CN107847862B - Nh3过量剂量耐受的scr催化剂 - Google Patents

Nh3过量剂量耐受的scr催化剂 Download PDFInfo

- Publication number

- CN107847862B CN107847862B CN201680042218.0A CN201680042218A CN107847862B CN 107847862 B CN107847862 B CN 107847862B CN 201680042218 A CN201680042218 A CN 201680042218A CN 107847862 B CN107847862 B CN 107847862B

- Authority

- CN

- China

- Prior art keywords

- scr catalyst

- catalyst

- scr

- catalytic article

- substrate

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000003054 catalyst Substances 0.000 title claims abstract description 208

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 claims abstract description 119

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 claims abstract description 104

- 239000000203 mixture Substances 0.000 claims abstract description 70

- 229910021529 ammonia Inorganic materials 0.000 claims abstract description 56

- 229910052697 platinum Inorganic materials 0.000 claims abstract description 47

- 230000003197 catalytic effect Effects 0.000 claims abstract description 39

- 238000000034 method Methods 0.000 claims abstract description 21

- 239000000758 substrate Substances 0.000 claims description 79

- 239000002808 molecular sieve Substances 0.000 claims description 49

- URGAHOPLAPQHLN-UHFFFAOYSA-N sodium aluminosilicate Chemical compound [Na+].[Al+3].[O-][Si]([O-])=O.[O-][Si]([O-])=O URGAHOPLAPQHLN-UHFFFAOYSA-N 0.000 claims description 49

- 239000011248 coating agent Substances 0.000 claims description 43

- 238000000576 coating method Methods 0.000 claims description 43

- 229910000069 nitrogen hydride Inorganic materials 0.000 claims description 35

- 229910052751 metal Inorganic materials 0.000 claims description 27

- 239000002184 metal Substances 0.000 claims description 27

- HNPSIPDUKPIQMN-UHFFFAOYSA-N dioxosilane;oxo(oxoalumanyloxy)alumane Chemical compound O=[Si]=O.O=[Al]O[Al]=O HNPSIPDUKPIQMN-UHFFFAOYSA-N 0.000 claims description 26

- 239000010457 zeolite Substances 0.000 claims description 24

- 229910021536 Zeolite Inorganic materials 0.000 claims description 23

- 239000010949 copper Substances 0.000 claims description 19

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 claims description 14

- 239000010953 base metal Substances 0.000 claims description 13

- 229910052802 copper Inorganic materials 0.000 claims description 13

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims description 12

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 claims description 11

- XEEYBQQBJWHFJM-UHFFFAOYSA-N iron Substances [Fe] XEEYBQQBJWHFJM-UHFFFAOYSA-N 0.000 claims description 9

- NUJOXMJBOLGQSY-UHFFFAOYSA-N manganese dioxide Inorganic materials O=[Mn]=O NUJOXMJBOLGQSY-UHFFFAOYSA-N 0.000 claims description 8

- 239000000377 silicon dioxide Substances 0.000 claims description 8

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 claims description 6

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 claims description 6

- 239000011572 manganese Substances 0.000 claims description 6

- 229910004625 Ce—Zr Inorganic materials 0.000 claims description 5

- 229910052878 cordierite Inorganic materials 0.000 claims description 5

- JSKIRARMQDRGJZ-UHFFFAOYSA-N dimagnesium dioxido-bis[(1-oxido-3-oxo-2,4,6,8,9-pentaoxa-1,3-disila-5,7-dialuminabicyclo[3.3.1]nonan-7-yl)oxy]silane Chemical group [Mg++].[Mg++].[O-][Si]([O-])(O[Al]1O[Al]2O[Si](=O)O[Si]([O-])(O1)O2)O[Al]1O[Al]2O[Si](=O)O[Si]([O-])(O1)O2 JSKIRARMQDRGJZ-UHFFFAOYSA-N 0.000 claims description 5

- 239000010931 gold Substances 0.000 claims description 5

- 239000011651 chromium Substances 0.000 claims description 4

- 229910052742 iron Inorganic materials 0.000 claims description 4

- 239000010948 rhodium Substances 0.000 claims description 4

- LEONUFNNVUYDNQ-UHFFFAOYSA-N vanadium atom Chemical compound [V] LEONUFNNVUYDNQ-UHFFFAOYSA-N 0.000 claims description 4

- 229910052684 Cerium Inorganic materials 0.000 claims description 3

- PWHULOQIROXLJO-UHFFFAOYSA-N Manganese Chemical compound [Mn] PWHULOQIROXLJO-UHFFFAOYSA-N 0.000 claims description 3

- ZOKXTWBITQBERF-UHFFFAOYSA-N Molybdenum Chemical compound [Mo] ZOKXTWBITQBERF-UHFFFAOYSA-N 0.000 claims description 3

- GWXLDORMOJMVQZ-UHFFFAOYSA-N cerium Chemical compound [Ce] GWXLDORMOJMVQZ-UHFFFAOYSA-N 0.000 claims description 3

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 claims description 3

- 229910052737 gold Inorganic materials 0.000 claims description 3

- 229910052748 manganese Inorganic materials 0.000 claims description 3

- 229910052750 molybdenum Inorganic materials 0.000 claims description 3

- 239000011733 molybdenum Substances 0.000 claims description 3

- GHOKWGTUZJEAQD-ZETCQYMHSA-N (D)-(+)-Pantothenic acid Chemical compound OCC(C)(C)[C@@H](O)C(=O)NCCC(O)=O GHOKWGTUZJEAQD-ZETCQYMHSA-N 0.000 claims description 2

- VYZAMTAEIAYCRO-UHFFFAOYSA-N Chromium Chemical compound [Cr] VYZAMTAEIAYCRO-UHFFFAOYSA-N 0.000 claims description 2

- KJTLSVCANCCWHF-UHFFFAOYSA-N Ruthenium Chemical compound [Ru] KJTLSVCANCCWHF-UHFFFAOYSA-N 0.000 claims description 2

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 claims description 2

- 229910052804 chromium Inorganic materials 0.000 claims description 2

- 229910017052 cobalt Inorganic materials 0.000 claims description 2

- 239000010941 cobalt Substances 0.000 claims description 2

- GUTLYIVDDKVIGB-UHFFFAOYSA-N cobalt atom Chemical compound [Co] GUTLYIVDDKVIGB-UHFFFAOYSA-N 0.000 claims description 2

- 229910052759 nickel Inorganic materials 0.000 claims description 2

- 229910052763 palladium Inorganic materials 0.000 claims description 2

- 229910052703 rhodium Inorganic materials 0.000 claims description 2

- MHOVAHRLVXNVSD-UHFFFAOYSA-N rhodium atom Chemical compound [Rh] MHOVAHRLVXNVSD-UHFFFAOYSA-N 0.000 claims description 2

- 229910052707 ruthenium Inorganic materials 0.000 claims description 2

- 229910052709 silver Inorganic materials 0.000 claims description 2

- 239000004332 silver Substances 0.000 claims description 2

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 claims description 2

- 229910052721 tungsten Inorganic materials 0.000 claims description 2

- 239000010937 tungsten Substances 0.000 claims description 2

- 238000010531 catalytic reduction reaction Methods 0.000 abstract description 3

- MWUXSHHQAYIFBG-UHFFFAOYSA-N nitrogen oxide Inorganic materials O=[N] MWUXSHHQAYIFBG-UHFFFAOYSA-N 0.000 description 114

- 239000010410 layer Substances 0.000 description 67

- 238000006243 chemical reaction Methods 0.000 description 35

- 239000007789 gas Substances 0.000 description 30

- 238000011068 loading method Methods 0.000 description 16

- 239000000463 material Substances 0.000 description 14

- 239000011148 porous material Substances 0.000 description 13

- 239000000919 ceramic Substances 0.000 description 12

- 230000015572 biosynthetic process Effects 0.000 description 9

- 238000001354 calcination Methods 0.000 description 9

- 238000006722 reduction reaction Methods 0.000 description 7

- 238000011144 upstream manufacturing Methods 0.000 description 7

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 6

- 229910002089 NOx Inorganic materials 0.000 description 5

- MCMNRKCIXSYSNV-UHFFFAOYSA-N Zirconium dioxide Chemical compound O=[Zr]=O MCMNRKCIXSYSNV-UHFFFAOYSA-N 0.000 description 5

- 230000032683 aging Effects 0.000 description 5

- 229910000323 aluminium silicate Inorganic materials 0.000 description 5

- 229910044991 metal oxide Inorganic materials 0.000 description 5

- 150000004706 metal oxides Chemical class 0.000 description 5

- 238000007254 oxidation reaction Methods 0.000 description 5

- GWEVSGVZZGPLCZ-UHFFFAOYSA-N Titan oxide Chemical compound O=[Ti]=O GWEVSGVZZGPLCZ-UHFFFAOYSA-N 0.000 description 4

- QPLDLSVMHZLSFG-UHFFFAOYSA-N Copper oxide Chemical compound [Cu]=O QPLDLSVMHZLSFG-UHFFFAOYSA-N 0.000 description 3

- JCXJVPUVTGWSNB-UHFFFAOYSA-N Nitrogen dioxide Chemical compound O=[N]=O JCXJVPUVTGWSNB-UHFFFAOYSA-N 0.000 description 3

- 150000001875 compounds Chemical class 0.000 description 3

- 239000012530 fluid Substances 0.000 description 3

- 238000009472 formulation Methods 0.000 description 3

- 229910052757 nitrogen Inorganic materials 0.000 description 3

- 230000003647 oxidation Effects 0.000 description 3

- 239000002243 precursor Substances 0.000 description 3

- 150000003839 salts Chemical class 0.000 description 3

- 239000002904 solvent Substances 0.000 description 3

- 239000005751 Copper oxide Substances 0.000 description 2

- CPLXHLVBOLITMK-UHFFFAOYSA-N Magnesium oxide Chemical compound [Mg]=O CPLXHLVBOLITMK-UHFFFAOYSA-N 0.000 description 2

- 239000007864 aqueous solution Substances 0.000 description 2

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 2

- 239000011575 calcium Substances 0.000 description 2

- 229910000422 cerium(IV) oxide Inorganic materials 0.000 description 2

- 238000002485 combustion reaction Methods 0.000 description 2

- 230000000052 comparative effect Effects 0.000 description 2

- 229910000431 copper oxide Inorganic materials 0.000 description 2

- 230000007613 environmental effect Effects 0.000 description 2

- 239000011777 magnesium Substances 0.000 description 2

- 239000010955 niobium Substances 0.000 description 2

- QJGQUHMNIGDVPM-UHFFFAOYSA-N nitrogen group Chemical group [N] QJGQUHMNIGDVPM-UHFFFAOYSA-N 0.000 description 2

- 231100001143 noxa Toxicity 0.000 description 2

- 239000001301 oxygen Substances 0.000 description 2

- 229910052760 oxygen Inorganic materials 0.000 description 2

- -1 silicalite Inorganic materials 0.000 description 2

- 229910010271 silicon carbide Inorganic materials 0.000 description 2

- HBMJWWWQQXIZIP-UHFFFAOYSA-N silicon carbide Chemical compound [Si+]#[C-] HBMJWWWQQXIZIP-UHFFFAOYSA-N 0.000 description 2

