CN100436756C - 用于供应蒸汽的组合式截止和控制阀 - Google Patents

用于供应蒸汽的组合式截止和控制阀 Download PDFInfo

- Publication number

- CN100436756C CN100436756C CNB031554539A CN03155453A CN100436756C CN 100436756 C CN100436756 C CN 100436756C CN B031554539 A CNB031554539 A CN B031554539A CN 03155453 A CN03155453 A CN 03155453A CN 100436756 C CN100436756 C CN 100436756C

- Authority

- CN

- China

- Prior art keywords

- valve

- control valve

- head

- valve seat

- steam

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 230000007704 transition Effects 0.000 claims abstract description 4

- 230000033001 locomotion Effects 0.000 claims description 19

- 238000007789 sealing Methods 0.000 claims description 6

- 230000006837 decompression Effects 0.000 claims 1

- 230000015572 biosynthetic process Effects 0.000 abstract description 3

- 230000008859 change Effects 0.000 description 4

- 239000012530 fluid Substances 0.000 description 2

- 238000000034 method Methods 0.000 description 2

- 230000000740 bleeding effect Effects 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 238000006073 displacement reaction Methods 0.000 description 1

- 230000006872 improvement Effects 0.000 description 1

- 210000003141 lower extremity Anatomy 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 230000002265 prevention Effects 0.000 description 1

- 230000008569 process Effects 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 230000000630 rising effect Effects 0.000 description 1

- 230000011664 signaling Effects 0.000 description 1

- 238000011144 upstream manufacturing Methods 0.000 description 1

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01L—CYCLICALLY OPERATING VALVES FOR MACHINES OR ENGINES

- F01L35/00—Lift valve-gear or valve arrangements specially adapted for machines or engines with variable fluid distribution

- F01L35/02—Valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K1/00—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces

- F16K1/32—Details

- F16K1/34—Cutting-off parts, e.g. valve members, seats

- F16K1/44—Details of seats or valve members of double-seat valves

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01D—NON-POSITIVE DISPLACEMENT MACHINES OR ENGINES, e.g. STEAM TURBINES

- F01D17/00—Regulating or controlling by varying flow

- F01D17/10—Final actuators

- F01D17/12—Final actuators arranged in stator parts

- F01D17/14—Final actuators arranged in stator parts varying effective cross-sectional area of nozzles or guide conduits

- F01D17/141—Final actuators arranged in stator parts varying effective cross-sectional area of nozzles or guide conduits by means of shiftable members or valves obturating part of the flow path

- F01D17/145—Final actuators arranged in stator parts varying effective cross-sectional area of nozzles or guide conduits by means of shiftable members or valves obturating part of the flow path by means of valves, e.g. for steam turbines

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K1/00—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces

- F16K1/02—Lift valves or globe valves, i.e. cut-off apparatus with closure members having at least a component of their opening and closing motion perpendicular to the closing faces with screw-spindle

- F16K1/06—Special arrangements for improving the flow, e.g. special shape of passages or casings

- F16K1/08—Special arrangements for improving the flow, e.g. special shape of passages or casings in which the spindle is perpendicular to the general direction of flow

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16K—VALVES; TAPS; COCKS; ACTUATING-FLOATS; DEVICES FOR VENTING OR AERATING

- F16K25/00—Details relating to contact between valve members and seats

- F16K25/04—Arrangements for preventing erosion, not otherwise provided for

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2220/00—Application

- F05D2220/30—Application in turbines

- F05D2220/31—Application in turbines in steam turbines

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8593—Systems

- Y10T137/86928—Sequentially progressive opening or closing of plural valves

- Y10T137/86936—Pressure equalizing or auxiliary shunt flow

- Y10T137/86944—One valve seats against other valve [e.g., concentric valves]

- Y10T137/86976—First valve moves second valve

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8593—Systems

- Y10T137/86928—Sequentially progressive opening or closing of plural valves

- Y10T137/86936—Pressure equalizing or auxiliary shunt flow

- Y10T137/86944—One valve seats against other valve [e.g., concentric valves]

- Y10T137/86984—Actuator moves both valves

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8593—Systems

- Y10T137/87917—Flow path with serial valves and/or closures

- Y10T137/88046—Biased valve with external operator

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Lift Valve (AREA)

- Control Of Turbines (AREA)

- Details Of Valves (AREA)

