EP0073346B1 - Verfahren und Vorrichtung zur Papierführung in Schreib- oder ähnlichen Büromaschinen - Google Patents

Verfahren und Vorrichtung zur Papierführung in Schreib- oder ähnlichen Büromaschinen Download PDFInfo

- Publication number

- EP0073346B1 EP0073346B1 EP82106848A EP82106848A EP0073346B1 EP 0073346 B1 EP0073346 B1 EP 0073346B1 EP 82106848 A EP82106848 A EP 82106848A EP 82106848 A EP82106848 A EP 82106848A EP 0073346 B1 EP0073346 B1 EP 0073346B1

- Authority

- EP

- European Patent Office

- Prior art keywords

- paper

- platen

- sheet

- stop

- holding rail

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired

Links

- 238000000034 method Methods 0.000 title claims description 9

- 238000007639 printing Methods 0.000 claims description 9

- 238000010438 heat treatment Methods 0.000 claims description 4

- 238000001035 drying Methods 0.000 claims description 3

- 229910000639 Spring steel Inorganic materials 0.000 claims description 2

- 229910052751 metal Inorganic materials 0.000 claims description 2

- 239000002184 metal Substances 0.000 claims description 2

- 238000006073 displacement reaction Methods 0.000 claims 2

- 239000000976 ink Substances 0.000 description 5

- 239000000463 material Substances 0.000 description 4

- 239000007921 spray Substances 0.000 description 4

- 238000010586 diagram Methods 0.000 description 2

- 238000009736 wetting Methods 0.000 description 2

- 229910052782 aluminium Inorganic materials 0.000 description 1

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 238000007641 inkjet printing Methods 0.000 description 1

- 238000003780 insertion Methods 0.000 description 1

- 230000037431 insertion Effects 0.000 description 1

- 230000007257 malfunction Effects 0.000 description 1

- 230000007246 mechanism Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J13/00—Devices or arrangements of selective printing mechanisms, e.g. ink-jet printers or thermal printers, specially adapted for supporting or handling copy material in short lengths, e.g. sheets

- B41J13/02—Rollers

- B41J13/036—Rollers co-operating with a roller platen

Definitions

- the invention relates to a method and a device for paper guidance in typewriters or similar office machines of the type specified in the preamble of claim 1.

- the pressure rollers consist of pressure rings and are arranged on a drive shaft in such a way that they drive the paper in the spaces between the sprayed characters.

- This paper transport is probably suitable for recordings in which the characters are at a certain distance from one another.

- facsimile and proportional font recordings smearing of the not yet smudge-proof letters cannot be avoided with this proposed arrangement.

- the invention has for its object to provide a paper guide device for typewriters or similar office machines, in which the paper pressure elements a constant distance between the recording medium and the write head in the area of the impression point and a contact of the pressure rollers with the sprayed letters or characters only after they have dried guaranteed. Blurring of the sprayed characters should therefore be avoided.

- This object is achieved by the invention characterized in claim 1.

- patent claim 7 enables simple adjustment and locking of the paper pressure rollers on the paper holding rail.

- the subject matter of claim 12 is characterized by a simple method for pulling in, transporting and ejecting paper sheets with the device according to the invention.

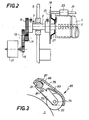

- Figures 1 and 2 contain a paper roll 1, which is rotatably mounted by means of a paper roll axis 3 in side walls 5 of a frame of typewriters or similar office machines.

- a gear 9 is arranged so that it can be screwed down and is arranged to be driven by a stepping motor 17 via intermediate wheels 11, 13 and 15.

- a rocker 19 is pivotally mounted, which has a paper holding rail 21 with paper holding rollers 23 and side parts 25 designed as bearing parts.

- a side part 25 is in frictional connection with a trailing spring 27 designed as a slip clutch.

- the side part 25 also has a stop arm 28 which interacts with fixed stops 29, 31.

- the stops 29, 31 can be made adjustable and serve as end positions for the rocker 19.

- One end position of the rocker 19 on the stop 31 is the paper receiving position and the other end position on the stop 29 is the normal writing position position for the rocker 19.

- the stop arm 28 of the rocker 19 can be locked in the paper receiving position by a locking pawl 33, which is cushioned on an arm 35 of a control lever 37 (39) and is rotatably mounted about a bearing axis 41.

- the control lever 37 is pivotable about an axis 43 and is operatively connected to a control magnet 47 via a second arm 45.

