CN100415485C - 用于测量模具型腔中的熔融材料的温度的方法和装置 - Google Patents

用于测量模具型腔中的熔融材料的温度的方法和装置 Download PDFInfo

- Publication number

- CN100415485C CN100415485C CNB038049988A CN03804998A CN100415485C CN 100415485 C CN100415485 C CN 100415485C CN B038049988 A CNB038049988 A CN B038049988A CN 03804998 A CN03804998 A CN 03804998A CN 100415485 C CN100415485 C CN 100415485C

- Authority

- CN

- China

- Prior art keywords

- nozzle

- thermocouple

- mold cavity

- temperature

- injection moulding

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Lifetime

Links

- 238000000034 method Methods 0.000 title claims description 20

- 239000012768 molten material Substances 0.000 title abstract 3

- 238000001746 injection moulding Methods 0.000 claims abstract description 42

- 239000000463 material Substances 0.000 claims description 37

- 238000001816 cooling Methods 0.000 claims description 30

- 238000000465 moulding Methods 0.000 claims description 5

- 230000001105 regulatory effect Effects 0.000 claims description 5

- 239000000155 melt Substances 0.000 abstract description 8

- 239000002826 coolant Substances 0.000 description 10

- 239000012530 fluid Substances 0.000 description 10

- 238000005259 measurement Methods 0.000 description 9

- 238000002347 injection Methods 0.000 description 8

- 239000007924 injection Substances 0.000 description 8

- 229920005644 polyethylene terephthalate glycol copolymer Polymers 0.000 description 4

- 230000004888 barrier function Effects 0.000 description 3

- 229920006038 crystalline resin Polymers 0.000 description 3

- 230000004927 fusion Effects 0.000 description 2

- 230000008569 process Effects 0.000 description 2

- 230000004044 response Effects 0.000 description 2

- 238000013459 approach Methods 0.000 description 1

- 230000008901 benefit Effects 0.000 description 1

- 239000012809 cooling fluid Substances 0.000 description 1

- 238000002425 crystallisation Methods 0.000 description 1

- 230000008025 crystallization Effects 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 230000001771 impaired effect Effects 0.000 description 1

- 239000012212 insulator Substances 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000000289 melt material Substances 0.000 description 1

- 230000004048 modification Effects 0.000 description 1

- 238000012986 modification Methods 0.000 description 1

- 239000004033 plastic Substances 0.000 description 1

- 229920003023 plastic Polymers 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/76—Measuring, controlling or regulating

- B29C45/78—Measuring, controlling or regulating of temperature

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C45/2737—Heating or cooling means therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/72—Heating or cooling

- B29C45/73—Heating or cooling of the mould

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C2045/2683—Plurality of independent mould cavities in a single mould

- B29C2045/2687—Plurality of independent mould cavities in a single mould controlling the filling thereof

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C45/2737—Heating or cooling means therefor

- B29C2045/274—Thermocouples or heat sensors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C45/2737—Heating or cooling means therefor

- B29C2045/274—Thermocouples or heat sensors

- B29C2045/2741—Plurality of independent thermocouples or heat sensors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76003—Measured parameter

- B29C2945/7604—Temperature

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76177—Location of measurement

- B29C2945/7618—Injection unit

- B29C2945/7621—Injection unit nozzle

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76177—Location of measurement

- B29C2945/76254—Mould

- B29C2945/76257—Mould cavity

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76177—Location of measurement

- B29C2945/76254—Mould

- B29C2945/76274—Mould runners, nozzles

- B29C2945/76277—Mould runners, nozzles nozzles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76177—Location of measurement

- B29C2945/76287—Moulding material

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76494—Controlled parameter

- B29C2945/76498—Pressure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76494—Controlled parameter

- B29C2945/76518—Energy, power

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76494—Controlled parameter

- B29C2945/76531—Temperature

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76494—Controlled parameter

- B29C2945/76545—Flow rate

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76494—Controlled parameter

- B29C2945/76622—Degree of crosslinking, solidification

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76655—Location of control

- B29C2945/76732—Mould

- B29C2945/76752—Mould runners, nozzles

- B29C2945/76755—Mould runners, nozzles nozzles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76655—Location of control

- B29C2945/76775—Fluids

- B29C2945/76785—Fluids hydraulic fluids

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C2945/00—Indexing scheme relating to injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould

- B29C2945/76—Measuring, controlling or regulating

- B29C2945/76929—Controlling method

- B29C2945/76939—Using stored or historical data sets

- B29C2945/76943—Using stored or historical data sets compare with thresholds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C45/2701—Details not specific to hot or cold runner channels

- B29C45/2703—Means for controlling the runner flow, e.g. runner switches, adjustable runners or gates

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/26—Moulds

- B29C45/27—Sprue channels ; Runner channels or runner nozzles

- B29C45/28—Closure devices therefor

- B29C45/2806—Closure devices therefor consisting of needle valve systems

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C45/00—Injection moulding, i.e. forcing the required volume of moulding material through a nozzle into a closed mould; Apparatus therefor

- B29C45/17—Component parts, details or accessories; Auxiliary operations

- B29C45/72—Heating or cooling

- B29C45/73—Heating or cooling of the mould

- B29C45/7337—Heating or cooling of the mould using gas or steam

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2105/00—Condition, form or state of moulded material or of the material to be shaped