Abstract

蒸汽阀(10)包括快动控制阀(17)和截止阀(19),该截止阀在关闭位置紧靠蒸汽流通道内的阀座(21)。在阀座下方的出口通道(50)具有过渡壁,它们提供经过该座进入出口的平滑而且连续的流动,借此减少压头损失。在该阀周围的滤网(54)具有容纳在入口壁内的支承结构(56)以便减少流动堵塞和涡旋形成。布置在控制阀上方的平衡腔(60)具有泄放孔(62),它用来平衡在平衡腔和蒸汽阀内的蒸汽压力,从而防止平衡腔的压降并促进控制阀的快速关闭。锯齿形螺纹(66)连接控制阀杆和控制阀头部以便阻止这些零件由于氧化物结垢而粘合。

Description

技术领域

本发明涉及蒸汽入口阀,并且尤其是涉及一种为了提供最佳流动性能而构成的组合的控制阀和截止阀,它具有平衡腔和泄放入口以便能快速关闭该控制阀。

背景技术

在一种例如美国专利No.6,070,605(其披露综合于此作为参考)描述和图解的典型蒸汽涡轮机控制阀中提供一种蒸汽入口阀,其包括控制或者阻止阀以及主截止阀或者回热停止阀,在后文中分别称之为控制阀和截止阀。该控制阀总体呈环形并具有多个边缘,该边缘用来在该控制阀关闭状态座落紧靠环形阀座。伺服阀通常相对于阀座定位该控制阀以便控制通过蒸汽入口的流量。截止阀包括盘状物,该盘状物布置在控制阀的环形空间内并且位于控制阀之下。

如同上文确认专利中提及的那样,截止阀一般跟随控制阀运动,以致于控制阀密封表面和截止阀下侧提供相对平滑的流道,该流道用于在该主截止阀处于开启状态时经过该控制和截止组合阀的蒸汽流。然而,截止阀的基本用途是响应快速关闭信号而迅速地关闭该蒸汽入口阀,从而迅速切断蒸汽通过该蒸汽入口阀的流动。该截止阀通过液压缸从入口下方进行控制,该液压缸的流体能快速排出,因而截止阀能迅速关闭紧靠该座。然而对于流动改进而言存在进一步减少压头损失和促进控制阀快速关闭的要求。

发明内容

按照本发明的优选实施例,提供一种用来为下游蒸汽机械装置供应蒸汽的蒸汽入口阀,并且其中该阀具有连接蒸汽出口和阀座的多个无涡旋平滑连续壁,借此改善通过该阀的流动性能。尤其是,在阀座下方并与该蒸汽入口阀出口连通的出口通道与阀座形成平滑连续的过度,从而基本上保持住流动横截面积。借助于这种结构,在阀座下方的增大腔完全消除。然而,流动面积的最小改变减小了通过该阀的速度头损失。此外,在该控制和截止阀的上游和周围提供环形滤网,而且该滤网的边缘容纳在阀座周围的凹槽之中。按照这种方式,基本上只是该滤网而且没有其任何安装结构暴露在朝向阀座的蒸汽流之中,这进一步消除流动方向的突然变化和因此产生的压头损失。

在本发明另一优选实施例中,在控制阀上方提供具有泄放孔的平衡腔。在用信号通知控制阀快速关闭蒸汽入口时,泄放孔平衡流经该阀的蒸汽和平衡腔内蒸汽之间的压力。这使平衡腔内的压力降最小化或者消除,不然的话该压降可能倾向于阻止控制阀朝阀座的运动。此外,锯齿形螺纹互连在该控制阀和控制阀杆之间。借助于使用这种类型的螺纹,允许使用中氧化物不可避免地结垢,但该结垢不足以造成该螺纹粘合和相互锁定。该阀对于为蒸汽涡轮机供应蒸汽来说特别有用。

在本发明的优选实施例中,提供一种用来为下游机械装置供应蒸汽的阀,其包括:大致呈环状的阀座,它限定蒸汽流通道;在该通道内的控制阀,其包括控制阀头部,该控制阀头部在该控制阀下游侧具有凹口,而且该控制阀头部可朝该阀座运动或远离阀座;截止阀,它具有大致在该凹口内部的截止阀头部和用来在截止阀关闭位置与该阀座接合的密封表面;以及出口通道,它在该阀座下方并与用来将供应蒸汽引导到所述机械装置的出口连通,该出口通道和该阀座具有多个壁,该壁在出口通道和该阀座之间形成平滑连续过渡而没有流向突然变化,以便在基本上不形成涡旋情况下将供应的蒸汽引导通过该座、经过该出口通道到达该出口,从而提供具有最小损失的最佳蒸汽流动性能。