- On the second arm 45 a stop pawl 49 with a stop 51 is rotatably arranged (52) through which

- the rocker 19 can be stopped when pivoting from the normal writing position into the first writing position such that the pressure rollers 23 are located directly above the print head 53 which can be moved along the paper roller 1. This lock is necessary when transporting the paper sheet against the paper feed direction, because the paper rolls hit the print head 53 still in the writing area and would cause malfunctions.

- the stop pawl 49 locks the rocker 19 only in the direction of rotation against the paper feed direction, while it springs resiliently in the paper feed direction.

- the latch 33 locks the rocker 19, however, in the paper feed direction and deflects resiliently in the reverse direction.

- a paper guide trough 55 with pressure rollers 57, 59 rotatably mounted in it, only two of which are shown in FIG. Between the pressure rollers 57, 59, the paper guide trough 55 has a recess 61 through which a sensing element 63 of a sensing switch 65 engages for paper polling.

- the feeler switch 65 is e.g. B. a microswitch, but it can also consist of a photo element.

- the print head 53 is an ink spray head which is arranged on a carriage 71 which is guided along the paper roll 1 on axes 67, 69.

- the carriage 71 is transported by a transport device, not shown, e.g. through a stepper motor.

- each pressure roller 23 of the rocker 19 is rotatably mounted (75) in a saddle-shaped roller holder 73 made of spring steel sheet.

- the roller holder 73 is mounted in a guide part 79, which is displaceable on the paper holding rail 21 and is designed as a profile rail, so that it can pivot about a bearing axis 81.

- the roll holder 73 has a projecting resilient arm 83 which produces a clamping effect on the paper holding rail 21 for the guide part 79 and presses the pressure roller 23 against the paper roll 1.

- the paper holding rail 21 has a cylindrical shape with a flattening 89, on which the guide part 79 is mounted such that it can be displaced and pivoted to a limited extent with a correspondingly designed bearing recess 87. If the guide part 79 is acted upon by finger pressure in the direction of arrow 85 in accordance with FIG. 3, then the clamping action between the paper holding rail 21 and the bearing recess 87 is released in such a way that the guide part 79 can be moved laterally slightly and is automatically locked when released.

- the method for feeding, transporting and ejecting paper sheets is explained below with reference to FIGS. 4 and 5 with the block diagram and the functional flow chart.

- the write head moves outside the write area. Only in this position are signals 99 sent from a paper feed key 101 of a keyboard 105 to a control element 97, which can be a microprocessor or a commercially available computer.

- the control element 97 receives the data, carries out certain calculations and sends drive pulses via amplifiers 91 and 95 to the stepping motor 17 for the paper roll 1 and to the control magnet 47 for the control lever 43.

- the control magnet 47 pivots the control lever 37 in a clockwise direction so that the Stop pawl 49 are brought out of the area of action of the rocker 19 and the latching pawl 33 into the area of action of this rocker 19.

- the stepping motor 17 is acted upon by the control element 97 with drive pulses such that the paper roll 1 is rotated backwards by 10 divisions.

- the paper roller 1 takes the rocker 19 with the paper holding rollers 23 clockwise from the normal writing position into the paper receiving position 111 via the drag spring 27.

- the pivoting movement of the rocker 19 is limited by the stop 31, the locking pawl 33 engaging behind the stop 27 of the rocker 19. This prevents the rocker 19 from pivoting back in the counterclockwise direction.

- the stepping motor 17 is acted upon by the control element 97 with drive pulses in the reverse direction of rotation in such a way that the paper roll is rotated by 15 divisions in the forward direction.

- the sensor 65 interrogates whether there is a paper sheet 107 in the paper guide trough 55. If a paper sheet 107 is present, then the paper roller is switched by 10 divisions in the forward direction until the paper sheet 107 is located under the paper holding rollers 23. Thereafter, the control magnet 47 is switched off by the control element 97 and the paper roll 1 is switched by a further four divisions in the forward direction to the first writing point 11.

- the stepper motor 107 for the carriage 71 with the spray head 53 receives drive pulses via the amplifier 93 from the control element 97.

- the write head 53 is thus brought into the write position, the write head 53 being guided directly under the paper pressure rollers 23 along the paper roller 1.

- the person operating the machine can start entering write commands.

- the coded signals 99 corresponding to the characters to be printed by the keyboard 105 are emitted to the control element 97, which emits corresponding spray commands to the write head 53.