- 239000000243 solution Substances 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- 239000000725 suspension Substances 0.000 description 2

- XOLBLPGZBRYERU-UHFFFAOYSA-N tin dioxide Chemical compound O=[Sn]=O XOLBLPGZBRYERU-UHFFFAOYSA-N 0.000 description 2

- 229910052720 vanadium Inorganic materials 0.000 description 2

- 229910052845 zircon Inorganic materials 0.000 description 2

- GFQYVLUOOAAOGM-UHFFFAOYSA-N zirconium(iv) silicate Chemical compound [Zr+4].[O-][Si]([O-])([O-])[O-] GFQYVLUOOAAOGM-UHFFFAOYSA-N 0.000 description 2

- MGWGWNFMUOTEHG-UHFFFAOYSA-N 4-(3,5-dimethylphenyl)-1,3-thiazol-2-amine Chemical compound CC1=CC(C)=CC(C=2N=C(N)SC=2)=C1 MGWGWNFMUOTEHG-UHFFFAOYSA-N 0.000 description 1

- OYPRJOBELJOOCE-UHFFFAOYSA-N Calcium Chemical compound [Ca] OYPRJOBELJOOCE-UHFFFAOYSA-N 0.000 description 1

- JJLJMEJHUUYSSY-UHFFFAOYSA-L Copper hydroxide Chemical compound [OH-].[OH-].[Cu+2] JJLJMEJHUUYSSY-UHFFFAOYSA-L 0.000 description 1

- 239000005750 Copper hydroxide Substances 0.000 description 1

- JPVYNHNXODAKFH-UHFFFAOYSA-N Cu2+ Chemical compound [Cu+2] JPVYNHNXODAKFH-UHFFFAOYSA-N 0.000 description 1

- FYYHWMGAXLPEAU-UHFFFAOYSA-N Magnesium Chemical compound [Mg] FYYHWMGAXLPEAU-UHFFFAOYSA-N 0.000 description 1

- 229910002651 NO3 Inorganic materials 0.000 description 1

- 229910052779 Neodymium Inorganic materials 0.000 description 1

- NHNBFGGVMKEFGY-UHFFFAOYSA-N Nitrate Chemical compound [O-][N+]([O-])=O NHNBFGGVMKEFGY-UHFFFAOYSA-N 0.000 description 1

- BPQQTUXANYXVAA-UHFFFAOYSA-N Orthosilicate Chemical compound [O-][Si]([O-])([O-])[O-] BPQQTUXANYXVAA-UHFFFAOYSA-N 0.000 description 1

- 229910052777 Praseodymium Inorganic materials 0.000 description 1

- 229910052581 Si3N4 Inorganic materials 0.000 description 1

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 1

- 159000000021 acetate salts Chemical class 0.000 description 1

- 238000003916 acid precipitation Methods 0.000 description 1

- 239000003463 adsorbent Substances 0.000 description 1

- HEHRHMRHPUNLIR-UHFFFAOYSA-N aluminum;hydroxy-[hydroxy(oxo)silyl]oxy-oxosilane;lithium Chemical compound [Li].[Al].O[Si](=O)O[Si](O)=O.O[Si](=O)O[Si](O)=O HEHRHMRHPUNLIR-UHFFFAOYSA-N 0.000 description 1

- CNLWCVNCHLKFHK-UHFFFAOYSA-N aluminum;lithium;dioxido(oxo)silane Chemical compound [Li+].[Al+3].[O-][Si]([O-])=O.[O-][Si]([O-])=O CNLWCVNCHLKFHK-UHFFFAOYSA-N 0.000 description 1

- BESJRHHIPGWPTC-UHFFFAOYSA-N azane;copper Chemical class N.[Cu] BESJRHHIPGWPTC-UHFFFAOYSA-N 0.000 description 1

- 229910052788 barium Inorganic materials 0.000 description 1

- DSAJWYNOEDNPEQ-UHFFFAOYSA-N barium atom Chemical compound [Ba] DSAJWYNOEDNPEQ-UHFFFAOYSA-N 0.000 description 1

- 239000011230 binding agent Substances 0.000 description 1

- 229910052791 calcium Inorganic materials 0.000 description 1

- UNYSKUBLZGJSLV-UHFFFAOYSA-L calcium;1,3,5,2,4,6$l^{2}-trioxadisilaluminane 2,4-dioxide;dihydroxide;hexahydrate Chemical compound O.O.O.O.O.O.[OH-].[OH-].[Ca+2].O=[Si]1O[Al]O[Si](=O)O1.O=[Si]1O[Al]O[Si](=O)O1 UNYSKUBLZGJSLV-UHFFFAOYSA-L 0.000 description 1

- 239000004202 carbamide Substances 0.000 description 1

- 150000001768 cations Chemical class 0.000 description 1

- CETPSERCERDGAM-UHFFFAOYSA-N ceric oxide Chemical compound O=[Ce]=O CETPSERCERDGAM-UHFFFAOYSA-N 0.000 description 1

- 229910052676 chabazite Inorganic materials 0.000 description 1

- 238000012993 chemical processing Methods 0.000 description 1

- 239000003638 chemical reducing agent Substances 0.000 description 1

- 239000003245 coal Substances 0.000 description 1

- 239000011247 coating layer Substances 0.000 description 1

- 229910052681 coesite Inorganic materials 0.000 description 1

- 239000000571 coke Substances 0.000 description 1

- 239000002131 composite material Substances 0.000 description 1

- 229910001956 copper hydroxide Inorganic materials 0.000 description 1

- 229910000365 copper sulfate Inorganic materials 0.000 description 1

- XTVVROIMIGLXTD-UHFFFAOYSA-N copper(II) nitrate Chemical compound [Cu+2].[O-][N+]([O-])=O.[O-][N+]([O-])=O XTVVROIMIGLXTD-UHFFFAOYSA-N 0.000 description 1

- ARUVKPQLZAKDPS-UHFFFAOYSA-L copper(II) sulfate Chemical compound [Cu+2].[O-][S+2]([O-])([O-])[O-] ARUVKPQLZAKDPS-UHFFFAOYSA-L 0.000 description 1

- OPQARKPSCNTWTJ-UHFFFAOYSA-L copper(ii) acetate Chemical compound [Cu+2].CC([O-])=O.CC([O-])=O OPQARKPSCNTWTJ-UHFFFAOYSA-L 0.000 description 1

- ZKXWKVVCCTZOLD-UHFFFAOYSA-N copper;4-hydroxypent-3-en-2-one Chemical compound [Cu].CC(O)=CC(C)=O.CC(O)=CC(C)=O ZKXWKVVCCTZOLD-UHFFFAOYSA-N 0.000 description 1

- 229910052593 corundum Inorganic materials 0.000 description 1

- 229910052906 cristobalite Inorganic materials 0.000 description 1

- 230000007423 decrease Effects 0.000 description 1

- 230000002939 deleterious effect Effects 0.000 description 1

- KZHJGOXRZJKJNY-UHFFFAOYSA-N dioxosilane;oxo(oxoalumanyloxy)alumane Chemical compound O=[Si]=O.O=[Si]=O.O=[Al]O[Al]=O.O=[Al]O[Al]=O.O=[Al]O[Al]=O KZHJGOXRZJKJNY-UHFFFAOYSA-N 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 230000000694 effects Effects 0.000 description 1

- 239000012013 faujasite Substances 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 230000005802 health problem Effects 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000002430 hydrocarbons Chemical class 0.000 description 1

- 229910010272 inorganic material Inorganic materials 0.000 description 1

- 239000011147 inorganic material Substances 0.000 description 1

- 238000005342 ion exchange Methods 0.000 description 1

- JEIPFZHSYJVQDO-UHFFFAOYSA-N iron(III) oxide Inorganic materials O=[Fe]O[Fe]=O JEIPFZHSYJVQDO-UHFFFAOYSA-N 0.000 description 1

- 229910052746 lanthanum Inorganic materials 0.000 description 1

- FZLIPJUXYLNCLC-UHFFFAOYSA-N lanthanum atom Chemical compound [La] FZLIPJUXYLNCLC-UHFFFAOYSA-N 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000007791 liquid phase Substances 0.000 description 1

- 229910052749 magnesium Inorganic materials 0.000 description 1

- HCWCAKKEBCNQJP-UHFFFAOYSA-N magnesium orthosilicate Chemical compound [Mg+2].[Mg+2].[O-][Si]([O-])([O-])[O-] HCWCAKKEBCNQJP-UHFFFAOYSA-N 0.000 description 1

- 239000000395 magnesium oxide Substances 0.000 description 1

- 239000000391 magnesium silicate Substances 0.000 description 1

- 229910052919 magnesium silicate Inorganic materials 0.000 description 1

- 235000019792 magnesium silicate Nutrition 0.000 description 1

- GEYXPJBPASPPLI-UHFFFAOYSA-N manganese(III) oxide Inorganic materials O=[Mn]O[Mn]=O GEYXPJBPASPPLI-UHFFFAOYSA-N 0.000 description 1

- QSHDDOUJBYECFT-UHFFFAOYSA-N mercury Chemical compound [Hg] QSHDDOUJBYECFT-UHFFFAOYSA-N 0.000 description 1

- 229910052753 mercury Inorganic materials 0.000 description 1

- 229910021645 metal ion Inorganic materials 0.000 description 1

- 230000000116 mitigating effect Effects 0.000 description 1

- 229910052680 mordenite Inorganic materials 0.000 description 1

- 229910052863 mullite Inorganic materials 0.000 description 1

- QEFYFXOXNSNQGX-UHFFFAOYSA-N neodymium atom Chemical compound [Nd] QEFYFXOXNSNQGX-UHFFFAOYSA-N 0.000 description 1

- 229910052758 niobium Inorganic materials 0.000 description 1

- GUCVJGMIXFAOAE-UHFFFAOYSA-N niobium atom Chemical compound [Nb] GUCVJGMIXFAOAE-UHFFFAOYSA-N 0.000 description 1

- 230000000737 periodic effect Effects 0.000 description 1

- 229910052670 petalite Inorganic materials 0.000 description 1

- 231100000614 poison Toxicity 0.000 description 1

- 238000002459 porosimetry Methods 0.000 description 1

- PUDIUYLPXJFUGB-UHFFFAOYSA-N praseodymium atom Chemical compound [Pr] PUDIUYLPXJFUGB-UHFFFAOYSA-N 0.000 description 1

- 239000011819 refractory material Substances 0.000 description 1

- 239000003870 refractory metal Substances 0.000 description 1

- VSZWPYCFIRKVQL-UHFFFAOYSA-N selanylidenegallium;selenium Chemical compound [Se].[Se]=[Ga].[Se]=[Ga] VSZWPYCFIRKVQL-UHFFFAOYSA-N 0.000 description 1

- 238000007086 side reaction Methods 0.000 description 1

- HQVNEWCFYHHQES-UHFFFAOYSA-N silicon nitride Chemical compound N12[Si]34N5[Si]62N3[Si]51N64 HQVNEWCFYHHQES-UHFFFAOYSA-N 0.000 description 1