在本发明的另一优选实施例中,提供一种用来将蒸汽供应到蒸汽涡轮机的阀,其包括:大致呈环状的阀座,它限定蒸汽流通道;在该通道内的控制阀,其包括控制阀头部,该控制阀头部在该控制阀下游侧具有凹口,而且该控制阀头部可朝该阀座运动或远离阀座;截止阀,它具有大致在该凹口内部的截止阀头部和用来在截止阀关闭位置与该阀座接合的密封表面;位于该阀座下方并与出口连通以便将供应的蒸汽引导到该涡轮机的出口通道;位于该控制阀头部上方并由在该控制阀头部一侧局部限定而且随该控制阀头部朝该阀座运动而增大的蒸汽平衡腔以及位于控制阀内部并与该平衡腔连通以便防止该平衡腔响应该控制阀头部朝该阀座的运动而降压的泄放孔。

在本发明的另一优选实施例中,提供一种用来将蒸汽供应到蒸汽涡轮机的阀,其包括:大致呈环状的阀座,它限定蒸汽流通道;在该通道内的控制阀,其包括控制阀头部,该控制阀头部在该控制阀下游侧具有凹口,而且该控制阀头部可朝该阀座运动或远离阀座;截止阀,它具有大致在该凹口内部的截止阀头部和用来在截止阀关闭位置与该阀座接合的密封表面;出口通道,它在该阀座下方并与用来将供应蒸汽引导到该涡轮机的出口连通,还包括连接在该控制阀头部和用来使该控制阀头部朝该阀座运动的致动器之间的阀杆以及使该阀杆和该控制阀头部相互连接的锯齿形螺纹。

附图说明

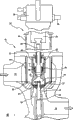

图1是根据本发明优选实施例构成的蒸汽阀的局部示意立视图,其中多个部分剖开;

图2是放大的局部断面图,其表示处于阀开启位置的流动控制阀和截止阀。

部件列表

蒸汽阀10、蒸汽阀体12、蒸汽入口14、蒸汽出口16、控制阀17、控制阀头部18、截止阀19、截止阀头部20、阀座21、控制阀致动器24、液压缸26、伺服阀28、十字头32、杆36、44、弹簧38、凹口40、环形表面41、出口通道50、环形滤网54、边缘56、平衡腔60、入口孔62、栓接轴环64。

具体实施方式

现在参见图1,它描述总体标号为10的蒸汽阀,该阀具有蒸汽阀体12、蒸汽入口14、蒸汽出口16、包括控制阀头部18的控制阀17以及包括截止阀头部20的截止阀19。在控制阀18上方设置总体标号为24的控制阀致动器,其包括由伺服阀28控制的液压缸26。该缸连接在十字头32上,进而又连接到杆36上,以便升高和降低控制阀17的阀头部18。弹簧38用来在接收到来自未示出的蒸汽阀控制系统的快速闭合信号情况下从缸26排出液压流体时迅速关闭控制阀17。可以理解,借助于使用伺服阀28,流量控制头部18相对于阀座21的位置能随涡轮机上的载荷变化而进行控制。

控制头部18具有环形的构形,它沿其下侧具有中空部或凹口40。处于关闭位置的控制阀头部18环形下边缘与该阀座接合和密封。截止阀头部20构造成容纳在凹口40内部,并且还在其下侧周围包括环形表面41以便在截止阀关闭位置与阀座21密封和接合。截止阀头部20安装在轴或杆44上,杆44延伸通过适当的密封件到达液压缸。如上文提及的美国专利No.6,070,605所述,通过现有技术中披露的控制系统,截止阀头部20跟随控制阀头部18运动。借助于跟随该控制阀的运动,控制阀头部18和截止阀头部20的组合体提供通过这些头部并通过该阀到达出口16的平稳分层蒸汽流动。欲知该控制阀和截止阀的工作详情,参见综合于此作为参考的美国专利No.6,070,605。

