CN1155467C - 复合材料、由其制备的制品及制备方法 - Google Patents

复合材料、由其制备的制品及制备方法 Download PDFInfo

- Publication number

- CN1155467C CN1155467C CNB961955805A CN96195580A CN1155467C CN 1155467 C CN1155467 C CN 1155467C CN B961955805 A CNB961955805 A CN B961955805A CN 96195580 A CN96195580 A CN 96195580A CN 1155467 C CN1155467 C CN 1155467C

- Authority

- CN

- China

- Prior art keywords

- matrix

- film

- layer

- polyurethane

- goods

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/003—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor characterised by the choice of material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/02—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles

- B29C43/10—Isostatic pressing, i.e. using non-rigid pressure-exerting members against rigid parts or dies

- B29C43/12—Isostatic pressing, i.e. using non-rigid pressure-exerting members against rigid parts or dies using bags surrounding the moulding material or using membranes contacting the moulding material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C43/00—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor

- B29C43/02—Compression moulding, i.e. applying external pressure to flow the moulding material; Apparatus therefor of articles of definite length, i.e. discrete articles

- B29C43/20—Making multilayered or multicoloured articles

- B29C43/203—Making multilayered articles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/06—Fibrous reinforcements only

- B29C70/08—Fibrous reinforcements only comprising combinations of different forms of fibrous reinforcements incorporated in matrix material, forming one or more layers, and with or without non-reinforced layers

- B29C70/086—Fibrous reinforcements only comprising combinations of different forms of fibrous reinforcements incorporated in matrix material, forming one or more layers, and with or without non-reinforced layers and with one or more layers of pure plastics material, e.g. foam layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/06—Fibrous reinforcements only

- B29C70/08—Fibrous reinforcements only comprising combinations of different forms of fibrous reinforcements incorporated in matrix material, forming one or more layers, and with or without non-reinforced layers

- B29C70/088—Fibrous reinforcements only comprising combinations of different forms of fibrous reinforcements incorporated in matrix material, forming one or more layers, and with or without non-reinforced layers and with one or more layers of non-plastics material or non-specified material, e.g. supports

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/30—Shaping by lay-up, i.e. applying fibres, tape or broadsheet on a mould, former or core; Shaping by spray-up, i.e. spraying of fibres on a mould, former or core

- B29C70/34—Shaping by lay-up, i.e. applying fibres, tape or broadsheet on a mould, former or core; Shaping by spray-up, i.e. spraying of fibres on a mould, former or core and shaping or impregnating by compression, i.e. combined with compressing after the lay-up operation

- B29C70/342—Shaping by lay-up, i.e. applying fibres, tape or broadsheet on a mould, former or core; Shaping by spray-up, i.e. spraying of fibres on a mould, former or core and shaping or impregnating by compression, i.e. combined with compressing after the lay-up operation using isostatic pressure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/30—Shaping by lay-up, i.e. applying fibres, tape or broadsheet on a mould, former or core; Shaping by spray-up, i.e. spraying of fibres on a mould, former or core

- B29C70/34—Shaping by lay-up, i.e. applying fibres, tape or broadsheet on a mould, former or core; Shaping by spray-up, i.e. spraying of fibres on a mould, former or core and shaping or impregnating by compression, i.e. combined with compressing after the lay-up operation

- B29C70/345—Shaping by lay-up, i.e. applying fibres, tape or broadsheet on a mould, former or core; Shaping by spray-up, i.e. spraying of fibres on a mould, former or core and shaping or impregnating by compression, i.e. combined with compressing after the lay-up operation using matched moulds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/54—Component parts, details or accessories; Auxiliary operations, e.g. feeding or storage of prepregs or SMC after impregnation or during ageing

- B29C70/545—Perforating, cutting or machining during or after moulding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/04—Layered products comprising a layer of synthetic resin as impregnant, bonding, or embedding substance

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/08—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/12—Layered products comprising a layer of synthetic resin next to a fibrous or filamentary layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/40—Layered products comprising a layer of synthetic resin comprising polyurethanes

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/04—Reinforcing macromolecular compounds with loose or coherent fibrous material

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/04—Reinforcing macromolecular compounds with loose or coherent fibrous material

- C08J5/046—Reinforcing macromolecular compounds with loose or coherent fibrous material with synthetic macromolecular fibrous material

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/12—Bonding of a preformed macromolecular material to the same or other solid material such as metal, glass, leather, e.g. using adhesives

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/30—Shaping by lay-up, i.e. applying fibres, tape or broadsheet on a mould, former or core; Shaping by spray-up, i.e. spraying of fibres on a mould, former or core

- B29C70/34—Shaping by lay-up, i.e. applying fibres, tape or broadsheet on a mould, former or core; Shaping by spray-up, i.e. spraying of fibres on a mould, former or core and shaping or impregnating by compression, i.e. combined with compressing after the lay-up operation

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C70/00—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts

- B29C70/04—Shaping composites, i.e. plastics material comprising reinforcements, fillers or preformed parts, e.g. inserts comprising reinforcements only, e.g. self-reinforcing plastics

- B29C70/28—Shaping operations therefor

- B29C70/40—Shaping or impregnating by compression not applied

- B29C70/42—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles

- B29C70/46—Shaping or impregnating by compression not applied for producing articles of definite length, i.e. discrete articles using matched moulds, e.g. for deforming sheet moulding compounds [SMC] or prepregs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2075/00—Use of PU, i.e. polyureas or polyurethanes or derivatives thereof, as moulding material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2305/00—Condition, form or state of the layers or laminate

- B32B2305/08—Reinforcements

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/40—Properties of the layers or laminate having particular optical properties

- B32B2307/412—Transparent

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2375/00—Polyureas; Polyurethanes

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2375/00—Characterised by the use of polyureas or polyurethanes; Derivatives of such polymers

- C08J2375/04—Polyurethanes

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10S—TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10S264/00—Plastic and nonmetallic article shaping or treating: processes

- Y10S264/90—Direct application of fluid pressure differential to shape, reshape, i.e. distort, or sustain an article or preform and heat-setting, i.e. crystallizing of stretched or molecularly oriented portion thereof

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/16—Two dimensionally sectional layer

- Y10T428/162—Transparent or translucent layer or section

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/16—Two dimensionally sectional layer

- Y10T428/163—Next to unitary web or sheet of equal or greater extent

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/19—Sheets or webs edge spliced or joined

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/19—Sheets or webs edge spliced or joined

- Y10T428/192—Sheets or webs coplanar

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/249921—Web or sheet containing structurally defined element or component

- Y10T428/249953—Composite having voids in a component [e.g., porous, cellular, etc.]

- Y10T428/249978—Voids specified as micro

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/29—Coated or structually defined flake, particle, cell, strand, strand portion, rod, filament, macroscopic fiber or mass thereof

- Y10T428/2913—Rod, strand, filament or fiber

- Y10T428/2933—Coated or with bond, impregnation or core

- Y10T428/2938—Coating on discrete and individual rods, strands or filaments

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T428/00—Stock material or miscellaneous articles

- Y10T428/29—Coated or structually defined flake, particle, cell, strand, strand portion, rod, filament, macroscopic fiber or mass thereof

- Y10T428/2913—Rod, strand, filament or fiber

- Y10T428/2933—Coated or with bond, impregnation or core

- Y10T428/294—Coated or with bond, impregnation or core including metal or compound thereof [excluding glass, ceramic and asbestos]

- Y10T428/2942—Plural coatings

- Y10T428/2947—Synthetic resin or polymer in plural coatings, each of different type

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/20—Coated or impregnated woven, knit, or nonwoven fabric which is not [a] associated with another preformed layer or fiber layer or, [b] with respect to woven and knit, characterized, respectively, by a particular or differential weave or knit, wherein the coating or impregnation is neither a foamed material nor a free metal or alloy layer

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/20—Coated or impregnated woven, knit, or nonwoven fabric which is not [a] associated with another preformed layer or fiber layer or, [b] with respect to woven and knit, characterized, respectively, by a particular or differential weave or knit, wherein the coating or impregnation is neither a foamed material nor a free metal or alloy layer

- Y10T442/2016—Impregnation is confined to a plane disposed between both major fabric surfaces which are essentially free of impregnating material

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/20—Coated or impregnated woven, knit, or nonwoven fabric which is not [a] associated with another preformed layer or fiber layer or, [b] with respect to woven and knit, characterized, respectively, by a particular or differential weave or knit, wherein the coating or impregnation is neither a foamed material nor a free metal or alloy layer

- Y10T442/2033—Coating or impregnation formed in situ [e.g., by interfacial condensation, coagulation, precipitation, etc.]