- 229910052851 sillimanite Inorganic materials 0.000 description 1

- 229910052642 spodumene Inorganic materials 0.000 description 1

- 229910052682 stishovite Inorganic materials 0.000 description 1

- 229910052712 strontium Inorganic materials 0.000 description 1

- CIOAGBVUUVVLOB-UHFFFAOYSA-N strontium atom Chemical compound [Sr] CIOAGBVUUVVLOB-UHFFFAOYSA-N 0.000 description 1

- 229910052715 tantalum Inorganic materials 0.000 description 1

- GUVRBAGPIYLISA-UHFFFAOYSA-N tantalum atom Chemical compound [Ta] GUVRBAGPIYLISA-UHFFFAOYSA-N 0.000 description 1

- JBQYATWDVHIOAR-UHFFFAOYSA-N tellanylidenegermanium Chemical compound [Te]=[Ge] JBQYATWDVHIOAR-UHFFFAOYSA-N 0.000 description 1

- 239000003440 toxic substance Substances 0.000 description 1

- 229910052905 tridymite Inorganic materials 0.000 description 1

- 239000002699 waste material Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

- 229910001845 yogo sapphire Inorganic materials 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/70—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of types characterised by their specific structure not provided for in groups B01J29/08 - B01J29/65

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/70—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of the iron group metals or copper

- B01J23/89—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of the iron group metals or copper combined with noble metals

- B01J23/8926—Copper and noble metals

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/46—Removing components of defined structure

- B01D53/54—Nitrogen compounds

- B01D53/58—Ammonia

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/74—General processes for purification of waste gases; Apparatus or devices specially adapted therefor

- B01D53/86—Catalytic processes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/92—Chemical or biological purification of waste gases of engine exhaust gases

- B01D53/94—Chemical or biological purification of waste gases of engine exhaust gases by catalytic processes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/92—Chemical or biological purification of waste gases of engine exhaust gases

- B01D53/94—Chemical or biological purification of waste gases of engine exhaust gases by catalytic processes

- B01D53/9404—Removing only nitrogen compounds

- B01D53/9409—Nitrogen oxides

- B01D53/9413—Processes characterised by a specific catalyst

- B01D53/9418—Processes characterised by a specific catalyst for removing nitrogen oxides by selective catalytic reduction [SCR] using a reducing agent in a lean exhaust gas

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/34—Chemical or biological purification of waste gases

- B01D53/92—Chemical or biological purification of waste gases of engine exhaust gases

- B01D53/94—Chemical or biological purification of waste gases of engine exhaust gases by catalytic processes

- B01D53/9404—Removing only nitrogen compounds

- B01D53/9409—Nitrogen oxides

- B01D53/9431—Processes characterised by a specific device

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J21/00—Catalysts comprising the elements, oxides, or hydroxides of magnesium, boron, aluminium, carbon, silicon, titanium, zirconium, or hafnium

- B01J21/02—Boron or aluminium; Oxides or hydroxides thereof

- B01J21/04—Alumina

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/38—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of noble metals

- B01J23/40—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of noble metals of the platinum group metals

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/38—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of noble metals

- B01J23/40—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of noble metals of the platinum group metals

- B01J23/42—Platinum

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/38—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of noble metals

- B01J23/54—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of noble metals combined with metals, oxides or hydroxides provided for in groups B01J23/02 - B01J23/36

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/70—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of the iron group metals or copper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/70—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of the iron group metals or copper

- B01J23/89—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of the iron group metals or copper combined with noble metals

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J23/00—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00

- B01J23/70—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of the iron group metals or copper

- B01J23/89—Catalysts comprising metals or metal oxides or hydroxides, not provided for in group B01J21/00 of the iron group metals or copper combined with noble metals

- B01J23/8906—Iron and noble metals

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/064—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof containing iron group metals, noble metals or copper

- B01J29/068—Noble metals

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/064—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof containing iron group metals, noble metals or copper

- B01J29/072—Iron group metals or copper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/076—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof containing arsenic, antimony, bismuth, vanadium, niobium, tantalum, polonium, chromium, molybdenum, tungsten, manganese, technetium or rhenium

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/40—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of the pentasil type, e.g. types ZSM-5, ZSM-8 or ZSM-11, as exemplified by patent documents US3702886, GB1334243 and US3709979, respectively

- B01J29/42—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of the pentasil type, e.g. types ZSM-5, ZSM-8 or ZSM-11, as exemplified by patent documents US3702886, GB1334243 and US3709979, respectively containing iron group metals, noble metals or copper

- B01J29/44—Noble metals

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/70—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of types characterised by their specific structure not provided for in groups B01J29/08 - B01J29/65

- B01J29/72—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of types characterised by their specific structure not provided for in groups B01J29/08 - B01J29/65 containing iron group metals, noble metals or copper

- B01J29/76—Iron group metals or copper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/70—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of types characterised by their specific structure not provided for in groups B01J29/08 - B01J29/65

- B01J29/72—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof of types characterised by their specific structure not provided for in groups B01J29/08 - B01J29/65 containing iron group metals, noble metals or copper

- B01J29/76—Iron group metals or copper

- B01J29/763—CHA-type, e.g. Chabazite, LZ-218

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J29/00—Catalysts comprising molecular sieves

- B01J29/04—Catalysts comprising molecular sieves having base-exchange properties, e.g. crystalline zeolites

- B01J29/06—Crystalline aluminosilicate zeolites; Isomorphous compounds thereof

- B01J29/80—Mixtures of different zeolites

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J35/00—Catalysts, in general, characterised by their form or physical properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J35/00—Catalysts, in general, characterised by their form or physical properties

- B01J35/19—Catalysts containing parts with different compositions

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J35/00—Catalysts, in general, characterised by their form or physical properties

- B01J35/50—Catalysts, in general, characterised by their form or physical properties characterised by their shape or configuration

- B01J35/56—Foraminous structures having flow-through passages or channels, e.g. grids or three-dimensional monoliths

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/02—Impregnation, coating or precipitation

- B01J37/024—Multiple impregnation or coating

- B01J37/0244—Coatings comprising several layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J37/00—Processes, in general, for preparing catalysts; Processes, in general, for activation of catalysts

- B01J37/02—Impregnation, coating or precipitation

- B01J37/024—Multiple impregnation or coating

- B01J37/0246—Coatings comprising a zeolite

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/18—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by methods of operation; Control

- F01N3/20—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by methods of operation; Control specially adapted for catalytic conversion ; Methods of operation or control of catalytic converters

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/18—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by methods of operation; Control

- F01N3/20—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by methods of operation; Control specially adapted for catalytic conversion ; Methods of operation or control of catalytic converters

- F01N3/2066—Selective catalytic reduction [SCR]

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/24—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by constructional aspects of converting apparatus

- F01N3/28—Construction of catalytic reactors

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N3/00—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust

- F01N3/08—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous

- F01N3/10—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust

- F01N3/24—Exhaust or silencing apparatus having means for purifying, rendering innocuous, or otherwise treating exhaust for rendering innocuous by thermal or catalytic conversion of noxious components of exhaust characterised by constructional aspects of converting apparatus

- F01N3/28—Construction of catalytic reactors

- F01N3/2803—Construction of catalytic reactors characterised by structure, by material or by manufacturing of catalyst support

- F01N3/2825—Ceramics

- F01N3/2828—Ceramic multi-channel monoliths, e.g. honeycombs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2251/00—Reactants

- B01D2251/20—Reductants

- B01D2251/206—Ammonium compounds

- B01D2251/2062—Ammonia

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/10—Noble metals or compounds thereof

- B01D2255/102—Platinum group metals

- B01D2255/1021—Platinum

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/20—Metals or compounds thereof

- B01D2255/207—Transition metals

- B01D2255/20738—Iron

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/20—Metals or compounds thereof

- B01D2255/207—Transition metals

- B01D2255/20761—Copper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/20—Metals or compounds thereof

- B01D2255/209—Other metals

- B01D2255/2092—Aluminium

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/50—Zeolites

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/90—Physical characteristics of catalysts

- B01D2255/902—Multilayered catalyst

- B01D2255/9022—Two layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2255/00—Catalysts

- B01D2255/90—Physical characteristics of catalysts

- B01D2255/911—NH3-storage component incorporated in the catalyst

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2257/00—Components to be removed

- B01D2257/40—Nitrogen compounds

- B01D2257/404—Nitrogen oxides other than dinitrogen oxide

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D2257/00—Components to be removed

- B01D2257/40—Nitrogen compounds

- B01D2257/406—Ammonia

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2229/00—Aspects of molecular sieve catalysts not covered by B01J29/00

- B01J2229/10—After treatment, characterised by the effect to be obtained

- B01J2229/18—After treatment, characterised by the effect to be obtained to introduce other elements into or onto the molecular sieve itself

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2229/00—Aspects of molecular sieve catalysts not covered by B01J29/00

- B01J2229/30—After treatment, characterised by the means used

- B01J2229/36—Steaming

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2330/00—Structure of catalyst support or particle filter

- F01N2330/06—Ceramic, e.g. monoliths

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2370/00—Selection of materials for exhaust purification

- F01N2370/02—Selection of materials for exhaust purification used in catalytic reactors

- F01N2370/04—Zeolitic material

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2510/00—Surface coverings

- F01N2510/06—Surface coverings for exhaust purification, e.g. catalytic reaction

- F01N2510/068—Surface coverings for exhaust purification, e.g. catalytic reaction characterised by the distribution of the catalytic coatings

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2570/00—Exhaust treating apparatus eliminating, absorbing or adsorbing specific elements or compounds

- F01N2570/14—Nitrogen oxides

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01N—GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR MACHINES OR ENGINES IN GENERAL; GAS-FLOW SILENCERS OR EXHAUST APPARATUS FOR INTERNAL COMBUSTION ENGINES

- F01N2570/00—Exhaust treating apparatus eliminating, absorbing or adsorbing specific elements or compounds

- F01N2570/18—Ammonia

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A50/00—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE in human health protection, e.g. against extreme weather

- Y02A50/20—Air quality improvement or preservation, e.g. vehicle emission control or emission reduction by using catalytic converters

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02C—CAPTURE, STORAGE, SEQUESTRATION OR DISPOSAL OF GREENHOUSE GASES [GHG]

- Y02C20/00—Capture or disposal of greenhouse gases

- Y02C20/10—Capture or disposal of greenhouse gases of nitrous oxide (N2O)

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/10—Internal combustion engine [ICE] based vehicles

- Y02T10/12—Improving ICE efficiencies

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Organic Chemistry (AREA)

- Materials Engineering (AREA)

- Crystallography & Structural Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Combustion & Propulsion (AREA)

- Environmental & Geological Engineering (AREA)

- Biomedical Technology (AREA)

- Analytical Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Toxicology (AREA)

- Ceramic Engineering (AREA)

- Catalysts (AREA)

- Exhaust Gas Treatment By Means Of Catalyst (AREA)

- Exhaust Gas After Treatment (AREA)

Abstract

公开了催化剂,其具有具有低氨储存量的载体载铂与Cu‑SCR催化剂或Fe‑SCR催化剂的共混物。催化剂还可以包含一种或两种另外的SCR催化剂。催化剂可以以多种构造中的一种存在。公开了包含这些催化剂的催化制品。催化制品可用于废气气体中NOx的选择性催化还原(SCR)和降低氨逸出量。描述了用于生产这样的制品的方法。还描述了将催化制品用于SCR工艺的方法,其中氨逸出量降低。