在截止阀头部20下方设置出口通道50,它引导蒸汽流通过该阀到达出口16。出口通道50和阀座21具有多个壁,这些壁在其间基本上形成平滑和连续的过渡而且不存在流动方向的任何突然变化。按照这种方式,通过阀座并经过出口通道到达出口的流过该阀蒸汽基本上没有涡旋,并且提供最佳的蒸汽流动特性,因而只有最小程度的损失。而且,出口通道50具有基本上不大于阀座21横截面积的横截面积和出口16。因此,在阀开启状态的蒸汽流模式倾向于没有显著涡旋因而压力损失最小的分层流动。

如图1所示,在控制阀17和截止阀19周围还提供环形滤网54。环形滤网54具有容纳在入口14壁内部形成的凹槽之中的边缘56。按照这种方式,滤网支承结构在蒸汽流道路径范围之外,因此蒸汽流通过环形滤网而不受到该滤网支承结构的任何阻碍。

本文中的蒸汽流阀还包括位于杆36周围并且连接在控制阀头部18上的平衡腔60。可以理解,当控制阀朝其开启和关闭位置运动时,由控制阀17局部限定的平衡腔60的容积是变化的。对于控制阀头部分18的快速关闭来说,重要的是在快速关闭运动期间使得施加在该阀上的任何阻力最小或消除。因此,由于控制阀头部朝阀座位移时平衡腔60的容积增大,泄放开口或入口孔62处于与平衡腔60以及与流过控制阀的蒸汽连通的状态。在控制阀17运动期间入口孔62能使平衡腔内的压力与入口蒸汽流压力平衡。因此在控制阀快速关闭朝阀座运动并且平衡腔60的容积增大时,平衡腔内与入口蒸汽流的压力平衡能防止平衡腔的压降或使其最小化,不然的话该压降可能抑制控制阀头部18朝阀座21的运动。

与蒸汽阀相关的许多问题之一是在整个使用期间氧化物结垢。可以理解,蒸汽阀需在例如为大约三至五年的多个使用周期之后拆卸和组装,因而能按照需要检查、再加工和/或更换各个零件。氧化物结垢频繁地造成拆卸该阀各个零件的很大困难。已变成特殊问题的区域是在控制阀杆和控制阀头部之间的接合处。阀杆36用拧紧在控制阀阴螺纹上的栓接轴环64连接在控制阀17上。这些螺纹上的氧化物结垢使该杆和控制阀的拆卸十分困难。然而,根据本发明的优选实施例,在该杆轴环和控制阀之间使用锯齿形螺纹。锯齿形螺纹66在该螺纹的后侧提供间隙,从而为氧化物结垢提供空间,但预防氧化物积聚到螺纹粘合因而防止该阀杆和控制阀拆卸的程度。

在结合目前认为是最实际和优选的实施例进行描述本发明的同时应该理解,本发明不受所披露实施例的限制,相反,它要覆盖包含在所附权利要求的精神和范围内的各种变型和等同结构。

Claims (9)

1.一种用来为下游机械装置供应蒸汽的阀(10),其包括:

限定蒸汽流通道并呈环状的阀座(21),

在所述通道内的控制阀(17),其包括控制阀头部(18),所述控制阀头部在所述控制阀下游侧具有凹口(40),而且所述控制阀头部可朝所述阀座运动或远离所述阀座;

截止阀(19),它具有在所述凹口内部的截止阀头部(20)和用来在截止阀关闭位置与所述阀座接合的密封表面(41);以及

出口通道(50),它在所述阀座下方并与用来将供应蒸汽引导到所述机械装置的出口(16)连通,所述出口通道具有不大于阀座横截面积的横截面积和出口,所述出口通道和所述阀座具有多个壁,该壁在该出口通道和该阀座之间形成平滑连续过渡而没有流向突然变化,以便在不形成涡旋情况下将供应的蒸汽引导通过所述座、经过所述出口通道到达所述出口,从而提供具有最小损失的蒸汽流动性能。

2.如权利要求1所述的阀,其特征在于,所述出口(16)与通过所述阀座的蒸汽流方向处于成直角的状态。

3.如权利要求2所述的阀,其特征在于,其包括在所述控制阀周围的滤网(54),所述滤网的边缘(56)容纳在到所述阀的入口通道(14)内并布置在所述入口和所述阀座之间,借此所述滤网的结构边缘在流道之外。

