document: T |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: GB Payment date: 19940322 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: AT Payment date: 19940421 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19940430 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: BE Payment date: 19940506 Year of fee payment: 13 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19940519 Year of fee payment: 13 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19950402 Ref country code: AT Effective date: 19950402 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19950430 Ref country code: CH Effective date: 19950430 Ref country code: BE Effective date: 19950430 |

|

| BERE | Be: lapsed |

Owner name: HONDA GIKEN KOGYO K.K. Effective date: 19950430 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19951101 |

|

| GBPC | Gb: european patent ceased through non-payment of renewal fee |

Effective date: 19950402 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee |

Effective date: 19951101 |