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/20—Coated or impregnated woven, knit, or nonwoven fabric which is not [a] associated with another preformed layer or fiber layer or, [b] with respect to woven and knit, characterized, respectively, by a particular or differential weave or knit, wherein the coating or impregnation is neither a foamed material nor a free metal or alloy layer

- Y10T442/2221—Coating or impregnation is specified as water proof

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/20—Coated or impregnated woven, knit, or nonwoven fabric which is not [a] associated with another preformed layer or fiber layer or, [b] with respect to woven and knit, characterized, respectively, by a particular or differential weave or knit, wherein the coating or impregnation is neither a foamed material nor a free metal or alloy layer

- Y10T442/2369—Coating or impregnation improves elasticity, bendability, resiliency, flexibility, or shape retention of the fabric

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/20—Coated or impregnated woven, knit, or nonwoven fabric which is not [a] associated with another preformed layer or fiber layer or, [b] with respect to woven and knit, characterized, respectively, by a particular or differential weave or knit, wherein the coating or impregnation is neither a foamed material nor a free metal or alloy layer

- Y10T442/273—Coating or impregnation provides wear or abrasion resistance

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/20—Coated or impregnated woven, knit, or nonwoven fabric which is not [a] associated with another preformed layer or fiber layer or, [b] with respect to woven and knit, characterized, respectively, by a particular or differential weave or knit, wherein the coating or impregnation is neither a foamed material nor a free metal or alloy layer

- Y10T442/2861—Coated or impregnated synthetic organic fiber fabric

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T442/00—Fabric [woven, knitted, or nonwoven textile or cloth, etc.]

- Y10T442/20—Coated or impregnated woven, knit, or nonwoven fabric which is not [a] associated with another preformed layer or fiber layer or, [b] with respect to woven and knit, characterized, respectively, by a particular or differential weave or knit, wherein the coating or impregnation is neither a foamed material nor a free metal or alloy layer

- Y10T442/2861—Coated or impregnated synthetic organic fiber fabric

- Y10T442/291—Coated or impregnated polyolefin fiber fabric

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Composite Materials (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Health & Medical Sciences (AREA)

- Materials Engineering (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Manufacturing & Machinery (AREA)

- Laminated Bodies (AREA)

- Reinforced Plastic Materials (AREA)

- Woven Fabrics (AREA)

- Acyclic And Carbocyclic Compounds In Medicinal Compositions (AREA)

Abstract

一种制品,包括(1)一种复合材料,该复合材料包括含纤维状或粒状增强材料的聚氨酯基体,该聚氨酯基体在增强材料周围通过形成聚氨酯的组分在低于增强材料熔点的温度下反应在现场形成;和(2)与复合材料的至少一个表面粘合的聚氨酯薄膜,该薄膜通过聚氨酯薄膜的羟基和现场形成的聚氨酯基体的NCO基因之间的反应而粘合于复合材料上。

Description

本发明领域

本发明涉及一些新的复合材料、由其制备的产品及制备方法。

背景技术

本发明的复合材料和制品优选用US 5,503,879中公开的方法和教导制备,该专利的全部内容这里作为参考引入。所述申请提及Chou等人的文章“复合材料”(

美国科学,1986年10月,Vol.255,No.4,p 192-203)。这篇包括对含有分散于各种基体材料中的纤维状材料的复合材料进行深入讨论的文章这里也作为参考引入。该文暗示(此暗示与工业上几十年的压力一致)复合材料的设计者和工程师一直在寻求高纤维基体粘合强度。US5,503,879公开了由弱粘合强度、软质回弹性复合材料带来的益处。

在US 5,503,879中,我公开了一种复合材料,它包括用纤维状材料增强的聚氨酯基体,例如一层或多层具有现场聚合的聚氨酯基体的织物,所述复合材料制备方法为:用形成聚氨酯的液态反应物润湿纤维状材料并使这些材料在温度低于纤维状材料的熔点下反应。随着固化进行,该反应导致形成固态聚合物基体。固化速率可通过催化剂和加热加速或通过加入其它化学物质或排出热延迟。

本发明概述

本发明涉及对US 5,503,879中的制品和方法的一些改进,这些改进使得能够生产具有所需的各种性能的复合材料制品,如改进的韧性,和生产三维制品的容易性,装饰持久性,控制柔软性,控制粘着力,可见的纹理和阻隔性能。本发明涉及的典型制品包括诸如鞋垫、旅行箱、家具部件、软管、管子、提包、旗子、遮棚、伞的柔软部分、装饰性窄胶带/条、标签、头盔、椅套起绒织物、手套、鞋类、小船、防护服及回弹性地板和墙壁覆盖材料等的各种制品,这些制品要求诸如柔韧性、韧性、装饰变化性和耐久性、和透气性/流体阻隔性的性能组合。

概而言之,本发明的制品包括:

(1)一种复合材料,如US 5,503,879中的复合材料,该材料包括包裹纤维状增强材料的固态聚氨酯基体,其中该基体通过在纤维状材料周围形成基体的液态材料反应在现场形成;和

(2)在复合材料(1)一面或两面上的热塑性聚合物薄膜或其等同物,该薄膜通过与聚氨酯基体粘附而粘合于复合材料上,该粘附是液态基体材料固化形成固态基体时发生的或增强的物理和/或化学反应的结果。

本发明的制品可按各种方法制备,例如通过将一层或多层呈扁平或弯曲表面的纤维状材料置于阳模上或横过阴模的模腔或置于配合模的各部分之间,用形成聚氨酯的反应物混合物润湿各层,将热塑性聚合物薄膜或其等同物在发生任何明显化学反应之前置于润湿层上,使所得叠铺料坯的各层按需要压实和按需要选取模具的形状,并使聚氨酯形成反应发生。如此制得聚合物薄膜与聚氨酯基体粘附结合的扁平或成型制品。

上述方法可按多种方式变化。例如,将纤维状材料层在含此层压材料的叠铺料坯置于模具上或用计量并混合的液体部分润湿叠铺料坯之前层压至聚合物薄膜上,所述液体部分将在薄膜的至少一个表面上以及在纤维状材料的纤维上、周围或之间形成固态基体。

纤维状材料层可在置于固态基体或模具上的同时被润湿。此外,可在纤维状材料层置于基体或模具上之前,将其(例如)通过与存在的计量并混合的共反应性部分一起通过辊隙而浸湿。

还可以将湿和干燥纤维状材料层用于同一叠铺料坯中,其中干燥层通过与湿层接触并将各层压实部分或彻底润湿。

还可以通过重复顺序排列纤维状材料润湿层、聚合物薄膜、润湿层、聚合物薄膜等至所需厚度,制备包括增强基体和聚合物薄膜的多个交替层的制品,只要各顺序层在明显形成聚氨酯之前合适地压实即可。

纤维状材料优选为针织、缝编、机织、编织或非织织物形式,尽管也可以使用纤维、长丝或纱线本身。然而优选织物,因为其与一层或多层聚合物膜相邻之前,易于用形成聚氨酯的反应物润湿和叠铺多层纤维。通常,将多个织物层铺在一起,将这些层用反应物润湿,将聚合物薄膜面对润湿层放置,并在聚氨酯反应明显进行前按需要重复此过程多次。

纤维状材料可为任何可市购的或设计的结构或组成,只要其熔点高于聚氨酯反应温度即可。例如,纤维状材料通常包括聚酯、聚乙烯、聚丙烯、聚芳酰胺和/或诸如不包含明显水分但对形成聚氨酯的反应物具有明显量反应位点的类似材料。在某些情况下,当需要更多的纤维基体粘合时或当固化借助水分进行,如湿致固化聚氨酯时,可以使用矿物(通常与粘合促进剂如硅烷一起)、动物、植物(包括人造纤维素塑料)、尼龙、丙烯酸系和类似纤维状材料。

热塑性聚合物薄膜还可以为任何所需组成如聚酯、聚氯乙烯或聚氟乙烯、聚碳酸酯、尼龙或聚氨酯的薄膜。当为提供改进的粘合力使用能与聚氨酯基体部分在形成基体时反应的具有OH基团的聚氨酯薄膜,尤其可获得所需的结果。使用聚氨酯薄膜(通常为热塑性聚氨酯薄膜)可获得所需性能如韧性、弹性、透明性(包括拉伸或拉伸/回复后的透明性)、着色性(包括薄膜上印花的良好清晰度)、阻隔性能(渗透性或抵抗各种流体通过的性能)、光稳定性和化学反应性。使用的薄膜可以为染色、印花、透明、光滑、纹饰、或穿孔/针孔薄膜。这些薄膜的厚度可在宽范围内变化并取决于所需制品。一个典型的例子是厚2密耳至100密耳的聚氨酯薄膜,但应理解可以使用其它类型的薄膜和厚度。

