WO2024190891A1 - 空気入りタイヤ用シールシート - Google Patents

空気入りタイヤ用シールシート Download PDFInfo

- Publication number

- WO2024190891A1 WO2024190891A1 PCT/JP2024/010150 JP2024010150W WO2024190891A1 WO 2024190891 A1 WO2024190891 A1 WO 2024190891A1 JP 2024010150 W JP2024010150 W JP 2024010150W WO 2024190891 A1 WO2024190891 A1 WO 2024190891A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- pneumatic tire

- sheet

- sealing

- sealing material

- material layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C1/00—Tyres characterised by the chemical composition or the physical arrangement or mixture of the composition

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08F—MACROMOLECULAR COMPOUNDS OBTAINED BY REACTIONS ONLY INVOLVING CARBON-TO-CARBON UNSATURATED BONDS

- C08F297/00—Macromolecular compounds obtained by successively polymerising different monomer systems using a catalyst of the ionic or coordination type without deactivating the intermediate polymer

- C08F297/02—Macromolecular compounds obtained by successively polymerising different monomer systems using a catalyst of the ionic or coordination type without deactivating the intermediate polymer using a catalyst of the anionic type

- C08F297/04—Macromolecular compounds obtained by successively polymerising different monomer systems using a catalyst of the ionic or coordination type without deactivating the intermediate polymer using a catalyst of the anionic type polymerising vinyl aromatic monomers and conjugated dienes

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09K—MATERIALS FOR MISCELLANEOUS APPLICATIONS, NOT PROVIDED FOR ELSEWHERE

- C09K3/00—Materials not provided for elsewhere

- C09K3/10—Materials in mouldable or extrudable form for sealing or packing joints or covers

Definitions

- the present invention relates to a sealing sheet for a pneumatic tire. More particularly, the present invention relates to a sealing sheet for a pneumatic tire for preventing puncture of the pneumatic tire.

- a foreign object with a sharp tip e.g., a nail, a piece of glass, etc.

- the foreign object with a sharp tip may pierce the pneumatic tire, forming a through hole in the pneumatic tire.

- air sealed inside the pneumatic tire may leak to the outside through the through hole, causing the pneumatic tire to be punctured. If the pneumatic tire is punctured, the mobile object will not be able to travel smoothly on the road surface, which is undesirable.

- Patent Document 1 discloses that a curable liquid such as latex is used as the sealing material composition for forming the sealing material layer.

- the present invention aims to provide a sealing sheet for pneumatic tires that can suppress deterioration of the sealing ability over time in through holes formed in pneumatic tires.

- the present inventors have found that in a sealing sheet for a pneumatic tire having a sealing material layer, when the storage modulus value of the sealing material layer at -20° C is G'1 , the probe tack value of the sealing material layer at 23°C is T, and the adhesive strength value of the sealing material layer to a tire at 23°C is A1, by setting the ratio of the product of the probe tack value T and the adhesive strength value A1 to the storage modulus value G'1 (A1 ⁇ T/ G'1 ) to be 12.0 or less. As a result, the present invention was achieved.

- the sealing sheet for a pneumatic tire according to the present invention is A sealant layer is provided,

- the storage modulus of the sealing material layer at ⁇ 20° C. is defined as G′1 ,

- the probe tack value of the sealing material layer at 23° C. is T,

- the ratio (A1 ⁇ T/G′ 1 ) of the product of the probe tack value T and the adhesive strength value A1 to the storage elastic modulus value G′ 1 is 12.0 or less.

- FIG. 1 is a cross-sectional view showing a configuration of a sealing sheet for a pneumatic tire according to one embodiment of the present invention.

- FIG. 4 is a cross-sectional view showing a configuration of a sealing sheet for a pneumatic tire according to another embodiment of the present invention.

- FIG. 4 is a cross-sectional view showing a configuration of a sealing sheet for a pneumatic tire according to still another embodiment of the present invention.

- FIG. 4 is a cross-sectional view showing a configuration of a sealing sheet for a pneumatic tire according to still another embodiment of the present invention.

- Schematic diagram showing a bicycle wheel. 6 is a schematic diagram showing a bicycle wheel cut along a plane perpendicular to the circumferential direction (sectional view taken along line VI-VI in FIG. 5).

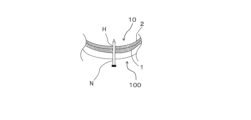

- FIG. 7 is a schematic diagram showing a state in which a nail is pierced in a pneumatic tire equipped with a sealing sheet for a pneumatic tire according to one embodiment of the present invention (an enlarged view of part A in FIG. 6 ).

- FIG. FIG. 7 is a cross-sectional view showing a state in which a nail is pulled out from a pneumatic tire equipped with a sealing sheet for a pneumatic tire according to one embodiment of the present invention (an enlarged view of part A in FIG. 6).

- sealing material composition for a pneumatic tire As alant composition for pneumatic tires, a sealing material composition for a pneumatic tire according to one embodiment of the present invention will be described. In the following, one embodiment of the present invention will be abbreviated as this embodiment.

- the sealing material composition for a pneumatic tire according to this embodiment is used to form a sealing material layer of a sealing sheet for a pneumatic tire according to each embodiment described later.

- the sealing material composition for a pneumatic tire according to the present embodiment preferably contains a thermoplastic elastomer as an organic component.

- thermoplastic elastomer examples include styrene-based thermoplastic elastomers and acrylic-based thermoplastic elastomers.

- styrene-based thermoplastic elastomer examples include styrene-ethylene-butadiene-styrene block copolymer (SEBS), styrene-isoprene-styrene block copolymer (SIS), styrene-isobutylene-styrene block copolymer (SIBS), styrene-butadiene-styrene block copolymer (SBS), and styrene-ethylene-propylene-styrene block copolymer (SEPS).

- SEBS styrene-ethylene-butadiene-styrene block copolymer

- SIBS styrene-isoprene-styrene block copolymer

- SIBS styrene-isobutylene-styrene block copolymer

- SBS styrene-butadiene-sty

- acrylic thermoplastic elastomer examples include a copolymer of an acrylic ester and 2-chloroethyl vinyl ether, a copolymer of an acrylic ester and acrylonitrile, and a copolymer of an acrylic ester and acrylic acid.

- the sealing material composition for pneumatic tires preferably contains the styrene-based thermoplastic elastomer as the thermoplastic elastomer, and among the styrene-based thermoplastic elastomers, it is more preferable that the sealing material composition for pneumatic tires contains at least one of the styrene-isoprene-styrene block copolymer (SIS) and the styrene-isobutylene-styrene block copolymer (SIBS).

- SIS styrene-isoprene-styrene block copolymer

- SIBS styrene-isobutylene-styrene block copolymer

- the mass average molecular weight of the thermoplastic elastomer is preferably 20,000 or more and 1,500,000 or less.

- the weight average molecular weight can be determined as a polystyrene-equivalent value based on gel permeation chromatography (GPC) measurement.

- the mass average molecular weight of the thermoplastic elastomer can be determined by measuring a sample obtained as follows using HLC-8420GPC manufactured by Tosoh Corporation under the following conditions. [How to obtain samples] (1) A sample taken from a sealing material composition for pneumatic tires containing a thermoplastic elastomer is prepared into a 1.0 g/L THF solution and allowed to stand overnight.

- the styrene-based thermoplastic elastomer preferably has a diblock ratio of 10% or more, and more preferably 20% or more.

- the styrene-based thermoplastic elastomer preferably has a diblock ratio of 80% or less.

- the diblock ratio is preferably 40% or more, and particularly preferably 50% or more.

- the styrene-based thermoplastic elastomer is the styrene-isobutylene-styrene copolymer (SIBS)

- SIBS styrene-isobutylene-styrene copolymer

- the pneumatic tire sealing material composition can exhibit more sufficient adhesiveness in a wide temperature range from low temperature (e.g., ⁇ 10° C.) to high temperature (e.g., 60° C.).

- the diblock rate (%) can be calculated by the following formula.

- Diblock ratio (%) parts by mass of diblock copolymer/(parts by mass of diblock copolymer+parts by mass of triblock copolymer) ⁇ 100

- the diblock ratio can be calculated from the area ratio of the peak attributable to the diblock copolymer and the peak attributable to the triblock copolymer in the obtained chart by measuring the molecular weight of the styrene-based thermoplastic elastomer by gel permeation chromatography (GPC).

- GPC gel permeation chromatography

- the styrene content (styrene amount) in the styrene-based thermoplastic elastomer is preferably 10% by mass or more, more preferably 13% by mass or more, and even more preferably 15% by mass or more.

- the styrene content in the styrene-based thermoplastic elastomer is preferably 40% by mass or less, more preferably 30% by mass or less, and even more preferably 25% by mass or less.