Description

发明领域

本发明涉及用于选择性催化还原(SCR)的催化剂、包含SCR催化剂的制品和制造这样的制品和使用这样的制品来减少氮氧化物(NOx) 的方法。

本发明的背景技术

柴油发动机、固定式燃气轮机和其它系统中烃燃烧产生了废气气体,所述废气气体需要处理以除去氮氧化物(NOx),所述废气气体包含 NO(一氧化氮)和NO2(二氧化氮),NO为所形成的NOx的主要部分。已知的是NOx导致多种人体健康问题,以及导致多种有害的环境影响,包括形成雾霾和酸雨。为了缓解来自废气气体中NOx的人类和环境影响,期望的是消除这些不期望的组分,其优选通过不产生其它有害或有毒物质的方法。

本发明涉及通过在包含具有低氨储存量的载体载铂与第一SCR 催化剂的共混物的催化剂的存在下使氮氧化物与含氮还原剂接触,将气体(例如车辆贫燃内燃发动机的废气气体)中的氮氧化物转化成氮气的方法。

由含氮化合物,例如氨或尿素选择性催化还原(SCR)NOx首先被开发用于处理工业固定应用。SCR技术首先在1970年代晚期在日本用于热电厂,并且从1980年代中期以来广泛应用于欧洲。在美国,在 1990年代将SCR系统引入用于燃气轮机并且在更近期已经用于燃煤电厂。除了燃煤废热发电厂和燃气轮机,SCR应用还包括化学处理工业中的锅炉和精炼厂加热器和设施、炉、焦炭炉、城市废物设施和焚烧炉。在更近期,在欧洲、日本和美国,研发了基于SCR技术的NOx还原系统用于多种车辆(机动)应用,例如用于处理柴油废气气体。

NH3SCR系统中发生若干化学反应,其全部代表将NOx还原成氮气的期望的反应。主导反应由反应(1)代表。

4NO+4NH3+O2→4N2+6H2O(1)

与氧竞争性的非选择性反应可能产生次级排放物或可能非生产性地消耗氨。一种这样的非选择性反应是氨的完全氧化,显示在反应(2) 中。

4NH3+5O2→4NO+6H2O(2)

而且,副反应可能导致不期望的产物例如N2O,如由反应(3)代表的。

4NH3+5NO+3O2→4N2O+6H2O(3)

期望的是具有这样的催化剂,其提供了增加的氮气(N2)收率和减少的N2O形成。

发明内容

在一个方面中,本发明涉及催化制品,所述催化制品包含:基材;第一涂层,其包含具有低氨储存量的载体载铂与第一SCR催化剂的共混物;第二涂层,其包含第二SCR催化剂;入口和出口,其中第一涂层置于基材上,第一SCR催化剂为Cu-SCR催化剂或Fe-SCR催化剂并且第二涂层至少部分地叠覆第一涂层。

在另一方面,本发明涉及催化制品,所述催化制品包含:基材;第一涂层,其包含具有低氨储存量的载体载铂与第一SCR催化剂的共混物;第二涂层,其包含第二SCR催化剂;入口和出口,其中第一涂层置于基材上,第一SCR催化剂为Cu-SCR催化剂或Fe-SCR催化剂并且第二涂层叠覆第一涂层沿入口至出口的轴的长度的至少20%。

在另一方面,本发明涉及包含催化制品和用于转化废气气体中 NOx和NH3的装置的废气系统,所述催化制品包含:基材;第一涂层,其包含具有低氨储存量的载体载铂与第一SCR催化剂的共混物;第二涂层,其包含第二SCR催化剂;入口和出口,其中第一涂层置于基材上,第一SCR催化剂为Cu-SCR催化剂或Fe-SCR催化剂并且第二涂层至少部分地叠覆第一涂层。

在又一方面,本发明涉及包含催化制品和用于转化废气气体中 NOx和NH3的装置的废气系统,所述催化制品包含:基材;第一涂层,其包含具有低氨储存量的载体载铂与第一SCR催化剂的共混物;第二涂层,其包含第二SCR催化剂;入口和出口,其中第一涂层置于基材上,第一SCR催化剂为Cu-SCR催化剂或Fe-SCR催化剂并且第二涂层叠覆第一涂层沿入口至出口的轴的长度的至少20%。

在又另一方面,本发明涉及用于改善在约200℃-约350℃的温度下的来自废气气体中的氨的N2收率的方法,所述方法包括使包含氨的废气气体与催化制品接触,所述催化制品包含:基材;第一涂层,其包含具有低氨储存量的载体载铂与第一SCR催化剂的共混物;第二涂层,其包含第二SCR催化剂;入口和出口,其中第一涂层置于基材上,第一SCR催化剂为Cu-SCR催化剂或Fe-SCR催化剂并且第二涂层至少部分地叠覆第一涂层。

在又一方面,减少由废气气体中的NOx和NH3形成的N2O的方法,所述方法包括使包含氨的废气气体与催化制品接触,所述催化制品包含:基材;第一涂层,其包含具有低氨储存量的载体载铂与第一 SCR催化剂的共混物;第二涂层,其包含第二SCR催化剂;入口和出口,其中第一涂层置于基材上,第一SCR催化剂为Cu-SCR催化剂或Fe-SCR催化剂并且第二涂层至少部分地叠覆第一涂层。

在进一步的方面中,处理包含NH3和NOx的废气气体的方法,所述方法包括使包含氨的废气气体与催化制品接触,所述催化制品包含:基材;第一涂层,其包含具有低氨储存量的载体载铂与第一SCR催化剂的共混物;第二涂层,其包含第二SCR催化剂;入口和出口,其中第一涂层置于基材上,第一SCR催化剂为Cu-SCR催化剂或Fe-SCR 催化剂并且第二涂层至少部分地叠覆第一涂层。

附图说明

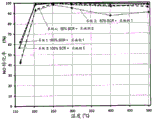

图1(a)为这样的图,其显示%NO转化率,使用实施例1-5,使用 100ppm NO,100ppmNH3,10%的O2,4.5%的CO2,4.5%的H2O,余量N2,在SV=120,000h-1下。

图1(b)为这样的图,其显示N2O形成的量,使用实施例1-5,使用100ppm NO,100ppmNH3,10%的O2,4.5%的CO2,4.5%的H2O,余量N2,在SV=120,000h-1下。

图1(c)为这样的图,其显示%NH3转化率,使用实施例1-5,使用 100ppm NO,100ppm NH3,10%的O2,4.5%的CO2,4.5%的H2O,余量N2,在SV=120,000h-1下。

图1(d)为这样的图,其显示%的N2收率,使用实施例1-5,使用 100ppm NO,100ppmNH3,10%的O2,4.5%的CO2,4.5%的H2O,余量N2,在SV=120,000h-1下。

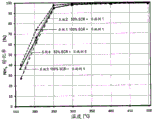

图2(a)为这样的图,其显示%NO转化率,使用实施例1-5,使用 100ppm NO,100ppm或140ppm NH3(ANR=1.0或1.4),10%的O2, 4.5%的CO2,4.5%的H2O,余量N2,在SV=60,000h-1下。

图2(b)为这样的图,其显示N2O形成的量,使用实施例1-5,使用100ppm NO,100ppm或140ppm NH3(ANR=1.0或1.4),10%的 O2,4.5%的CO2,4.5%的H2O,余量N2,在SV=60,000h-1下。

图2(c)为这样的图,其显示%NH3转化率,使用实施例1-5,使用 100ppm NO,100ppm或140ppm NH3(ANR=1.0或1.4),10%的O2, 4.5%的CO2,4.5%的H2O,余量N2,在SV=60,000h-1下。

图2(d)为这样的图,其显示%的N2收率,使用实施例1-5,使用 100ppm NO,100ppm或140ppm NH3(ANR=1.0或1.4),10%的O2, 4.5%的CO2,4.5%的H2O,余量N2,在SV=60,000h-1下。

图3(a)为这样的图,其显示%NO转化率,使用系统1-4,使用 300ppm NO,500ppmNH3,10%的O2,4.5%的CO2,4.5%的H2O,余量N2,在SV=120,000h-1下。

图3(b)为这样的图,其显示N2O形成的量,使用系统1-4,使用 300ppm NO,500ppmNH3,10%的O2,4.5%的CO2,4.5%的H2O,余量N2,在SV=120,000h-1下。

图3(c)为这样的图,其显示%NH3转化率,使用系统1-4,使用 300ppm NO,500ppmNH3,10%的O2,4.5%的CO2,4.5%的H2O,余量N2,在SV=120,000h-1下。

图3(d)为这样的图,其显示%的N2收率,使用系统1-4,使用 300ppm NO,500ppmNH3,10%的O2,4.5%的CO2,4.5%的H2O,余量N2,在SV=120,000h-1下。

发明详述

如本说明书和所附权利要求中使用的,单数形式的“a”、“an”和“the”包括多数多数指示物,除非上下文清楚地另有指示。因此,例如,对“催化剂”的引述包括两种或更多种催化剂的混合物,等等。

如本文所用的,术语“氨逸出”,意为穿过SCR催化剂的未反应的氨的量。

术语“具有低氨储存量的载体”意为储存小于0.001mmol NH3/m3载体的载体。具有低氨储存量的载体优选为骨架类型选自以下的分子筛或沸石:AEI、ANA、ATS、BEA、CDO、CFI、CHA、CON、DDR、 ERI、FAU、FER、GON、IFR、IFW、IFY、IHW、IMF、IRN、IRY、 ISV、ITE、ITG、ITN、ITR、ITW、IWR、IWS、IWV、IWW、JOZ、 LTA、LTF、MEL、MEP、MFI、MRE、MSE、MTF、MTN、MTT、 MTW、MVY、MWW、NON、NSI、RRO、RSN、RTE、RTH、RUT、 RWR、SEW、SFE、SFF、SFG、SFH、SFN、SFS、SFV、SGT、SOD、 SSF、SSO、SSY、STF、STO、STT、SVR、SVV、TON、TUN、UOS、 UOV、UTL、UWY、VET、VNI。更优选地,分子筛或沸石的骨架类型选自BEA、CDO、CON、FAU、MEL、MFI和MWW,甚至更优选骨架类型选自BEA和MFI。

如本文所用的,术语“煅烧(calcine)”,或“煅烧(calcination)”,意为在空气或氧气中加热材料。该定义与煅烧的IUPAC定义一致。 (IUPAC.Compendium of ChemicalTerminology,2nd ed.(the"Gold Book")。A.D.McNaught和A.Wilkinson编译。BlackwellScientific Publications,Oxford(1997)。XML在线更正版本: http://goldbook.iupac.org(2006-),M.Nic,J.Jirat,B.Kosata生成;A. Jenkins编译更新。ISBN0-9678550-9-8。doi:10.1351/goldbook)。进行煅烧以将金属盐分解并且促进催化剂内的金属离子交换并且还将催化剂粘附至基材。煅烧中使用的温度取决于待煅烧的材料中的组分并且通常为约300℃-约900℃,持续大约1-8小时。在一些情况下,煅烧可以进行至最高约1200℃的温度。在涉及本文描述的方法的应用中,煅烧通常在约400℃-约700℃的温度下进行大约1-8小时,优选在约400℃-约650℃的温度下进行大约1-4小时。