如上所述,薄膜可以是透明的或可以染色或在其表面上带有图案、印花、纹饰、压花、构形(topography)等。在本发明的一个实施方案中,基体中的织物层可具有颜色、印花或图案,因此若聚氨酯基体和聚合物薄膜是透明的,则可显示色彩、印花或图案,同时由聚合物薄膜防止磨损、磨蚀、太阳光损害等。

在另一实施方案中,薄膜本身可在其暴露的表面上或与基体相邻的内表面上带有色彩、印花或图案,后一情形中薄膜本身起到保护色彩、印花或图案的作用。

当聚氨酯在现场形成时,可用柔韧性或刚性模具,如紧靠刚性模具或刚性模具上的真空袋成型本发明的制品。此外,可用隔离膜促使固化制品从模具底中剥离。若要求与所需的构形或与(例如)3-D模具相符,则隔离膜可为弹性的,或该隔离膜可合适地为尺寸稳定的、光滑表面的或纹理的。该隔离膜还可用于调节形状或使制品具有特殊的纹饰或对制品压花。当基体部分或完全固化后除去该隔离膜。

还可用织物材料代替隔离膜或与隔离膜一起使用以提供所需的外表面。这可通过将织物覆盖于已用形成聚氨酯基体的反应物混合物润湿的纤维状材料上实现。在本实施方案中,织物材料应在形成聚氨酯的反应发生至显著程度之前覆盖于润湿的纤维状材料上。该织物还可用于模塑制品表面或其本身可变为制品的一个整体部分。若织物用于模塑制品或使制品压花,则应选取不与形成聚氨酯的反应物反应的织物以便于其脱模。另一方面,若试图使薄膜成为制品表面的固定部分,则优选应选择与形成聚氨酯的反应物反应或机械粘合并提供其它所需表面特性的织物,例如按需要使或防止聚氨酯树脂完全或部分渗胶。

当使用前一自然段中描述的织物时,该织物就其组成和/或结构而言可在很宽范围内变化。由趋于疏水的合成纤维如聚酯、聚乙烯、聚芳酰胺、聚丙烯等组成的织物是优选的。然而对于某些湿致固化的聚氨酯,亲水性纤维是合适的。

用于本实施方案中的织物可以为机织、非织、针织、编织、缝编织物或其组合,这些织物可非必要地用无纬纱线或长丝或不等长切断纤维或连续纤维代替或与它们一起使用。

可用各种方式生产本发明制品。例如,若需要,在形成复合材料期间可以使用真空袋、压板、传动带或辊隙压力。例如可用这些工艺使复合材料具有所需的压实性、表面纹理或构形。一个优选的实施方案是使用当制品形成时起到全部或部分真空袋作用的薄膜。当薄膜与基体粘合后,它成为制品的固定层。

通常,当使用塑料真空袋时,它本身为隔离材料或通常将隔离材料置于含润湿纤维层的塑料真空袋与其上放置的织物和/或薄膜之间。当形成聚氨酯基体时施加真空。袋的内表面在真空作用下被吸至紧靠隔离层,当形成聚氨酯基体时该隔离层紧压在增强的或成为表面的织物或阻隔薄膜上。

对于本发明的另一个特点,本发明的制品可垂直或以任何其它所需角度切割,因此暴露基体内纤维状增强材料的纤维末端。这样做的目的是使制得的制品具有提高耐磨性的表面或出于装饰或其它方面的考虑。根据该实施方案,可使用或不使用卷芯卷绕纤维增强的单层聚氨酯基体,优选纤维增强并用聚合物薄膜分离或覆盖的多层聚氨酯基体,由此形成圆柱型复合制品。此制品可在横切纵轴的方向切割以提供包括具有暴露增强纤维末端的基体的圆片或类似衬垫的复合材料制品。该方法可用于制备其中需要耐磨表面的制动衬片、鞋底、鞋后跟底层(top lift)或其类似物。根据本实施方案,可通过将一层或多层润湿织物与织物层上和/或织物层之间的一层或多层聚合物薄膜共卷绕于卷芯上,然后将该卷绕物固化在现场形成聚氨酯基体,于卷芯上直接形成要切割的制品。若使用多层聚合物薄膜层,通常将一层穿孔。

此外,可将要切割的制品在润湿下不用卷芯下收卷,然后固化和切割。

也可以不将制品本身收卷或收卷于卷芯上,而简单地以合适的角度切割制品(无论其为单层或相似或不相似材料的多个交替层),由此暴露纤维末端。为提供特殊的粘着力/滑爽性或装饰效果,所述角度可与任何增强/防磨表面纤维的轴向垂直,尽管在某些情况下其它切割角也是合适的。

在申请流水号08/236,258中使用的形成聚氨酯的反应物可用于本发明目的。这些反应物是特别合适的,因为它们容易润湿纤维增强材料,同时反应物具有低分子量且颗粒尺寸小,因此反应物的运动性能高,有助于润湿纤维组分的表面。此外,可控制其反应速率以在出现明显反应之前进行所需层叠并压实所需数量的层。该方法还有助于在基体变为固态之前形成制品,以避免基体变为固体后因模塑造成在基体上或增强纤维上的永久应力。

通常,形成聚氨酯的反应物包括(A)脂族或芳族异氰酸酯,如异氰酸酯预聚物如异佛尔酮二异氰酸酯或二苯基甲烷二异氰酸酯和(B)羟基组分如聚醚或聚酯多醇或其与其它化学物质如聚丙二醇的混合物。任何常规形成聚氨酯的组分可用于此目的,只要聚氨酯反应在温度低于纤维组分的熔点下进行即可。优选通过如下方式形成聚氨酯:将反应物(A)和(B)分别预热至(例如)温度30-80℃,将反应物计量并混合,然后采用喷涂、镘涂或在夹辊之间将反应物混合物施于纤维组分上,将纤维组分投入模具中或保持于室温(18-32℃)或高温(高达纤维组分的熔点)下,同时使纤维组分彻底润湿。随后的现场反应是放热反应,必要时可加以控制,以保持温度刚好低于所用纤维的熔点。加热使固化加速是有利的。通常,保持温度低于约70℃,尽管对于某些纤维状材料可使用更高的温度,例如高达约120℃。

作为本发明具体实施方案的一个例子,将由高韧度聚乙烯纤维组成的多层非织织物相互覆盖于其上并用形成聚氨酯的反应物润湿。将6密耳厚的热塑性透明脂族阻隔聚氨酯薄膜置于润湿织物叠铺料坯的外表面。压实借助真空进行。然后使聚氨酯形成反应按US 5,503,879中描述的通常方式进行,由此围绕聚乙烯纤维形成聚氨酯基材,其中聚氨酯薄膜与纤维粘合。所得复合材料的厚度为约0.01至10英寸,尽管也可有效地采用其它厚度。

可选用上面例子中所用的聚氨酯薄膜以提供具有各种表面特性的制品。例如,薄膜可容易吸收油墨并由此提供在薄膜表面染色或印刷的方式。可选择具有适合高清晰度印刷的平表面或另一表面的薄膜或适合印染极好色彩深度的染色方式。通过真空处理有利地施加聚氨酯阻隔层作为真空袋整体或其一部分或将聚氨酯阻隔层施于塑料袋或其类似物中,这样在现场形成聚氨酯基体时,可除去影响制品颜色或性能的气泡。当形成聚氨酯基材时,这可通过将纹饰的隔离片设置于叠铺料坯的一面或两面上并将真空袋设置于叠铺料坯的一面或两面上实现。这必须在聚氨酯基体变为固态之前,优选在反应物部分为液态并可流动时进行。在复合材料的薄膜与纤维增强基体之间获得粘附力。在不受这一解释的限制下,认为在带有反应性OH基团的聚氨酯薄膜与存在于一种基体反应物中的NCO基团之间,按所需NCO与相应其它基体反应物中OH的比例超过1∶1的量发生反应。通常反应物NCO∶OH为1.05∶1至1.15∶1对于提供所需的基体形成反应并余下一些NCO与薄膜材料中的OH反应是合适的。因此该薄膜化学粘附于基体上,尽管机械粘附也是可能的。可通过将液态聚氨酯形成反应物压入存在于薄膜或纤维中的表面缺陷或设计的接收形状或孔中和其周围,然后在保持压实条件下进行固化,可以控制所述机械粘附力。