- the paper roll 1 is advanced in a known manner in the paper feed direction, the rocker 19 being taken from the first writing position 11 into the normal writing position 1.

- the paper roller 1 is switched on alone.

- the normal writing position 1 is arranged far enough from the writing point that the sprayed characters have already dried when they come into contact with the drive rollers 23. A blurring of the sprayed characters is avoided since the paper sheet 107 is always kept tight on the paper roller 1 in the writing area.

- Warning signals are issued four divisions before the end of the paper reaches the writing point.

- the keyboard On reaching the end of the paper the keyboard is then locked, whereby the functions "roller return” and “backspace” can still be executed.

- the paper end of the sheet 107 is still in the paper guide trough 55 such that the paper end still rests tightly on the paper roller 1 and therefore cannot approach the ink spray head 53.

- the paper eject button 103 in the keyboard 105 is operated.

- a coded signal is given to the control element 97, as a result of which drive pulses are sent via the amplifier 93 to the stepper motor 108 for the carriage 71.

- the carriage 71 with the writing head 53 is thereby moved outside the writing area.

- the stepper motor 17 also receives drive pulses from the control element 97 via the amplifier 91 in order to rotate the paper roll by 10 divisions in the paper ejection direction. After a further transport of 10 divisions of the paper roll 1, a paper request is made via the sensor switch 65.

- the stepper motor 17 receives so many drive pulses from the control element 97 that the paper roll 1 is switched forward by a further 20 divisions. This ensures that the paper sheet 107 is securely conveyed into the tray. Thereupon a new paper sheet 107 is pushed over a guide 109 into the feed nip between the paper roller 1 and the paper guide trough 55, whereby the paper feed button 101 can be operated again. The new paper sheet 107 is drawn in in the manner already described above. With the turning back of the paper roll 1 and the swinging back of the rocker 19 from the normal writing position I into the paper receiving position 111, the paper sheet 107 is automatically aligned.

- the device according to the invention and the method according to the invention enable paper sheets to be securely drawn in, transported and ejected.

- the paper roll 1 is designed as a hollow roll, the roll casing of which is made of metal, e.g. is made of aluminum and has a heating element inside.

- This heating element can be an infrared lamp, a heating coil or another heat radiator.

- the paper roll 1 has a substantially larger diameter than the known paper rolls, as a result of which excessive curvature of a paper sheet after being guided around the heated paper roll 1 is avoided.

Landscapes

- Handling Of Cut Paper (AREA)

- Handling Of Sheets (AREA)

- Delivering By Means Of Belts And Rollers (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE3133297 | 1981-08-22 | ||

| DE19813133297 DE3133297A1 (de) | 1981-08-22 | 1981-08-22 | Verfahren und vorrichtung zur papierfuehrung in schreib- oder aehnlichen bueromaschinen |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| EP0073346A2 EP0073346A2 (de) | 1983-03-09 |

| EP0073346A3 EP0073346A3 (en) | 1983-12-21 |

| EP0073346B1 true EP0073346B1 (de) | 1985-05-22 |

Family

ID=6139911

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| EP82106848A Expired EP0073346B1 (de) | 1981-08-22 | 1982-07-29 | Verfahren und Vorrichtung zur Papierführung in Schreib- oder ähnlichen Büromaschinen |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US4500219A (ja) |

| EP (1) | EP0073346B1 (ja) |

| JP (1) | JPS5887081A (ja) |

| DE (2) | DE3133297A1 (ja) |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60131279A (ja) * | 1983-12-20 | 1985-07-12 | Nippon Digital Kenkyusho:Kk | 単票用紙の終端まで印字可能なプリンタの用紙送り機構 |

| CA1244371A (en) * | 1984-08-31 | 1988-11-08 | Mitsuhiro Taketani | Printing apparatus |

| JPH0528047Y2 (ja) * | 1985-02-04 | 1993-07-19 | ||

| JPH0657464B2 (ja) * | 1985-04-09 | 1994-08-03 | ブラザー工業株式会社 | 印字装置 |

| GB2195320B (en) * | 1986-09-29 | 1990-10-03 | Oa Tech Inc | Sheet discharge device |

| JP2735286B2 (ja) * | 1989-04-26 | 1998-04-02 | 株式会社日立製作所 | 用紙位置決め機構 |

| DE3943227A1 (de) * | 1989-12-22 | 1991-07-04 | Mannesmann Ag | Vorrichtung fuer den transport von einzelblaettern oder papierbahnen wechselnder bzw. unterschiedlicher breite und/oder dicke |