如本文所用的,术语“约”意为大约并且指的是所关联术语的值的任选±25%,优选±10%,更优选地,±5%,或最优选±1%。

在就各种数值要素提供的一个或多个范围时,所述一个或多个范围可以包括值,除非另有规定。

如本文所用的,术语“N2选择性”意为氨到氮气的百分比转化率。

在本发明的一个方面中,催化剂包含具有低氨储存量的载体载铂与第一SCR催化剂的组合。具有低氨储存量的载体载铂与第一SCR 催化剂的组合为(a)具有低氨储存量的载体载铂与第一SCR催化剂的共混物,或(b)双层,其具有包含第一SCR催化剂的顶部层和包含具有低氨储存量的载体载铂的底部层,其中底部层可以置于基材上。具有低氨储存量的载体可以为含硅载体,其中含硅载体可以包含二氧化硅或二氧化硅与氧化铝的比例为至少以下之一的沸石:≥100,≥200,≥250,≥300,≥400,≥500,≥750和≥1000。在本发明的各方面,第一 SCR催化剂优选为Cu-SCR催化剂或Fe-SCR催化剂,更优选Cu-SCR 催化剂。

共混物中第一SCR催化剂的量与具有低氨储存量的载体载铂的量的比例可以为3:1-300:1(包括端值),基于这些组分的重量计。共混物中第一SCR催化剂的量与具有低氨储存量的载体载铂的量的优选比例为7:1-100:1(包括端值),基于这些组分的重量计。更优选地,共混物中第一SCR催化剂的量与具有低氨储存量的载体载铂的量的比例为10:1-50:1(包括端值),基于这些组分的重量计。

术语“活性组分载量”是指共混物中铂的载体的重量+铂的重量+ 第一SCR催化剂的重量。铂可以以约0.01-约0.25wt%(包括端值)的活性组分载量存在于催化剂中。优选地,铂可以以0.04-0.2wt%(包括端值)的活性组分载量存在于催化剂中。更优选地,铂可以以0.07-0.17 wt%(包括端值)的活性组分载量存在于催化剂中。最优选地,铂可以以0.05-0.15wt%(包括端值)的活性组分载量存在于催化剂中。

SCR催化剂

在各种实施方案中,组合物可以包含一种、两种或三种SCR催化剂。第一SCR催化剂,其总是存在于组合物中,可以存在于:(1)与具有低氨储存量的载体载Pt的共混物中或(2)顶部层中(在催化剂存在于双层中并且Pt存在于底部层中时)。第一SCR催化剂优选为Cu-SCR 催化剂或Fe-SCR催化剂,更优选Cu-SCR催化剂。Cu-SCR催化剂包含铜和分子筛。Fe-SCR催化剂包含铁和分子筛。分子筛进一步描述如下。铜或铁可以位于分子筛的骨架内和/或分子筛内的骨架外(可交换)位点中。

第二和第三SCR催化剂可以相同或不同。第二和第三SCR催化剂可以为贱金属的氧化物、分子筛、经金属交换的分子筛或其混合物。贱金属可以选自钒(V)、钼(Mo)和钨(W)、铬(Cr)、铈(Ce)、锰(Mn)、铁(Fe)、钴(Co)、镍(Ni)和铜(Cu),及其混合物。由耐火金属氧化物(例如氧化铝、二氧化硅、氧化锆、二氧化钛、二氧化铈及其组合)上负载的钒组成的SCR组合物是公知的并且广泛地在商业上用于机动应用中。典型的组合物描述在美国专利号4,010,238和4,085,193中,其全部内容以引用方式并入本文。商业上尤其是移动应用中使用的组合物包含TiO2、WO3和V2O5分别以5-20wt%和0.5-6wt%的浓度分散在其上。第二SCR催化剂可以包含促进的-Ce-Zr或促进的-MnO2。这些催化剂可以包含其它无机材料例如SiO2和ZrO2,其充当粘合剂和促进剂。

在SCR催化剂为贱金属或混合的贱金属氧化物时,催化剂制品可以进一步包含至少一种贱金属促进剂。如本文所用的,“促进剂”理解意为在添加至催化剂中时增加催化剂活性的物质。贱金属促进剂可以为金属、金属氧化物或其混合物的形式。至少一种贱金属催化剂促进剂可以选自钕(Nd)、钡(Ba)、铈(Ce)、镧(La)、镨(Pr)、镁(Mg)、钙 (Ca)、锰(Mn)、锌(Zn)、铌(Nb)、锆(Zr)、钼(Mo)、锡(Sn)、钽(Ta)、锶(Sr)及其氧化物。至少一种贱金属催化剂促进剂可以优选为MnO2、 Mn2O3、Fe2O3、SnO2、CuO、CoO、CeO2及其混合物。至少一种贱金属催化剂促进剂可以以水溶液中的盐(例如硝酸盐或乙酸盐)的形式添加至催化剂。至少一种贱金属催化剂促进剂和至少一种贱金属催化剂(例如,铜)可以从水溶液浸渍至(一种或多种)氧化物载体材料上,可以添加至包含(一种或多种)氧化物载体材料的载体涂层中,或可以浸渍至先前用载体涂层涂覆的载体上。

SCR催化剂可以包含分子筛或经金属交换的分子筛。如本文使用的,“分子筛”理解意为包含精准和均一尺寸的孔,可以作为吸附剂用于气体或液体的亚稳定材料。小到足以穿过孔的分子被吸附,而较大的分子不被吸附。分子筛可以为沸石分子筛、非沸石分子筛或其混合物。

沸石分子筛为具有International Zeolite Association(IZA)发布的 Databaseof Zeolite Structures中列出的骨架结构的任何一种的微孔硅铝酸盐。骨架结构包括但不限于CHA、FAU、BEA、MFI、MOR 类型的那些。具有这些结构的沸石的非限定性实例包括菱沸石、八面沸石、沸石Y、超稳定沸石Y、β沸石、丝光沸石、硅质岩、沸石X 和ZSM-5。硅铝酸盐沸石可以具有至少约5,优选至少约20的二氧化硅/氧化铝摩尔比例(SAR)(定义为SiO2/Al2O3),有用的范围为约 10-200。

SCR催化剂的任一种可以包含小孔、中孔或大孔分子筛或其组合。“小孔分子筛”为包含8个四面体原子的最大环尺寸的分子筛。“中孔分子筛”为包含10个四面体原子的最大环尺寸的分子筛。“大孔分子筛”为包含12个四面体原子的最大环尺寸的分子筛。第二和/或第三SCR催化剂可以包含小孔分子筛选自硅铝酸盐分子筛、金属- 取代硅铝酸盐分子筛、铝磷酸盐(AlPO)分子筛、金属-取代铝磷酸盐 (MeAlPO)分子筛、硅铝磷酸盐(SAPO)分子筛和金属取代硅铝磷酸盐 (MeAPSO)分子筛,及其混合物。

SCR催化剂的任一种可以包含小孔分子筛,所述小孔分子筛选自以下骨架类型:ACO、AEI、AEN、AFN、AFT、AFX、ANA、APC、 APD、ATT、CDO、CHA、DDR、DFT、EAB、EDI、EPI、ERI、GIS、GOO、IHW、ITE、ITW、LEV、KFI、MER、MON、NSI、 OWE、PAU、PHI、RHO、RTH、SAT、SAV、SFW、SIV、THO、 TSC、UEI、UFI、VNI、YUG和ZON,及其混合物和/或共生物。优选小孔分子筛选自以下骨架类型:CHA,LEV,AEI,AFX,ERI, SFW,KFI,DDR和ITE。

SCR催化剂的任一种可以包含中孔分子筛,所述中孔分子筛选自以下骨架类型:AEL、AFO、AHT、BOF、BOZ、CGF、CGS、CHI、 DAC、EUO、FER、HEU、IMF、ITH、ITR、JRY、JSR、JST、LAU、LOV、MEL、MFI、MFS、MRE、MTT、MVY、MWW、NAB、NAT、 NES、OBW、PAR、PCR、PON、PUN、RRO、RSN、SFF、SFG、 STF、STI、STT、STW、SVR、SZR、TER、TON、TUN、UOS、 VSV、WEI和WEN,及其混合物和/或共生物。优选地,中孔分子筛选自以下骨架类型:MFI、FER和STT。

SCR催化剂的任一种可以包含大孔分子筛,所述大孔分子筛选自以下骨架类型:AFI、AFR、AFS、AFY、ASV、ATO、ATS、BEA、 BEC、BOG、BPH、BSV、CAN、CON、CZP、DFO、EMT、EON、EZT、FAU、GME、GON、IFR、ISV、ITG、IWR、IWS、IWV、 IWW、JSR、LTF、LTL、MAZ、MEI、MOR、MOZ、MSE、MTW、 NPO、OFF、OKO、OSI、RON、RWY、SAF、SAO、SBE、SBS、 SBT、SEW、SFE、SFO、SFS、SFV、SOF、SOS、STO、SSF、SSY、 USI、UWY和VET,及其混合物和/或共生物。优选地,大孔分子筛选自以下骨架类型:MOR、OFF和BEA。

经金属交换的分子筛可以具有沉积至分子筛的通道、空穴或笼内或外部表面上的骨架外位点上的来自周期表VB、VIB、VIIB、VIIIB、 IB或IIB族之一的至少一种金属。金属可以具有若干形式之一,包括但不限于零价金属原子或簇、孤立的阳离子、单核或多核氧基阳离子 (oxycation),或作为扩展的金属氧化物。优选地,金属可以为铁、铜,及其混合物,或其组合。

使用金属前体在适合的溶剂中的混合物或溶液将金属与沸石组合。术语“金属前体”意为可以分散在沸石上以赋予催化-活性金属组分的任何化合物或络合物。由于使用其它溶剂的经济和环境问题两者,优选溶剂为水。在使用铜(其为优选的金属)时,适合的络合物或化合物包括但不限于,无水和水合硫酸铜、硝酸铜、乙酸铜、乙酰基丙酮酸铜、氧化铜、氢氧化铜,和铜氨络合物(例如[Cu(NH3)4]2+)的盐。本发明不局限于特定类型、组合物或纯度的金属前体。可以将分子筛添加至金属组分的溶液以形成悬浮液,然后允许其反应,以便金属组分分散在沸石上。金属可以分散在孔通道中以及分子筛的外表面上。金属可以以离子形式或作为金属氧化物分散。例如,铜可以作为铜(II) 离子、铜(I)离子或作为氧化铜分散。可以将包含金属的分子筛与悬浮液的液体相分离,洗涤,并且干燥。然后可以将所得的包含金属的分子筛煅烧以将金属固定在分子筛中。优选地,第二和第三催化剂包含 Cu-SCR,和Fe-SCR、钒、促进的Ce-Zr或促进的MnO2。

经金属交换的分子筛可以包含约0.10wt%和约10wt%的位于分子筛的通道、空穴或笼内或外部表面上的骨架外位点上的VB、VIB、 VIIB、VIIIB、IB或IIB族金属。优选地,骨架外金属可以以约0.2wt%和约5wt%的量存在。