若需要,可在热塑性聚氨酯薄膜任何一面上提供印刷图案。还可以染色或使整个薄膜完全着色。也可在固化之前和在固化后(但不是优选的)将基体染色或完全着色。还可以在基体形成前,将一些或所有增强织物染色或印花。如此做的一个优点是增强织物的颜色在基体固化后不会迁移,保护颜色不受紫外线、磨蚀、和聚氨酯基体(它本身是透明的)带来的类似危害的影响,可以使用因划线或类似处理在其它方面不合格的印刷材料和工艺。

在本发明的另一实施方案中,纤维组分通过加入粒状增强材料或填料或着色物质全部或部分代替或补充。所述粒状材料包括(例如)金属、塑料或橡胶颗粒、矿物或无机填料物质或有机颜料。这些粒状增强材料的其它例子包括碳化硅、二氧化硅、炭黑、氧化锌、二氧化钛、有机颜料或微球。

附图的简要说明

本发明将通过附图进行说明,其中图1-6图示本发明的各方面。

图1(a)-图1(e)为说明本发明方法的示意图;

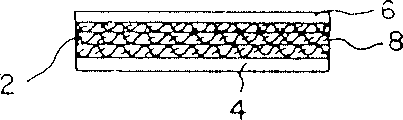

图2为一种压实基本上为图1所示湿叠铺料坯的方式的示意图,其中不同之处在于增加了底部薄膜(6)和顶部薄膜(6);

图3为用包括阳模和阴模部分的模具制备本发明制品的一种方式的示意图;

图4为根据本发明制备的制品的切割面示意图;

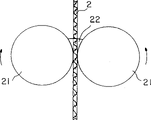

图5为形成聚氨酯的反应物润湿织物的一种方式的示意图;

图6为进一步说明本发明特点的示意图。

本发明的详细描述

更具体地,图1(a)-1(e)一般性说明本发明方法,其中如图1(a)所示,三层织物(2)相互覆盖于其上,并且该三层织物处于合适的支撑物或基底(4)上。然后如图1(b)所示将该叠铺料坯用形成聚氨酯的液体反应组分彻底润湿。此外,这些织物层(2)也可在层叠于该叠铺料坯上之前润湿。如图1(c)所示,在织物层(2)的叠铺料坯之后,将聚合物薄膜(6),例如热塑性聚氨酯薄膜覆盖于湿叠铺料坯上。如图1(d)所示将所得叠铺料坯压实或一起挤压,然后如图1(e)所示在聚氨酯形成并固化时保持此位置,得到薄膜(6)与复合材料牢固粘合的固体制品,所述复合材料材料来自于围绕织物层(2)现场形成的聚氨酯基体(8)。

如上所述,薄膜(6)的内或外表面可以在其任一侧面上附带印花或图案。若需要,薄膜(6)的外表面还可具有无光漆或其类似物。此外织物(2)可附带印花或图案。织物和/或薄膜还可以着色,尽管若在织物上或薄膜底部或第二个侧面上存在图案或印花,薄膜优选为透明的,这样可看到图案或印花。

薄膜、织物和聚氨酯基体中的一种或多种可被染色,以在最后的制品中获得最终所需的效果。

薄膜(6)还可设置于织物层的另一侧面,即与支撑物(4)相邻的侧面。该薄膜就其组成、结构、颜色等而言与顶部薄膜可以相同或不同。

图2给出一种压实基本上为图1所示湿叠铺料坯的方式,不同的是增加底部薄膜(6)和顶部薄膜(6)。尽管给出了支撑物或基底(4),但这是非必要的。在这种情况下,湿叠铺料坯和其支撑物(4)处于塑料袋(10)内。当通过管(12)抽真空时,袋在该结构周围塌陷,由此随着在现场形成和固化聚氨酯使薄膜和织物层挤压在一起。脱模剂或薄膜(未示出)或排气助剂可置于袋(10)的内表面与基体之间,当基体固化时使该袋不与制品表面粘附或有助于除去空气。此外,形成真空袋的薄膜可与基体粘合并变为形成的制品的固定部分。

图3图解说明用包括阳模和阴模部分(14)和(16)的模具制备本发明制品的另一方式。在所示的实施方案中,将隔离膜(18)设置于模具部分(14)和聚合物薄膜(6)之间。如图所示,该结构包括顶部和底部聚合物薄膜(6),它们在成型和固化后都与基体(8)和织物增强材料(2)的复合材料粘合。显然,当形成和固化聚氨酯基体时,在加压下模具部分(14)和(16)装配在一起使结构成型。

图4图解说明根据本发明制备的制品的切割面。在该实施方案中,将一层或多层润湿织物层围绕卷芯(19)卷绕,首先将织物层用聚氨酯反应物润湿。将聚合物薄膜(6)围绕织物层和在现场形成并固化的聚氨酯基体卷绕,然后从卷芯上取出该管状结构并横切所得制品的纵轴切割,由此提供(例如)薄片、圆片或其类似物。图4表示当仅包括一层织物增强材料(2)时切割后得到的截面。标号(20)表示增强织物的纤维的暴露末端。通过合适地选取织物,暴露的纤维末端可用于提供在其它性能中具有突出耐磨性的表面。聚合物薄膜(6)的带或层与织物层交替,由此提供图4所示的切割表面特性的另一些变化。

图5说明用形成聚氨酯的反应物润湿织物的一种方式。根据本实施方案,将干燥增强织物(2)加入从动夹辊(21)的辊隙中。将计量并混合的形成聚氨酯的反应物胶泥保持于辊隙中。当织物从辊隙另一面排出时被反应物彻底润湿。

图6说明本发明的重要特点,其中阻隔膜(6)构成塑料袋整体或一部分,该塑料袋用于将织物(2)和薄膜(6)的润湿叠铺料坯压实以在阳模(24)的基底(4)上固化。将阻隔膜(6)在(22)处密封于支撑物(4)上并围绕润湿织物(2),然后通过管(12)抽真空,如图3所示。如此提供制备本发明模塑制品的一种高效方式,其中使薄膜(6)与织物紧紧相贴,由此在模具上形成叠铺料坯时与聚氨酯基体粘合。

本发明通过下面的实施例更详细地描述,但这些实施例不以任何方式限制本发明。

实施例1

本实施例涉及使用(A)芳族热塑性聚氨酯薄膜(Argotec,Inc.,产品序号18402),15密耳厚,其Durometer Shore A硬度为约88,和(B)约22密耳厚的聚酯针织织物,包括两层双轴聚酯纱线,在每个轴上有17根/英寸,取向角+45°至-45°,1000-旦尼尔,192根长丝(Hoechst Celanese型787)和一层非织织物Sontara 8001聚酯(Dupont)和通过非织织物并围绕所述纱线针织的聚酯针织纱线(1层适度取向的190旦尼尔、34根长丝)。这些纤维比这里使用的两种聚氨酯都更硬。

层(A)和(B)交替覆盖以提供包括相互覆盖于其上的各10层(A)和(B)的交替层结构。当覆盖每一层(B)时,将该层用按其纤维重量计约1.5倍的形成交联聚氨酯液体基体材料的100%共反应性部分润湿,并将该层设置于相应层(A)上。包围纤维组分B的固化基体材料的Shore A Durometer为约55。

所得制品固化后包括复合材料和与复合材料粘合的热塑性聚氨酯薄膜(A)交替层,所述复合材料由分散于现场形成的热固性聚氨酯基体中的织物(B)组成。在此情况下,一个暴露的侧表面为分散于聚氨酯基体中的织物(B)的复合材料,而薄膜(A)构成另一个暴露侧表面。然而,可排列这些层以在两个侧面上提供薄膜(A)或织物基体复合材料。

通过将润湿织物(B)和薄膜(A)的叠铺料坯置于塑料袋中并施加真空除去任何残留的空气,实施上述实施例。薄膜(A)可为真空袋整体或其一部分。用真空袋加工还起到使各层更紧密压实的作用。作为使用真空袋的另一种方式,可借助压板或挤压辊向形成层的结构施加压实压力,由此得到具有所需密度、厚度、渗透性、纹理、构形或类似性能的最终制品。

实施例2

将实施例1中描述的层(A)和层(B)交替层卷绕于卷芯上形成圆柱形,此时基体仍为液态。对弹性聚氨酯薄膜(A)拉伸提供合适的压实力。在制品固化并除去卷芯后,将制品垂直于其轴切开形成薄片,该薄片表面具有复合材料层的一些暴露纤维末端和薄膜(A)上的一些层或带。如此提供了大大增强耐磨性和粘着力的表面。切割的表面包括较硬薄膜(A)和较软复合材料的带。在该复合材料内,其硬度存在多种变化,因为聚氨酯基体与纤维组分的硬度不同。这些硬度变化增强了对接触表面(如铺地砖)的粘着力/滑爽性的控制。