| US5098211A (en) * | 1990-02-07 | 1992-03-24 | Seiko Epson Corporation | Sheet feeding mechanism for printing apparatus |

| KR0141226B1 (ko) * | 1993-09-29 | 1998-07-01 | 김광호 | 보더레스 프린터 |

| KR0132870B1 (ko) * | 1993-09-29 | 1998-04-15 | 김광호 | 프린터의 인쇄장치 및 그 방법 |

| JPH10202964A (ja) * | 1996-11-21 | 1998-08-04 | Fuji Photo Film Co Ltd | カラーサーマルプリント方法及びプリンタ |

| US5954440A (en) * | 1996-11-28 | 1999-09-21 | Agfa-Gevaert | Thermal printer with sheet pressure means |

Family Cites Families (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE1066593B (de) * | 1959-10-08 | Olympia Werke A.G., Wilhelmshaven | Aus dem Bereich der Typenbewegung schwenkbare Zeileneinstellschiene | |

| US1988189A (en) * | 1931-09-23 | 1935-01-15 | Underwood Elliott Fisher Co | Typewriting machine |

| US2210168A (en) * | 1939-08-28 | 1940-08-06 | Royal Typewriter Co Inc | Typewriting machine |

| US3199864A (en) * | 1963-02-21 | 1965-08-10 | Pitney Bowes Inc | Document handling apparatus |

| US3814011A (en) * | 1970-02-16 | 1974-06-04 | Casio Computer Co Ltd | System for advancing a writing head for printer |

| US3732810A (en) * | 1971-03-31 | 1973-05-15 | Burroughs Corp | Character aligning restraints for high speed printers |

| US3915281A (en) * | 1973-11-08 | 1975-10-28 | Victor Comptometer Corp | Platen and paper roll support and drive mechanism |

| US3981388A (en) * | 1974-11-20 | 1976-09-21 | Giuliani Robert L | Automatic bottom margin signal system for typewriters |

| DE2633498A1 (de) * | 1976-07-26 | 1978-02-02 | Siemens Ag | Anordnung zum einstellen der querspalten eines formulars fuer drucker, insbesondere fernschreibmaschinen |

| JPS53115234A (en) * | 1977-03-18 | 1978-10-07 | Oki Electric Ind Co Ltd | Solid ink facsimile typing system |

| US4138102A (en) * | 1977-03-30 | 1979-02-06 | Xerox Corporation | Automatic document processing device |

| DE2756904C3 (de) * | 1977-12-16 | 1981-06-11 | Mannesmann AG, 4000 Düsseldorf | Vorrichtung zum Herstellen bedruckter Streifen aus einem Papierband |

-

1981

- 1981-08-22 DE DE19813133297 patent/DE3133297A1/de not_active Withdrawn

-

1982

- 1982-07-29 DE DE8282106848T patent/DE3263748D1/de not_active Expired

- 1982-07-29 EP EP82106848A patent/EP0073346B1/de not_active Expired

- 1982-08-11 JP JP57138637A patent/JPS5887081A/ja active Granted

- 1982-08-18 US US06/409,050 patent/US4500219A/en not_active Expired - Fee Related

Also Published As

| Publication number | Publication date |

|---|---|

| JPS5887081A (ja) | 1983-05-24 |

| EP0073346A2 (de) | 1983-03-09 |

| EP0073346A3 (en) | 1983-12-21 |

| US4500219A (en) | 1985-02-19 |

| JPH0263070B2 (ja) | 1990-12-27 |

| DE3133297A1 (de) | 1983-03-03 |

| DE3263748D1 (en) | 1985-06-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| DE69627120T2 (de) | Druckgerät und Verfahren | |

| DE3855597T2 (de) | Aufzeichnungsgerät | |

| DE69031135T2 (de) | Farbstrahlaufzeichnungsvorrichtung | |

| DE19716895B4 (de) | Adaptives Druckverfahren | |

| DE69331898T2 (de) | Bogenförderapparat | |

| EP0073346B1 (de) | Verfahren und Vorrichtung zur Papierführung in Schreib- oder ähnlichen Büromaschinen | |

| DE69129909T2 (de) | Aufzeichnungsgerät zur Durchführung einer Aufzeichnung mittels eines Tintenstrahlaufzeichnungskopfes | |