经金属交换的分子筛可以为负载在小孔分子筛上的铜(Cu),其具有催化剂总重量的约0.1-约20.0wt%的铜。更优选铜以催化剂总重量的约0.5wt%-约15wt%存在。最优选铜以催化剂总重量的约1wt%- 约9wt%存在。

在本发明的第一方面,具有低氨储存量的载体载铂与第一SCR催化剂的共混物可以进一步包含钯(Pd)、金(Au)、银(Ag)、钌(Ru)或铑(Rh) 中的至少一种。

用于催化剂的基材可以为通常用于制备包含流通式或过滤器式结构,例如蜂窝式结构、挤出载体、金属基材或SCRF的汽车催化剂的任何材料。优选基材具有多个从基材入口延伸至出口面的细小、平行气体流动通路,使得通路对流体流动是开放的。这样的单块载体可以包含每平方英寸横截面最高约700或更多个流动通路(或“泡孔”),尽管可以使用少得多的流动通路。例如,载体可以具有约7-600,更通常约100-600个泡孔/平方英寸(“cpsi”)。通路(其是从流体入口至其流体出口的基本上直的路径)由壁(SCR催化剂作为“载体涂层”涂覆至所述壁上)限定,以便流动穿过通路的气体接触催化材料。单块基材的流动通路为薄壁通道,其可以具有任何适合的横截面积形状,例如梯形、矩形、方形、三角形、正弦形、六边形、椭圆形、圆形等。本发明不限于特定的基材类型、材料或几何形状。

陶瓷基材可以由任何适合的耐火材料(例如堇青石、堇青石-α氧化铝、α-氧化铝、碳化硅、氮化硅、氧化锆、莫来石、锂辉石、氧化铝-二氧化硅氧化镁、锆硅酸盐、硅线石、镁硅酸盐、锆石、叶长石、硅铝酸盐及其混合物)制造。

壁流动基材也可以由陶瓷纤维复合材料材料形成,例如由堇青石和碳化硅形成的那些。这样的材料能够经受在处理废气料流中遇到的环境,特别是高温。

基材可以高孔隙率基材。术语“高孔隙率基材”是指具有约40%- 约80%的孔隙率的基材。高孔隙率基材可以具有优选至少约45%的孔隙率,更优选至少约50%的孔隙率。高孔隙率基材可以具有优选小于约75%的孔隙率,更优选小于约70%的孔隙率。术语孔隙率,如本文所用的,是指总孔隙率,优选如使用水银孔隙率法测量的。

优选地,基材可以堇青石、高孔隙率堇青石、金属基材、挤出SCR、过滤器或SCRF。

可以使用本领域中已知的方法,将包含具有低NH3储存量的载体载铂与第一SCR催化剂的共混物(其中第一SCR催化剂优选为 Cu-SCR催化剂或Fe-SCR催化剂)的载体涂层施涂至基材的入口侧。在施涂载体涂层之后,可以将组合物干燥和煅烧。在组合物包含第二SCR时,可以将第二SCR在单独的载体涂层中施涂至具有底部层的经煅烧的制品,如以上描述的。在施涂第二载体涂层之后,可以将其干燥和煅烧,如针对第一层所进行的。

可以将具有含铂层的基材在300℃-1200℃,优选400℃-700℃,和更优选450℃-650℃的温度下干燥和煅烧。煅烧优选在干燥条件下进行,但是其也可以水热地(即,在一些水份含量的存在下)进行。煅烧可以进行约30分钟-约4小时,优选约30分钟-约2小时,更优选约30分钟-约1小时的时间。

在本发明的一个方面中,废气系统包含(1)催化制品和(2)用于转化废气气体中NOx和NH3的装置,所述催化制品包含:基材;第一涂层,其包含具有低氨储存量的载体载铂与第一SCR催化剂的共混物;第二涂层,其包含第二SCR催化剂;入口和出口,其中第一涂层置于基材上,第一SCR催化剂为Cu-SCR催化剂或Fe-SCR催化剂并且第二涂层至少部分地叠覆第一涂层。就至少部分的系统操作时间而言,废气系统可以具有>1.0的ANR。废气系统可以进一步包含提供<100%的 NOx转化率的第三SCR催化剂,其中第三SCR催化剂为仅Cu-沸石的SCR催化剂并且第三催化剂放置在催化剂制品的废气气体流动上游,所述催化剂制品包含:基材;第一涂层,其包含具有低氨储存量的载体载铂与第一SCR催化剂的共混物;第二涂层,其包含第二SCR 催化剂;入口和出口,其中第一涂层置于基材上,第一SCR催化剂为 Cu-SCR催化剂或Fe-SCR催化剂并且第二涂层至少部分地叠覆第一涂层。第二SCR催化剂可以包含促进的-Ce-Zr或促进的-MnO2。

在本发明的另一方面,废气系统包含(1)催化制品和(2)用于转化废气气体中NOx和NH3的装置,所述催化制品包含:基材;第一涂层,其包含具有低氨储存量的载体载铂与第一SCR催化剂的共混物;第二涂层,其包含第二SCR催化剂;入口和出口,其中第一涂层置于基材上,第一SCR催化剂为Cu-SCR催化剂或Fe-SCR催化剂并且第二涂层叠覆第一涂层沿入口至出口的轴的长度的至少20%。就至少部分的系统操作时间而言,废气系统可以具有>1.0的ANR。废气系统可以进一步包含提供<100%的NOx转化率的第三SCR催化剂,其中第三SCR 催化剂为仅Cu-沸石的SCR催化剂并且第三催化剂放置在催化剂制品的废气气体流动上游,所述催化剂制品包含:基材;第一涂层,其包含具有低氨储存量的载体载铂与第一SCR催化剂的共混物;第二涂层,其包含第二SCR催化剂;入口和出口,其中第一涂层置于基材上,第一SCR催化剂为Cu-SCR催化剂或Fe-SCR催化剂并且第二涂层至少部分地叠覆第一涂层。第二SCR催化剂可以包含促进的-Ce-Zr或促进的-MnO2。

在本发明的另一方面,改善在约200℃-约350℃的温度下的来自废气气体中的氨的N2收率的方法包括使包含氨的废气气体与催化制品接触,所述催化制品包含:基材;第一涂层,其包含具有低氨储存量的载体载铂与第一SCR催化剂的共混物;第二涂层,其包含第二 SCR催化剂;入口和出口,其中第一涂层置于基材上,第一SCR催化剂为Cu-SCR催化剂或Fe-SCR催化剂并且第二涂层至少部分地叠覆第一涂层。相比于包含其中第一SCR催化剂作为第一层存在并且负载的铂存在于第二层中并且包含NH3和NO的气体穿过第一层然后穿过第二层的类似配制物的催化剂,收率的改善可以为约10%-约20%。

在本发明的另一方面,减少由废气气体中的NOx和NH3形成的 N2O的方法包括使包含氨的废气气体与催化制品接触,所述催化制品包含:基材;第一涂层,其包含具有低氨储存量的载体载铂与第一SCR 催化剂的共混物;第二涂层,其包含第二SCR催化剂;入口和出口,其中第一涂层置于基材上,第一SCR催化剂为Cu-SCR催化剂或 Fe-SCR催化剂并且第二涂层至少部分地叠覆第一涂层。相比于包含其中第一SCR催化剂作为第一层存在并且负载的铂存在于第二层中并且包含NH3和NO的气体穿过第一层然后穿过第二层的类似配制物的催化剂,N2O形成的减少可以为约20%-约80%。

在本发明的另一方面,使用催化制品处理包含NH3和NOx的废气 气体的方法,所述催化制品包含:基材;第一涂层,其包含具有低氨 储存量的载体载铂与第一SCR催化剂的共混物;第二涂层,其包含第二SCR催化剂;入口和出口,其中第一涂层置于基材上,第一SCR催化剂为Cu-SCR催化剂或Fe-SCR催化剂并且第二涂层至少部分地叠覆第一涂层。

以下实施例仅仅展示本发明;本领域技术人员会认识到本发明的精神和权利要求的范围内的多种变型。

实施例

实施例1-双层配制物-具有Cu-SCR顶部层的氧化铝载Pt

将具有氧化铝底部层载Pt和SCR顶部层的双层配制物用作对比实施例。

使用载体涂层将底部层施涂至陶瓷基材,所述载体涂层包含氧化铝载0.3wt%的Pt。将载体涂层施涂至陶瓷基材,并且然后使用真空将载体涂层顺着基材牵动。在约500℃下将制品干燥和煅烧约1小时。制品上Pt的载量为3g/ft3。

使用包含Cu-CHA的第二载体涂层将顶部层施涂至使用底部层涂覆的基材,并且然后使用真空将载体涂层顺着基材牵动。在约500℃下将制品干燥和煅烧约1小时。顶部层中Cu-CHA的载量为1.8g/in3。该材料为实施例1。通过将实施例1的样品在620℃下在包含10%的 H2O的气氛中老化50小时制备经老化的样品。

实施例2-双层配制物-较高载量的氧化铝载Pt,Cu-SCR顶部层

将氧化铝底部层载Pt和SCR顶部层的双层配制物用作对比实施例。

使用载体涂层将底部层施涂至陶瓷基材,所述载体涂层包含氧化铝和裸沸石的共混物载的0.17wt%的Pt。将载体涂层施涂至陶瓷基材,并且然后使用真空将载体涂层顺着基材牵动。在约500℃下将制品干燥和煅烧约1小时。制品上Pt的载量为3g/ft3。

使用包含Cu-CHA的第二载体涂层将顶部层施涂至使用底部层涂覆的基材,并且然后使用真空将载体涂层顺着基材牵动。在约500℃下将制品干燥和煅烧约1小时。顶部层中Cu-CHA的载量为2.7g/in3。该材料为实施例2。通过将实施例2的样品在620℃下在包含10%的 H2O的气氛中老化50小时制备经老化的样品。

实施例3-MFI沸石(SAR=2100)载1wt%的Pt与底部层中的 Cu-CHA和顶部层中的Cu-CHA的双层共混物,Pt底部层的完全长度被Cu-CHA顶部层覆盖。

使用载体涂层将底部层施涂至陶瓷基材,所述载体涂层包含 ZSM-5(SAR=2100的MFI骨架)载4wt%的Pt与Cu-CHA的共混物。将载体涂层施涂至陶瓷基材,并且然后使用真空将载体涂层顺着基材牵动。在约500℃下将制品干燥和煅烧约1小时。制品上Pt、沸石和 Cu-CHA的载量分别为3g/ft3、0.18g/in3和1.8g/in3。

使用包含Cu-CHA的第二载体涂层将顶部层施涂至使用底部层涂覆的基材,并且然后使用真空将载体涂层顺着基材牵动至基材长度的约50%的距离。在约500℃下将制品干燥和煅烧约1小时。顶部层中 Cu-CHA的载量为1.8g/in3。在沿着制品的长度的恰当的位置处将制品切割以形成新的较小的制品,其100%的共混物底部层被Cu-CHA 顶部层覆盖。该材料为实施例3。通过将实施例3的样品在620℃下在包含10%的H2O的气氛中老化50小时制备经老化的样品。

实施例4-MFI沸石(SAR=2100)载2wt%的Pt与底部层中的 Cu-CHA和顶部层中的Cu-CHA的双层共混物,Pt底部层的完全长度被Cu-CHA顶部层覆盖。