作为上述方法的另一种方式,将多层结构以矩形块形式铺成平行层后切开,切割沿横切层平面而非其侧面的方向进行,使纤维末端暴露。

下面的100%形成聚氨酯的共反应物组合物用于上述实施例1和2中。该产品可以Q-thane QC 4191 A/B市购(K.J.Quinn & Co.),它包括如下组分A和组分B:

组分A:亚甲基双(4-环己基异氰酸酯)

聚(氧化丙烯二醇)

单体二醇

此预聚物(组分A)具有约15%的NCO。

组分B:聚酯多醇(官能度>2.0)

单体二醇

二月桂酸二丁基锡催化剂

将100重量份组分A和304重量份组分B计量并混合形成聚氨酯基体。在与组分A掺混之前将组分B预热至约70℃以有助于精确计量和充分混合。将此混合物在约50℃下涂于纤维上。在室温(约25℃)下层叠层(A)和(B)。压实后,将这些例子在60℃下(根据加入的催化剂量)过夜固化。固化的聚氨酯树脂显示极好的水解稳定性。该固化制品的模量低,符合柔韧性制品的需要。

Q-thane LQC 24-195 A/B是QC 4191 A/B的芳族形式。它价格较低,当不要求最大耐光牢度时是合适的。24-195 A/B的组分A含有二苯基甲烷-4,4′-二异氰酸酯(由两种或多种异构体的物理混合物组成)。QC 24-195的组分B基本上具有与4191的组分B相同的组成。QC 24-195 A/B可取代前面实施例1和2中的QC4191A/B。

本发明的其它特点将通过下面的实施例说明。

实施例3

将Argotec透明93 AV脂族热塑性聚氨酯阻隔薄膜(A)(3密耳厚,Shore硬度为约93)的分离层印上正常影像(在一种情况下)和其镜像(在另一情况下),将这些层在织物(B)的两侧上对齐层叠并且两种影像都面对织物(B),后者为聚丙烯纬纱和聚酯经纱的1盎司/码2机织织物。薄膜层(A)覆盖于织物层(B)的两侧之前,立即将织物用约1盎司/码2与实施例1和2中使用的相同树脂体系润湿,形成热固性聚氨酯基体,并在发生任何明显交联反应之前覆盖薄膜层(A)并压实于织物(A)的两面上。然后,用与实施例1和2中相同的条件在现场形成聚氨酯基体,其中薄膜层(A)对齐排列。固化后,除薄膜上的印花外,制品基本上是透明和清澈的。

在这种情况下,固化用向叠铺料坯或组件施加压力的压板进行。此外,可用真空获得类似结果。

所得制品可用于提供标签、证章、旗子、遮棚、旗帜、柔韧性标牌、装饰胶带制品、衣料织物或其类似物,该制品两面上的非常厚的韧性阻隔膜起到防止磨损、阳光损害等的作用。例如,该制品可用薄膜保护的印刷油墨制备,产生的旗子图案不与其它表面直接接触或暴露于射线或磨掉或减弱这些标志的污染物下。切割和弯曲后,边不会被磨损。

应注意实施例3中描述的步骤可以变化。例如,可用仅一层阻隔薄膜覆盖复合材料的一个表面,而不覆盖其两个表面。其它变化也是明显的。

实施例4

将Du Pont Xymid 1573的缝编拉伸织物,包括染成灰色的Dacron、Lycra和Kevlar纤维(其聚集区域重量约8盎司/码2),用作层(B)。将该层以其“背面”或缝编面朝向阳模放置,该阳模为鞋楦形状。然后将层(B)用前面实施例中的QC4191A/B润湿,树脂与纤维的比例为约1.8∶1。

将一面上具有印刷图案的Argotec透明93AV脂族热塑性聚氨酯阻隔膜(A)(7密耳厚),以印刷图案面向润湿层(B)放置在润湿层(B)上。施加真空,用薄膜(A)作为真空袋的一部分。将薄膜(B)拉伸使其与模具匹配,对润湿织物进行同样处理,同时将薄膜(A)与织物相互面对面挤压,使(B)的液体树脂部分润湿(A)的表面。然后将形成聚氨酯的液态反应物固化,使层(B)和层(A)挤压在一起与模具匹配。层(A)和层(B)在其界面处粘合。在这种情况下,模具为聚乙烯鞋楦,制品为可洗涤的灰色鞋面,该鞋面具有其上印有装饰性图案的透明、耐久性韧性表层。

可用实施例4中给出的方法制备各种制品。例如若模具为Teflon圆柱形棒,其中层(A)将该棒完全包裹并且层(A)面对棒,而层(B)类似地在层(A)上包裹棒,当基体树脂固化时可形成软管或管道。Xymid的拉伸特性影响合适的压实性能,因为在包裹过程中它被适当拉伸。特别是当热塑性聚氨酯条、线材、纤维长丝或纱线和润湿织物共卷绕时,所得制品具有与模具表面相匹配的光滑阻隔内表面,该表面由纤维增强复合材料支撑,该复合材料提供聚氨酯基体复合材料的外表面以增强保护性能并降低软管弯曲时扭结的趋势。

实施例5

采用实施例4中描述的相同组分和方法,并用阴模取代阳模,其模腔为鞋底形状。将颗粒,如由废轮胎制备的含水量大于0.1%的碎片和热塑性聚氨酯粒料(它们都与使用的固化基体充分粘附)投入模具中,并用Q-thaneQC 27-127润湿。Q-thane QC 27-127为单组分聚氨酯形成组合物,它包括:

二苯基甲烷-4,4′-二异氰酸酯

聚(氧化丙烯)二醇(官能度>2.0)

带有羟基的烃树脂和

固化催化剂,如湿致固化时所需的二甲基乙醇胺。

当用作基体材料时,这种树脂对颗粒、碎片、粒料等具有良好粘合性。

尽管这是一种单组分湿致固化聚氨酯,但来自其单组分之外的水分源,如环境水分、表面水分或机械加入的水分对于进行固化是合适的。此外或补充地,可加入其他多醇代替水分或补充水分。

在润湿拉伸织物放置于模具开口之间、润湿的碎片-粒料分布于模具模腔内、热塑性聚氨酯薄膜面对拉伸织物放置并用作真空袋的一部分等条件下,将该叠铺料坯通过真空吸入模具的模腔中并在其中压实,将树脂固化并压实。用作真空袋结构一部分的热塑性聚氨酯薄膜变为制品的固定部分。这是形成鞋底和鞋面的一种有利方式。

此外,用形成水固化聚氨酯的液体润湿的碎片/粒料可按实施例2所述形成螺旋形或矩形结构。

若不需要阻隔膜变为如此模塑的结构的固定部分,则可用拉伸隔离膜(例如使最终制品具有合适纹理的硅橡胶)取代上述热塑性聚氨酯。

实施例6

在具有头盔形状模腔的阴模(这样该阴模具有负撑压深度(negativedraw),即必须将该部分弯曲以便将其从该模具中取出)中放置通过真空吸入其模腔的白色7密耳厚脂族热塑性Argotec AV93薄膜,并保持其紧靠模具。将用计量并混合A和B部分而得的Q-thane QC 4270润湿的湿尼龙5盎司/码2合适圆形针织物放置在模具的模腔上,其中拉伸物如硅橡胶隔离膜与织物在其远离模具一面接触。将此隔离膜/织物同时吸入模具中,使润湿的织物在出现初始固化时与白色薄膜接触压实。借助一些加压空气,可从模具中取出部分固化部件,以恢复其模塑形状,尽管其最终ShoreD硬度为约70。从模具中取出后,将模塑部件在约90℃下固化约16小时以达到最终硬度。

Q-thane QC 4270 A/B包括:

组分A:二苯基甲烷-4,4′-二异氰酸酯

聚(四亚甲基醚二醇)

聚醚多醇

聚(氧化丙烯)多醇

改性MDI(例如Dow 2143L)

组分B:单体二醇固化剂(可变化分子量和官能度以改变固化聚

氨酯的硬度、物理性能、透明度等。)