- B29K2105/25—Solid

- B29K2105/253—Preform

Abstract

一种注塑装置,包括具有歧管通道的歧管,该歧管通道用于接受压力下的熔融材料的熔体流并且将该熔体流传送到喷嘴的喷嘴通道中。模具型腔接受来自喷嘴的熔体流,喷嘴通道经由模具浇口与模具型腔相通。热电偶与模具型腔中的模具型芯相连,以便测量模具型腔中的熔融材料的温度。

Description

技术领域

本发明涉及一种注塑装置,尤其是用于测量模具型腔中的熔融材料的温度的方法和装置。

背景技术

注塑装置中的温度的准确控制对于在注塑工艺中维持生产率和产品质量的控制来说是很重要的。通常设置了加热器来加热流经歧管和喷嘴的熔体,并且设置冷却通道来冷却模具型腔中的熔体。在注射期间,熔体必须保持在熔体材料所要求的温度范围内。一旦将熔体注射到模具型腔中,熔体便以预定的速度冷却,从而生产出模制品。这一预定冷却速度至少部分地根据熔体在进入到模具型腔中时的温度来计算。

在多型腔的注塑装置中,进入模具型腔的熔体的温度通常在从一个模具型腔到另一模具型腔之间有所变化。这样,对于各模具型腔中的塑料而言,最优的冷却时间可能稍有不同。对于使用半结晶树脂的注塑应用而言,这一温度变化通常会导致生产出质量较差的模制品。

半结晶树脂的一种普遍应用是在聚对苯二甲酸乙二醇酯(PET)预成型件的生产中。为了生产出高质量的预成型件,半结晶树脂必须在模具型腔中冷却足够的时间,以允许预成型件在被顶出前固化,同时避免形成结晶部分。结晶部分通常形成在模具浇口附近的预成型件的底部中。结晶部分使得预成型件变脆,因此在进行吹塑模制时可能会裂开。

已经进行了许多种尝试来优化PET预成型件的冷却,以便有效地生产出高质量的模制产品。例如,2001年1月9日授予HuskyInjection Molding Systems Ltd.的题为“预成型件的后模制冷却方法和装置”的美国专利No.6171541公开了一种快速注塑工艺,其中在完成冷却工序之前将模制品从模具中顶出来。

2001年8月21日授予Husky Injection Molding Systems Ltd.的题为“型芯流体速度诱导器”的美国专利No.6276922公开了一种位于冷却供应管的出口处的诱导器,其用于改善整个型芯上的冷却供应循环。

2001年1月23日授予Jobst Gellert的题为“注塑冷却用的型腔镶件”的美国专利No.6176700公开了一种注塑装置,其包括具有冷却流体流动通道的型腔镶件,该通道在镶件的整体内部和外部之间延伸。型腔镶件用于改善模制品的冷却工艺。喷嘴包括有热电偶,其可测量熔融材料在离开喷嘴时的温度。

尽管所有这些尝试均可改善模制品的冷却工艺,然而测量模具型腔中的熔融材料的温度的方法并未得到改进。由于在喷嘴出口处可能存在较大的温度差异,因此希望能得到针对该区域的额外的温度测量。因此,本发明的一个目的是提供一种用于测量模具型腔中的熔融材料的温度的方法和装置。

发明内容

根据本发明的一个方面,提供了一种注塑装置,包括:具有歧管通道的歧管,所述歧管通道用于接受压力下的熔融材料的熔体流并且将所述熔体流传送到喷嘴的喷嘴通道中;用于接受来自所述喷嘴的熔体流的模具型腔,所述喷嘴通道经由模具浇口与所述模具型腔相通;和位于模具型腔的热电偶,其用于测量所述模具型腔中的熔融材料的温度,其中所述喷嘴包括一个喷嘴加热器,所述热电偶连接到一个控制器,其特征在于,位于模具型腔的靠近所述模具浇口处的热电偶所测量的温度用于控制所述喷嘴加热器。

根据本发明的另一方面,提供了一种模制部件的方法,包括:将熔融材料的熔体流在压力下从歧管的歧管通道中经由喷嘴的喷嘴通道和模具浇口传送到模具型腔中,所述熔体流被与所述喷嘴相连的喷嘴加热器所加热;使用第一热电偶来测量所述模具型腔中的熔融材料的温度;和使用第二热电偶来测量所述喷嘴中的熔融材料的温度;其特征在于,模具型腔中的所述第一热电偶用于控制喷嘴加热器。

附图说明

下面将参考附图来更充分地介绍本发明的实施例,在图中:

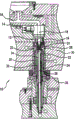

图1是根据本发明一个实施例的多型腔注塑装置的一部分的剖视图;

图2是根据本发明另一实施例的图1所示注塑装置的一部分的放大视图;

图3是根据本发明另一实施例的注塑装置的示意性剖视图;

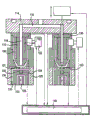

图4是根据本发明另一实施例的多型腔注塑装置的一部分的剖视图;

图5是根据本发明的共注塑装置;和

图6是具有浇口的注塑装置的示意性剖视图,该浇口装有用于调节浇口尺寸的阀。

具体实施方式

现在来看图1,图中显示了用于模制瓶子预成型件的多型腔注塑装置10的一部分。该注塑装置与在2001年1月23日授予Gellert的美国专利No.6176700所公开的相似,该专利的内容通过引用结合于本文中。如图所示,注塑装置10包括歧管14,其具有熔融材料从中流过的歧管熔体通道16。喷嘴12的喷嘴通道18接受来自歧管14的熔融材料,并经由模具浇口21将熔融材料流引入到模具型腔20中,在该型腔中可以形成模制出的瓶子预成型件(未示出)。在喷嘴12中设有喷嘴热电偶19,以便测量熔融材料在其被注射到模具型腔20中时的温度。