使用载体涂层将底部层施涂至陶瓷基材,所述载体涂层包含 ZSM-5(SAR=2100的MFI骨架)载4wt%的Pt与Cu-CHA的共混物。将载体涂层施涂至陶瓷基材,并且然后使用真空将载体涂层顺着基材牵动。在约500℃下将制品干燥和煅烧约1小时。制品上Pt、沸石和 Cu-CHA的载量分别为3g/ft3,0.09g/in3,和0.9g/in3。

使用包含Cu-CHA的第二载体涂层将顶部层施涂至使用底部层涂覆的基材,并且然后使用真空将载体涂层顺着基材牵动至基材长度的约50%的距离。在约500℃下将制品干燥和煅烧约1小时。顶部层中 Cu-CHA的载量为1.8g/in3。在沿着制品的长度的恰当的位置处将制品切割以形成新的较小的制品,其100%的共混物底部层被Cu-CHA 顶部层覆盖。该材料为实施例4。通过将实施例4的样品在620℃下在包含10%的H2O的气氛中老化50小时制备经老化的样品。

实施例5-MFI沸石(SAR=2100)载4wt%的Pt与底部层中的 Cu-CHA和顶部层中的Cu-CHA的双层共混物,Pt底部层的完全长度被Cu-CHA顶部层覆盖。

使用载体涂层将底部层施涂至陶瓷基材,所述载体涂层包含 ZSM-5(SAR=2100的MFI骨架)载4wt%的Pt与Cu-CHA的共混物。将载体涂层施涂至陶瓷基材,并且然后使用真空将载体涂层顺着基材牵动。在约500℃下将制品干燥和煅烧约1小时。制品上Pt、沸石和 Cu-CHA的载量分别为3g/ft3,0.045g/in3,和0.9g/in3。

使用包含Cu-CHA的第二载体涂层将顶部层施涂至使用底部层涂覆的基材,并且然后使用真空将载体涂层顺着基材牵动至基材长度的约50%的距离。在约500℃下将制品干燥和煅烧约1小时。顶部层中 Cu-CHA的载量为1.8g/in3。在沿着制品的长度的恰当的位置处将制品切割以形成新的较小的制品,其100%的共混物底部层被Cu-CHA 顶部层覆盖。该材料为实施例5。通过将实施例5的样品在620℃下在包含10%的H2O的气氛中老化50小时制备经老化的样品。

图1显示了实施例1-5的在GHSV=120,000h-1下的NO+NH3反应性能。相比于实施例1和2,实施例3、4和5显著减少了N2O形成,在200-300℃,N2O减少最高为85%。实施例3、4和5中NO转化率和N2收率也显著更高。这些结果说明在实施例3、4和5中,Cu上的 SCR反应得到促进并且Pt上的非选择性NH3+NO反应(主要产物为 N2O)并且伴生的Pt上的NH3氧化(其减少了Cu上的SCR反应可得的 NH3)得到最小化。尽管实施例2、4和5包含相同量的Cu-SCR催化剂,在实施例4和5中,N2O的形成低得多并且NO转化率高得多。这些结果表明沸石载Pt+Cu-SCR共混物底部层组合物对减少的N2O 形成减少和改善的N2选择性负主要责任,而通过简单地增加顶部层中的Cu-SCR的量可以实现的益处极少。

图2显示了实施例1、3和5中在GHSV=60,000h-1下具有不同 ANR(氨与NO比例)的NO+NH3反应性能。将ANR从1.0增加至1.4 改善了全部催化剂中的NO转化率,表明对于优化的NOx去除效率, ANR>1是期望的。在1.4的高ANR(即,没有足够NO来与全部NH3反应,导致来自Cu-SCR组分的NH3逸出)下,全部三个催化剂测试显示在250℃以上几乎没有NH3逸出。因为在全部三种催化剂中对NH3氧化具有高度活性的Pt的存在,这是预期的。然而,在实施例3和5中,在250℃下,NO转化率高了约10%并且N2O形成低了75%。实施例3和5证明了在NOx和NH3都存在于进料中时Cu-催化的SCR 反应得到促进并且Pt-催化的非选择性NO+NH3反应得到最小化。

系统的比较:

系统 组合物

1) 100%的Cu-SCR上游(SV=75,000h-1)+实施例1下游(SV=120,000h-1)

2) 50%的Cu-SCR上游(SV=150,000h-1)+实施例1下游(SV=120,000h-1)

3) 100%的Cu-SCR上游(SV=75,000h-1)+实施例5下游(SV=120,000h-1)

4) 50%的Cu-SCR上游(SV=150,000h-1)+实施例5下游(SV=120,000h-1)

图3显示了具有在上游中各种体积的Cu-SCR催化剂和Cu-SCR 下游的实施例1和5的系统上的NO+NH3反应性能。

系统1与系统3的比较:

两个系统在前部具有相同的完全尺寸的SCR,具有足以完全地除去300ppm NO+300ppm NH3的体积。后部ASC催化剂仅仅对氧化 200ppm的未反应的NH3负责。如预期的,在NO和NH3转化率上,两个系统之间区别极小。然而,系统3中N2O形成低得多,其中实施例5为下游(作为ASC催化剂),这归因于其N2O形成更低。

系统2与系统4的比较:

两个系统在前部具有相同的半尺寸的SCR,具有不足以完全除去 300ppm NO的体积,导致NO和NH3逸出。在实施例1下游的情况下,由于前SCR体积减小,NO转化率显著降低并且N2O形成显著增加,表示Pt上发生NH3氧化和非选择性NH3+NO反应。相反,在实施例5下游的情况下,NO转化率没有明显的降低并且N2O形成几乎没有增加,表明Pt上的非选择性NH3+NO反应得到最小化。

前述实施例仅仅意图作为展示;所附权利要求限定了本发明的范围。

Claims (15)

1.催化制品,其包含基材,所述基材具有入口和出口并且涂覆有:第一涂层,其包含具有低氨储存量的载体载铂与第一SCR催化剂的共混物;第二涂层,其包含第二SCR催化剂;

其中所述第二涂层至少部分地叠覆所述第一涂层,并且其中所述第一SCR催化剂为Cu-SCR催化剂或Fe-SCR催化剂,其中所述具有低氨储存量的载体为含硅载体,所述含硅载体包括二氧化硅与氧化铝的比例为≥100的沸石,

所述具有低氨储存量的载体意为储存小于0.001mol NH3/m3载体的载体。

2.根据权利要求1所述的催化制品,其中所述第二涂层完全地叠覆所述第一涂层。

3.根据权利要求1所述的催化制品,其中所述具有低氨储存量的载体为含硅载体,所述含硅载体包括二氧化硅与氧化铝的比例为≥1000的沸石。

4.根据权利要求1所述的催化制品,其中包含具有低氨储存量的载体载铂的共混物进一步包含钯(Pd)、金(Au)、银(Ag)、钌(Ru)或铑(Rh)中的至少一种。

5.根据权利要求1所述的催化制品,其中所述第一SCR催化剂包含承载在分子筛上的Cu或Fe,所述分子筛选自以下骨架类型:ACO、AEI、AEN、AFN、AFT、AFX、ANA、APC、APD、ATT、CDO、CHA、DDR、DFT、EAB、EDI、EPI、ERI、GIS、GOO、IHW、ITE、ITW、LEV、KFI、MER、MON、NSI、OWE、PAU、PHI、RHO、RTH、SAT、SAV、SIV、THO、TSC、UEI、UFI、VNI、YUG、ZON、BEA、MFI和FER及其混合物和/或共生物。

6.根据权利要求1所述的催化制品,其中所述第二SCR催化剂为负载于分子筛上的贱金属,其中所述贱金属选自钒(V)、钼(Mo)和钨(W)、铬(Cr)、铈(Ce)、锰(Mn)、铁(Fe)、钴(Co)、镍(Ni)、和铜(Cu),及其混合物。

7.根据权利要求1所述的催化制品,其中相比于包含其中第一SCR催化剂作为第一层存在并且铂存在于第二层中并且包含NH3和NO的气体穿过第一层然后穿过第二层的可比配制物的催化剂,该催化剂提供了在200℃-300℃的温度下的来自氨的N2收率的改善,其中N2收率的改善为至少10%。

8.根据权利要求1所述的催化制品,其中相比于包含其中第一SCR催化剂作为第一层存在并且铂存在于第二层中并且包含NH3和NO的气体穿过第一层然后穿过第二层的可比配制物的催化剂,该催化剂提供了在200℃-350℃的温度下的减少的由NH3和NOx形成的N2O。

9.根据权利要求1所述的催化制品,其中所述基材为堇青石、高孔隙率堇青石、金属基材、挤出蜂窝体或过滤器。

10.根据权利要求1所述的催化制品,其中所述第二SCR催化剂位于所述催化剂的入口侧上,所述催化剂包含具有低氨储存量的载体载铂与第一SCR催化剂的共混物。

11.根据权利要求1所述的催化制品,其中所述第二SCR催化剂位于所述催化剂的出口侧上,所述催化剂包含具有低氨储存量的载体载铂与第一SCR催化剂的共混物。

12.根据权利要求11所述的催化制品,其中所述第二SCR催化剂包含促进的-Ce-Zr或促进的-MnO2。

13.根据权利要求1所述的催化制品,其中所述第二涂层叠覆所述第一涂层沿入口至出口的轴的长度的至少20%。

14.改善在200℃-350℃的温度下的来自废气气体中的氨和NOx的N2收率的方法,所述方法包括使包含氨的废气气体与根据权利要求1所述的催化制品接触。

15.处理包含氨和NOx的废气气体的方法,所述方法包括使包含氨的废气气体与根据权利要求1所述的催化制品接触。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201562181479P | 2015-06-18 | 2015-06-18 | |

| US62/181,479 | 2015-06-18 | ||

| PCT/US2016/037740 WO2016205441A1 (en) | 2015-06-18 | 2016-06-16 | Nh3 overdosing-tolerant scr catalyst |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN107847862A CN107847862A (zh) | 2018-03-27 |

| CN107847862B true CN107847862B (zh) | 2020-12-18 |

Family

ID=56404284

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201680042218.0A Active CN107847862B (zh) | 2015-06-18 | 2016-06-16 | Nh3过量剂量耐受的scr催化剂 |