1,4-丁二醇

可按需要变化%NCO,但通常为14.5%。

应将组分A和B按重量比A∶B约87∶13进行动态混合。

固化后,不透明基体对于头盔外表面上的白色薄膜是合适的背衬,因为从外面观察色彩合适并且基体-薄膜粘合力强。

可对上述方式进行一些改进,例如,可用聚丙烯针织物作为增强织物。通常该针织物为溶液染色的4盎司/码2拉伸织物。还可用透明外阻隔热塑性聚氨酯膜和透明基体获得颜色变化。此外,该薄膜可具有一些印刷的第二或内表面以获得另外的颜色变化。还可以将染料加入这里使用的任何树脂体系中,通常在与相应异氰酸酯组分混合前加入多醇组分中,或加入单组分树脂体系中以获得颜色变化。

上面的描述是仅用于说明目的,显然可进行其它变化或替换。因此本发明范围将通过后面的权利要求限定。

Claims (26)

1、一种制品,其包括(1)一种复合材料,该复合材料包括含纤维状或粒状增强材料的聚氨酯基体,该聚氨酯在增强材料周围通过形成聚氨酯的组分在低于增强材料熔点的温度下反应在现场形成;和(2)与复合材料的至少一个表面粘合的聚氨酯薄膜,该薄膜通过聚氨酯薄膜的羟基和现场形成的聚氨酯基体的NCO基团之间的反应而粘合于复合材料上。

2、权利要求1的制品,其中纤维状增强材料包括一层和多层织物层。

3、权利要求2的制品,其中增强材料包括多层的机织、针织、编织、缝编或非织织物重叠层。

4、权利要求1的制品,其中将多层纤维状增强材料与紧靠至少某些层或处于至少某些层之间的聚合物薄膜一起层叠。

5、权利要求1的制品,其中至少一层薄膜或纤维状增强材料带有印花或图案或被染色。

6、权利要求5的制品,其中基体是透明的。

7、权利要求2的制品,其具有暴露的织物增强材料的纤维末端。

8、权利要求4的制品,其中通过基体或薄膜防止印刷油墨或颜色被磨蚀。

9、权利要求1的制品,其中通过更软和更硬的材料带或区域增强粘着力。

10、权利要求1的制品,其是可洗涤的。

11、一种制备复合制品的方法,该复合制品包括(1)含纤维状增强材料的聚氨酯基体和(2)与基体的表面粘合的薄膜,所述方法包括用具有一定比例以提供过量的NCO基团的形成聚氨酯的液体反应物混合物润湿一层或多层纤维状增强材料,将含有反应性羟基的热塑性聚氨酯薄膜在聚氨酯形成反应开始之前置于润湿的层上,和进行所述反应以在所述纤维状增强材料周围现场形成用作基体的聚氨酯,热塑性聚氨酯薄膜紧靠所述纤维状材料层保持,同时形成聚氨酯基体,由此在薄膜和基体之间通过热塑性聚氨酯薄膜的反应性羟基和基体反应物混合物中的NCO基团之间的反应产生化学键。

12、权利要求11的方法,其中将多层用形成聚氨酯的反应物混合物润湿的纤维状增强材料层与紧靠至少某些层或处于至少某些层之间的聚氨酯薄膜一起层叠。

13、权利要求11的方法,其中纤维状增强材料包括织物。

14、权利要求11的方法,其中至少一层薄膜或纤维状增强材料带有印花或图案或被染色。

15、权利要求14的方法,其中基体是透明的。

16、权利要求11的方法,其中润湿层位于模具中或模具上,并且当在现场形成聚氨酯时将制品成型为所需形状。

17、权利要求11的方法,其中聚氨酯薄膜通过真空与润湿层接触,以在形成基体前压实该组件。

18、权利要求11的方法,其中将用形成聚氨酯的液体反应物润湿的至少一层纤维状材料层围绕卷芯卷绕,将薄膜在拉伸下围绕润湿层卷绕,然后在现场形成聚氨酯基体。

19、权利要求18的方法,其中在聚氨酯基体固化后通过薄膜和基体切割制品以提供具有暴露的纤维状材料末端的切割表面。

20、一种制备复合材料的方法,该复合材料包括(1)含纤维状增强材料的聚氨酯基体和(2)与基体的表面粘合的薄膜层,所述方法包括用具有一定比例以提供过量的NCO基团的形成聚氨酯的液体反应物混合物涂敷纤维状增强材料,在涂敷所述纤维状增强材料时,使含有反应性羟基的热塑性聚氨酯薄膜与反应物混合物接触,和在聚氨酯形成反应开始之前,施以真空以除去残留的气体和压实增强材料和薄膜,薄膜紧靠所述纤维状增强材料保持,同时形成聚氨酯基体,由此在薄膜和基体之间通过热塑性聚氨酯薄膜的反应性羟基和基体反应物混合物中的NCO基团之间的反应产生化学键。

21、权利要求20的方法,其中薄膜为真空袋的形式,由此该袋构成复合材料薄膜的至少一部分。

22、权利要求21的方法,其中薄膜为复合材料提供了表面构造。

23、权利要求21的方法,其中薄膜在其外或内表面具有印花或图案。

24、权利要求23的方法,其中印花或图案在薄膜相邻基体的内表面上。

25、权利要求20的方法,其包括交替层叠放置(1)带有形成聚氨酯的反应物的纤维状增强材料和(2)所述聚氨酯薄膜,将该层叠物放入塑料真空袋中,加热并施与真空以除去残留的气体和压实层叠物,同时所述形成聚氨酯的反应物反应以形成所述基体,其中薄膜与基体化学键合。

26、由权利要求20或25的方法获得的复合材料。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US08/476,112 | 1995-06-07 | ||

| US08/476,112 US5874133A (en) | 1995-06-07 | 1995-06-07 | Process for making a polyurethane composite |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1190930A CN1190930A (zh) | 1998-08-19 |

| CN1155467C true CN1155467C (zh) | 2004-06-30 |

Family

ID=23890551

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB961955805A Expired - Fee Related CN1155467C (zh) | 1995-06-07 | 1996-06-04 | 复合材料、由其制备的制品及制备方法 |

Country Status (10)

| Country | Link |

|---|---|

| US (3) | US5874133A (zh) |

| EP (1) | EP0837770B1 (zh) |

| JP (1) | JP3955322B2 (zh) |

| CN (1) | CN1155467C (zh) |

| AT (1) | ATE229879T1 (zh) |

| CA (1) | CA2223431C (zh) |

| DE (1) | DE69625485T2 (zh) |

| IN (1) | IN190702B (zh) |

| TW (1) | TW342361B (zh) |

| WO (1) | WO1996040503A1 (zh) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107385629A (zh) * | 2016-05-17 | 2017-11-24 | 韩国卡奔株式会社 | 具有改善的疲劳强度的柔性次级气体隔板及其制造方法 |

Families Citing this family (61)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5874133A (en) * | 1995-06-07 | 1999-02-23 | Randemo, Inc. | Process for making a polyurethane composite |

| JP3921854B2 (ja) * | 1998-12-17 | 2007-05-30 | 東レ株式会社 | 透湿防水素材およびその製造方法 |

| ATE221906T1 (de) * | 1999-01-26 | 2002-08-15 | Huntsman Int Llc | Geschäumte thermoplastische polyurethane |

| US6558784B1 (en) | 1999-03-02 | 2003-05-06 | Adc Composites, Llc | Composite footwear upper and method of manufacturing a composite footwear upper |

| US6395401B1 (en) * | 1999-08-11 | 2002-05-28 | Mbt Holding Ag | Bond-compatible composite membrane |

| US6374565B1 (en) * | 1999-11-09 | 2002-04-23 | Foster-Miller, Inc. | Foldable member |

| US20030019180A1 (en) * | 1999-11-09 | 2003-01-30 | Warren Peter A. | Foldable member |

| US8074324B2 (en) * | 1999-11-09 | 2011-12-13 | Foster-Miller, Inc. | Flexible, deployment rate damped hinge |

| US6585151B1 (en) | 2000-05-23 | 2003-07-01 | The Regents Of The University Of Michigan | Method for producing microporous objects with fiber, wire or foil core and microporous cellular objects |

| ES2168979B1 (es) * | 2000-08-11 | 2003-09-16 | Indesproin S L | Material compactado que comprende un elastomero de poliuretano y caucho, un procedimiento para su obtencion y aplicaciones. |

| US6676882B2 (en) | 2001-08-28 | 2004-01-13 | Lockheed Martin Corporation | Methods of hot-melt resin impregnation of 3-D, woven, textile preforms |

| DE10154472A1 (de) * | 2001-11-08 | 2003-05-22 | Fehrer F S Gmbh & Co Kg | Flächiges Bauteil aus Kunststoff, insbesondere Lehnenverkleidung |

| US20030156499A1 (en) * | 2002-02-15 | 2003-08-21 | Miller Brian D. | Method of improving the transparency of scratched dial covers and repair kit |