模具型腔20设置在型腔板30中,并且由模具型芯22的第一模具型腔表面34和模板组件35所限定的第二模具型腔表面24来界定。模具型芯22的第一模具型腔表面34与瓶子预成型件的内表面相接触,而第二模具型腔表面24与瓶子预成型件的外表面相接触。中央流体冷却管道26延伸穿过模具型芯22。冷却剂流经中央流体冷却管道26,从而冷却模制出的瓶子预成型件。模具型腔20的第二模具型腔表面24由冷却管路28来冷却,其延伸穿过型腔板30。适当的冷却剂包括水、油或气体。模具型芯22的中央流体冷却管道26和型腔板30的冷却管路28通常不共用一种冷却剂。

注塑装置10还包括热电偶32,其沿着它的一部分长度延伸穿过模具型芯22。在模具型芯22中钻出了用于容纳热电偶32的孔。热电偶32可测量模具型腔20中的熔融材料的温度。

在操作中,熔体流在压力下经过歧管通道16流入到注塑装置10的多个喷嘴12的喷嘴通道18中。然后熔体流被注射到模具型腔20中。在注射完成后由流经相应的中央流体冷却管道26的冷却剂来冷却各个模具型腔20。一旦过去预定的冷却时间,就将所模制出的预成型件从模具型腔20中顶出。

所模制出的预成型件的冷却速度取决于流经中央流体冷却管道26的冷却剂的温度以及流经型腔板30的冷却管路28的冷却剂的温度。由于具有多个模具型腔20的注塑装置通常使同一冷却剂经由各模具型腔20的中央流体冷却管道26而循环,因此当冷却剂流经各个模具型腔20时,冷却剂可能不会处于精确相同的温度下。这样,各模具型腔20的冷却速度将有所不同。

通过对在模具浇口21的附近即在模具型腔20和喷嘴12中的熔融材料进行两种独立的温度测量,便可提高测量的精度和可靠性。另外,模具型芯22上的热电偶32使得能够更加容易地确定预成型件中的结晶原因。可以理解,可顺序地或同时地通过热电偶32和喷嘴热电偶19来测量温度。

现在来看图2,图中显示了另一种装置。在该装置中,热电偶32设置在更接近于模具型芯22的末端23的位置处。在图3所示在装置中,在模具型芯22中设置了一对热电偶32a和32b。具体地说,热电偶32a设置在模具型芯22的表面,而热电偶32b设置在中央流体冷却管道26中。

在图1,2和3所示的注塑装置中,热电偶32或热电偶32a和32b与喷嘴热电偶19的组合具有还能提供失效保护的优点。如果喷嘴热电偶19因任一原因而失效,仍可通过使用热电偶32,32a或32b来确定模具型腔20的温度。

在2000年6月20日授予Gellert的美国专利No.6077067中公开了一种不同类型的冷却型芯,该专利的内容通过引用结合于本文中。本领域的技术人员可以理解,可通过与结合图1,2和3所述的类似方式将至少一个热电偶连接到Gellert专利所公开的冷却型芯中。

来看图4,下面将介绍用于模制PET预成型件的多型腔注塑装置100,其类似于图1所示的注塑装置。注塑装置100包括歧管114,其具有从中延伸穿过的歧管熔体通道116。歧管熔体通道116与机器喷嘴(未示出)相通,以便从中接受熔体流。热流道喷嘴112包括喷嘴通道118,其用于从歧管熔体通道116中接受熔融材料的熔体流。喷嘴加热器150与喷嘴112相连,以便加热通过各喷嘴通道118的熔体流。喷嘴加热器150包括用于调节加热器输出的加热器控制部件152。模具型腔120设于各喷嘴112的嘴头附近并与喷嘴通道118相通,以便经由相应的模具浇口121和123来接受熔融材料流。

模具浇口121是热浇口,而模具浇口123是阀浇口。阀针130延伸穿过喷嘴通道118,以便打开和关闭阀浇口123。这种类型的浇口设置允许对流经模具浇口123的熔体体积进行调节。阀针式浇口系统在本领域中是众所周知的,因此这里不再进一步介绍。

喷嘴热电偶119与喷嘴112相连,以便在熔融材料注射到模具型腔120中时测量其温度。

各模具型腔120由模具型芯122的第一模具型腔表面134和模板125的第二模具型腔表面124来界定。模具型芯122的第一模具型腔表面134与瓶子预成型件的内表面相接触,而第二模具型腔表面124与瓶子预成型件的外表面相接触。中央流体冷却管道126延伸穿过模具型芯122,以便冷却所模制出的预成型件。在各模具型腔120的模具型芯122中设有热电偶132,以便测量模具型腔120中的熔体流的温度。如图所示,热电偶132位于模具型芯134的末端处,然而可以理解,热电偶132也可位于模具型芯122上的任何其它的适当点处。

控制器140可与喷嘴热电偶119和模具型腔热电偶132进行通信,以便从中接收温度信息。控制器140还可与喷嘴加热器150的加热器控制部件152进行通信,以便允许控制器140可调节喷嘴加热器150的输出。可对控制器140进行编程,从而至少包括用于模具型腔120中的熔体的预定目标温度数据。控制器140包括逻辑处理器,其能够将由热电偶132提供的实际温度测量与模具型腔的预定目标温度进行比较,并计算出用于各喷嘴118的加热器控制部件152的输入设定。