| DE3342894A1 (de) | Kassette fuer einen schreibkopf einer tintenschreibvorrichtung in einer schreibmaschine | |

| DE69228889T2 (de) | Tintenstrahlaufzeichnungsgerät | |

| DE68923045T2 (de) | Antriebsmechanismus zur Anwendung in einem Drucker. | |

| DE69813451T2 (de) | Rückhalteplatte in einer Bogenzuführeinrichtung | |

| DE3119025A1 (de) | Thermodrucker | |

| DE2829827A1 (de) | Fuehrungseinrichtung fuer aufzeichnungstraeger bei druckwerken | |

| DE69016975T2 (de) | Kombinierte Andruckwalze und Wagenführung für einen Drucker. | |

| DE69723637T2 (de) | Tintenstrahldruckvorrichtung mit Trommelkopf | |

| US6250754B1 (en) | Duplex printer | |

| DE69204573T2 (de) | Tintenstrahldrucker. | |

| DE2428354A1 (de) | Belegverarbeitende maschine fuer edvanlagen | |

| EP0461118B1 (de) | Vorrichtung zum transport von aufzeichnungsblättern in einem tintendrucker | |

| DE2855253A1 (de) | Tintenspritz-, -schreib-, -druckwerk | |

| DE3850266T2 (de) | Vorrichtung zur Handhabung von Aufzeichnungsträgern für einen kompakten Drucker mit einer Vielzahl auf einem hin und her bewegbaren Schlitten angeordneten Druckköpfen. | |

| DE4034327A1 (de) | Drucker zum bedrucken von computerendlospapier | |

| DE69119474T2 (de) | Schreibgerät mit einer elektronischen Schreibmaschine | |

| DE10330847A1 (de) | Druckmechanismus | |

| DE3204348C2 (de) | Papiereinzug für Drucker |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PUAI | Public reference made under article 153(3) epc to a published international application that has entered the european phase |

Free format text: ORIGINAL CODE: 0009012 |

|

| AK | Designated contracting states |

Designated state(s): CH DE FR GB IT LI NL SE |

|

| PUAL | Search report despatched |

Free format text: ORIGINAL CODE: 0009013 |

|

| AK | Designated contracting states |

Designated state(s): CH DE FR GB IT LI NL SE |

|

| 17P | Request for examination filed |

Effective date: 19831110 |

|

| ITF | It: translation for a ep patent filed | ||

| GRAA | (expected) grant |

Free format text: ORIGINAL CODE: 0009210 |

|

| AK | Designated contracting states |

Designated state(s): CH DE FR GB IT LI NL SE |

|

| REF | Corresponds to: |

Ref document number: 3263748 Country of ref document: DE Date of ref document: 19850627 |

|

| ET | Fr: translation filed | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: NL Payment date: 19850731 Year of fee payment: 4 |

|

| PLBE | No opposition filed within time limit |

Free format text: ORIGINAL CODE: 0009261 |

|

| STAA | Information on the status of an ep patent application or granted ep patent |

Free format text: STATUS: NO OPPOSITION FILED WITHIN TIME LIMIT |

|

| 26N | No opposition filed | ||

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: SE Effective date: 19860730 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Free format text: OLYMPIA AKTIENGESELLSCHAFT |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: NL Effective date: 19870201 |

|

| NLV4 | Nl: lapsed or anulled due to non-payment of the annual fee | ||

| GBPC | Gb: european patent ceased through non-payment of renewal fee | ||

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PFA Free format text: AEG OLYMPIA AKTIENGESELLSCHAFT |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: CD |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: GB Effective date: 19881121 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: FR Payment date: 19890531 Year of fee payment: 8 |

|

| ITTA | It: last paid annual fee | ||

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: CH Payment date: 19890928 Year of fee payment: 8 |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: LI Effective date: 19900731 Ref country code: CH Effective date: 19900731 |

|

| PGFP | Annual fee paid to national office [announced via postgrant information from national office to epo] |

Ref country code: DE Payment date: 19900731 Year of fee payment: 9 |

|

| REG | Reference to a national code |

Ref country code: CH Ref legal event code: PL |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: FR Effective date: 19910329 |

|

| REG | Reference to a national code |

Ref country code: FR Ref legal event code: ST |

|

| PG25 | Lapsed in a contracting state [announced via postgrant information from national office to epo] |

Ref country code: DE Effective date: 19920401 |

|

| EUG | Se: european patent has lapsed |

Ref document number: 82106848.3 Effective date: 19870609 |