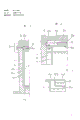

CN1022335C - 水热合成用容器 - Google Patents

水热合成用容器 Download PDFInfo

- Publication number

- CN1022335C CN1022335C CN90101411.7A CN90101411A CN1022335C CN 1022335 C CN1022335 C CN 1022335C CN 90101411 A CN90101411 A CN 90101411A CN 1022335 C CN1022335 C CN 1022335C

- Authority

- CN

- China

- Prior art keywords

- container

- buffer chamber

- inner tubular

- tubular

- tubular container

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J19/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J19/02—Apparatus characterised by being constructed of material selected for its chemically-resistant properties

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J3/00—Processes of utilising sub-atmospheric or super-atmospheric pressure to effect chemical or physical change of matter; Apparatus therefor

- B01J3/04—Pressure vessels, e.g. autoclaves

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J3/00—Processes of utilising sub-atmospheric or super-atmospheric pressure to effect chemical or physical change of matter; Apparatus therefor

- B01J3/04—Pressure vessels, e.g. autoclaves

- B01J3/046—Pressure-balanced vessels

-

- C—CHEMISTRY; METALLURGY

- C30—CRYSTAL GROWTH

- C30B—SINGLE-CRYSTAL GROWTH; UNIDIRECTIONAL SOLIDIFICATION OF EUTECTIC MATERIAL OR UNIDIRECTIONAL DEMIXING OF EUTECTOID MATERIAL; REFINING BY ZONE-MELTING OF MATERIAL; PRODUCTION OF A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; SINGLE CRYSTALS OR HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; AFTER-TREATMENT OF SINGLE CRYSTALS OR A HOMOGENEOUS POLYCRYSTALLINE MATERIAL WITH DEFINED STRUCTURE; APPARATUS THEREFOR

- C30B7/00—Single-crystal growth from solutions using solvents which are liquid at normal temperature, e.g. aqueous solutions

- C30B7/10—Single-crystal growth from solutions using solvents which are liquid at normal temperature, e.g. aqueous solutions by application of pressure, e.g. hydrothermal processes

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2219/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J2219/02—Apparatus characterised by their chemically-resistant properties

- B01J2219/0204—Apparatus characterised by their chemically-resistant properties comprising coatings on the surfaces in direct contact with the reactive components

- B01J2219/0236—Metal based

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Crystallography & Structural Chemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Crystals, And After-Treatments Of Crystals (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP63194338A JPH0722692B2 (ja) | 1988-08-05 | 1988-08-05 | 水熱合成用容器 |

| CN90101411.7A CN1022335C (zh) | 1988-08-05 | 1990-02-03 | 水热合成用容器 |

| DE4003377A DE4003377C1 (cg-RX-API-DMAC7.html) | 1988-08-05 | 1990-02-05 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP63194338A JPH0722692B2 (ja) | 1988-08-05 | 1988-08-05 | 水熱合成用容器 |

| CN90101411.7A CN1022335C (zh) | 1988-08-05 | 1990-02-03 | 水热合成用容器 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1053819A CN1053819A (zh) | 1991-08-14 |

| CN1022335C true CN1022335C (zh) | 1993-10-06 |

Family

ID=36754727

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN90101411.7A Expired - Fee Related CN1022335C (zh) | 1988-08-05 | 1990-02-03 | 水热合成用容器 |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JPH0722692B2 (cg-RX-API-DMAC7.html) |

| CN (1) | CN1022335C (cg-RX-API-DMAC7.html) |

| DE (1) | DE4003377C1 (cg-RX-API-DMAC7.html) |

Families Citing this family (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE4229468C2 (de) * | 1992-09-03 | 1995-06-14 | Streitenberg Hubert Dr Med | Behälter für vom Bakterienbefall bedrohte flüssige oder pastöse Inhaltsstoffe |

| US5552039A (en) * | 1994-07-13 | 1996-09-03 | Rpc Waste Management Services, Inc. | Turbulent flow cold-wall reactor |

| JP3366820B2 (ja) * | 1997-02-19 | 2003-01-14 | 株式会社日立製作所 | 酸化処理方法とその装置及び反応容器 |

| SE518803C2 (sv) | 1999-09-03 | 2002-11-26 | Chematur Eng Ab | Metod och reaktionssystem med högt tryck och hög temperatur som är lämpat för superkritisk vattenoxidation |

| US6398867B1 (en) * | 1999-10-06 | 2002-06-04 | General Electric Company | Crystalline gallium nitride and method for forming crystalline gallium nitride |

| PL207400B1 (pl) | 2001-06-06 | 2010-12-31 | Ammono Społka Z Ograniczoną Odpowiedzialnością | Sposób i urządzenie do otrzymywania objętościowego monokryształu azotku zawierającego gal |