在操作中,熔体流在压力下经由歧管通道116流入到注塑装置100的多个喷嘴112的喷嘴通道118中。然后熔体流被注射到模具型腔120中。在注射工艺开始时,将温度测量从喷嘴热电偶119和模具型腔热电偶132中发送给控制器140。然后控制器140将模具型腔120的温度与目标温度相比较。如果模具型腔120的温度低于目标温度,则控制器140发送信号给加热器控制部件152,将加热器的输出提高一定的量。类似的,如果模具型腔120的温度高于目标温度,则控制器140发送信号给加热器控制部件152,将加热器的输出降低一定的量。加热器热电偶119用作检验装置,以保证喷嘴加热器150正确地操作。控制器允许独立地调节进入到各模具型腔120中的熔体的温度,以便保证熔体的温度在注塑装置100的各模具型腔120中保持一致。

在注射之后通过流经相应中央流体冷却管道126的冷却剂来冷却各模具型腔120。一旦过去预定的冷却时间,就将所模制出的预成型件从模具型腔120中顶出。

在模具浇口123具有阀针130的情况下,控制器140也可以控制阀针的行程。这就使得能够响应于由热电偶119,132所提供的温度信息来调节进入到模具型腔中的熔体体积。

现在来看图5,图中大致显示了共注塑装置50。该共注塑装置与在1986年9月2日授予Krishnakumar等人的美国专利No.4609516中所公开的相似,该专利的内容通过引用结合于本文中。 共注塑装置50包括模具型腔52,其由模具型芯56的第一模具型腔表面55和模板组件57的第二模具型腔表面54来界定。热电偶62位于模具型芯56上,以便测量模具型腔52内的温度。第二热电偶(未示出)安装在第一热电偶62的下游。

在共注塑工艺中,第一熔融材料从喷嘴58中经由模具浇口64进入到模具型腔52中,而内部熔融阻挡层则经由第二材料分配器60而进入到第一材料中。成品是一种具有被第一材料层所包围的阻挡层的模制品。在共注塑工艺期间,第一熔融材料层在模具型腔52中冷却,并成为熔融阻挡层的隔热体。为了保证有高质量的模制品,测量模具型腔52的入口处的各熔融材料的温度是很关键的。位于模具型芯56上的热电偶为操作人员提供了重要的信息,因此可对温度进行优化以生产出高质量的模制产品。

或者,热电偶62可以与如图3所示的热电偶32a和32b类似的方式来安装。

来看图6,图中显示了具有浇口82的注塑装置80,该浇口设有可轴向运动阀84以调节浇口的大小。阀84由驱动器86来控制。图6所示的注塑装置80具有大模具型腔88。该注塑装置与在1996年9月17日授予Kazmer的美国专利No.5556582中所公开的相似,该专利的内容也通过引用结合于本文中。

在大模具型腔如图6所示的模具型腔88中,在填充模具型腔时熔融材料保持在预定的温度下是很重要的。如果熔融材料在填满模具型腔之前冷却,那么所得模制品的质量将受损。通常来说,在各浇口82处设有热电偶(未示出),以便可测量熔融材料在其流入到模具型腔88中时的温度。在离各浇口82为预定的距离处设置了第二热电偶90,以便提供对模具型腔88中的熔融材料的额外温度测量。这一附加热电偶90提供了信息,从而可以监控模具型腔88中的模制品的温度差异。

图5所示的共注塑装置50和图6所示的注塑装置80也可包括控制器40。控制器40可以与针对图4所示注塑装置100所介绍的那样来操作,使得能够响应于由模具型腔中的热电偶所提供的温度信息来调节进入到模具型腔中的熔体流的温度。

本领域的技术人员可以理解,在本申请中讨论的热电偶可以是适用于注塑装置的任何类型的热电偶。或者,除此之外还可以使用绕线电阻温度检测器、热敏电阻和固态传感器。在一个优选实施例中,可采用由Minco Products Inc.制造的薄膜电阻温度检测器来代替热电偶119和132。

虽然已经介绍了本发明的优选实施例,然而本领域的技术人员可以理解,在不脱离由所附权利要求限定的本发明的精神和范围的前提下,可以对本发明进行多种变更和修改。这里讨论的所有专利及出版物均整体地结合于本文中。

Claims (16)

1. 一种注塑装置(100),包括:

具有歧管通道(116)的歧管(114),所述歧管通道用于接受压力下的熔融材料的熔体流并且将所述熔体流传送到喷嘴(112)的喷嘴通道(118)中;

用于接受来自所述喷嘴(112)的熔体流的模具型腔(120),所述喷嘴通道(118)经由模具浇口(121)与所述模具型腔(120)相通;和

位于模具型腔(120)的热电偶(132),其用于测量所述模具型腔(120)中的熔融材料的温度,其中所述喷嘴(112)包括一个喷嘴加热器(150),所述热电偶(132)连接到一个控制器(140);

其特征在于,位于模具型腔(120)的靠近所述模具浇口(121)处的热电偶(132)所测量的温度用于控制所述喷嘴加热器(150)。

2. 根据权利要求1所述的注塑装置(100),其特征在于,所述热电偶(132)连接到所述模具型芯(122)。

3. 根据权利要求1所述的注塑装置(100),其特征在于,所述热电偶(132)连接到所述模具浇口(121)。

4. 根据权利要求1所述的注塑装置(100),其特征在于,所述喷嘴(112)具有喷嘴热电偶(119),所述喷嘴热电偶(119)用于测量所述喷嘴加热器(150)附近的温度。