- the diblock ratio in the styrene-based thermoplastic elastomer can be adjusted by changing the ratio of the amount of polymerization initiator and coupling agent used during polymerization (amount of coupling agent/amount of polymerization initiator).

- the pneumatic tire sealing material composition preferably contains either a softener or a tackifier as the organic component. Furthermore, the pneumatic tire sealing material composition may contain an anti-aging agent, etc.

- softener examples include paraffins, waxes, naphthenes, aromatics, asphalts, drying oils (e.g., linseed oil, etc.), animal and vegetable oils, petroleum oils (e.g., process oil, etc.), polybutene, polyisobutylene, ethylene- ⁇ -olefin co-oligomers, low-molecular-weight polyethylene glycol, phthalates, phosphates, stearic acid or its esters, and alkylsulfonates.

- the softening agents may be used alone or in combination of two or more kinds.

- the pneumatic tire sealing material composition preferably contains polybutene as the softening agent.

- the sealing material composition for pneumatic tires preferably contains 10 parts by mass or more of the softener relative to 100 parts by mass of the thermoplastic elastomer, more preferably contains 20 parts by mass or more, and even more preferably contains 40 parts by mass or more.

- the sealing material composition for pneumatic tires preferably contains 150 parts by mass or less of the softener per 100 parts by mass of the thermoplastic elastomer, more preferably contains 130 parts by mass or less, and even more preferably contains 110 parts by mass or less.

- tackifiers examples include rosin-based resins, terpene-based resins, styrene-based resins, petroleum-based resins, and phenol-based resins, as well as hydrogenated resins obtained by hydrogenating these resins. These tackifiers may be used alone or in combination of two or more kinds.

- rosin-based resins examples include rosin resin, rosin ester resin, and rosin phenol resin.

- the terpene resin may be any compound having a structural unit derived from isoprene, and examples thereof include terpene resins, aromatic modified terpene resins, and terpene phenol resins.

- styrene-based resins include resins obtained by copolymerizing a styrene-based monomer, such as ⁇ -methylstyrene or ⁇ -methylstyrene, with an aliphatic monomer.

- Examples of petroleum-based resins include C5-based hydrocarbon resins obtained by copolymerizing C5 fractions such as pentene, isoprene, piperine, and 1,3-pentadiene produced by thermal decomposition of petroleum naphtha; and C9-based hydrocarbon resins (aromatic petroleum resins) obtained by copolymerizing C9 fractions such as indene and vinyltoluene produced by thermal decomposition of petroleum naphtha.

- Examples of phenol-based resins include alkylphenol-based resins, xylylene formaldehyde resins, resols, and novolacs.

- the pneumatic tire sealing material composition preferably contains, as the tackifier, at least one selected from the group consisting of a rosin-based resin, a terpene-based resin, and a petroleum-based resin.

- the sealing material composition for pneumatic tires preferably contains 50 parts by mass or more of the tackifier relative to 100 parts by mass of the thermoplastic elastomer, more preferably contains 70 parts by mass or more, and even more preferably contains 90 parts by mass or more.

- the sealing material composition for pneumatic tires preferably contains 400 parts by mass or less of the tackifier per 100 parts by mass of the thermoplastic elastomer, more preferably contains 380 parts by mass or less, even more preferably contains 350 parts by mass or less, and even more preferably contains 140 parts by mass or less.

- the pneumatic tire sealing material composition preferably contains, as the tackifier, the rosin ester resin, the C9 hydrocarbon resin (aromatic petroleum resin), and the terpene resin.

- the terpene resin is preferably contained in an amount of 40 parts by mass or more, more preferably 50 parts by mass or more, and even more preferably 70 parts by mass or more, per 100 parts by mass of the thermoplastic elastomer.

- the terpene resin is preferably contained in an amount of 110 parts by mass or less, more preferably 100 parts by mass or less, and even more preferably 90 parts by mass or less, per 100 parts by mass of the thermoplastic elastomer resin.

- the C9 hydrocarbon resin is preferably contained in an amount of 5 parts by mass or more, and more preferably 7 parts by mass or more, per 100 parts by mass of the thermoplastic elastomer.

- the C9 hydrocarbon resin is contained in an amount of preferably 15 parts by mass or less, more preferably 12 parts by mass or less, and even more preferably 9 parts by mass or less, per 100 parts by mass of the thermoplastic elastomer.

- the rosin ester resin is preferably contained in an amount of 10 parts by mass or more, more preferably 15 parts by mass or more, and even more preferably 18 parts by mass or more, per 100 parts by mass of the thermoplastic elastomer.

- the rosin ester resin is contained in an amount of preferably 30 parts by mass or less, more preferably 25 parts by mass or less, and even more preferably 22 parts by mass or less, per 100 parts by mass of the thermoplastic elastomer.

- the pneumatic tire sealing material composition may contain only a C5 hydrocarbon resin as the tackifier.

- the C5 hydrocarbon resin is preferably contained in an amount of 80 parts by mass or more, more preferably 100 parts by mass or more, and even more preferably 120 parts by mass or more, per 100 parts by mass of the thermoplastic elastomer.

- the C5 hydrocarbon resin is contained in an amount of preferably 200 parts by mass or less, more preferably 180 parts by mass or less, even more preferably 160 parts by mass or less, and still more preferably 140 parts by mass or less, relative to 100 parts by mass of the thermoplastic elastomer.

- the pneumatic tire sealing material composition contains only a C5 hydrocarbon resin as the tackifier, it is preferable that the pneumatic tire sealing material composition further contains the softener.

- the pneumatic tire sealing material composition may contain, as the tackifier, a copolymer resin of C5 hydrocarbons and C9 hydrocarbons (aromatic hydrocarbons).

- the copolymer resin is preferably contained in a total amount of 40 parts by mass or more, more preferably 60 parts by mass or more, and even more preferably 80 parts by mass or more, per 100 parts by mass of the thermoplastic elastomer.

- the copolymer resin is preferably contained in a total amount of 400 parts by mass or less, more preferably 300 parts by mass or less, and even more preferably 250 parts by mass or less, per 100 parts by mass of the thermoplastic elastomer.

- thermoplastic elastomer is the styrene-isoprene-styrene copolymer (SIS) and the diblock ratio is 40% or more

- the probe tack value and adhesive strength of the sheet material layer tend to both increase, while the storage modulus tends to decrease. Therefore, in this case, it is preferable that the sealing material composition contains the tackifier resin. This makes it possible to increase the storage modulus of the sheet material layer, and specifically, to make the storage modulus at -20°C a preferred value of 0.5 MPa or more.

- the thermoplastic elastomer is the styrene-isoprene-styrene copolymer (SIS) and the diblock ratio is 30% or less

- the storage modulus of the sheet material layer tends to be high, while the probe tack value and adhesive strength tend to be low. Therefore, in this case, it is preferable that the sealing material composition contains both the tackifier and the softener. This can increase the probe tack value and adhesive strength of the sealing material layer, specifically, the probe tack value at 23°C can be set to a preferred value of 0.05 MPa or more, and the adhesive strength to a tire at 23°C can be set to a preferred value of 1.0 N/20 mm or more.

- SIS styrene-isoprene-styrene copolymer

- the sheet material composition may be made of the styrene-isobutylene-styrene copolymer (SIBS) since the sheet material layer can have a preferable probe tack value, adhesion, and storage modulus.

- the sheet material composition may contain the softener together with the styrene-isobutylene-styrene copolymer (SIBS) in order to increase adhesion while decreasing the storage modulus of the sheet material composition.

- antioxidant various known antioxidants can be used.

- the antiaging agent include phosphorus-based antiaging agents, phenol-based antiaging agents, hindered amine-based antiaging agents, benzotriazole-based antiaging agents, aromatic amine-based antiaging agents, and sulfur-based antiaging agents.

- the pneumatic tire sealing material composition may contain one kind of the above-mentioned antioxidant alone, or may contain two or more kinds of the above-mentioned antioxidants.

- the sealing material composition for pneumatic tires contains the antioxidant, the thermoplastic elastomer contained in the sealing material composition for pneumatic tires can be inhibited from being deteriorated due to oxidation.

- the sealing material composition for a pneumatic tire preferably contains 1 part by mass or more of the antioxidant per 100 parts by mass of the thermoplastic elastomer.

- the pneumatic tire sealing material composition may contain 2 parts by mass or more, or 3 parts by mass or more of the antioxidant based on 100 parts by mass of the thermoplastic elastomer.

- the sealing material composition for pneumatic tires may contain 10 parts by mass or less, 8 parts by mass or less, or 6 parts by mass or less of the antioxidant relative to 100 parts by mass of the thermoplastic elastomer.

- the sealing material composition for a pneumatic tire may contain an inorganic component.

- the pneumatic tire sealing material composition may contain an inorganic filler and an inorganic colorant as the inorganic components.

- the pneumatic tire sealing material composition preferably contains the inorganic filler as the inorganic component.

- the inorganic filler examples include calcium carbonate (eg, heavy calcium carbonate and light calcium carbonate), calcium stearate, talc, titanium oxide, silica, and magnesium oxide. Of these, it is preferable to use calcium carbonate, and of the calcium carbonate, it is preferable to use ground calcium carbonate.

- the calcium stearate also functions as a lubricant.

- the pneumatic tire sealing material composition preferably contains 0.1 part by mass or more of the inorganic filler relative to 100 parts by mass of the thermoplastic elastomer, more preferably contains 0.2 part by mass or more, and even more preferably contains 0.4 part by mass or more.

- the sealing material composition for pneumatic tires preferably contains 10 parts by mass or less of the inorganic filler relative to 100 parts by mass of the thermoplastic elastomer, more preferably contains 5 parts by mass or less, and even more preferably contains 1 part by mass or less of the inorganic filler.

- the inorganic colorant it is preferable to use carbon, and it is more preferable to use carbon black.

- the pneumatic tire sealing material composition preferably contains the inorganic colorant in a range of 1 part by mass to 10 parts by mass per 100 parts by mass of the thermoplastic elastomer.

- the ratio (A1 ⁇ T/G′1 ) of the product of the probe tack value T and the adhesive strength A1 to the storage modulus value G′1 can be suitably adjusted to 12.0 or less.

- the sealing sheet for a pneumatic tire according to this embodiment includes a sealing material layer.

- the storage modulus of the sealing material layer at ⁇ 20° C. is defined as G′1

- the probe tack value of the sealing material layer at 23° C. is T

- the ratio (A1 ⁇ T/G′ 1 ) of the product of the probe tack value T and the adhesive strength value A1 to the storage elastic modulus value G′ 1 is 12.0 or less.

- the sealing material layer is formed from the sealing material composition for a pneumatic tire according to this embodiment.

- the sealing sheet for pneumatic tires of this embodiment when a sealing material layer is attached to the inner surface of a pneumatic tire, when a foreign object with a sharp tip (e.g., a nail, a piece of glass, etc.) that has pierced the pneumatic tire is pulled out of the pneumatic tire to form a through hole, the sealing material layer can suitably fill the through hole with a part of the sealing material layer. As a result, it is possible to suitably prevent air inside the pneumatic tire from leaking out to the outside. That is, the sealing sheet for a pneumatic tire according to this embodiment has a sealing material layer that can exhibit good sealing properties.

- the storage modulus G'1 of the sealing material layer at -20°C can be measured using a dynamic viscoelasticity measuring device (manufactured by TA instruments, product name "ARES-G2").

- a dynamic viscoelasticity measuring device manufactured by TA instruments, product name "ARES-G2"

- the sealing material layer having a planar dimension of ⁇ 8 mm ⁇ thickness of 1.0 mm can be used.

- the measurement sample can be obtained by punching out the sealing material layer having a thickness of 1.0 mm using a jig so as to have a planar dimension of ⁇ 8 mm.

- the measurement conditions are as follows: [Measurement conditions] ⁇ Probe: ⁇ 8mm ⁇ Deformation mode: sine wave ⁇ Frequency: 1Hz Heating rate: 5°C/min ⁇ Measurement temperature: -60°C ⁇ 150°C Then, by reading the value of the storage modulus at -20°C from the obtained data, G'1 can be obtained.

- the probe tack value T at 23° C. can be measured using a probe tack measuring device (manufactured by RHESCA, product name "TACKINESS Model TAC-II”).

- the measurement sample can be obtained by cutting the sealing material layer having a thickness of 1.0 mm to have planar dimensions of 20 mm ⁇ 40 mm.

- the measurement procedure is as follows. (1) Using a double-sided adhesive tape (manufactured by Nitto Denko Corporation, product name "No. 5610"), one side of the measurement sample (planar dimensions 20 mm x 40 mm) is attached to one side of a slide glass (manufactured by Matsunami Glass Industry Co., Ltd., planar dimensions 26 mm x 76 mm).

- the lamination is carried out using a 2 kg hand roller.

- the probe tack value of the exposed surface of the measurement sample is measured using the probe tack measuring device under the following measurement conditions: The probe tack value is measured in an environment of 23°C. [Measurement conditions] Measurement mode: Static Probe mode Probe terminal: 5 mm ⁇ SUS probe terminal Probe descent speed (Immersion speed): 120 mm/min Test speed: 120 mm/min ⁇ Preload: 100gf ⁇ Press time: 1 sec The above measurement is carried out at any five points on the exposed surface of the measurement sample. The five measured values are then arithmetically averaged to obtain a probe tack value T.

- the adhesive strength value A1 can be measured as follows.

- the measurement tires were tubeless tires (Formula Pro Hookless Tubeless RBCC 700 ⁇ 25C) manufactured by Inoue Rubber Co., Ltd. In the examples described later, a tubeless tire with manufacturer's part number 190636 was used.

- a test piece for measuring adhesive strength is cut out into a small piece having a width of 20 mm from the sealing material layer having a thickness of 0.5 mm.

- a polyethylene terephthalate (PET) resin film (thickness: 25 ⁇ m) is attached to one surface of the test piece for measuring adhesive strength to obtain a laminate.

- the laminate and the test tire are aged for one hour under conditions of a temperature of 23° C. and a relative humidity of 50% RH.

- the exposed surface of the test piece for adhesive strength measurement in the laminate is attached to the inner surface of the tire to be tested by moving a 2 kg roller back and forth once.

- the test tire with the laminate attached thereto is further aged for 30 minutes under conditions of a temperature of 23°C and a relative humidity of 50% RH, and then the adhesive strength of the test piece for adhesion measurement to the test tire is measured using a tensile tester under conditions of a peel angle of 180° and a tensile speed of 300 mm/min.

- the adhesive strength is measured for three samples.

- the arithmetic mean of the adhesive strength values obtained for the three samples is designated as the adhesive strength value A1.

- the adhesive strength value A1 of the sealing material layer is preferably 1.0 N/20 mm or more, more preferably 2.0 N/20 mm or more, and even more preferably 2.5 N/20 mm or more.

- the adhesive strength value A1 of the sealing material layer is preferably 30 N/20 mm or less, more preferably 25 N/20 mm or less, and even more preferably 20 N/20 mm or less.

- A1 ⁇ T/ G′1 is more preferably 11.0 or less, more preferably 10.0 or less, and even more preferably 6.0 or less.

- the sealing material layer in the sealing sheet for a pneumatic tire according to this embodiment can further prevent air inside the pneumatic tire from leaking (leaking) to the outside. That is, such a sealing sheet for a pneumatic tire has a sealing material layer that can exhibit even better sealing properties.

- the sealing material layer in the sealing sheet for a pneumatic tire according to this embodiment can better follow the foreign object with a sharp tip, and therefore can suitably seal the through hole formed in the pneumatic tire by the foreign object with a sharp tip.

- A1 ⁇ T/ G′1 may be 0.001 or more, 0.01 or more, or 0.02 or more.

- the storage elastic modulus value G'1 is preferably 0.50 MPa or more. Since the storage elastic modulus value G'1 is within the above range, the sealing material layer in the sealing sheet for a pneumatic tire according to this embodiment can further suppress the air inside the pneumatic tire from leaking (leaking) to the outside. That is, such a sealing sheet for a pneumatic tire has a sealing material layer that can exhibit even better sealing properties.

- the storage elastic modulus value G'1 is preferably 1.0 MPa or more, particularly preferably 1.5 MPa or more.

- the sealing material layer in the sealing sheet for a pneumatic tire according to this embodiment can better follow the foreign object having a sharp tip when the foreign object having a sharp tip is pulled out of the tire. This makes it possible to more effectively seal through holes formed in the tire due to foreign objects having sharp edges.

- the storage elastic modulus value G'1 may be 100 MPa or less, 80 MPa or less, or 60 MPa or less.

- the probe tack value T is preferably 0.05 MPa or more.

- the sealing material layer in the sealing sheet for a pneumatic tire according to this embodiment can exhibit good adhesion to the inner surface of the pneumatic tire.

- the probe tack value T is more preferably 0.10 or more.

- the probe tack value may be 2.0 MPa or less, 1.0 MPa or less, or 0.75 MPa or less.

- the storage elastic modulus G'2 of the sealing material layer at 23° C. is preferably 0.50 MPa or less, and more preferably 0.20 MPa or less.

- the lower limit of the storage elastic modulus G'2 is usually 0.01 MPa.

- the storage modulus value G'2 can be obtained by reading the storage modulus value at 23° C. from the data obtained by measuring according to the same procedure as in the case of the storage modulus value G'1 .

- the adhesive strength value A2 is preferably 1.0 N/20 mm or more, more preferably 2.0 N/20 mm or more, and even more preferably 3.0 N/20 mm or more.

- the sealing material layer in the sealing sheet for pneumatic tires preferably has an adhesive strength value A2 of 20 N/20 mm or less, more preferably 18 N/20 mm or less, even more preferably 16 N/20 mm or less, and even more preferably 10 N/20 mm or less.

- the adhesive strength value A2 can be measured as follows. (1') to (4') The measurement is carried out in the same manner as in (1) to (4) of the measurement method for the adhesive strength value A1. (5') The test tire with the laminate attached thereto is cured for 60 minutes under a temperature condition of -20°C, and then the adhesive strength of the small piece of sheet body to the test tire is measured using a tensile tester under conditions of a peel angle of 180° and a tensile speed of 300 mm/min. The adhesive strength is also measured for three samples. The arithmetic mean of the adhesive strength values obtained for the three samples is designated as the adhesive strength value A2.

- the sealing sheet for a pneumatic tire according to this embodiment includes a base layer that is laminated on one surface of the sealing material layer or disposed inside the sealing material layer. That is, the base layer may be laminated on one surface of the sealing material layer or disposed inside the sealing material layer.

- a sealing sheet 10 for a pneumatic tire includes a sealing material layer 1 and a base material layer 2 laminated on one surface of the sealing material layer 1 .

- the sealing material layer 1 is attached to the inner surface of a pneumatic tire mounted on the wheel of a moving body such as a bicycle or a motorcycle.

- pneumatic tires include tubeless tires and tubeless ready tires.

- a tubeless tire refers to a tire that does not have a tube on its inner surface, but has an inner liner made of a rubber sheet instead of the tube

- a tubeless ready tire refers to a tire that does not have a tube on its inner surface, and does not have an inner liner either.

- Examples of vehicles on which such pneumatic tires are mounted include road bikes, gravel road bikes, cross bikes, and mountain bikes.

- the sealing material layer 1 is formed from the sealing material composition for a pneumatic tire.

- the sealing material layer 1 can be obtained by mixing and kneading the above-mentioned organic and inorganic components in the amounts described above, and then forming the resulting sealing material composition for pneumatic tires into a sheet shape on the substrate layer 2 (by applying a paste).

- a batch type kneader such as a kneader, Banbury mixer, or mixing roll, or a continuous kneader such as a twin-screw kneader is used, and for forming into a sheet, a molding device such as an extruder, calendar roll, or press (heat press) is used.

- the sealing material layer 1 may be produced by using a hot melt coater.

- the sealing material composition for pneumatic tires having hot melt properties may be applied to one side of the substrate layer 2 to a predetermined thickness while being heated to a temperature of, for example, about 200° C. using the hot melt coater.

- the thickness of the sealing material layer 1 is preferably 50 ⁇ m or more, more preferably 100 ⁇ m or more, even more preferably 150 ⁇ m or more, and even more preferably 200 ⁇ m or more.

- the thickness of the sealing material layer 1 is preferably 1500 ⁇ m or less, more preferably 1200 ⁇ m or less, even more preferably 1000 ⁇ m or less, and even more preferably 800 ⁇ m or less.

- the sealing material layer 1 may have a single layer structure, or may have a laminated structure of two or more layers having different compositions.

- the single-layer structure means a structure made of one type of sealing material composition for pneumatic tires. Therefore, a structure in which a plurality of layers formed from one type of pneumatic tire sealing material composition are laminated is a single layer structure.

- the sealing material layer 1 is constructed by laminating two or more layers having different compositions, it is sufficient that at least one of the layers satisfies the relationship that the ratio (A1 ⁇ T/G′1 ) of the product of the probe tack value T and the adhesive strength value A1 to the storage modulus value G′1 is 12.0 or less.

- the ratio (A1 ⁇ T/G′1 ) of the product of the probe tack value T and the adhesive strength value A1 to the storage modulus value G′1 is 12.0 or less.

- the ratio (A1 ⁇ T/G′1 ) of the product of the probe tack value T and the adhesive strength value A1 to the storage modulus value G′1 is 12.0 or less.

- the base layer 2 is made of a sheet material.

- the base layer 2 supports the sealing material layer 1 so as to maintain a predetermined shape.

- the substrate layer 2 functions to protect the surface of the sealing material layer 1 that is not attached to the adherend (the inner surface of the pneumatic tire). That is, the base layer 2 also functions as an adhesive blocking layer.

- the sheet material can be made of various known materials.

- the base layer 2 is preferably made of a sheet material selected from the group consisting of a fiber sheet, a foamed sheet, a solidreat, and a multi-layer sheet formed by laminating at least two of these materials.

- the sheet material can be an organic fiber sheet, an inorganic fiber sheet, a rubber foam sheet, a plastic foam sheet, a rubber solid sheet (non-foamed sheet), a plastic solid sheet (non-foamed sheet), a metal solid sheet, a metal solid sheet laminated with a plastic solid sheet, or the like.

- the sheet material is preferably a fiber sheet.

- the fibers constituting the fiber sheet may be synthetic resin fibers such as synthetic plastic fibers and synthetic rubber fibers; natural fibers such as cellulose fibers; and organic fibers such as semi-synthetic fibers.

- the fibers constituting the fiber sheet may be metal fibers such as copper fibers, aluminum fibers, and iron fibers; glass fibers; basalt fibers; alumina fibers; ceramic fibers such as rock wool; and inorganic fibers such as carbon fibers.

- the fibers constituting the fiber sheet are preferably synthetic resin fibers.

- the synthetic resin fibers include fibers made of thermoplastic resins and fibers made of thermosetting resins.

- the synthetic resin fibers are preferably fibers made of a thermoplastic resin.

- thermoplastic resin examples include polyolefin resins such as polyethylene (PE) and polypropylene (PP); polyester resins such as polyethylene terephthalate (PET), polyethylene naphthalate (PEN), polylactic acid (PLA), and polybutylene succinate (PBS); polyamide resins such as polyamide 6 and polyamide 6,6; and cellulose resins such as cellulose acetate.

- PET polyethylene terephthalate

- PEN polyethylene naphthalate

- PBS polybutylene succinate

- polyamide resins such as polyamide 6 and polyamide 6,6

- cellulose resins such as cellulose acetate.

- thermoplastic resins may be used alone or in combination of two or more.

- polyolefin-based resins and polyester-based resins as the thermoplastic resins.

- the polyolefin resin it is preferable to use polypropylene (PP), and as the polyester resin, it is preferable to use polyethylene terephthalate (PET).

- the fiber sheet may be a nonwoven fabric sheet or a woven fabric sheet.

- the nonwoven fabric sheet may be produced by any of various known methods.

- the nonwoven fabric sheet may be produced by either a dry method or a wet method.

- Examples of the nonwoven fabric sheet include a spunbond nonwoven fabric sheet, a thermal bond nonwoven fabric sheet, a chemical bond nonwoven fabric sheet, a stitch bond nonwoven fabric sheet, a needle punch nonwoven fabric sheet, a melt blown nonwoven fabric sheet, a spun lace nonwoven fabric sheet, and a steam jet nonwoven fabric sheet.

- the nonwoven fabric sheet preferably has a basis weight of 10 g/m 2 or more, more preferably 20 g/m 2 or more, and even more preferably 30 g/m 2 or more.

- the nonwoven fabric sheet has a basis weight of preferably 200 g/m2 or less , more preferably 180 g/m2 or less , and even more preferably 160 g/m2 or less .

- the base material layer 2 formed of the nonwoven fabric sheet has sufficient tensile strength.

- the woven fabric sheet can be produced using various known looms.

- the woven fabric sheet may be woven in any manner. Examples of the woven fabric sheet include a plain weave sheet, a twill weave sheet, and a satin weave sheet.

- the above-mentioned fiber sheet is advantageous over a solid rubber sheet or a solid plastic sheet in that it has high puncture resistance when pierced by a foreign object with a sharp tip (for example, a nail, a piece of glass, etc.).

- the components contained in the sealing material layer 1, such as a tackifier may migrate to the inside of the base layer 2.

- the sheet material constituting the base layer 2 is preferably a multi-layer sheet constituted by laminating the fiber sheet and the solid sheet. In such a multi-layer sheet, it is preferable that a sealing material layer 1 is laminated on the exposed surface of the solid sheet.

- Such a multilayer sheet is one formed by laminating a fiber sheet and a solid sheet of a polyolefin resin (such as a polyethylene sheet or a polypropylene sheet) that is thinner than the fiber sheet.

- the sheet material constituting the base layer 2 may be a multi-layer sheet formed by laminating a spunbond nonwoven fabric and a meltblown nonwoven fabric having finer fibers and a denser weave than the spunbond nonwoven fabric.

- a sealing material layer 1 is laminated on the exposed surface of the melt-blown nonwoven fabric.

- the sheet material constituting the base layer 2 may be a solid plastic sheet (non-foamed sheet).

- the plastic solid sheet may be a thermoplastic polyurethane film made by using a thermoplastic polyurethane resin as the plastic.

- An example of a commercially available thermoplastic polyurethane film is "Tough Grace TG88-I 25/50” manufactured by Takeda Sangyo Kaisha. "TOUGH GRACE TG88-I 25/50” is a 25 ⁇ m thick urethane film with a 50 ⁇ m thick polyethylene release liner laminated on one surface thereof.

- the base layer 2 is constructed by laminating a release liner on one surface of a urethane film

- the release liner is peeled off from one surface of the urethane film.

- the thickness of the base layer 2 is preferably 5 ⁇ m or more, more preferably 10 ⁇ m or more, even more preferably 15 ⁇ m or more, and even more preferably 20 ⁇ m or more.

- the thickness of the base layer 2 is preferably 3 mm or less, more preferably 2 mm or less, and even more preferably 1 mm or less.

- the sealing sheet 10 for a pneumatic tire may include a sealing material layer 1 and a base material layer 2 disposed inside the sealing material layer 1. Even when the sealing sheet 10 for a pneumatic tire is configured as shown in FIG. 2, the base layer 2 can support the sealing material layer 1 so as to maintain a predetermined shape.

- the sealing sheet for a pneumatic tire 10 according to the modified example shown in FIG. 2 can be produced by impregnating the sheet material that will become the base layer 2 in the sealing material composition for a pneumatic tire.

- the sealing sheet 10 for a pneumatic tire includes a sealing material layer 1, an optional base material layer 2 laminated on one surface of the sealing material layer 1, and an adhesive layer 3 laminated on the other surface (exposed surface) of the sealing material layer 1.

- a configuration including an adhesive layer 3 as shown in Figure 3 can be adopted. That is, in such a sealing sheet 10 for a pneumatic tire, it is preferable that the adhesive layer 3 ensures adhesion to the adherend (the inner surface of the pneumatic tire).

- the sealing sheet for pneumatic tires 10 can be produced by obtaining the sealing sheet for pneumatic tires 10 as shown in Figure 1, and then forming (pasting) an adhesive composition containing a predetermined amount of organic and inorganic components into a sheet shape on the exposed surface of the sealing material layer 1 to obtain the adhesive layer 3.

- the pressure-sensitive adhesive composition can be obtained by using various kneading machines, similarly to the sealing material composition.

- the molding into a sheet can be carried out using a molding device such as an extruder, a calendar roll, or a press (heat press) in the same manner as described above.

- the adhesive layer 3 preferably has an adhesive strength A1' to the tire at 23°C of 10 N/20 mm or more, and more preferably 20 N/20 mm or more.

- the adhesive layer 3 may contain butyl rubber as an organic component.

- Butyl rubber is a copolymer of isobutene (isobutylene) and a small amount of isoprene (isobutylene-isoprene).

- Examples of butyl rubber include synthetic butyl rubber and regenerated butyl rubber.

- the pressure-sensitive adhesive layer 3 preferably contains synthetic butyl rubber as a main component.

- the adhesive layer 3 preferably contains 70% by mass or more of synthetic butyl rubber based on the total amount of butyl rubber, more preferably contains 80% by mass or more, even more preferably contains 90% by mass or more, and particularly preferably contains 100% by mass. That is, it is particularly preferable that all of the butyl rubber contained in the pressure-sensitive adhesive layer 3 is synthetic butyl rubber.

- the recycled butyl rubber is obtained by recycling rubber products (e.g., tires, tubes, etc.) made from butyl rubber as a raw material with oil such as pine oil or mineral oil, and therefore the recycled butyl rubber contains residual oil as an impurity.

- the mass average molecular weight of the butyl rubber is preferably 30,000 or more and 1,500,000 or less.

- the weight average molecular weight can be determined as a polystyrene-equivalent value measured by gel permeation chromatography (GPC).

- GPC gel permeation chromatography

- the GPC method can be carried out in the same manner as described in the method for measuring the mass average molecular weight of a thermoplastic elastomer.

- the mass average molecular weight of the butyl rubber is more preferably 200,000 or more, and further preferably 300,000 or more.

- the mass average molecular weight of the butyl rubber is more preferably 800,000 or less, and further preferably 700,000 or less.

- the pressure-sensitive adhesive layer 3 may contain an elastomer component other than butyl rubber as an organic component.

- the elastomer component other than butyl rubber include rubbers other than butyl rubber and thermoplastic elastomers.

- Examples of rubbers other than butyl rubber include polyisobutylene rubber, acrylic rubber, silicone rubber, urethane rubber, vinyl alkyl ether rubber, polyvinyl alcohol rubber, polyvinylpyrrolidone rubber, polyacrylamide rubber, cellulose rubber, natural rubber, butadiene rubber, chloroprene rubber, styrene-butadiene rubber, acrylonitrile-butadiene rubber, isoprene rubber, and ethylene-propylene rubber (EPDM).

- polyisobutylene rubber acrylic rubber, silicone rubber, urethane rubber, vinyl alkyl ether rubber, polyvinyl alcohol rubber, polyvinylpyrrolidone rubber, polyacrylamide rubber, cellulose rubber, natural rubber, butadiene rubber, chloroprene rubber, styrene-butadiene rubber, acrylonitrile-butadiene rubber, isoprene rubber, and ethylene-propylene rubber (EPDM).

- EPDM ethylene-propylene rubber

- thermoplastic elastomer may be the same as that described above.

- the pressure-sensitive adhesive layer 3 may contain only the thermoplastic elastomer as the rubber other than the butyl rubber. In such a case, the pressure-sensitive adhesive layer 3 may contain 70% by mass or more of the butyl rubber and 30% by mass or less of the thermoplastic elastomer, when the combined content of the butyl rubber and the content of the thermoplastic elastomer is taken as 100% by mass. In the above case, the pressure-sensitive adhesive layer 3 may contain 80% by mass or more of the butyl rubber and 20% by mass or less of the thermoplastic elastomer. Furthermore, in the above case, the pressure-sensitive adhesive layer 3 may contain the thermoplastic elastomer in an amount of 1% by mass or more, 2% by mass or more, or 3% by mass or more.

- the pressure-sensitive adhesive layer 3 may contain 70% by mass or more of synthetic butyl rubber as the butyl rubber, 80% by mass or more, 90% by mass or more, or 100% by mass.

- the pressure-sensitive adhesive layer 3 may contain the butyl rubber as described above and may also contain only a thermoplastic elastomer as the rubber other than the butyl rubber.

- the content of the butyl rubber and the content of the thermoplastic elastomer may be as described above.

- the pressure-sensitive adhesive layer 3 preferably contains the elastomer component in an amount of 8% by mass or more, and more preferably 10% by mass or more.

- the pressure-sensitive adhesive layer 3 may contain the elastomer component in an amount of 100% by mass, 90% by mass or less, 70% by mass or less, or 50% by mass or less.

- the elastomer component is a general term including butyl rubber, rubber other than butyl rubber, and thermoplastic elastomer.

- the pressure-sensitive adhesive layer 3 may contain, as organic components other than the elastomer component, a softener, a tackifier, an anti-aging agent, and the like.

- a softener As the softener, the tackifier, and the antioxidant, the same ones as those explained above can be used.

- the pressure-sensitive adhesive layer 3 may contain an inorganic component.

- the pressure-sensitive adhesive layer 3 may contain an inorganic filler and an inorganic colorant as inorganic components.

- the pressure-sensitive adhesive layer 3 preferably contains an inorganic filler as an inorganic component.

- As the inorganic filler and the inorganic colorant the same ones as those explained above can be used.

- the pressure-sensitive adhesive layer 3 preferably contains calcium carbonate as the inorganic filler.

- the content of the inorganic filler in the pressure-sensitive adhesive layer 3 is preferably 90% by mass or less, more preferably 80% by mass or less, and even more preferably 70% by mass or less.

- the pressure-sensitive adhesive layer 3 preferably contains 500 parts by mass or less of the inorganic component per 100 parts by mass of the elastomer component, more preferably 450 parts by mass or less, and even more preferably 400 parts by mass or less.

- the pressure-sensitive adhesive layer 3 preferably contains 50 parts by mass or more of the inorganic component per 100 parts by mass of the elastomer component, more preferably 150 parts by mass or more, and even more preferably 270 parts by mass or more.

- the thickness of the pressure-sensitive adhesive layer 3 is preferably 50 ⁇ m or more, and more preferably 100 ⁇ m or more.

- the thickness of the pressure-sensitive adhesive layer 3 is preferably 500 ⁇ m or less, and more preferably 400 ⁇ m or less.

- the sealing sheet 10 for pneumatic tires includes a sealing material layer 1 and a release liner 4 laminated to the sealing material layer 1.

- the sealing material layer 1 has a first surface, which is an adhesive surface that is adhered to the tire, and a second surface opposite to the first surface.

- the release liner 4 is laminated to the second surface.

- the sealing material layer 1 in the process of attaching the sealing material layer 1 to the tire, the sealing material layer 1 can be brought into contact with the tire while pressing the outer surface of the release liner 4 with a finger or the like. This makes it easier to make the sealing material layer 1 fit the tire.

- the tensile modulus of the release liner 4 at 23°C is 4000 MPa or less. This can improve the workability of attaching it to tires with curved surfaces with a large curvature, such as bicycle tires. It is also more preferable that the tensile modulus of the release liner 4 at 23°C is 1000 MPa or more. This can prevent damage to the release liner 4 due to pressure during the above work.

- the tensile modulus of the release liner 4 at 23° C. is calculated from the results of a tensile test.

- the tensile test is carried out under the following measurement conditions. [Measurement conditions] Test environment: 23°C ⁇ 2°C, 50% RH ⁇ 10% RH ⁇ Test piece shape: width 10 mm, length 50 mm Pulling speed: 300 mm/min. Chuck distance: 10 mm.

- the tensile modulus Et is calculated from the slope of the stress-strain curve for the strain at two specified points (the ratio of the tensile stress within the tensile proportional limit to the corresponding strain).

- the thickness of the release liner 4 is preferably 0.02 mm or more, more preferably 0.05 mm or more, and even more preferably 0.08 mm or more.

- the thickness of the release liner layer 4 is preferably 0.8 mm or less, more preferably 0.5 mm or less, and even more preferably 0.3 mm or less.

- the sealing sheet 10 for pneumatic tires may be wound into a roll before use (e.g., during storage) so that the release liner 4 is disposed on the outside and the sealing material layer 1 is disposed on the inside, in order to make it compact.

- the tolerance of the thickness of the sealing material layer 1, based on the average thickness of the sealing material layer 1, is 25% or less of said average thickness, and more preferably less than 20%. This makes it easier for the inner surface of the sealing material layer 1 in the nth turn to come into contact with the outer surface of the release liner 4 in the n-1th turn, making it easier to maintain the roll shape.

- the edge portions on both sides of the release liner 4 are preferably dry edge portions 41 on which the sealant layer 1 is not laminated.

- the width of each dry edge portion 41 is preferably 1 mm or more. This makes it possible to prevent the glue from spilling out of the release liner 4 when the pneumatic tire sealing sheet 10 is rolled. This makes it easier to attach the sealant layer 1 to the tire. Furthermore, by pinching the dry edge portions 41, the release liner 4 can be easily peeled off from the sealant layer 1 attached to the tire. Furthermore, during peeling, inadvertent peeling of the sealant layer 1 attached to the tire can be suppressed.

- the release liner 4 may be, for example, a resin film or a paper film.

- resin films include polyethylene terephthalate resin film, polyethylene film, and polypropylene film. It is preferable that at least the lamination surface of the release liner 4 with the sealing material layer 1 is treated with a surface treatment agent.

- surface treatment agents include silicone-based surface treatment agents and fluorine-based surface treatment agents.

- an adhesive layer 3 may be laminated on the surface of the sealing material layer 1 opposite the second surface.

- the thickness of the sealing sheet 10 for pneumatic tires according to each embodiment is preferably 50 ⁇ m or more, more preferably 100 ⁇ m or more, even more preferably 150 ⁇ m or more, even more preferably 200 ⁇ m or more, and particularly preferably 500 ⁇ m or more.

- the thickness of the sealing sheet 10 for a pneumatic tire is preferably 2500 ⁇ m or less, more preferably 2000 ⁇ m or less, even more preferably 1500 ⁇ m or less, and particularly preferably 1000 ⁇ m or less.

- the ratio of the thickness of the seal sheet 10 for pneumatic tires to the thickness of the release liner 4 is preferably 30 or less, more preferably 25 or less, even more preferably 20 or less, and particularly preferably 10 or less.

- the ratio of the thickness of the sealing sheet 10 for a pneumatic tire to the thickness of the release liner 4 is preferably 0.5 or more, more preferably 1 or more, and even more preferably 2 or more.

- the sealing sheet 10 for a pneumatic tire according to each embodiment preferably has a mass per unit volume of 1500 g/m2 or less , more preferably 1300 g/m2 or less , and even more preferably 1200 g/m2 or less .

- the sealing sheet for a pneumatic tire according to each embodiment can be made relatively lightweight.

- the sealing sheet 10 for a pneumatic tire according to each embodiment preferably has a mass per unit volume of 50 g/m2 or more , more preferably 100 g/m2 or more , and even more preferably 200 g/m2 or more .

- the mass per unit volume is within the above numerical range, the sealing sheet for a pneumatic tire according to each embodiment can stably exhibit sealing properties.

- the mass per unit volume of the sealing sheet for a pneumatic tire means the mass per unit volume of the sealing material layer 1.

- the mass per unit volume of the sealing sheet for a pneumatic tire means the combined value of the mass per unit volume of the sealing material layer 1 and the mass per unit volume of the base layer 2.

- the mass per unit volume of the sealing sheet for a pneumatic tire means the combined value of the mass per unit volume of the sealing material layer 1, the mass per unit volume of the base layer 2, and the mass per unit volume of the adhesive layer 3.

- the mass does not include the release liner.

- the sealing sheet 10 for a pneumatic tire according to each embodiment is preferably configured in a tape shape.

- the width of a pneumatic tire according to the ETRTO standard is W0 (mm) and the dimension in the width direction of the pneumatic tire sealing sheet 10 to be attached to the inside of the pneumatic tire (tape width: mm) is W1

- the tape width W1 is 10% or more of the width W0 of the pneumatic tire.

- the ratio of the tape width W1 to the pneumatic tire width W0 ( W1 / W0 x 100) may be 25% or more, 50% or more, or 100% or more.

- the tape width W1 preferably corresponds to the width of a bicycle tire in the ETRTO standard, and is more preferably 25 to 62 mm.

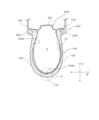

- Such a sealing sheet 10 for a pneumatic tire can cover the inner surface of the ground contact portion 110 of the pneumatic tire 100 shown in Fig. 6 and a part of the inner surface of the side wall portion 120. This allows the ground contact portion 110, where through holes are relatively likely to occur, to be reliably covered with the sealing sheet 10 for a pneumatic tire. Furthermore, of the inner surfaces of the pneumatic tire 100, the inner surface of the portion transitioning from the ground contact portion 110 to the side wall portion 120 is a curved surface with a large curvature, so that a sheet having the above-mentioned release liner is effective for such a curved surface. It should be noted that the width here does not include the release liner.

- the wheel 1000 includes a pneumatic tire 100 and a wheel 200 on which the pneumatic tire 100 is mounted.

- the wheel 200 may be of the disc type or of the spoke type. It should be noted that the wheel 200 shown in FIG. 5 is of a spoke type.

- the wheel 200 comprises a disk-shaped hub 210 located at the center of the wheel 1000 and rotatably attached to a bicycle fork (not shown), a number of spokes 220 extending radially outward from the outer periphery of the hub 210, and a rim 230 fixed by the spokes 220.

- the rim 230 includes a base portion 231 to which the outer ends of the spokes 220 are fixed.

- the base portion 231 has a cylindrical shape with the rotation axis of the wheel 1000 as its central axis.

- the dimension of the base portion 231 in the axial direction (the width direction W of the pneumatic tire 100 ) is approximately the same as the width of the pneumatic tire 100 .

- the rim 230 includes a pair of flange portions 232 extending outward in the radial direction D from both axial ends of the base portion 231 .

- the pneumatic tire 100 is attached to the wheel 200 with both ends in the width direction W inserted inside the flange portions 232 .

- a base portion 231 and a flange portion 232 extending outward in the radial direction D from both ends of the base portion 231 have an inverted U-shaped cross-sectional shape in a plane perpendicular to the circumferential direction C of the wheel 1000.

- the pneumatic tire 100 has a U-shaped cross section.

- a U-shaped bottom portion facing the base portion 231 serves as a ground contact portion 110 that comes into contact with the ground.

- the pneumatic tire 100 includes sidewall portions 120 each extending inward in a radial direction D from both ends of a ground contact portion 110 in a width direction W of the pneumatic tire 100 .

- the pneumatic tire 100 is provided with a bead portion 140 that protrudes slightly outward in the axial direction at the end of the side wall portion 120 on the side opposite the ground contact portion 110 .

- the tip of the flange 232 has a shape that is bent inward in the width direction W (hook-shaped), and both ends of the pneumatic tire 100 in the width direction W are disposed inside the tip.

- the pneumatic tire 100 is attached to the rim 230 with the bead portion 140 and the side wall portion 120 in the vicinity of the bead portion 140 abutting against the inside of the flange portion 232 and with the bead portion 140 engaged with the tip portion of the flange portion 232 .

- the wheel 1000 is provided with a valve 240 for pressurizing a gas such as air or nitrogen gas into an internal space S surrounded by the rim 230 and the pneumatic tire 100 .

- a gas such as air or nitrogen gas

- the pair of side wall portions 120 spaced apart in the width direction W are deformed in directions away from each other and come into strong contact with the flange portion 232. This allows the pneumatic tire 100 to be firmly fixed to the rim 230.

- the wheel 1000 does not have a tube that expands in the interior space S.

- the wheel 1000 is provided with a sealing sheet 10 for a pneumatic tire on the inner surface of a pneumatic tire 100 .

- details of the configuration of the sealing sheet for a pneumatic tire 10 are omitted in Fig. 6. That is, Fig. 6 shows a configuration of the sealing sheet for a pneumatic tire 10 in which the sealing material layer 1, the base material layer 2, etc. are omitted.

- a through hole H is formed in the pneumatic tire 100 from the outer surface (the surface in contact with the road surface) toward the inner surface. If the bicycle is ridden on the road with the nail N still stuck in the pneumatic tire 100, the wheel 200 on which the pneumatic tire 100 is mounted will be damaged by the nail N, so the bicycle rider usually pulls out the nail N from the pneumatic tire 100. As a result, the through-hole H is exposed in the pneumatic tire 100 (see FIG. 7B).

- the sealing material layer 1 provided in the sealing sheet 10 for pneumatic tires must have physical properties that enable it to follow the outward pulling of the nail N when it is pulled outward.

- the sealing material layer 1 must have the physical property of firmly adhering to the rod-shaped portion of the nail N, and must also have a suitable hardness to follow the nail N as it is pulled outward and fill in part of the exposed through hole H, as shown in Figure 7B.

- the sealing material layer 1 forming the sealing material must have an appropriate hardness. Taking the above into consideration, the sealing material layer 1 needs to have adhesive properties to firmly adhere to the rod-shaped portion of the nail N, as well as suitable viscoelastic properties to prevent it from being pushed out to the outside of the pneumatic tire 100 when it fills part of the through hole H or becomes a sealant within the through hole H.

- the sealing material layer 1 has a specific relationship between the storage modulus value G'1, which is a parameter of the viscoelastic properties, and the probe tack value T and the adhesive strength A1, which are parameters related to adhesion. That is, the sealing material layer 1 in the sealing sheet 10 for a pneumatic tire satisfies a specific relationship in which the ratio (A1 ⁇ T/G′ 1 ) of the product of the probe tack value T and the adhesive strength A1 to the storage modulus value G′ 1 is 12.0 or less.

- the sealing material layer 1 can form a sealant that preferably fills a portion of the exposed through hole H in the pneumatic tire 100, and can sufficiently prevent the sealant from being pushed out to the outside of the pneumatic tire 100 due to the internal pressure of the pneumatic tire 100 that rises when the tire is driven on a road surface.

- the sealing sheet 10 for the pneumatic tire is attached so as to cover at least an area of 0.1L on both sides in the width direction W from the lowest point 100b.

- the pneumatic tire sealing sheet 10 is preferably provided so as to cover 10% or more of the widthwise length (2L) along the inner side of the pneumatic tire 100 .

- the sealing sheet 10 for pneumatic tires be arranged to cover 15% or more of the widthwise length (2L) along the inner surface of the pneumatic tire 100, and it is even more preferable that it be arranged to cover 20% or more.

- the pneumatic tire sealing sheet 10 may be provided so as to cover 100% or less of the length (2L) in the width direction along the inner surface of the pneumatic tire 100.

- a sealant layer is provided, When the storage modulus value of the sealing material layer at ⁇ 20° C. is G′1 , the probe tack value of the sealing material layer at 23° C. is T, and the adhesive strength value of the sealing material layer to a tire at 23° C. is A1, A ratio (A1 ⁇ T/G′ 1 ) of the product of the probe tack value T and the adhesive strength value A1 to the storage modulus value G′ 1 is 12.0 or less.

- thermoplastic elastomer is a styrene-based thermoplastic elastomer.

- sealing sheet for a pneumatic tire according to any one of (1) to (10) above, wherein the sealing material layer is configured by laminating two or more layers having different compositions.

- the sealing sheet for a pneumatic tire according to any one of (10) to (13) above which has a width that is 10% or more of the width of the pneumatic tire as defined by the ETRTO standard.

- the sealing material layer is formed in a tape shape and further includes a release liner laminated on the sealing material layer, The sealing sheet for a pneumatic tire according to any one of (1) to (14) above, wherein the release liner is laminated on a side of the sealing material layer opposite to a side that is adhered to the tire.

- the release liner is wound in a roll shape so as to be disposed on the outside,

- a tolerance of the thickness of the sealing material layer when the average thickness of the sealing material layer is used as a reference is 25% or less of the average thickness.

- each dry edge portion has a width of 1 mm or more.

- the sealing sheet for pneumatic tires according to the present invention is not limited to the above embodiment. Furthermore, the sealing sheet for pneumatic tires according to the present invention is not limited by the above-mentioned effects.

- the sealing sheet for pneumatic tires according to the present invention can be modified in various ways without departing from the gist of the present invention.

- Elastomer Component (a) Thermoplastic Elastomer Styrene-Isoprene-Styrene Copolymer (SIS) SIS1: styrene content 15% by mass, diblock ratio 78% SIS2: styrene content 16% by mass, diblock ratio 56% SIS3: styrene content 14% by mass, diblock ratio 26% Styrene-isobutylene-styrene copolymer (SIBS) SIBS1: styrene content 14% by mass, diblock ratio 26% SIS1 is a product manufactured by Nippon Zeon Corporation under the trade name "Quintac 3520", SIS2 is a product manufactured by Nippon Zeon Corporation under the trade name "Quintac 3433N”, SIS3 is a product manufactured by Nippon Zeon Corporation under the trade name "Quintac 3421”, and SIBS1 is

- Tackifier 1 Terpene resin a (trade name "YS Resin PX1150N” manufactured by Yasuhara Chemical Co., Ltd., softening point 115°C)

- Tackifier 2 Terpene resin b (trade name "YS Resin PX300N” manufactured by Yasuhara Chemical Co., Ltd., softening point 30°C)

- Tackifier 3 Aromatic petroleum resin (product name "SYLVARES SA140” manufactured by Kraton Corporation, softening point 137°C)

- Tackifier 4 Rosin ester (trade name "Pensel D-160” manufactured by Arakawa Chemical Industries, Ltd., softening point 150 to 165°C)

- Tackifier 5 C5-based hydrocarbon T-REZ RC093, a product name of TonenGeneral Sekiyu K.K., softening point 93°C

- Inorganic filler Calcium carbonate Heavy calcium carbonate (manufactured by Maruo Calcium Co., Ltd., sieve residue (350 mesh) 0.5% or less (compliant with JIS K5101))

- Colorant/carbon Seest 3H (Tokai Carbon Co., Ltd., carbon black)

- sealing material composition for pneumatic tires according to Examples 1 to 13 and Comparative Examples 1 and 2.

- the sealing material composition for a pneumatic tire will simply be referred to as a sealing material composition.

- Example 1 The sealing material composition of Example 1 was applied to an exposed surface (a surface on which the release liner was not attached) of a substrate layer (a urethane film with a release liner (trade name "Tough Grace TG88-I 25/50" manufactured by Takeda Sangyo Kaisha, Ltd.; urethane film thickness: 25 ⁇ m, release liner (made of polyethylene) thickness: 50 ⁇ m) to form a sealing material layer.

- a substrate layer a urethane film with a release liner (trade name "Tough Grace TG88-I 25/50” manufactured by Takeda Sangyo Kaisha, Ltd.; urethane film thickness: 25 ⁇ m, release liner (made of polyethylene) thickness: 50 ⁇ m

- the exposed surface of the base material layer was coated with a hot melt coater while being heated to 150° C. to a thickness of 0.5 mm to form a sealing material layer.

- the pressure-sensitive adhesive composition according to Example 1 was applied to the exposed surface of the sealing material layer to form a pressure-sensitive adhesive layer.

- the adhesive composition of Example 1 was transfer-coated onto the exposed surface of the sealing material layer using a calendar roll (four 8-inch rolls) while heating to 80° C., to form an adhesive layer having a thickness of 0.1 mm.

- the pressure-sensitive adhesive composition of Example 1 contained 10 parts by mass of SIS2 as a thermoplastic elastomer, 90 parts by mass of JSR BUTYL 268 as a butyl rubber, 15 parts by mass of tackifier 5, 260 parts by mass of hydrocarbon-based polybutene (PB1300) as a softener, 380 parts by mass of calcium bicarbonate, and 3 parts by mass of carbon (SIST 3H). Then, the urethane film with the release liner was entirely peeled off to obtain the sealing sheet for a pneumatic tire according to Example 1. That is, the sealing sheet for a pneumatic tire according to Example 1 did not include a base material layer. In the following, the sealing sheet for a pneumatic tire will be simply referred to as a sealing sheet.

- Example 2 A sealing sheet according to Example 2 was obtained in the same manner as in Example 1, except that only the release liner was peeled off from the urethane film with the release liner. That is, the sealing sheet according to Example 2 had a urethane film having a thickness of 25 ⁇ m as a base layer.

- Example 3 A sealing sheet according to Example 3 was obtained in the same manner as in Example 2, except that the mass of the sealing material layer and the total mass of the sealing sheet were changed as shown in Table 2.

- Example 4 A sealing sheet of Example 4 was obtained in the same manner as in Example 2, except that the sealing composition of Example 4 was used instead of the sealing composition of Example 2, and the adhesive layer was not formed.

- Example 5 A sealing sheet according to Example 5 was obtained in the same manner as in Example 4, except that the sealing composition according to Example 5 was used instead of the sealing composition according to Example 4.

- Example 6 A sealing sheet according to Example 6 was obtained in the same manner as in Example 2, except that the sealing composition according to Example 6 was used instead of the sealing composition according to Example 2.

- Example 7 A sheet according to Example 7 was obtained in the same manner as in Example 1, except that the sealing material composition according to Example 7 was used instead of the sealing material composition according to Example 1.

- Example 8 A sealing material composition for forming a first layer and a sealing material composition for forming a second layer were used instead of the sealing material composition for Example 2, and a pressure-sensitive adhesive layer was not formed.

- the sealing sheet for Example 8 was obtained in the same manner as in Example 2, except that a sealing material composition for forming a first layer and a sealing material composition for forming a second layer were used instead of the sealing material composition for Example 2, and a pressure-sensitive adhesive layer was not formed.

- the sealant composition for forming the first layer had the same composition as the sealant composition of Example 1, and the sealant composition for forming the second layer had the same composition as the sealant composition of Example 4.

- the first and second sealing material layers were formed on the base material layer in this order.

- the second sealing material layer had an exposed surface (adhesive surface).

- the first sealing material layer had a thickness of 0.15 mm

- the second sealing material layer had a thickness of 0.8 mm.

- Example 9 A sealing sheet according to Example 9 was obtained in the same manner as in Example 4, except that the base layer was not formed.

- Example 10 A sealing sheet according to Example 10 was obtained in the same manner as in Example 9, except that the elastic modulus of the release liner was set to 3600 MPa.

- Example 11 A sealing sheet according to Example 11 was obtained in the same manner as in Example 9, except that the elastic modulus of the release liner was set to 4200 MPa.

- Example 12 A sealing sheet according to Example 12 was obtained in the same manner as in Example 9, except that the thickness tolerance of the sheet material layer was set to 25%.

- Example 13 A sealing sheet according to Example 13 was obtained in the same manner as in Example 9, except that the thickness tolerance of the sheet material layer was set to 40%.

- ethylene propylene diene rubber (EPDM, trade name "X-3042E” manufactured by Mitsui Chemicals, Inc.) was used to form a sealing material layer (EPDM layer) on the exposed surface (surface where the release liner was not attached) of a base layer (urethane film with release liner (trade name "Tough Grace TG88-I 25/50” manufactured by Takeda Sangyo Kaisha, Ltd.; urethane film thickness 25 ⁇ m, release liner (made of polyethylene) thickness 50 ⁇ m).

- the sealing material layer was formed by applying the ethylene propylene diene rubber to a thickness of 0.5 mm while heating the rubber to 140° C.

- Example 3 an adhesive layer was formed on the sealing material layer to obtain a laminate in which the release liner, the sealing material layer, and the adhesive layer were laminated in this order. Then, the release liner was peeled off from the laminate to obtain a sealing sheet according to Comparative Example 3.

- the adhesive strength to the test tire was measured according to the method described in the above embodiment.

- the adhesive strength of the sealing material layer was measured at -20°C (A2) and at 23°C (A1).

- the adhesive strength of the adhesive layer to the tubeless tire was also measured.

- the adhesive strength of the adhesive layer was also measured at -20°C (A2') and at 23°C (A1'). The results are shown in Tables 2 to 5 below.

- the sealing performance was evaluated when a through hole was formed in a pneumatic tire using the sealing sheet according to each example.

- the evaluation of the sealing property was carried out according to the following procedure.

- the evaluation of the sealing property was carried out in an environment at a temperature of 23°C.

- (1) The seal sheet according to each example is cut into a small piece of seal sheet having planar dimensions of 30 mm x 50 mm, and then the small piece of seal sheet is attached to the inside of the test tire.

- the small piece of seal sheet has an adhesive layer

- the small piece of seal sheet is attached to the inside of the tire to be measured via the adhesive layer.

- the small piece of sealing sheet When the small piece of sealing sheet does not have an adhesive layer, the small piece of sealing sheet is attached to the inside of the tire to be measured via a sealing material layer.

- the tire for measurement with the small piece of the seal sheet attached to the inside is mounted on a wheel (manufactured by Shimano Corporation, product name "WH-RS500", rim profile: width 20.8 mm, height 24 mm). The measurement tire is mounted on the wheel without injecting a sealant material into the inside of the measurement tire.

- Air is again pumped into the inside of the test tire mounted on the wheel up to the specified pressure (95 psi (approximately 0.66 MPa)), and then a round nail with a thickness of 2.1 mm ( ⁇ 2.1 mm) is inserted to a depth of 20 mm into the area where the sheet sticker of the small piece is attached. Thereafter, the round nail is pulled out of the test tire to form a through hole in the test tire.

- the time when the through hole is formed i.e., when the round nail is pulled out

- the time when the through hole is formed is set as the observation starting point (0 min), and the pressure change is observed for a certain period of time (approximately 5 minutes) to determine the leak rate V2 (psi/min) after the through hole is formed.

- the difference (V 2 -V 1 ) between the leak rate V 2 and the leak rate V 1 is calculated, and the calculated value (relative rate) is set as the leak rate V 3 . That is, the closer the leak rate V3 is to 0, the greater the sealing effect of the sealing sheet. Taking the above into consideration, the sealing performance was evaluated according to the following criteria. Excellent: 0 ⁇ V 3 ⁇ 0.50 Good: 0.50 ⁇ V3 ⁇ 3.0 Not possible: 3.0 ⁇ V3 The leak rate V3 value and the evaluation results of the sealing property are shown in Tables 2 to 5 below.

- the seal sheet according to each example was used to evaluate the roll shape retention.

- Thiickness Tolerance/Average Thickness Measurement A first measurement point is selected in the length direction of the sealing sheet according to each example. The thickness is measured in 5 mm increments from one end of the width including the first measurement point to the other end. Next, the thickness is measured in 5 mm increments from one end of the width including a second measurement point 30 cm away from the first measurement point in the length direction to the other end. The average, maximum, and minimum values are calculated using all the thickness measurements. The calculated average value is the "average thickness" (mm) of the sealing sheet, and the difference between the maximum and minimum values is the "thickness tolerance" (mm).

- the roll shape retention is evaluated according to the following evaluation criteria.

- Tables 2 to 5 below also show the thickness of the base material layer, the mass of the base material layer, the thickness of the sealing material layer, the mass of the sealing material layer, the thickness of the adhesive layer, the mass of the adhesive layer, and the total mass of the sealing sheet.

- the sealing material layer was constructed by laminating two layers (first and second layers) with different compositions, so in the column for Example 8 in Table 3 below, the thickness and mass of each layer are listed, as well as the combined thickness and mass of the two layers.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Organic Chemistry (AREA)

- Materials Engineering (AREA)

- Inorganic Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)