| MY141883A (en) | 2001-06-06 | 2010-07-16 | Ammono Sp Zoo | Process and apparatus for obtaining bulk mono-crystalline gallium-containing nitride |

| JP2003063889A (ja) * | 2001-08-24 | 2003-03-05 | Tokyo Denpa Co Ltd | 単結晶育成用容器 |

| JP4693351B2 (ja) | 2001-10-26 | 2011-06-01 | アンモノ・スプウカ・ジ・オグラニチョノン・オドポヴィエドニアウノシツィオン | エピタキシャル成長用基板 |

| CN1300901C (zh) | 2001-10-26 | 2007-02-14 | 波兰商艾蒙诺公司 | 使用氮化物块状单晶层的发光元件结构 |

| JP4416648B2 (ja) | 2002-05-17 | 2010-02-17 | アンモノ・スプウカ・ジ・オグラニチョノン・オドポヴィエドニアウノシツィオン | 発光素子の製造方法 |

| EP1514958B1 (en) | 2002-05-17 | 2014-05-14 | Ammono S.A. | Apparatus for obtaining a bulk single crystal using supercritical ammonia |

| CN1297695C (zh) * | 2003-04-25 | 2007-01-31 | 郎丽红 | 人工石英晶体的高压釜 |

| JP4276627B2 (ja) | 2005-01-12 | 2009-06-10 | ソルボサーマル結晶成長技術研究組合 | 単結晶育成用圧力容器およびその製造方法 |

| CN112442730A (zh) * | 2019-08-29 | 2021-03-05 | 桂林百锐光电技术有限公司 | 一种温差水热法生长大尺寸体单晶的装置 |

-

1988

- 1988-08-05 JP JP63194338A patent/JPH0722692B2/ja not_active Expired - Lifetime

-

1990

- 1990-02-03 CN CN90101411.7A patent/CN1022335C/zh not_active Expired - Fee Related

- 1990-02-05 DE DE4003377A patent/DE4003377C1/de not_active Expired - Lifetime

Also Published As

| Publication number | Publication date |

|---|---|

| DE4003377C1 (cg-RX-API-DMAC7.html) | 1991-08-08 |

| CN1053819A (zh) | 1991-08-14 |

| JPH0722692B2 (ja) | 1995-03-15 |

| JPH0243939A (ja) | 1990-02-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN1022335C (zh) | 水热合成用容器 | |

| Espie et al. | Experimental study of the influence of interfacial energies and reactivity on wetting in metal/oxide systems | |

| Donaldson et al. | A sample holding technique for study of crystal growth in silicate melts | |

| KR20080003930A (ko) | 유리 제조 시스템에서 하나 또는 그 이상의 용기 주위의환경을 조절하는 시스템 및 방법 | |

| MY123825A (en) | Process for producing glass substrate for information recording medium and process for producing recording medium using said glass substrate. | |

| SE465431B (sv) | Saett att framstaella zirkonium eller hafnium vid vilket en tetraklorid av metallen reduceras med magnesium | |

| EP0233564A2 (de) | Vorrichtung zur Beseitigung von Wasserstoff | |

| CN1199834A (zh) | 使用热胀材料的节流阀 | |

| DE3874423T2 (de) | Sonde zur bestimmung der konzentration eines gases in geschmolzenem metall. | |

| US20040007790A1 (en) | Method and apparatus for producing semiconductor or metal particles | |

| US5057286A (en) | Vessel for use in hydrothermal synthesis | |

| CN85107485A (zh) | 一种用于热浸涂镀及真空蒸镀的两用连续涂镀设备 | |

| JP2003176197A (ja) | 単結晶育成容器 | |

| US6652644B1 (en) | Adjusting lithium oxide concentration in wafers using a two-phase lithium-rich source | |

| US4356141A (en) | Method of casting silicon into thin sheets | |

| JPS6417866A (en) | Formation of film of high-melting-point metal | |

| GB2112749A (en) | Method of sampling a liquid in a container | |

| KR920003914B1 (ko) | 열수합성용 용기 | |

| Shinoda et al. | Interfacial compatibility in ceramic-fibre-reinforced metal composites | |

| JP2003063889A (ja) | 単結晶育成用容器 | |

| RU2033255C1 (ru) | Способ изготовления ячейки для проведения реакции с агрессивными летучими веществами | |

| JP2005206416A (ja) | 単結晶育成容器 | |

| JPH03275135A (ja) | 酸性条件下における高温圧力容器及びその腐食防止方法 | |

| Gerard et al. | Study of hydride forming system by thermogravimetry. Role of the sample mass in exothermic kinetics. | |

| Allaire | Vacuum refining of copper matte |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C19 | Lapse of patent right due to non-payment of the annual fee | ||

| CF01 | Termination of patent right due to non-payment of annual fee |