4.如权利要求1所述的阀,其特征在于,其包括蒸汽平衡腔(60)以及泄放孔(62),所述平衡腔位于所述控制阀头部上方并由在所述控制阀头部一侧局部限定并随所述控制阀头部朝所述阀座运动而增大,而所述泄放孔位于所述控制阀内部并与所平衡腔连通以便防止所述平衡腔响应所述控制阀头部朝所述阀座的运动造成的减压。

5.如权利要求4所述的阀,其特征在于,其包括到所述阀的入口通道(14)以便蒸汽流过所述阀,所述泄放孔处于与所述入口通道连通状态。

6.如权利要求1所述的阀,其特征在于,其包括阀杆(36)以及锯齿形螺纹(66),所述阀杆连接在所述控制阀和用来使所述控制阀朝所述阀座运动的致动器之间,而所述锯齿形螺纹使所述阀杆和所述控制阀头部相互连接。

7.如权利要求4所述的阀,其特征在于,其包括在所述控制阀周围的滤网(54),所述滤网的结构边缘(56)容纳在到所述阀的入口通道(14)内并布置在所述入口和所述阀座之间,借此所述滤网的结构边缘在流道之外。

8.如权利要求4所述的阀,其特征在于,其包括阀杆(36)以及锯齿形螺纹(66),所述阀杆连接在所述控制阀和用来使所述控制阀头部朝所述阀座运动的致动器之间,而所述锯齿形螺纹使所述阀杆和所述控制阀头部相互连接。

9.如权利要求4所述的阀,其特征在于,其包括滤网(54)、阀杆(36)及锯齿形螺纹(66),所述滤网(54)在所述控制阀周围,所述滤网的边缘(56)容纳在到所述阀的入口通道内并布置在所述入口和所述阀座之间,借此所述滤网的结构边缘在流道之外,所述阀杆(36)连接在所述控制阀头部和用来使所述控制阀头部朝所述阀座运动的致动器(24)之间,而所述锯齿形螺纹使所述阀杆和所述控制阀头部相互连接。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US10/233,606 US6655409B1 (en) | 2002-09-04 | 2002-09-04 | Combined stop and control valve for supplying steam |

| US10/233606 | 2002-09-04 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1488840A CN1488840A (zh) | 2004-04-14 |

| CN100436756C true CN100436756C (zh) | 2008-11-26 |

Family

ID=29549685

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB031554539A Expired - Fee Related CN100436756C (zh) | 2002-09-04 | 2003-09-04 | 用于供应蒸汽的组合式截止和控制阀 |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US6655409B1 (zh) |

| JP (1) | JP4472297B2 (zh) |

| KR (1) | KR100814172B1 (zh) |

| CN (1) | CN100436756C (zh) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103534518A (zh) * | 2011-02-18 | 2014-01-22 | 西门子公司 | 阀组件 |

| CN106795972A (zh) * | 2014-10-08 | 2017-05-31 | Spx流动有限公司 | 具有柔性塞的平衡双座球形阀 |

Families Citing this family (57)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20070272687A1 (en) * | 2006-05-26 | 2007-11-29 | Brian John Clark | Method and apparatus for covering a pressure vessel |

| US7543604B2 (en) * | 2006-09-11 | 2009-06-09 | Honeywell International Inc. | Control valve |

| JP4776494B2 (ja) * | 2006-10-18 | 2011-09-21 | 株式会社東芝 | 蒸気弁および蒸気タービン |

| US7596428B2 (en) * | 2007-03-29 | 2009-09-29 | General Electric Company | Methods and apparatuses for monitoring steam turbine valve assemblies |

| JP5022853B2 (ja) * | 2007-10-03 | 2012-09-12 | 株式会社東芝 | 蒸気弁および発電設備 |

| EP2068055A1 (de) | 2007-12-07 | 2009-06-10 | Siemens Aktiengesellschaft | Ventilantrieb |

| JP5022887B2 (ja) * | 2007-12-25 | 2012-09-12 | 株式会社東芝 | 蒸気弁装置および蒸気タービンプラント |

| GB2462266A (en) * | 2008-07-30 | 2010-02-03 | Cummins Turbo Tech Ltd | Variable geometry turbine with filter |

| ES2426465T3 (es) * | 2008-12-22 | 2013-10-23 | Artemis Intelligent Power Limited | Conjunto de válvula |

| EP2230429A1 (de) | 2009-03-16 | 2010-09-22 | Siemens Aktiengesellschaft | Platzsparendes Regel-Schnellschluss-Ventil für eine Dampfturbine |