Country Status (9)

| Country | Link |

|---|---|

| US (3) | US9878287B2 (zh) |

| EP (1) | EP3310462B1 (zh) |

| JP (1) | JP6830451B2 (zh) |

| KR (1) | KR102527239B1 (zh) |

| CN (1) | CN107847862B (zh) |

| DE (1) | DE102016111000A1 (zh) |

| GB (1) | GB2541500B (zh) |

| RU (1) | RU2715539C2 (zh) |

| WO (1) | WO2016205441A1 (zh) |

Families Citing this family (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016205441A1 (en) * | 2015-06-18 | 2016-12-22 | Johnson Matthey Public Limited Company | Nh3 overdosing-tolerant scr catalyst |

| WO2017134585A1 (en) * | 2016-02-03 | 2017-08-10 | Basf Corporation | Multi-layer catalyst composition for internal combustion engines |

| WO2018183457A1 (en) * | 2017-03-29 | 2018-10-04 | Johnson Matthey Public Limited Company | Asc with platinum group metal in multiple layers |

| RU2759680C2 (ru) * | 2017-03-30 | 2021-11-16 | Джонсон Мэтти Паблик Лимитед Компани | Катализатор asc/dec с генерированием экзотермического эффекта, сконцентрированного в задней зоне |

| GB2577967B (en) * | 2017-03-30 | 2021-06-09 | Johnson Matthey Plc | Platinum group metal and base metal on a molecular sieve for PNA-SCR-ASC close-coupled systems |

| RU2759670C2 (ru) | 2017-03-30 | 2021-11-16 | Джонсон Мэтти Паблик Лимитед Компани | Одноблочный, вплотную соединенный катализатор scr/asc/pna/doc |

| GB201705158D0 (en) * | 2017-03-30 | 2017-05-17 | Johnson Matthey Plc | Catalyst article for use in a emission treatment system |

| CN109833907B (zh) * | 2017-11-29 | 2021-10-15 | 中国科学院大连化学物理研究所 | 一种具备储放氨性能的低温耐硫焦炉烟气脱硝催化剂 |

| CN111432914A (zh) * | 2017-12-13 | 2020-07-17 | 庄信万丰股份有限公司 | 具有对n2的更大选择性的改善的nh3减排 |

| BR112020017976A2 (pt) * | 2018-03-14 | 2020-12-22 | Johnson Matthey Public Limited Company | Artigo catalítico, sistema de exaustão, método para melhorar a conversão de nh3 de um gás de exaustão, e, método para tratamento de gás de exaustão |

| GB201805312D0 (en) * | 2018-03-29 | 2018-05-16 | Johnson Matthey Plc | Catalyst article for use in emission treatment system |

| US10953366B2 (en) * | 2018-04-20 | 2021-03-23 | GM Global Technology Operations LLC | Nitrogen oxides and hydrocarbon storage catalyst and methods of using the same |

| US11549417B2 (en) * | 2018-04-23 | 2023-01-10 | Basf Corporation | Selective catalytic reduction catalyst for the treatment of an exhaust gas of a diesel engine |

| CN109306886A (zh) * | 2018-11-22 | 2019-02-05 | 江苏海事职业技术学院 | 一种海洋船舶内燃机循环燃烧系统 |

| EP4072707A1 (en) * | 2019-12-10 | 2022-10-19 | Johnson Matthey Public Limited Company | Zoned ammonia slip catalyst for improved selectivity, activity and poison tolerance |

| CN110961144A (zh) * | 2019-12-14 | 2020-04-07 | 中触媒新材料股份有限公司 | 一种具有cha/lev拓扑结构共生复合分子筛及其制备方法和scr应用 |

| CN110961146A (zh) * | 2019-12-14 | 2020-04-07 | 中触媒新材料股份有限公司 | 一种具有cha/rth拓扑结构共生复合分子筛及其制备方法和scr应用 |

| CN110961148A (zh) * | 2019-12-14 | 2020-04-07 | 中触媒新材料股份有限公司 | 一种aei/lev结构共生复合分子筛及其制备方法和scr应用 |

| CN110961147A (zh) * | 2019-12-14 | 2020-04-07 | 中触媒新材料股份有限公司 | 一种aei/rth结构共生复合分子筛及其制备方法和scr应用 |

| CN111001437A (zh) * | 2019-12-14 | 2020-04-14 | 中触媒新材料股份有限公司 | 一种aei/afx结构共生复合分子筛及其制备方法和scr应用 |

| CN111001436A (zh) * | 2019-12-14 | 2020-04-14 | 中触媒新材料股份有限公司 | 一种具有aei/kfi结构共生复合分子筛及其制备方法和scr应用 |

| CN110961145A (zh) * | 2019-12-14 | 2020-04-07 | 中触媒新材料股份有限公司 | 一种具有cha/afx结构共生复合分子筛及其制备方法和scr应用 |

| CN111013648A (zh) * | 2019-12-14 | 2020-04-17 | 中触媒新材料股份有限公司 | 一种具有cha/kfi结构共生复合分子筛及其制备方法和scr应用 |

| US11187128B2 (en) * | 2020-03-09 | 2021-11-30 | Progress Rail Services Corporation | After-treatment system for repower locomotives |

| US11712685B2 (en) | 2020-03-31 | 2023-08-01 | Johnson Matthey Public Limited Company | Ammonia slip catalyst with in-situ PT fixing |

| US12048919B2 (en) * | 2020-03-31 | 2024-07-30 | Massachusetts Institute Of Technology | Catalytic compositions for the oxidation of substrates |

| CN111203268B (zh) * | 2020-04-21 | 2020-09-08 | 稀土催化创新研究院(东营)有限公司 | 一种低温高效氨氧化催化剂 |

| JP2024537958A (ja) * | 2021-10-12 | 2024-10-18 | ジョンソン マッセイ (シャンハイ) ケミカルズ リミテッド | 改善されたアンモニア排出制御を有するcngエンジン排気ガス処理のための新規ゾーン触媒 |

| JP7372302B2 (ja) * | 2021-12-06 | 2023-10-31 | 株式会社キャタラー | 排ガス浄化触媒装置 |

| WO2023198574A1 (de) * | 2022-04-11 | 2023-10-19 | Umicore Ag & Co. Kg | Abgassystem für überwiegend stöchiometrisch betriebene verbrennungsmotoren aufweisend einen katalysator zur verminderung der ammoniakemissionen |

| CN118002195B (zh) * | 2024-04-09 | 2024-06-11 | 昆明贵研催化剂有限责任公司 | 一种柴油机用耦合型三效催化剂及其制备方法 |

Family Cites Families (31)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS5523086B2 (zh) | 1973-03-26 | 1980-06-20 | ||

| US4085193A (en) | 1973-12-12 | 1978-04-18 | Mitsubishi Petrochemical Co. Ltd. | Catalytic process for reducing nitrogen oxides to nitrogen |

| JP2614337B2 (ja) * | 1989-11-30 | 1997-05-28 | 新日鐵化学株式会社 | ベンジルビフェニルの製造方法 |

| CN1025865C (zh) * | 1990-12-24 | 1994-09-07 | 中国石油化工总公司石油化工科学研究院 | 含β沸石的重整催化剂 |

| JPH05320074A (ja) * | 1992-05-18 | 1993-12-03 | Nippon Steel Chem Co Ltd | 2,6−ジアルキルナフタレンの製造方法 |

| JPH09253453A (ja) * | 1996-03-19 | 1997-09-30 | Nissan Motor Co Ltd | 排ガス浄化方法 |

| JP2000262860A (ja) * | 1999-03-16 | 2000-09-26 | Mazda Motor Corp | 排気ガス浄化装置 |

| JP2001179095A (ja) * | 1999-12-22 | 2001-07-03 | Toyota Motor Corp | 排気ガス浄化用触媒の製造方法 |

| CN1176748C (zh) * | 2002-09-30 | 2004-11-24 | 厦门大学 | 分子筛为载体的合成柴油的催化剂 |

| KR100765413B1 (ko) * | 2005-07-06 | 2007-10-09 | 희성촉매 주식회사 | 암모니아 산화촉매 및 이를 이용한 슬립 암모니아 또는폐암모니아 처리장치 |

| US7981834B2 (en) * | 2006-03-16 | 2011-07-19 | Ict Co., Ltd. | Adsorbent for hydrocarbons, catalyst for exhaust gas purification and method for exhaust gas purification |

| CN100998941B (zh) * | 2007-01-04 | 2012-09-05 | 华东理工大学 | 一种前置催化剂及其制备方法 |

| EP1961933B1 (de) * | 2007-02-23 | 2010-04-14 | Umicore AG & Co. KG | Katalytisch aktiviertes Dieselpartikelfilter mit Ammoniak-Sperrwirkung |

| KR101358482B1 (ko) * | 2007-02-27 | 2014-02-05 | 바스프 카탈리스트 엘엘씨 | 구리 cha 제올라이트 촉매 |

| JP5110954B2 (ja) * | 2007-05-09 | 2012-12-26 | エヌ・イーケムキャット株式会社 | 選択還元型触媒を用いた排気ガス浄化触媒装置並びに排気ガス浄化方法 |

| US8636959B2 (en) * | 2007-05-09 | 2014-01-28 | N.E. Chemcat Corporation | Selective catalytic reduction type catalyst, and exhaust gas purification equipment and purifying process of exhaust gas using the same |

| JP4886613B2 (ja) * | 2007-06-22 | 2012-02-29 | 田中貴金属工業株式会社 | 窒素酸化物浄化触媒及びこれを用いた窒素酸化物浄化方法 |

| US8524185B2 (en) * | 2008-11-03 | 2013-09-03 | Basf Corporation | Integrated SCR and AMOx catalyst systems |

| US8337791B2 (en) * | 2008-12-03 | 2012-12-25 | Daiichi Kigenso Kagaku Kogyo Co., Ltd. | Exhaust gas purification catalyst, exhaust gas purification apparatus using the same and exhaust gas purification method |

| KR101448734B1 (ko) * | 2009-03-09 | 2014-10-08 | 현대자동차 주식회사 | 질소 산화물 저감 촉매 및 이를 이용한 배기 장치 |

| US8293182B2 (en) * | 2010-05-05 | 2012-10-23 | Basf Corporation | Integrated SCR and AMOx catalyst systems |

| US8722000B2 (en) * | 2011-03-29 | 2014-05-13 | Basf Corporation | Multi-component filters for emissions control |

| CN103476495B (zh) * | 2011-03-31 | 2016-01-20 | 恩亿凯嘉股份有限公司 | 氨氧化催化剂以及使用了其的废气净化装置和废气净化方法 |

| US8101146B2 (en) * | 2011-04-08 | 2012-01-24 | Johnson Matthey Public Limited Company | Catalysts for the reduction of ammonia emission from rich-burn exhaust |

| GB201221025D0 (en) * | 2012-11-22 | 2013-01-09 | Johnson Matthey Plc | Zoned catalysed substrate monolith |

| CN103011192B (zh) * | 2012-12-17 | 2014-10-08 | 中国海洋石油总公司 | 一种含分子筛的硅铝载体及其制备方法 |

| JP6470734B2 (ja) * | 2013-03-14 | 2019-02-13 | ビーエーエスエフ コーポレーション | 選択的接触還元触媒システム |

| CN104549435B (zh) * | 2013-10-12 | 2017-05-31 | 中国石油化工股份有限公司 | 一种稀土改性的zsm‑5分子筛催化剂及其制备方法和应用 |

| JP5888312B2 (ja) * | 2013-11-29 | 2016-03-22 | トヨタ自動車株式会社 | 排ガス浄化用触媒 |

| KR102531436B1 (ko) * | 2015-06-18 | 2023-05-12 | 존슨 맛쎄이 퍼블릭 리미티드 컴파니 | 낮은 n2o 형성을 가진 암모니아 슬립 촉매 |

| WO2016205441A1 (en) * | 2015-06-18 | 2016-12-22 | Johnson Matthey Public Limited Company | Nh3 overdosing-tolerant scr catalyst |

-

2016

- 2016-06-16 WO PCT/US2016/037740 patent/WO2016205441A1/en active Application Filing

- 2016-06-16 JP JP2017565294A patent/JP6830451B2/ja active Active