| US6910304B2 (en) * | 2002-04-02 | 2005-06-28 | Foster-Miller, Inc. | Stiffener reinforced foldable member |

| US6902436B2 (en) * | 2002-07-15 | 2005-06-07 | Sheng Hsin Liao | Car lighter plug of quick disassembly |

| US20040084197A1 (en) * | 2002-11-01 | 2004-05-06 | Bortz Kent P. | Process for making polyethylene laminate composites |

| US6908979B2 (en) * | 2002-11-18 | 2005-06-21 | Huntsman International Llc | Polyurethane elastomer gels |

| AU2003292727A1 (en) * | 2002-12-27 | 2004-07-29 | Nagase Chemtex Corporation | Method for producing fiber-reinforced thermoplastic plastic and fiber-reinforced thermoplastic prastic |

| US20080014817A1 (en) * | 2003-03-31 | 2008-01-17 | Xymid, Llc | Abrasion-Resistant Composites with In-Situ Activated Matrix Resin |

| US7264861B2 (en) * | 2003-03-31 | 2007-09-04 | Xymid, Llc | Abrasion-resistant composites with in-situ activated matrix resin |

| US7249943B2 (en) | 2003-08-01 | 2007-07-31 | Alliant Techsystems Inc. | Apparatus for forming composite stiffeners and reinforcing structures |

| US7029267B2 (en) * | 2003-10-23 | 2006-04-18 | Saint- Gobain Technical Fabrics Canada, Ltd | Reusable vacuum bag and methods of its use |

| US7178267B2 (en) * | 2003-12-12 | 2007-02-20 | Polyworks, Inc. | Method for forming footwear structures using thermoforming |

| CN1206953C (zh) * | 2004-02-23 | 2005-06-22 | 谭哲豪 | 采用真空液压制造头盔的方法 |

| US20060201026A1 (en) * | 2005-03-14 | 2006-09-14 | Le Vine Jan F | Percussive devices for footwear |

| US10035932B2 (en) | 2007-09-25 | 2018-07-31 | Aero Advanced Paint Technology, Inc. | Paint replacement films, composites therefrom, and related methods |

| US10981371B2 (en) | 2008-01-19 | 2021-04-20 | Entrotech, Inc. | Protected graphics and related methods |

| US20090184207A1 (en) * | 2008-01-22 | 2009-07-23 | Warren Peter A | Synchronously self deploying boom |

| CN101585239A (zh) * | 2008-05-22 | 2009-11-25 | 拜耳材料科技贸易(上海)有限公司 | 一种鞋帮及其制备方法和用途 |

| US8367304B2 (en) | 2008-06-08 | 2013-02-05 | Apple Inc. | Techniques for marking product housings |

| CN101337434B (zh) * | 2008-06-23 | 2010-08-11 | 无锡吉兴汽车部件有限公司 | 一种汽车天窗遮阳板的生产方法 |

| US9752022B2 (en) | 2008-07-10 | 2017-09-05 | Avery Dennison Corporation | Composition, film and related methods |

| US20100031535A1 (en) * | 2008-08-05 | 2010-02-11 | Gregory Ross Leedy | Printed sole for a shoe and method of making |

| US20100078259A1 (en) * | 2008-09-30 | 2010-04-01 | Honeywell International Inc. | Flowbodies and methods of forming flowbodies |

| US9173336B2 (en) | 2009-05-19 | 2015-10-27 | Apple Inc. | Techniques for marking product housings |

| US8663806B2 (en) | 2009-08-25 | 2014-03-04 | Apple Inc. | Techniques for marking a substrate using a physical vapor deposition material |

| US9845546B2 (en) | 2009-10-16 | 2017-12-19 | Apple Inc. | Sub-surface marking of product housings |

| US8809733B2 (en) | 2009-10-16 | 2014-08-19 | Apple Inc. | Sub-surface marking of product housings |

| US8282757B2 (en) | 2009-11-10 | 2012-10-09 | Alliant Techsystems Inc. | Automated composite annular structure forming |

| US9662841B2 (en) | 2009-11-10 | 2017-05-30 | Orbital Atk, Inc. | Radially extending composite structures |

| JP2013521162A (ja) | 2010-03-04 | 2013-06-10 | エイブリィ デニソン コーポレーション | 非pvcフィルム及び非pvcフィルムラミネート |

| SE534868C2 (sv) | 2010-05-07 | 2012-01-24 | Mips Ab | Hjälm med glidningsfrämjare anordnad vid ett energiabsorberande lager |

| DK2388131T3 (en) | 2010-05-20 | 2016-12-19 | Siemens Ag | A method for forming a wind turbine blade using a release film and the film |

| US8724285B2 (en) | 2010-09-30 | 2014-05-13 | Apple Inc. | Cosmetic conductive laser etching |

| US9232837B2 (en) | 2011-02-10 | 2016-01-12 | Max Mirani Investments, Llc | Luggage with crushable, resilient portions and methods for manufacturing it |

| US20120242013A1 (en) * | 2011-03-25 | 2012-09-27 | Foamtech Polymer Co., Ltd. | Shaping Device of PU Three-dimensional Objects and Its Shaping Method Thereof |

| US20120248001A1 (en) * | 2011-03-29 | 2012-10-04 | Nashner Michael S | Marking of Fabric Carrying Case for Portable Electronic Device |

| MX346688B (es) | 2012-02-20 | 2017-03-29 | Avery Dennison Corp | Película multicapa para sistemas multifuncionales de inyección de tinta. |

| US9809018B2 (en) * | 2012-03-14 | 2017-11-07 | B/E Aerospace, Inc. | Composite structural element and method |

| RU2507071C1 (ru) * | 2012-06-18 | 2014-02-20 | Министерство промышленности и торговли Российской Федерации (Минпромторг России) | Способ получения трехслойного полимерного композиционного материала (тспкм) |

| US9314871B2 (en) | 2013-06-18 | 2016-04-19 | Apple Inc. | Method for laser engraved reflective surface structures |

| US9434197B2 (en) | 2013-06-18 | 2016-09-06 | Apple Inc. | Laser engraved reflective surface structures |

| MX2016007964A (es) | 2013-12-30 | 2016-09-09 | Avery Dennison Corp | Pelicula protectora de poliuretano. |

| US10189297B2 (en) * | 2014-04-28 | 2019-01-29 | Kaysi Darrah | Wall appliqué |

| CN104626597A (zh) * | 2015-01-29 | 2015-05-20 | 柳州市俊杰汽配制造有限公司 | 汽车内饰制造工艺 |

| WO2018057379A1 (en) | 2016-09-20 | 2018-03-29 | Aero Advanced Paint Technology, Inc. | Paint film appliques with reduced defects, articles, and methods |

| CN114953652A (zh) | 2017-12-15 | 2022-08-30 | 西部制药服务有限公司 | 光滑膜层压弹性体制品 |

| WO2020044078A1 (en) * | 2018-08-29 | 2020-03-05 | Vetex Nv | Marking element comprising a reinforcement fabric |

| US10999917B2 (en) | 2018-09-20 | 2021-05-04 | Apple Inc. | Sparse laser etch anodized surface for cosmetic grounding |

| CN110142907A (zh) * | 2019-05-17 | 2019-08-20 | 广州市勇源冰雪运动用品有限公司 | 一种曲棍球头盔摆件制作工艺 |

| US11820890B2 (en) | 2021-04-01 | 2023-11-21 | Stratasys Inc | Pulverulent thermoplastic polymer blends |