| US20110162735A1 (en) * | 2010-01-04 | 2011-07-07 | General Electric Company | Flow guided steam strainer for steam turbine valves |

| JP5611005B2 (ja) * | 2010-11-22 | 2014-10-22 | 三菱重工業株式会社 | 蒸気タービン用加減弁および組合せ蒸気弁 |

| JP5674521B2 (ja) * | 2011-03-25 | 2015-02-25 | 株式会社東芝 | 蒸気弁装置および蒸気タービンプラント |

| ITMI20110830A1 (it) * | 2011-05-12 | 2012-11-13 | Alstom Technology Ltd | Valvola per una turbina a vapore 700 c |

| PL218378B1 (pl) | 2011-07-15 | 2014-11-28 | Gen Electric | Zespół zaworowy |

| US9557059B2 (en) | 2011-12-15 | 2017-01-31 | Honeywell International Inc | Gas valve with communication link |

| US9074770B2 (en) | 2011-12-15 | 2015-07-07 | Honeywell International Inc. | Gas valve with electronic valve proving system |

| US8947242B2 (en) | 2011-12-15 | 2015-02-03 | Honeywell International Inc. | Gas valve with valve leakage test |

| US9851103B2 (en) | 2011-12-15 | 2017-12-26 | Honeywell International Inc. | Gas valve with overpressure diagnostics |

| US8899264B2 (en) | 2011-12-15 | 2014-12-02 | Honeywell International Inc. | Gas valve with electronic proof of closure system |

| US8839815B2 (en) | 2011-12-15 | 2014-09-23 | Honeywell International Inc. | Gas valve with electronic cycle counter |

| US8905063B2 (en) | 2011-12-15 | 2014-12-09 | Honeywell International Inc. | Gas valve with fuel rate monitor |

| US9835265B2 (en) | 2011-12-15 | 2017-12-05 | Honeywell International Inc. | Valve with actuator diagnostics |

| US9846440B2 (en) | 2011-12-15 | 2017-12-19 | Honeywell International Inc. | Valve controller configured to estimate fuel comsumption |

| US9995486B2 (en) | 2011-12-15 | 2018-06-12 | Honeywell International Inc. | Gas valve with high/low gas pressure detection |

| US10422531B2 (en) | 2012-09-15 | 2019-09-24 | Honeywell International Inc. | System and approach for controlling a combustion chamber |

| US9234661B2 (en) | 2012-09-15 | 2016-01-12 | Honeywell International Inc. | Burner control system |

| KR20170029651A (ko) | 2012-12-21 | 2017-03-15 | 미츠비시 히타치 파워 시스템즈 가부시키가이샤 | 증기밸브 및 증기터빈 |

| EP2868970B1 (en) | 2013-10-29 | 2020-04-22 | Honeywell Technologies Sarl | Regulating device |

| US10024439B2 (en) | 2013-12-16 | 2018-07-17 | Honeywell International Inc. | Valve over-travel mechanism |

| US9279345B2 (en) | 2014-01-17 | 2016-03-08 | General Electric Company | Steam turbomachine valve having a valve member and seal assembly |

| US9279344B2 (en) * | 2014-02-24 | 2016-03-08 | General Electric Company | Valve poppet element defining balance chamber |

| EP2987962A1 (de) * | 2014-08-22 | 2016-02-24 | Siemens Aktiengesellschaft | Anordnung zum Verbinden eines Ventils mit einem Gehäuse |

| US9841122B2 (en) | 2014-09-09 | 2017-12-12 | Honeywell International Inc. | Gas valve with electronic valve proving system |

| US9645584B2 (en) | 2014-09-17 | 2017-05-09 | Honeywell International Inc. | Gas valve with electronic health monitoring |

| CA2949650C (en) | 2014-09-18 | 2018-11-20 | Halliburton Energy Services, Inc. | Adjustable steam injection tool |

| CN104454037B (zh) * | 2014-10-24 | 2016-04-20 | 东方电气集团东方汽轮机有限公司 | 汽轮机高压主汽调节阀阀杆与十字套联接结构 |

| US10503181B2 (en) | 2016-01-13 | 2019-12-10 | Honeywell International Inc. | Pressure regulator |

| US9683454B1 (en) | 2016-06-29 | 2017-06-20 | General Electric Company | Method and system for monitoring non-rotating turbomachine parts |

| US10151216B2 (en) | 2016-08-31 | 2018-12-11 | General Electric Technology Gmbh | Insulation quality indicator module for a valve and actuator monitoring system |

| US10544700B2 (en) | 2016-08-31 | 2020-01-28 | General Electric Technology Gmbh | Advanced startup counter module for a valve and actuator monitoring system |

| US10626749B2 (en) | 2016-08-31 | 2020-04-21 | General Electric Technology Gmbh | Spindle vibration evaluation module for a valve and actuator monitoring system |

| US10156153B2 (en) | 2016-08-31 | 2018-12-18 | General Electric Technology Gmbh | Advanced tightness test evaluation module for a valve and actuator monitoring system |

| US10871081B2 (en) | 2016-08-31 | 2020-12-22 | General Electric Technology Gmbh | Creep damage indicator module for a valve and actuator monitoring system |

| US10066501B2 (en) | 2016-08-31 | 2018-09-04 | General Electric Technology Gmbh | Solid particle erosion indicator module for a valve and actuator monitoring system |

| US10564062B2 (en) | 2016-10-19 | 2020-02-18 | Honeywell International Inc. | Human-machine interface for gas valve |

| JP6666280B2 (ja) * | 2017-02-15 | 2020-03-13 | 三菱日立パワーシステムズ株式会社 | 開閉弁、及び蒸気タービン |

| US10233786B2 (en) | 2017-03-28 | 2019-03-19 | General Electric Technology Gmbh | Actuator spring lifetime supervision module for a valve and actuator monitoring system |

| CN107255183A (zh) * | 2017-08-14 | 2017-10-17 | 上海核阀门股份有限公司 | 蜗壳降噪截止阀 |

| JP6946154B2 (ja) * | 2017-11-17 | 2021-10-06 | 三菱重工コンプレッサ株式会社 | 弁装置及び蒸気タービン |

| JP7051398B2 (ja) * | 2017-11-30 | 2022-04-11 | 三菱重工業株式会社 | 開閉弁及び蒸気タービンシステム |

| CN109958480B (zh) * | 2017-12-22 | 2021-09-17 | 中核核电运行管理有限公司 | 国产650mw核电汽轮机主调阀内漏改进方法 |

| US11073281B2 (en) | 2017-12-29 | 2021-07-27 | Honeywell International Inc. | Closed-loop programming and control of a combustion appliance |

| US10697815B2 (en) | 2018-06-09 | 2020-06-30 | Honeywell International Inc. | System and methods for mitigating condensation in a sensor module |

| JP7381226B2 (ja) * | 2019-06-17 | 2023-11-15 | 株式会社東芝 | 弁装置、発電設備および弁装置の弁座 |

| JP7417511B2 (ja) * | 2020-12-16 | 2024-01-18 | 三菱重工コンプレッサ株式会社 | 弁装置及び蒸気タービン |

| CN114278396A (zh) * | 2021-12-03 | 2022-04-05 | 哈尔滨汽轮机厂有限责任公司 | 一种具备连续调节蒸汽流量功能的汽轮机用中压调节阀门 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4114652A (en) * | 1975-04-30 | 1978-09-19 | Bbc Brown Boveri & Company Limited | Combined stop and control valve |

| US4114651A (en) * | 1975-04-30 | 1978-09-19 | Bbc Brown Boveri & Company Limited | Combined stop and control valve |

| US4121617A (en) * | 1975-04-30 | 1978-10-24 | Bbc Brown, Boveri & Company Limited | Combined stop and control valve |

| US4384593A (en) * | 1980-03-10 | 1983-05-24 | Bbc Brown Boveri And Company Limited | Shutoff element for gaseous media with a device for damping self-excited acoustical vibrations in cavities |

| US4481776A (en) * | 1980-12-02 | 1984-11-13 | Hitachi, Ltd. | Combined valve |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CH539805A (de) * | 1971-09-24 | 1973-07-31 | Bbc Brown Boveri & Cie | Kombiniertes Schnellschluss- und Regelventil |

| JPS6038521B2 (ja) * | 1981-01-21 | 1985-09-02 | 株式会社日立製作所 | 組合せ蒸気弁 |

| JP3771378B2 (ja) * | 1998-07-07 | 2006-04-26 | 株式会社日立製作所 | 蒸気弁 |

| US6070605A (en) | 1999-01-25 | 2000-06-06 | General Electric Co. | Steam turbine valve disk vibration reducer |

| JP2001004062A (ja) * | 1999-06-17 | 2001-01-09 | Benkan Corp | 流量制御用バルブ |

-

2002

- 2002-09-04 US US10/233,606 patent/US6655409B1/en not_active Expired - Lifetime

-

2003

- 2003-08-29 KR KR1020030060135A patent/KR100814172B1/ko active IP Right Grant

- 2003-09-03 JP JP2003310814A patent/JP4472297B2/ja not_active Expired - Lifetime

- 2003-09-04 CN CNB031554539A patent/CN100436756C/zh not_active Expired - Fee Related

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4114652A (en) * | 1975-04-30 | 1978-09-19 | Bbc Brown Boveri & Company Limited | Combined stop and control valve |

| US4114651A (en) * | 1975-04-30 | 1978-09-19 | Bbc Brown Boveri & Company Limited | Combined stop and control valve |

| US4121617A (en) * | 1975-04-30 | 1978-10-24 | Bbc Brown, Boveri & Company Limited | Combined stop and control valve |

| US4384593A (en) * | 1980-03-10 | 1983-05-24 | Bbc Brown Boveri And Company Limited | Shutoff element for gaseous media with a device for damping self-excited acoustical vibrations in cavities |

| US4481776A (en) * | 1980-12-02 | 1984-11-13 | Hitachi, Ltd. | Combined valve |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103534518A (zh) * | 2011-02-18 | 2014-01-22 | 西门子公司 | 阀组件 |

| CN106795972A (zh) * | 2014-10-08 | 2017-05-31 | Spx流动有限公司 | 具有柔性塞的平衡双座球形阀 |

| CN106795972B (zh) * | 2014-10-08 | 2019-07-09 | Spx流动有限公司 | 具有柔性塞的平衡双座球形阀 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP4472297B2 (ja) | 2010-06-02 |

| KR100814172B1 (ko) | 2008-03-14 |

| JP2004100698A (ja) | 2004-04-02 |

| US6655409B1 (en) | 2003-12-02 |

| CN1488840A (zh) | 2004-04-14 |

| KR20040021538A (ko) | 2004-03-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN100436756C (zh) | 用于供应蒸汽的组合式截止和控制阀 | |

| JP2004100698A5 (zh) | ||

| KR101375391B1 (ko) | 밸브 어셈블리 | |

| CN101576193A (zh) | 回流防止器 | |

| GB2117875A (en) | Solenoid valves having power amplifiers | |

| US8333218B2 (en) | Proportional pressure controller | |

| WO2013111503A1 (ja) | アクチュエータ | |

| GB2256031A (en) | Automatic bleed valve | |

| US4724866A (en) | Speed control valve | |

| US6349920B1 (en) | Poppet valve shaping for quick valve opening | |

| JPH06100289B2 (ja) | パイロツト弁 | |

| CN115978212B (zh) | 一种自带止回功能的截止阀 | |

| JPH08506886A (ja) | 蒸気変換弁 | |

| US5105847A (en) | Gas pressure control valve cartridge | |

| KR20140104599A (ko) | 이중 유로 글로브 밸브 | |

| JP4842716B2 (ja) | パイロットチェック弁及びこれを備えた流体圧回路 | |

| KR20140036590A (ko) | 방식 전환 가능형 유체 이송제어용 개폐밸브 | |

| KR200467301Y1 (ko) | 저진동 저소음 볼륨 부스터 | |

| JP3852917B2 (ja) | 開放弁 | |

| US20040129908A1 (en) | Valve assembly | |

| CN215257980U (zh) | 一种可进行状态转换的分流阀结构 | |

| WO2002090778A3 (de) | Hydraulische steueranordnung mit wegeventil zur steuerung eines einfachwirkenden hydraulischen verbrauchers hinsichtlich richtung und geschwindigkeit | |

| KR200380300Y1 (ko) | 가변 오리피스 및 이를 구비한 유압회로 | |

| CN2699087Y (zh) | 恒压防滴阀 | |

| CN107061818B (zh) | 一种减压阀门 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| CF01 | Termination of patent right due to non-payment of annual fee |

Granted publication date: 20081126 Termination date: 20200904 |

|

| CF01 | Termination of patent right due to non-payment of annual fee |