5. 根据权利要求4所述的注塑装置(100),其特征在于,所述喷嘴热电偶(119)通过调节所述喷嘴加热器(150),以控制熔体的温度,即使位于所述模具型腔(120)的所述热电偶(132)失效。

6. 根据权利要求1-5中任一项所述的注塑装置(100),其特征在于,可移动的阀针(130)控制从所述喷嘴(112)流到所述模具型腔(120)的熔体流。

7. 根据权利要求6所述的注塑装置(100),其特征在于,所述阀针(130)的移动由所述控制器(140)控制,该控制器接收来自所述喷嘴热电偶(119)的数据。

8. 根据权利要求1至5中任一项所述的注塑装置(100),其特征在于,所述喷嘴加热器(150)连接到所述控制器(140),所述控制器(140)接收来自喷嘴(112)下游的至少一个热电偶(132)的输出温度,并且比较所述输出温度和预定目标温度,从而调节所述喷嘴加热器(150)的加热器输出。

9. 根据权利要求8所述的注塑装置,其特征在于,设有位于多个模具型腔(120)中的多个热电偶(132)和包含在多个喷嘴(112)中的多个喷嘴加热器(150),所述控制器(140)与所述多个热电偶(132)及所述多个喷嘴加热器(150)连接。

10. 根据权利要求9所述的注塑装置,其特征在于,所述控制器(140)根据由各个所述多个模具型腔(120)的相应的热电偶(132)所提供的温度独立地调节各个所述多个喷嘴(112)的所述喷嘴加热器(150)。

11. 一种模制部件的方法,包括:

将熔融材料的熔体流在压力下从歧管(114)的歧管通道(116)中经由喷嘴(112)的喷嘴通道(118)和模具浇口(121)传送到模具型腔(120)中,所述熔体流被与所述喷嘴(112)相连的喷嘴加热器(150)所加热;

使用第一热电偶(132)来测量所述模具型腔(120)中的熔融材料的温度;和

使用第二热电偶(119)来测量所述喷嘴(112)中的熔融材料的温度;

其特征在于,所述模具型腔(120)中的所述第一热电偶(132)用于控制所述喷嘴加热器(150)。

12. 根据权利要求11所述的方法,其特征在于,所述温度通过所述第一热电偶(132)和所述第二热电偶(119)来同时测量。

13. 根据权利要求11所述的方法,其特征在于,所述温度通过所述第一热电偶(132)和所述第二热电偶(119)来顺序地测量。

14. 根据权利要求11至13中任一项所述的方法,还包括:

将所述模具型腔(120)中的所述熔融材料的所述温度提供给控制器(140);

将所述模具型腔(120)中的所述熔融材料的所述温度与存储在所述控制器(140)中的预定目标温度相比较;和

调节所述喷嘴加热器(150)的输出,以便使进入所述模具型腔(120)的熔融材料的所述温度与所述预定目标温度相符。

15. 根据权利要求14所述的方法,其特征在于,所述第一热电偶(132)位于一个冷却管道(126)内,该冷却管道穿过一个所述模具型腔(120)的模具型芯(122)。

16. 根据权利要求14所述的方法,其特征在于,所述第一热电偶(132)位于所述模具型腔(120)的模具浇口(121)的区域内。

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US34627902P | 2002-01-09 | 2002-01-09 | |

| US60/346,279 | 2002-01-09 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN1638943A CN1638943A (zh) | 2005-07-13 |

| CN100415485C true CN100415485C (zh) | 2008-09-03 |

Family

ID=23358697

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CNB038049988A Expired - Lifetime CN100415485C (zh) | 2002-01-09 | 2003-01-09 | 用于测量模具型腔中的熔融材料的温度的方法和装置 |

Country Status (9)

| Country | Link |

|---|---|

| US (2) | US6936199B2 (zh) |

| EP (2) | EP1463621B1 (zh) |

| JP (1) | JP4350520B2 (zh) |

| CN (1) | CN100415485C (zh) |

| AT (1) | ATE373558T1 (zh) |

| AU (1) | AU2003202931A1 (zh) |

| CA (1) | CA2473112C (zh) |

| DE (2) | DE60316405T2 (zh) |

| WO (1) | WO2003059598A1 (zh) |

Families Citing this family (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CA2392610C (en) | 2002-07-05 | 2010-11-02 | Long Manufacturing Ltd. | Baffled surface cooled heat exchanger |

| US7105123B2 (en) * | 2003-02-20 | 2006-09-12 | Mold-Masters Limited | Heat dissipation device for and method of dissipating heat from a manifold |

| US7210917B2 (en) * | 2003-12-30 | 2007-05-01 | Mold-Masters Limited | Two position double injection molding apparatus |

| US8066498B2 (en) * | 2005-09-29 | 2011-11-29 | Tdk Corporation | Magnetic field molding device, method for producing ferrite magnet, and die |

| DE102006021229A1 (de) * | 2006-05-06 | 2007-11-15 | Mht Mold & Hotrunner Technology Ag | Bodeneinsatz mit Wärmeisolation |

| US7421310B2 (en) * | 2006-06-12 | 2008-09-02 | Husky Injection Molding Systems Ltd. | Method and apparatus for controlling cooling rates during post-mold cooling of a molded article |

| CA2591730A1 (en) * | 2006-06-16 | 2007-12-16 | Mold-Masters Limited | Open loop pressure control for injection molding |

| US20080035299A1 (en) * | 2006-08-11 | 2008-02-14 | Husky Injection Molding Systems Ltd. | Detection of plug blow from metal-molding system, amongst other things |

| US20080085334A1 (en) * | 2006-10-10 | 2008-04-10 | Husky Injection Molding Systems Ltd. | Hot Runner System Sensor |

| US7731489B2 (en) * | 2006-12-21 | 2010-06-08 | Mold-Masters (2007) Limited | Valve for co-injection molding apparatus |

| DE602007005081D1 (de) * | 2006-12-22 | 2010-04-15 | Mold Masters 2007 Ltd | Spritzgießsystem mit einem Bus |

| US7412301B1 (en) | 2007-02-08 | 2008-08-12 | Husky Injection Molding Systems Ltd. | Identifying quality molded article based on determination of plug blow |

| CA2687680C (en) * | 2007-08-24 | 2011-11-29 | Husky Injection Molding Systems Ltd. | An apparatus for controlling melt flow in a melt distribution network |

| TW200927448A (en) * | 2007-12-28 | 2009-07-01 | Univ Chung Yuan Christian | Temperature control system for forming machine and control method thereof |

| US7762802B2 (en) * | 2008-02-21 | 2010-07-27 | Husky Injection Molding Systems, Ltd. | Mold insert stack for use in an injection mold and a coupler thereof |

| EP2632685A1 (en) * | 2010-10-27 | 2013-09-04 | Husky Injection Molding Systems S.A. | Mold-tool system including air cavity circuit, and means for forcing relatively cooler air stream to air cavity circuit |

| CN102848521A (zh) * | 2011-06-29 | 2013-01-02 | 深圳富泰宏精密工业有限公司 | 用于注塑成型模具的灌嘴及该注塑成型模具 |

| US9387616B2 (en) | 2012-08-03 | 2016-07-12 | Otto Männer Innovation GmbH | Hot runner injection molding apparatus with additional controller |

| DE102014114874A1 (de) * | 2013-11-22 | 2015-05-28 | Christopherus Bader | Verfahren zum Regeln der Füllung von zumindest einer Kavität |

| CN105108974B (zh) * | 2015-09-28 | 2016-09-28 | 湖南昊兴机械科技有限公司 | 一种大容量塑料瓶的管胚注塑成型方法及管胚模 |

| CN116669881A (zh) * | 2021-03-31 | 2023-08-29 | 住友重机械工业株式会社 | 注射成型机 |

| CN114894332B (zh) * | 2022-05-12 | 2023-01-24 | 中科航星科技有限公司 | 航空发动机尾喷管的测温装置 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1063443A (zh) * | 1991-01-25 | 1992-08-12 | 乔布斯特·乌尔里克·盖勒特 | 在喷嘴的前部中具有整体冷却的注射成型装置 |

| EP0655306A2 (en) * | 1993-11-03 | 1995-05-31 | Schmalbach-Lubeca AG | Manufacturing of multi-layer preforms with scrap PET |

| CN1252023A (zh) * | 1997-04-16 | 2000-05-03 | 哈斯基注模系统有限公司 | 非晶体塑料制品的局部结晶方法和装置 |

| US6332770B1 (en) * | 1999-06-09 | 2001-12-25 | Husky Injection Molding Systems, Ltd. | Apparatus for localized preform cooling outside the mold |

Family Cites Families (41)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| AT333024B (de) † | 1972-12-05 | 1976-10-25 | Fur Verbrennungsmotoren Prof D | Digitale regelanordnung fur einen druckmittelbetatigten arbeitszylinder einer schneckenspritzgiessmaschine |

| JPS5851126A (ja) | 1981-09-22 | 1983-03-25 | Toshiba Mach Co Ltd | 金型ゲ−トバランス制御方法およびその装置 |

| JPS58142831A (ja) * | 1982-02-19 | 1983-08-25 | Kobe Steel Ltd | 射出成形機の制御方法 |

| CA1193817A (en) * | 1983-02-24 | 1985-09-24 | Jobst U. Gellert | Injection molding core ring gate system |

| US4609516A (en) * | 1984-02-17 | 1986-09-02 | Continental Pet Technologies, Inc. | Method of forming laminated preforms |

| DE3833868A1 (de) * | 1988-10-05 | 1990-04-12 | Hofstetter Ag Otto | Verfahren zum spritzgiessen von pet-formlingen und anguss-system |

| CA1292848C (en) | 1989-02-14 | 1991-12-10 | Jobst Ulrich Gellert | Injection molding system having a valve member with a ribbed insulative portion |

| JPH054262A (ja) * | 1991-02-05 | 1993-01-14 | Mitsubishi Electric Corp | 成型用金型 |

| JP2991789B2 (ja) | 1991-02-19 | 1999-12-20 | モールド・マスターズ株式会社 | プラスチック成形用加熱ノズル |

| CA2079390C (en) * | 1991-10-16 | 1996-08-27 | Akira Nonomura | Multi-cavity mold, method of fabricating same and molding control method using said mold |

| US5235737A (en) | 1991-12-13 | 1993-08-17 | Gellert Jobst U | Method of making an injection molding nozzle with a heating element extending outward between adjacent collar portions |

| CA2101480C (en) | 1993-07-28 | 2001-09-11 | Jobst Ulrich Gellert | Injection molding nozzle which retains a thermocouple element |

| CA2123360C (en) * | 1994-05-11 | 2004-07-20 | Jobst Ulrich Gellert | Injection molding nozzle with two removable inserts |

| JPH08118387A (ja) | 1994-09-01 | 1996-05-14 | Sumitomo Chem Co Ltd | 熱可塑性樹脂成形体の製造方法 |

| US5772933A (en) * | 1994-10-12 | 1998-06-30 | Kotzab; Werner | Method for tempering an injection mold having at least one heated nozzle or hot runner |

| US5556582A (en) * | 1995-02-17 | 1996-09-17 | Stanford University | Injection molding gate flow control |

| JPH09159539A (ja) * | 1995-12-04 | 1997-06-20 | Ikegami Seiko Kk | 樹脂表面温度センサー |

| US5736173A (en) * | 1996-04-24 | 1998-04-07 | Zygo Mold Limited | Preform injection mould with slide taper locks |

| US5804228A (en) * | 1996-08-21 | 1998-09-08 | Caco Pacific Corporation | Minimum vestige nozzle assembly for plastics injection molding |

| US5871786A (en) | 1997-04-04 | 1999-02-16 | Kona Corporation | Tip heated hot runner nozzle |

| US6287107B1 (en) | 1997-09-02 | 2001-09-11 | Synventive Molding Solutions, Inc. | Apparatus for proportionally controlling fluid delivery to a mold |

| CH692383A5 (de) | 1997-09-16 | 2002-05-31 | Kk Holding Ag | Verfahren zur Regelung der Heisskanalheizung eines Mehrkavitäten-Spritzgiesswerkzeugs. |

| DE19749495C2 (de) | 1997-11-08 | 2001-03-01 | Werner Kotzab | Verfahren zum Temperieren einer Spritzgieß- oder Druckgießform |

| US5853631A (en) * | 1997-12-08 | 1998-12-29 | D-M-E Company | Mold heater startup method |

| US6171541B1 (en) * | 1998-03-31 | 2001-01-09 | Husky Injection Molding Systems Ltd. | Preform post-mold cooling method and apparatus |

| DE29909535U1 (de) * | 1998-06-02 | 1999-08-12 | Engel Gmbh Maschbau | Spritzgießeinrichtung zur Herstellung einer Vielzahl von Kunststoffteilen |

| US6261084B1 (en) | 1998-08-28 | 2001-07-17 | Synventive Moldings Solutions Canada, Inc. | Elastically deformable nozzle for injection molding |

| DE69803355T2 (de) * | 1998-11-02 | 2002-09-19 | Aasted Mikroverk Aps | System zur Herstellung von Schalen aus fetthaltigen, schokoladeähnlichen Massen unter Druckaufbildung |

| CA2255800C (en) * | 1998-12-07 | 2008-06-10 | Jobst Ulrich Gellert | Injection molding cooling core having a ribbed cap |

| US6220850B1 (en) * | 1999-02-16 | 2001-04-24 | Husky Injection Molding Systems Ltd. | Mold gate insert |

| CA2262176C (en) * | 1999-02-17 | 2008-04-22 | Jobst Ulrich Gellert | Injection molding cooled cavity insert |

| US6529796B1 (en) | 1999-07-21 | 2003-03-04 | Caco Pacific Corporation | Closed loop interactive controller |

| US6276922B1 (en) * | 1999-08-24 | 2001-08-21 | Husky Injection Molding Systems Ltd. | Core fluid velocity inducer |

| US6264460B1 (en) * | 1999-12-09 | 2001-07-24 | Pechiney Emballage Flexible Europe | Injection gate insulating and cooling apparatus |

| JP2001225349A (ja) * | 2000-02-15 | 2001-08-21 | Teijin Chem Ltd | グラデーション色彩を有する成形品の製造方法 |

| US6394784B1 (en) | 2000-03-08 | 2002-05-28 | Mold-Masters Limited | Compact cartridge hot runner nozzle |

| CA2412802A1 (en) † | 2000-06-16 | 2001-12-20 | Mold-Masters Limited | Thermally balanced hot runner nozzle |

| DE10112126B4 (de) | 2001-03-14 | 2004-03-25 | Priamus System Technologies Ag | Verfahren zum automatischen Balancieren der volumetrischen Füllung von Kavitäten |

| DE50202221C5 (de) | 2001-04-05 | 2018-12-27 | Priamus System Technologies Ag | Verfahren zum füllen der kavität eines werkzeuges |

| DE10117001A1 (de) | 2001-04-05 | 2002-11-07 | Frey Juergen | Verfahren zum Herstellen eines Formteiles in einem Formwerkzeug |

| FR2829058B1 (fr) | 2001-09-06 | 2005-05-13 | Delachaux Sa | Procede et dispositif d'injection d'une matiere thermoplastique dans une empreinte d'un moule |

-

2003

- 2003-01-09 WO PCT/US2003/000539 patent/WO2003059598A1/en active IP Right Grant

- 2003-01-09 DE DE60316405T patent/DE60316405T2/de not_active Expired - Lifetime

- 2003-01-09 CA CA002473112A patent/CA2473112C/en not_active Expired - Lifetime

- 2003-01-09 CN CNB038049988A patent/CN100415485C/zh not_active Expired - Lifetime

- 2003-01-09 AT AT03702045T patent/ATE373558T1/de not_active IP Right Cessation

- 2003-01-09 AU AU2003202931A patent/AU2003202931A1/en not_active Abandoned

- 2003-01-09 JP JP2003559744A patent/JP4350520B2/ja not_active Expired - Fee Related

- 2003-01-09 DE DE2003192193 patent/DE10392193T5/de not_active Withdrawn

- 2003-01-09 US US10/338,744 patent/US6936199B2/en not_active Ceased

- 2003-01-09 EP EP03702045A patent/EP1463621B1/en not_active Expired - Lifetime

- 2003-01-09 EP EP07018109.4A patent/EP1862292B2/en not_active Expired - Lifetime

-

2007

- 2007-08-30 US US11/847,881 patent/USRE40952E1/en not_active Expired - Lifetime

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1063443A (zh) * | 1991-01-25 | 1992-08-12 | 乔布斯特·乌尔里克·盖勒特 | 在喷嘴的前部中具有整体冷却的注射成型装置 |

| EP0655306A2 (en) * | 1993-11-03 | 1995-05-31 | Schmalbach-Lubeca AG | Manufacturing of multi-layer preforms with scrap PET |

| CN1252023A (zh) * | 1997-04-16 | 2000-05-03 | 哈斯基注模系统有限公司 | 非晶体塑料制品的局部结晶方法和装置 |

| US20010016239A1 (en) * | 1997-04-16 | 2001-08-23 | Husky Injection Molding Systems Ltd. | Partial crystallization method and apparatus of amorphous plastic articles |

| US6332770B1 (en) * | 1999-06-09 | 2001-12-25 | Husky Injection Molding Systems, Ltd. | Apparatus for localized preform cooling outside the mold |

Also Published As

| Publication number | Publication date |

|---|---|

| US20030155674A1 (en) | 2003-08-21 |

| WO2003059598A1 (en) | 2003-07-24 |

| CA2473112C (en) | 2009-03-17 |

| DE10392193T5 (de) | 2005-01-13 |

| DE60316405T2 (de) | 2008-01-17 |

| DE60316405D1 (de) | 2007-10-31 |

| AU2003202931A1 (en) | 2003-07-30 |

| JP2005515084A (ja) | 2005-05-26 |

| US6936199B2 (en) | 2005-08-30 |

| EP1463621B1 (en) | 2007-09-19 |

| EP1463621A1 (en) | 2004-10-06 |

| JP4350520B2 (ja) | 2009-10-21 |

| EP1862292A3 (en) | 2007-12-26 |

| USRE40952E1 (en) | 2009-11-10 |

| EP1862292B2 (en) | 2020-01-08 |

| EP1862292A2 (en) | 2007-12-05 |

| ATE373558T1 (de) | 2007-10-15 |

| CN1638943A (zh) | 2005-07-13 |

| EP1862292B1 (en) | 2012-03-07 |

| CA2473112A1 (en) | 2003-07-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN100415485C (zh) | 用于测量模具型腔中的熔融材料的温度的方法和装置 | |

| JP2662023B2 (ja) | 射出成形方法及びその装置 | |

| CA2000162C (en) | Method for injection moulding blanks and gate system | |

| JPH05345334A (ja) | バルブゲートを備えたランナーレス射出成形方法およびその装置 | |

| US5776514A (en) | On-demand fast cycle mold | |

| CN101088738A (zh) | 用于注射成型的开环压力控制 | |

| CN101132898A (zh) | 用于注模机的模具 | |

| JP2005515084A5 (zh) | ||

| US20040131715A1 (en) | Method for regulating the contraction of molded parts | |

| US7950918B2 (en) | Apparatus for controlling melt flow in a melt distribution network | |

| TWI380861B (zh) | 基於柱塞吹出之測定辨認模造物品之品質之方法 | |

| US7841854B2 (en) | Temperature adjustment mechanism for injection molding machine | |

| CA3037952C (en) | Apparatus and method for heating a side gate nozzle | |

| TW202110608A (zh) | 用於控制個別流動波前層之間的共射出塑膠壓力比率之方法 | |

| JP3219308B2 (ja) | 射出成形方法 | |

| JP2023007628A (ja) | 射出成形金型 | |

| JPH08118426A (ja) | ホットランナ装置 | |

| JPH049144Y2 (zh) | ||

| JP2000015639A (ja) | 成形装置の材料供給方法、成形品及び、成形装置 | |

| CS245377B1 (cs) | Způsob a zařízení pro formování předmětů vstřikováním termoplastických látek | |

| JPH04358815A (ja) | 射出成形用金型の温度調節方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| C06 | Publication | ||

| PB01 | Publication | ||

| C10 | Entry into substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| C14 | Grant of patent or utility model | ||

| GR01 | Patent grant | ||

| C56 | Change in the name or address of the patentee | ||

| CP01 | Change in the name or title of a patent holder |

Address after: Ontario, Canada Patentee after: Mold-Masters (2007) Ltd. Address before: Ontario, Canada Patentee before: Mold-Masters (2007) Ltd. |

|

| C56 | Change in the name or address of the patentee |

Owner name: MASTERTON MOLD (2007) CO., LTD. Free format text: FORMER NAME: STANDARD MODULE (2007) CO., LTD. |

|

| CX01 | Expiry of patent term |

Granted publication date: 20080903 |

|

| CX01 | Expiry of patent term |