Family Cites Families (29)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3087201A (en) * | 1960-03-02 | 1963-04-30 | Us Rubber Co | Method of injection molding fabricreinforced articles |

| US3152949A (en) * | 1960-11-02 | 1964-10-13 | American Enka Corp | Reinforced plastic article with improved surface properties |

| NL6801826A (zh) * | 1968-02-09 | 1969-08-12 | ||

| DE1803790A1 (de) * | 1968-10-18 | 1970-05-27 | Bayer Ag | Fasergelege fuer die Armierung von Schaumstoffkoerpern und Verfahren zur Herstellung dieser Schaumstoffkoerper |

| DE2231411C3 (de) * | 1972-06-27 | 1980-02-21 | Bayer Ag, 5090 Leverkusen | Verbundmaterialien und Verfahren zu ihrer Herstellung |

| US4051100A (en) * | 1973-06-04 | 1977-09-27 | Caterpillar Tractor Co. | Fluoroelastomer-based composite material |

| US4015039A (en) * | 1973-07-02 | 1977-03-29 | Allied Chemical Corporation | Fibrous dispersion aid for thermoplastics |

| US4023835A (en) * | 1975-05-02 | 1977-05-17 | Ewing Engineering Company | Conformable thin-wall shear-resistant coupling and pipe assembly |

| DE2967578D1 (en) * | 1978-03-23 | 1986-03-27 | Ici Plc | Process for the manufacture of a glass fibre-reinforced plastics article and a glass fibre paste or slurry for use in the process |

| DE2963531D1 (en) * | 1978-07-01 | 1982-10-07 | Bayer Ag | Process for the manufacture of glass fibre reinforced plastic layers and their use in sandwich constructions |

| DE2921162A1 (de) * | 1979-05-25 | 1980-12-04 | Bayer Ag | Hitzehaertbare formmassen und verfahren zur herstellung von formkoerpern |

| US4353955A (en) * | 1981-11-12 | 1982-10-12 | Basf Wyandotte Corporation | Polyurethane foam - fabric composite |

| DE3242089A1 (de) * | 1982-11-13 | 1984-05-17 | Basf Ag | Verfahren zur kontinuierlichen herstellung von halbzeug aus faserverstaerkten, thermoplastischen polyurethanen |

| DE3343125A1 (de) * | 1983-11-29 | 1985-06-05 | Basf Ag, 6700 Ludwigshafen | Verstaerkte, kompakte oder zellige polyurethan-formteile, verfahren zu deren herstellung aus hitzehaertbaren einkomponenten-polyurethan-formulierungen und deren verwendung |

| US4651445A (en) * | 1985-09-03 | 1987-03-24 | Hannibal Alan J | Composite sole for a shoe |

| US4695509A (en) * | 1985-12-23 | 1987-09-22 | Allied Corporation | Polyamide fiber reinforcement in thermoset polyurethane composites |

| US4738999A (en) * | 1986-03-31 | 1988-04-19 | Lord Corporation | Fiber reinforced composites |

| US4766014A (en) * | 1986-12-11 | 1988-08-23 | Lorica S.P.A. | Process for producing artificial leather similar to real leather by chemically processing synthetic sheet material |

| US4894281A (en) * | 1987-05-29 | 1990-01-16 | Mitsui Petrochemical Industries, Ltd. | Fiber-reinforced polymer molded body |

| US4916000A (en) * | 1987-07-13 | 1990-04-10 | Allied-Signal Inc. | Ballistic-resistant composite article |

| US4892780A (en) * | 1987-07-16 | 1990-01-09 | Cochran William H | Fiber reinforcement for resin composites |

| US4883700A (en) * | 1987-08-03 | 1989-11-28 | Allied-Signal Inc. | Composite and article using short length fibers at oblique angles |

| US5149739A (en) * | 1988-08-01 | 1992-09-22 | The Bfgoodrich Company | Fiber-reinforced thermoplastic elastomer polyurethane compositions with either modified and/or unmodified polyolefins |

| US4936085A (en) * | 1989-06-13 | 1990-06-26 | Kolmes Nathaniel H | Yarn and glove |

| WO1992000191A1 (en) * | 1990-06-22 | 1992-01-09 | Cochran William H | Composites |

| US5503879A (en) * | 1990-06-22 | 1996-04-02 | Randemo Inc. | Method of making a flexible composites |

| US5234757A (en) * | 1991-04-30 | 1993-08-10 | The Dexter Corporation | Expandable films and molded products therefrom |

| DE69410375T2 (de) * | 1993-09-17 | 1998-09-17 | Allied Signal Inc | Hochfester Verbundwerkstoff |

| US5874133A (en) * | 1995-06-07 | 1999-02-23 | Randemo, Inc. | Process for making a polyurethane composite |

-

1995

- 1995-06-07 US US08/476,112 patent/US5874133A/en not_active Expired - Fee Related

-

1996

- 1996-05-31 IN IN1002CA1996 patent/IN190702B/en unknown

- 1996-06-04 EP EP96917902A patent/EP0837770B1/en not_active Expired - Lifetime

- 1996-06-04 DE DE69625485T patent/DE69625485T2/de not_active Expired - Fee Related

- 1996-06-04 CA CA002223431A patent/CA2223431C/en not_active Expired - Fee Related

- 1996-06-04 WO PCT/US1996/008285 patent/WO1996040503A1/en active IP Right Grant

- 1996-06-04 CN CNB961955805A patent/CN1155467C/zh not_active Expired - Fee Related

- 1996-06-04 JP JP50093897A patent/JP3955322B2/ja not_active Expired - Fee Related

- 1996-06-04 AT AT96917902T patent/ATE229879T1/de not_active IP Right Cessation

- 1996-06-06 TW TW085106795A patent/TW342361B/zh active

-

1998

- 1998-11-06 US US09/187,418 patent/US6156403A/en not_active Expired - Fee Related

-

2000

- 2000-09-12 US US09/659,339 patent/US6540867B1/en not_active Expired - Fee Related

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN107385629A (zh) * | 2016-05-17 | 2017-11-24 | 韩国卡奔株式会社 | 具有改善的疲劳强度的柔性次级气体隔板及其制造方法 |

| CN107385629B (zh) * | 2016-05-17 | 2019-05-31 | 韩国卡奔株式会社 | 具有改善的疲劳强度的柔性次级气体隔板及其制造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP0837770A1 (en) | 1998-04-29 |

| CA2223431A1 (en) | 1996-12-19 |

| DE69625485T2 (de) | 2003-10-09 |

| JPH11506707A (ja) | 1999-06-15 |

| EP0837770A4 (en) | 2000-04-05 |

| IN190702B (zh) | 2003-08-16 |

| US6156403A (en) | 2000-12-05 |

| JP3955322B2 (ja) | 2007-08-08 |

| CA2223431C (en) | 2007-02-13 |

| ATE229879T1 (de) | 2003-01-15 |

| CN1190930A (zh) | 1998-08-19 |

| TW342361B (en) | 1998-10-11 |

| DE69625485D1 (de) | 2003-01-30 |

| US6540867B1 (en) | 2003-04-01 |

| EP0837770B1 (en) | 2002-12-18 |

| WO1996040503A1 (en) | 1996-12-19 |

| US5874133A (en) | 1999-02-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1155467C (zh) | 复合材料、由其制备的制品及制备方法 | |

| KR101005507B1 (ko) | 피혁상 시트 | |

| JP3767826B2 (ja) | 皮革様シートの製造方法 | |

| TW202231209A (zh) | 具有結構性色彩的物件 | |

| CN1136784A (zh) | 体育用球及其制造方法 | |

| JP2007523232A5 (zh) | ||

| CN109337029A (zh) | 一种高耐磨tpu/硅胶复合材料及其制备方法 | |

| CN113646369A (zh) | 可再循环的结构着色的结构和物品以及使结构和物品再循环的方法 | |

| KR20060127979A (ko) | 피혁형 시트의 제조 방법 | |

| CN105209245B (zh) | 用于制作具有用包封层处理过的张力构件的皮带的方法以及如此生产的皮带 | |

| CN1228821A (zh) | 水-汽-透过的复合材料 | |

| EP2287395A1 (en) | Leather-like sheet having excellent grip performance and artificial leather product using the same | |

| CN1358810A (zh) | 着色的辐射固化抗磨层 | |

| US11498312B2 (en) | Thermally-bondable multi-layered composite film for manufacturing outdoor clothing, and method for manufacturing same | |

| TWI510357B (zh) | 用於鞋加強件之複合層狀結構及其製造方法 | |

| JP3516845B2 (ja) | 表面物性に優れた立体感のある合成皮革 | |

| KR102130552B1 (ko) | 재사용 가능한 지지 원단을 구비한 결합기재를 이용하여 인조피혁을 제조하는 방법 | |

| JPS6057844B2 (ja) | 人工皮革靴の製造方法 | |

| CN2838339Y (zh) | 防水耐磨鞋面 | |

| CN1038921C (zh) | 鞋用加硫橡胶制品的制造方法 | |

| JP2009024271A (ja) | 皮革様立毛シート | |

| CN118756398A (zh) | 夜光纱线制备方法、智能终端保护壳及其制备方法 | |

| JP3371054B2 (ja) | 合成皮革の製造方法 | |

| JPH0428328A (ja) | バーコード付レンタル用マット | |

| JPH0151255B2 (zh) |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: GR Ref document number: 1047367 Country of ref document: HK |

|

| REG | Reference to a national code |

Ref country code: HK Ref legal event code: WD Ref document number: 1015319 Country of ref document: HK |

|

| C19 | Lapse of patent right due to non-payment of the annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |