WO2022018921A1 - 積層吸音材 - Google Patents

積層吸音材 Download PDFInfo

- Publication number

- WO2022018921A1 WO2022018921A1 PCT/JP2021/016192 JP2021016192W WO2022018921A1 WO 2022018921 A1 WO2022018921 A1 WO 2022018921A1 JP 2021016192 W JP2021016192 W JP 2021016192W WO 2022018921 A1 WO2022018921 A1 WO 2022018921A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- layer

- density

- absorbing material

- sound absorbing

- density layer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B25/00—Layered products comprising a layer of natural or synthetic rubber

- B32B25/10—Layered products comprising a layer of natural or synthetic rubber next to a fibrous or filamentary layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/12—Layered products comprising a layer of synthetic resin next to a fibrous or filamentary layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/22—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed

- B32B5/24—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer

- B32B5/26—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer another layer next to it also being fibrous or filamentary

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R13/00—Elements for body-finishing, identifying, or decorating; Arrangements or adaptations for advertising purposes

- B60R13/08—Insulating elements, e.g. for sound insulation

-

- G—PHYSICS

- G10—MUSICAL INSTRUMENTS; ACOUSTICS

- G10K—SOUND-PRODUCING DEVICES; METHODS OR DEVICES FOR PROTECTING AGAINST, OR FOR DAMPING, NOISE OR OTHER ACOUSTIC WAVES IN GENERAL; ACOUSTICS NOT OTHERWISE PROVIDED FOR

- G10K11/00—Methods or devices for transmitting, conducting or directing sound in general; Methods or devices for protecting against, or for damping, noise or other acoustic waves in general

- G10K11/16—Methods or devices for protecting against, or for damping, noise or other acoustic waves in general

-

- G—PHYSICS

- G10—MUSICAL INSTRUMENTS; ACOUSTICS

- G10K—SOUND-PRODUCING DEVICES; METHODS OR DEVICES FOR PROTECTING AGAINST, OR FOR DAMPING, NOISE OR OTHER ACOUSTIC WAVES IN GENERAL; ACOUSTICS NOT OTHERWISE PROVIDED FOR

- G10K11/00—Methods or devices for transmitting, conducting or directing sound in general; Methods or devices for protecting against, or for damping, noise or other acoustic waves in general

- G10K11/16—Methods or devices for protecting against, or for damping, noise or other acoustic waves in general

- G10K11/162—Selection of materials

- G10K11/168—Plural layers of different materials, e.g. sandwiches

Definitions

- the present invention relates to a laminated sound absorbing material. More specifically, the present invention relates to a laminated sound absorbing material containing at least two layers, a high-density layer and a low-density layer.

- Sound absorbing materials are used in various fields such as automobiles, railroad vehicles, aircraft, buildings, and acoustic facilities.

- a sound absorbing material in which a fiber layer and a porous layer are laminated is known.

- Patent Document 1 proposes a sound absorbing material in which a fiber layer having an air permeability of 30 to 220 cc / cm 2 ⁇ sec is arranged on the incident side and a porous layer is arranged on the non-incident side and laminated.

- Patent Document 2 proposes a sound absorbing material in which a porous sound absorbing body and two or more non-woven fabrics are laminated, and the non-woven fabric is a long fiber non-woven fabric which is stretched and arranged.

- Patent Document 3 proposes a laminated sound absorbing material which is an ethylene / propylene / diene rubber foam having a low density layer and a high density layer, and the low density layer has an open cell structure.

- Patent Document 4 proposes a sound absorbing material for construction in which a first layer is made of silicone rubber and a second layer is laminated with glass wool or rock wool.

- Patent Document 5 proposes a sound absorbing material in which the first layer is synthetic rubber and the second and third layers are non-woven fabrics.

- the above-mentioned laminated sound absorbing material of the prior art has a problem that the sound absorbing performance is low in the low frequency region.

- Electric vehicles whose demand and production volume have been increasing in recent years, run on electricity as an energy source and electric motors as a power source, so they do not generate noise from internal combustion engines and are quiet.

- road noise which is the frictional noise between the tire and the ground, which was previously unnoticeable because of the noise, becomes apparent.

- the frequency of this road noise is said to be 500 Hz or less.

- the present invention provides a laminated sound absorbing material having high sound absorbing performance in a low frequency region of 500 Hz or less that can cope with the road noise in order to solve the conventional problem.

- the laminated sound absorbing material of the present invention is a laminated sound absorbing material containing at least two layers, a high-density layer and a low-density layer, and the density of the high-density layer is 100 kg / m 3 or more and 400 kg / m 3 or less, and the low density.

- the density of the density layer is 10 kg / m 3 or more and 75 kg / m 3 or less

- the air permeability of the high density layer is 0 cm / sec or more and less than 30 cm / sec by the Frazier method

- the sound absorbing material is vertical at a frequency of 300 Hz.

- the incident sound absorption coefficient is 15% or more.

- the laminated sound absorbing material of the present invention includes at least two layers, a high-density layer and a low-density layer, and the density of the high-density layer is 100 kg / m 3 or more and 400 kg / m 3 or less, and the density of the low-density layer is 10 kg. / m 3 or more 75 kg / m 3 or less, the high-density layer is air permeability is less than 0 cm / sec or more 30 cm / sec by Frazier method, the sound absorbing material, normal incidence sound absorption coefficient at the frequency 300Hz 15% From the above, it is possible to provide a laminated sound absorbing material having high sound absorbing performance in a low frequency region of 500 Hz or less. As a result, it can cope with road noise.

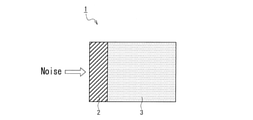

- FIG. 1 is a schematic cross-sectional view of a laminated sound absorbing material according to an embodiment of the present invention.

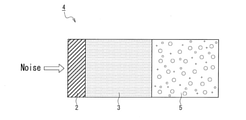

- FIG. 2 is a schematic cross-sectional view of a laminated sound absorbing material according to another embodiment of the present invention.

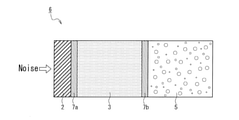

- FIG. 3 is a schematic cross-sectional view of the laminated sound absorbing material according to still another embodiment of the present invention.

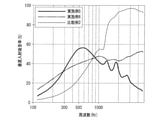

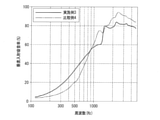

- FIG. 4 is a vertical incident sound absorption coefficient graph of Examples 1 to 4 and Comparative Example 1 of the present invention.

- FIG. 5 is a vertical incident sound absorption coefficient graph of Examples 5 to 6 and Comparative Example 2 of the present invention.

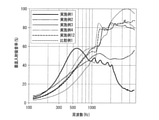

- FIG. 6 is a vertical incident sound absorption coefficient graph of Examples 7 to 10 and Comparative Example 3 of the present invention.

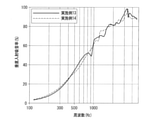

- FIG. 7 is a vertical incident sound absorption coefficient graph of Example 9 (without adhesive layer) and Example 11 (with adhesive layer) of the present invention.

- FIG. 8 is a vertical incident sound absorption coefficient graph of Example 3 and Comparative Example 4 of the present invention.

- FIG. 9 is a vertical incident sound absorption coefficient graph of Example 12, Examples 1 to 4 and Comparative Example 1 of the present invention.

- FIG. 10 is a vertical incident sound absorption coefficient graph of Examples 13 and 14 of the present invention.

- FIG. 11 is a vertical incident sound absorption coefficient graph of Examples 15 to 20 of the present invention.

- the present invention is a laminated sound absorbing material including at least two layers, a high-density layer and a low-density layer.

- the high-density layer and the low-density layer may be one layer or a plurality of layers, respectively.

- the density of the high-density layer is 100 kg / m 3 or more and 400 kg / m 3 or less, preferably 105 kg / m 3 or more and 380 kg / m 3 or less, and more preferably 110 kg / m 3 or more and 360 kg / m 3 or less.

- the high-density layer vibrates effectively, and the sound absorption in the low frequency region becomes good.

- the density of the low-density layer is 10 kg / m 3 or more and 75 kg / m 3 or less, preferably 13 kg / m 3 or more and 70 kg / m 3 or less, and more preferably 16 kg / m 3 or more and 60 kg / m 3 or less.

- the high-density layer has an air permeability of 0 cm / sec or more and less than 30 cm / sec according to the Frazier method.

- the vertical incident sound absorption coefficient at a frequency of 300 Hz is preferably 15% or more and 100% or less, and more preferably 16% or more and 99% or less.

- the sound absorbing material preferably has a vertically incident sound absorption coefficient of 30% or more at a frequency of 500 Hz. This makes it possible to provide a laminated sound absorbing material having high sound absorbing performance in a low frequency region that can cope with road noise.

- the vertical incident sound absorption coefficient at a frequency of 500 Hz is preferably 30% or more and 100% or less, and more preferably 31% or more and 99% or less.

- the relationship between the vertical incident sound absorption coefficient (A) at a frequency of 300 Hz and the vertical incident sound absorption coefficient (B) at a frequency of 500 Hz is preferably A ⁇ B.

- the sound absorbing material is preferably arranged so that the high-density layer is in the incident direction of sound. As a result, when the sound comes into contact with the sound absorbing material, the high-density layer vibrates effectively, and the sound absorbing efficiency in the low frequency region can be improved.

- the high-density layer is preferably at least one selected from an elastic body, a foam, and a non-woven fabric.

- an elastic body natural rubber, synthetic rubber, synthetic resin elastomer and the like can be used.

- the foam a rubber foam, a polyurethane foam, a polyolefin resin foam, or the like can be used.

- the foam can be either a continuous foam or an independent foam, but a continuous foam is preferable.

- the foaming ratio is preferably 2 to 10 times.

- the non-woven fabric synthetic fiber non-woven fabric is preferable, and short fiber non-woven fabric and long fiber non-woven fabric can be used.

- the method for producing the non-woven fabric is not particularly limited. These may be used alone or laminated.

- the low density layer preferably contains a non-woven fabric.

- a non-woven fabric synthetic fiber non-woven fabric is preferable, and short fiber non-woven fabric and long fiber non-woven fabric can be used.

- the method for producing the non-woven fabric is not particularly limited.

- a foam such as a rubber foam, a polyurethane foam, or a polyolefin resin foam can be used by laminating it with a non-woven fabric.

- the thickness of the high-density layer is preferably 0.01 mm or more and 20 mm or less, more preferably 0.02 mm or more and 15 mm or less, and further preferably 0.04 mm or more and 10 mm or less.

- the thickness of the low density layer is preferably 3 mm or more and 80 mm or less, more preferably 5 mm or more and 65 mm or less, and further preferably 7 mm or more and 50 mm or less.

- the thickness of the laminated sound absorbing material is preferably 3.01 mm or more and 100 mm or less, more preferably 5 mm or more and 80 mm or less, and further preferably 7 mm or more and 60 mm or less. If the thickness is 3.01 mm or more, the sound absorbing performance in the low frequency region is good, and if the thickness is 100 mm or less, the sound absorbing material is excellent in space saving.

- the high-density layer and the low-density layer may or may not be laminated and integrated by using an adhesive, double-sided tape, or the like.

- the adhesive or double-sided tape may be applied or attached to the entire surface of the adhesive surface, or may be applied or attached in a dot shape, a linear shape, or a grid pattern.

- the high-density layer and the low-density layer may be adhered by mixing the heat-sealed fibers and heating them in a subsequent step.

- a heat-sealing sheet may be sandwiched between the layers and heated in a subsequent step to bond the high-density layer and the low-density layer.

- the high-density layer is preferably one layer, and the low-density layer is preferably two layers.

- the low-density layer may be one layer, but if two layers are used, the sound is reflected by each layer, the sound propagation becomes complicated, and the sound absorption coefficient can be easily controlled.

- Both the high-density layer and the low-density layer are preferably non-woven fabrics. This makes it easier to improve the sound absorption coefficient in the high frequency range.

- thermoformability can be easily imparted and controlled.

- the laminated sound absorbing material is useful as a sound absorbing material for road noise of automobiles. It is useful as a sound absorbing material for road noise of electric vehicles (EVs). It can be incorporated in places around automobile tires, dashboards, interior surfaces, etc.

- the laminated sound absorbing material of the present invention is preferably formed on a long sheet and is preferably commercialized in a rolled state. If it is a long sheet, it can be cut into a size and shape suitable for the purpose.

- the roll shape is convenient for transportation, movement, and supply.

- FIG. 1 is a schematic cross-sectional view of the laminated sound absorbing material 1 according to the embodiment of the present invention.

- the laminated sound absorbing material 1 is composed of a high-density layer 2 and a low-density layer 3.

- FIG. 2 is a schematic cross-sectional view of the laminated sound absorbing material 4 according to another embodiment of the present invention.

- the laminated sound absorbing material 4 is composed of a high-density layer 2 and low-density layers 3 and 5. In this embodiment, no adhesive is used, only the layers are overlapped, and they are not integrated.

- FIG. 1 is a schematic cross-sectional view of the laminated sound absorbing material 1 according to the embodiment of the present invention.

- the laminated sound absorbing material 1 is composed of a high-density layer 2 and a low-density layer 3.

- no adhesive is used, only the layers are overlapped, and they are not integrated.

- FIG 3 is a schematic cross-sectional view of the laminated sound absorbing material 6 according to still another embodiment of the present invention, in which the adhesive layers 7a and 7b are interposed between the layers of the high-density layer 2 and the low-density layers 3 and 5, respectively. Is.

- the measurement method is as follows. ⁇ Vertical incident sound absorption coefficient> After collecting a sample with a diameter of 40 mm and laminating under each condition, a vertical incident sound absorption coefficient measuring device "WinZac MTX manufactured by Nippon Acoustic Engineering Co., Ltd.” was used to comply with ASTM E 1050, and the frequency range of the sample was 117 to 5000 Hz. The vertical incident sound absorption coefficient of was measured. ⁇ Breathability> The air permeability was measured by a Frazier type air permeability tester manufactured by Toyo Seiki Seisakusho Co., Ltd. in accordance with JIS L1096. ⁇ Thickness> It was measured using a thickness gauge. ⁇ Others> It was measured according to JIS or the measuring method specified by the industry.

- the first layer is a high-density layer

- the second and third layers are low-density layers.

- First layer As a high-density layer, a layer of three natural rubber sheets (manufactured by Miyahara Rubber Industry Co., Ltd., trade name "Thomson # 17") was used. The density was 223 kg / m 3 , the mass per unit area (hereinafter referred to as "mass”) was 835 g / m 2 , and the thickness was 4 mm.

- Second layer As a low-density layer, a needle-punched non-woven fabric made of acrylic fiber (manufactured by Mitsubishi Chemical Corporation, trade name "Bonnel") having a fineness of 2.2 decitex (fiber diameter of 18 ⁇ m) and a fiber length of 51 mm was used. The density was 41 kg / m 3 , the mass was 326 g / m 2 , and the thickness was 8 mm.

- Third layer As a low-density layer, a needle-punched non-woven fabric made of acrylic fiber (manufactured by Mitsubishi Chemical Corporation, trade name “Bonnel”) having a fineness of 2.2 decitex (fiber diameter of 18 ⁇ m) and a fiber length of 51 mm was used. The density was 36 kg / m 3 , the mass was 286 g / m 2 , and the thickness was 8 mm. In this example, no adhesive was used, only the layers were overlapped, and they were not integrated.

- Example 2 A polyurethane sheet (manufactured by Inoac Corporation, trade name "F-140”) was used as a high-density layer. The density was 133 kg / m 3 , the mass was 1329 g / m 2 , and the thickness was 10 mm. Second layer: As a low-density layer, a needle-punched non-woven fabric made of acrylic fiber (manufactured by Mitsubishi Chemical Corporation, trade name “Bonnel”) having a fineness of 2.2 decitex (fiber diameter of 18 ⁇ m) and a fiber length of 51 mm was used. The density was 41 kg / m 3 , the mass was 326 g / m 2 , and the thickness was 8 mm. Other than that, it was carried out in the same manner as in Example 1.

- First layer As a high-density layer, a polyester long fiber non-woven fabric (manufactured by JXTG, trade name "Milife MF-M20", average fiber diameter 3 ⁇ m) was used. The density was 351 kg / m 3 , the mass was 20 g / m 2 , and the thickness was 0.06 mm.

- Second layer As a low-density layer, a needle-punched non-woven fabric made of acrylic fiber (manufactured by Mitsubishi Chemical Corporation, trade name "Bonnel”) having a fineness of 2.2 decitex (fiber diameter of 18 ⁇ m) and a fiber length of 51 mm was used.

- the density was 41 kg / m 3 , the mass was 326 g / m 2 , and the thickness was 8 mm.

- Third layer As a low-density layer, a needle-punched non-woven fabric made of acrylic fiber (manufactured by Mitsubishi Chemical Corporation, trade name "Bonnel") having a fineness of 1.1 decitex (fiber diameter of 11 ⁇ m) and a fiber length of 44 mm was used. The density was 47 kg / m 3 , the mass was 465 g / m 2 , and the thickness was 10 mm. Other than that, it was carried out in the same manner as in Example 1.

- Example 4 As a high-density layer, a meltblown long-fiber non-woven fabric using polypropylene (manufactured by PolyMirae, trade name "Moplen-HP461X”) and an average fiber diameter of 1 ⁇ m were used. The density was 113 kg / m 3 , the mass was 60 g / m 2 , and the thickness was 0.53 mm. Other than that, it was carried out in the same manner as in Example 3.

- Polypropylene manufactured by PolyMirae, trade name "Moplen-HP461X”

- First layer As a high-density layer, a meltblown long-fiber non-woven fabric using polypropylene (manufactured by PolyMirae, trade name "Moplen-HP461X”) and an average fiber diameter of 1 ⁇ m were used. The density was 96 kg / m 3 , the mass was 24 g / m 2 , and the thickness was 0.25 mm.

- Second layer As a low-density layer, a needle-punched non-woven fabric made of acrylic fiber (manufactured by Mitsubishi Chemical Corporation, trade name "Bonnel”) having a fineness of 2.2 decitex (fiber diameter of 18 ⁇ m) and a fiber length of 51 mm was used.

- the density was 41 kg / m 3 , the mass was 326 g / m 2 , and the thickness was 8 mm.

- Third layer As a low-density layer, a needle-punched non-woven fabric made of acrylic fiber (manufactured by Mitsubishi Chemical Corporation, trade name "Bonnel") having a fineness of 3.3 decitex (fiber diameter 27 ⁇ m) and a fiber length of 76 mm was used. The density was 31 kg / m 3 , the mass was 310 g / m 2 , and the thickness was 10 mm. Other than that, it was carried out in the same manner as in Example 1. The above conditions and results are summarized in Table 1. Further, FIG. 4 shows the vertical incident sound absorption coefficient graphs of Examples 1 to 4 and Comparative Example 1.

- First layer The same natural rubber sheet as in Example 1 was used as the high-density layer.

- Second layer As a low-density layer, a needle-punched non-woven fabric made of acrylic fiber (manufactured by Mitsubishi Chemical Corporation, trade name "Bonnel") having a fineness of 2.2 decitex (fiber diameter of 18 ⁇ m) and a fiber length of 51 mm was used. The density was 41 kg / m 3 , the mass was 326 g / m 2 , and the thickness was 8 mm.

- Third layer As a low-density layer, a needle-punched non-woven fabric made of acrylic fiber (manufactured by Mitsubishi Chemical Corporation, trade name "Bonnel") having a fineness of 1.1 decitex (fiber diameter of 11 ⁇ m) and a fiber length of 44 mm was used. The density was 47 kg / m 3 , the mass was 465 g / m 2 , and the thickness was 10 mm. Other than that, it was carried out in the same manner as in Example 1.

- Example 6 As the high-density layer, the polyurethane sheet used in Example 2 was used instead of the natural rubber sheet. Other than that, it was carried out in the same manner as in Example 5.

- Comparative Example 2 First layer: As the high-density layer, the same procedure as in Example 5 was carried out except that the polypropylene meltblown long fiber non-woven fabric used in Comparative Example 1 was used instead of the natural rubber sheet. Table 2 summarizes the above conditions and results. Further, FIG. 5 shows the vertical incident sound absorption coefficient graphs of Examples 5 to 6 and Comparative Example 2.

- First layer As a high-density layer, three natural rubber sheets were laminated and a thickness of 4 mm was used.

- Second layer As a low-density layer, a needle-punched non-woven fabric made of acrylic fiber (manufactured by Mitsubishi Chemical Corporation, trade name "Bonnel") having a fineness of 2.2 decitex (fiber diameter of 18 ⁇ m) and a fiber length of 51 mm was used. The density was 41 kg / m 3 , the mass was 326 g / m 2 , and the thickness was 8 mm.

- Third layer A polyurethane sheet (manufactured by Inoac Corporation, trade name "F-9L”) was used as a low-density layer. The density was 29 kg / m 3 , the mass was 286 g / m 2 , and the thickness was 10 mm. Other than that, it was carried out in the same manner as in Example 1.

- Example 8 As the high-density layer, the polyurethane sheet used in Example 2 was used instead of the natural rubber sheet. Other than that, it was carried out in the same manner as in Example 7.

- Example 9 First layer: As the high-density layer, the polyester long fiber non-woven fabric used in Example 3 was used instead of the natural rubber sheet. Other than that, it was carried out in the same manner as in Example 7.

- Example 10 First layer: As the high-density layer, the polypropylene meltblown long fiber non-woven fabric used in Example 4 was used instead of the natural rubber sheet. Other than that, it was carried out in the same manner as in Example 7.

- Comparative Example 3 First layer: As the high-density layer, the same procedure as in Example 7 was carried out except that the polypropylene meltblown long fiber non-woven fabric used in Comparative Example 1 was used instead of the natural rubber sheet. The above conditions and results are summarized in Table 3. Further, FIG. 6 shows the vertical incident sound absorption coefficient graphs of Examples 7 to 10 and Comparative Example 3.

- the laminated sound absorbing materials of Examples 1 to 10 have a high vertical incident sound absorption coefficient at a frequency of 500 H or less, and have high sound absorption performance in a low frequency region that can cope with road noise. Was confirmed.

- Example 11 In Example 9, each layer was laminated without using an adhesive, but this example is an example in which an adhesive layer is interposed between each of the first layer, the second layer, and the third layer.

- a heat-sealing sheet manufactured by Shimizu Sou Co., Ltd., trade name "PA110-12", mass 12 g / m 2

- the bonding method as shown in the adhesive layers 7a and 7b of FIG. 3, the heat-sealed sheet was sandwiched and heat-treated at 135 ° C. for 5 minutes for bonding.

- Table 4 The results of Example 9 and Example 11 are summarized in Table 4. Further, FIG. 7 is a vertical incident sound absorption coefficient graph of Example 9 (without an adhesive layer) and Example 11 (with an adhesive layer) of the present invention.

- This comparative example is an example when the density of the low density layer (second layer and third layer) is outside the range of the present invention.

- First layer As a high-density layer, a polyester long fiber non-woven fabric (manufactured by JXTG, trade name "Milife MF-M20", average fiber diameter 3 ⁇ m) was used. The density was 351 kg / m 3 , the mass was 20 g / m 2 , and the thickness was 0.06 mm.

- Second layer As a low-density layer, a melt-blown long-fiber non-woven fabric using polypropylene (manufactured by Prime Polymer Co., Ltd., trade name "S119") and an average fiber diameter of 21 ⁇ m were used. The density was 85 kg / m 3 , the mass was 680 g / m 2 , and the thickness was 8 mm.

- Third layer As a low-density layer, a melt-blown long-fiber non-woven fabric using polypropylene (manufactured by Prime Polymer Co., Ltd., trade name "S119”) and an average fiber diameter of 21 ⁇ m were used. The density was 86 g / m 3 , the mass was 863 g / m 2 , and the thickness was 10 mm. The conditions and results are shown in Table 5 and FIG. 8 in comparison with Example 3.

- the sound absorbing low frequency ability in the region is not preferable.

- Example 12 First layer: As a high-density layer, a polybutylene terephthalate long fiber non-woven fabric (manufactured by Kuraray, trade name "BTS0040EM", average fiber diameter 3 ⁇ m) was used. This non-woven fabric is a melt blown (MB) non-woven fabric. The density was 154 kg / m 3 , the mass was 40 g / m 2 , and the thickness was 0.26 mm. Other than that, it was carried out in the same manner as in Example 3. The conditions and results are shown in Table 6, and FIG. 9 shows the vertical incident sound absorption coefficient graphs of Example 12, Examples 1 to 4, and Comparative Example 1.

- Example 12 also had a good vertical incident sound absorption coefficient at 500 Hz or less.

- First layer As a high-density layer, a polybutylene terephthalate long fiber non-woven fabric (manufactured by Kuraray, trade name "BTS0040EM", average fiber diameter 3 ⁇ m) was used. The density was 154 kg / m 3 , the mass was 40 g / m 2 , and the thickness was 0.26 mm.

- Second layer As a low density layer, a needle punched non-woven fabric made of polyester fiber (manufactured by Teijin Limited) having a fineness of 2.2 decitex (fiber diameter of 14 ⁇ m) and a fiber length of 51 mm was used.

- the density was 38 kg / m 3 , the mass was 315 g / m 2 , and the thickness was 9 mm.

- Third layer As a low-density layer, a needle-punched non-woven fabric made of polyester fiber (manufactured by Teijin Limited) having a fineness of 2.2 decitex (fiber diameter of 14 ⁇ m) and a fiber length of 51 mm was used. The density was 40 kg / m 3 , the mass was 358 g / m 2 , and the thickness was 9 mm.

- An adhesive layer was interposed between each of the first layer, the second layer, and the third layer for adhesion.

- a heat-sealing sheet (manufactured by Kureha Tech Co., Ltd., trade name "LNS3010", mass 10 g / m 2 ) was used as the adhesive layer for adhesion.

- the bonding method similarly to the adhesive layers 7a and 7b of FIG. 3, the heat-sealed sheet was sandwiched and heat-treated at 100 ° C. for 5 minutes for bonding.

- Example 14 First layer: As a high-density layer, a polybutylene terephthalate long fiber non-woven fabric (manufactured by Kuraray, trade name "BTS0040EM", average fiber diameter 3 ⁇ m) was used. The density was 154 kg / m 3 , the mass was 40 g / m 2 , and the thickness was 0.26 mm.

- BTS0040EM polybutylene terephthalate long fiber non-woven fabric

- Second layer As a low density layer, fineness 2.2 decitex (fiber diameter 14 ⁇ m), polyester fiber with fiber length 51 mm (manufactured by Teijin Corporation) 80% by mass and fineness 2.2 decitex (fiber diameter 19 ⁇ m), fiber length 51 mm A needle punched non-woven fabric made of 20% by mass of polyester core-sheath fiber (manufactured by HUVIS) was used. The density was 36 kg / m 3 , the mass was 326 g / m 2 , and the thickness was 9 mm.

- Third layer As a low density layer, fineness 2.2 decitex (fiber diameter 14 ⁇ m), polyester fiber with fiber length 51 mm (manufactured by Teijin Corporation) 80% by mass and fineness 2.2 decitex (fiber diameter 19 ⁇ m), fiber length 51 mm A needle punched non-woven fabric made of 20% by mass of polyester core-sheath fiber (manufactured by HUVIS) was used. The density was 37 kg / m 3 , the mass was 334 g / m 2 , and the thickness was 9 mm. An adhesive layer was interposed between each of the first layer, the second layer, and the third layer for adhesion.

- a heat-sealing sheet manufactured by Kureha Tech Co., Ltd., trade name "LNS3010", mass 10 g / m 2 ) was used for adhesion.

- the bonding method similarly to the adhesive layers 7a and 7b of FIG. 3, the heat-sealed sheet was sandwiched and heat-treated at 100 ° C. for 5 minutes for bonding.

- the conditions and results of Examples 13 and 14 are shown in Table 7, and FIG. 10 shows a vertical incident sound absorption coefficient graph of Examples 13 and 14.

- the stiffness and softness were measured according to the method described in the 6.7.4 Galle method of JIS L1913.

- thermoformability As is clear from Table 7 and FIG. 9, there was no significant change in the vertical incident sound absorption coefficient (%) at 300 Hz and 500 Hz depending on the presence or absence of thermoformability. However, if it has thermoformability, the rigidity and softness are improved, and the handleability is excellent.

- Example 15 First layer: As a high-density layer, a polybutylene terephthalate long fiber non-woven fabric (manufactured by Kuraray, trade name "BTS0040EM", average fiber diameter 3 ⁇ m) was used. The density was 154 kg / m 3 , the mass was 40 g / m 2 , and the thickness was 0.26 mm.

- BTS0040EM polybutylene terephthalate long fiber non-woven fabric

- Second layer As a low density layer, fineness 2.2 decitex (fiber diameter 14 ⁇ m), polyester fiber with fiber length 51 mm (manufactured by Teijin Corporation) 80% by mass and fineness 4.4 decitex (fiber diameter 23 ⁇ m), fiber length 51 mm A needle punched non-woven fabric made of 20% by mass of polyester core-sheath fiber (manufactured by Toray Co., Ltd.) was used. The density was 38 kg / m 3 , the mass was 342 g / m 2 , and the thickness was 9 mm.

- Third layer As a low-density layer, fineness 2.2 decitex (fiber diameter 14 ⁇ m), polyester fiber with fiber length 51 mm (manufactured by Teijin Corporation) 80% by mass and fineness 4.4 decitex (fiber diameter 23 ⁇ m), fiber length 51 mm A needle punched non-woven fabric made of 20% by mass of polyester core-sheath fiber (manufactured by Toray Co., Ltd.) was used. The density was 34 kg / m 3 , the mass was 302 g / m 2 , and the thickness was 9 mm.

- Second layer, third layer The same as in Example 15 was produced by changing the mass and thickness.

- Second layer, third layer The same as in Example 15 was produced by changing the mass and thickness.

- Example 18 First layer: As the high-density layer, the polyester long fiber non-woven fabric used in Example 3 was used. Other than that, it was carried out in the same manner as in Example 15.

- Example 19 First layer: As the high-density layer, the polyester long fiber non-woven fabric used in Example 3 was used. Other than that, it was carried out in the same manner as in Example 16.

- Example 20 First layer: As the high-density layer, the polyester long fiber non-woven fabric used in Example 3 was used. Other than that, it was carried out in the same manner as in Example 17.

- Second layer, third layer The same as in Example 15 was produced by changing the mass and thickness.

- Example 22 First layer: As the high-density layer, the polyester long fiber non-woven fabric used in Example 3 was used. Other than that, it was carried out in the same manner as in Example 21. The conditions and results of Examples 15 to 22 are summarized in Table 8 and a vertical incident sound absorption coefficient graph is shown in FIG.

- the laminated sound absorbing materials of Examples 15 to 22 had an excellent vertical incident sound absorption coefficient (%) of 500 Hz or less.

- Examples 17 and 20 to 22 were excellent.

- the laminated sound absorbing material of the present invention is useful as a sound absorbing material for road noise of automobiles, and can be incorporated into a place around a tire of an automobile, a dashboard, an interior surface, or the like.

Landscapes

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Acoustics & Sound (AREA)

- Multimedia (AREA)

- Mechanical Engineering (AREA)

- Laminated Bodies (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2021569465A JPWO2022018921A1 (enExample) | 2020-07-21 | 2021-04-21 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020-124598 | 2020-07-21 | ||

| JP2020124598 | 2020-07-21 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2022018921A1 true WO2022018921A1 (ja) | 2022-01-27 |

Family

ID=79728589

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2021/016192 Ceased WO2022018921A1 (ja) | 2020-07-21 | 2021-04-21 | 積層吸音材 |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JPWO2022018921A1 (enExample) |

| WO (1) | WO2022018921A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2023127710A (ja) * | 2022-03-02 | 2023-09-14 | 川崎重工業株式会社 | 音響構造材及び構造体 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010085873A (ja) * | 2008-10-02 | 2010-04-15 | Kuraray Kuraflex Co Ltd | 複層吸音材 |

| WO2019172016A1 (ja) * | 2018-03-08 | 2019-09-12 | Jnc株式会社 | 積層吸音材 |

| JP6646267B1 (ja) * | 2019-03-22 | 2020-02-14 | Jnc株式会社 | 積層吸音材 |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6603121B2 (ja) * | 2014-12-24 | 2019-11-06 | 日東電工株式会社 | 吸音材 |

| MX2017011285A (es) * | 2015-03-12 | 2018-01-23 | Toray Industries | Tela no tejida laminada. |

-

2021

- 2021-04-21 JP JP2021569465A patent/JPWO2022018921A1/ja active Pending

- 2021-04-21 WO PCT/JP2021/016192 patent/WO2022018921A1/ja not_active Ceased

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2010085873A (ja) * | 2008-10-02 | 2010-04-15 | Kuraray Kuraflex Co Ltd | 複層吸音材 |

| WO2019172016A1 (ja) * | 2018-03-08 | 2019-09-12 | Jnc株式会社 | 積層吸音材 |

| JP6646267B1 (ja) * | 2019-03-22 | 2020-02-14 | Jnc株式会社 | 積層吸音材 |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2023127710A (ja) * | 2022-03-02 | 2023-09-14 | 川崎重工業株式会社 | 音響構造材及び構造体 |

Also Published As

| Publication number | Publication date |

|---|---|

| JPWO2022018921A1 (enExample) | 2022-01-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| EP1612768B1 (en) | Ultralight soundproof material | |

| CN103260954B (zh) | 汽车用消音片及其制造方法以及汽车用挡板消音垫 | |

| JP5608383B2 (ja) | 自動車用エンジンアンダーカバー | |

| CN104395954A (zh) | 防音材 | |

| KR101317818B1 (ko) | 흡음성능이 개선된 자동차용 대쉬 인너 인슐레이터 | |

| JP3930506B2 (ja) | 超軽量な防音材 | |

| JP2013522094A5 (enExample) | ||

| CN105474305B (zh) | 吸音材料及带吸音材料的线束 | |

| JP2007515339A (ja) | 特に自動車用の多層音波吸収軽量部材 | |

| EP2937858B1 (en) | Dash pad for vehicle | |

| JP7326649B2 (ja) | 自動車用遮音材 | |

| JP2010234991A (ja) | 車両用防音材 | |

| JP3347253B2 (ja) | 自動車用サイレンサーパッド | |

| JP2021043388A (ja) | 吸遮音材 | |

| JP6585918B2 (ja) | 自動車用低重量吸音型ダッシュパッド | |

| JP4691388B2 (ja) | 超軽量な防音材 | |

| WO2022018921A1 (ja) | 積層吸音材 | |

| JPH11217051A (ja) | 自動車用内装材 | |

| KR100916279B1 (ko) | 자동차용 흡차음재 | |

| JP3930484B2 (ja) | 超軽量な防音材 | |

| EP3413302B1 (en) | Sound attenuation sheet | |

| JP2005121994A (ja) | 超軽量な防音材 | |

| JP2014029504A (ja) | 防音材 | |

| JP2014028611A (ja) | 自動車用防音材 | |

| KR101497379B1 (ko) | 자동차용 인슐레이션 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| ENP | Entry into the national phase |

Ref document number: 2021569465 Country of ref document: JP Kind code of ref document: A |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 21844617 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 21844617 Country of ref document: EP Kind code of ref document: A1 |