WO2022009487A1 - クリップ構造及びピン部材 - Google Patents

クリップ構造及びピン部材 Download PDFInfo

- Publication number

- WO2022009487A1 WO2022009487A1 PCT/JP2021/013253 JP2021013253W WO2022009487A1 WO 2022009487 A1 WO2022009487 A1 WO 2022009487A1 JP 2021013253 W JP2021013253 W JP 2021013253W WO 2022009487 A1 WO2022009487 A1 WO 2022009487A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- protrusion

- leg

- clip structure

- pin member

- pedestal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16B—DEVICES FOR FASTENING OR SECURING CONSTRUCTIONAL ELEMENTS OR MACHINE PARTS TOGETHER, e.g. NAILS, BOLTS, CIRCLIPS, CLAMPS, CLIPS OR WEDGES; JOINTS OR JOINTING

- F16B19/00—Bolts without screw-thread; Pins, including deformable elements; Rivets

- F16B19/04—Rivets; Spigots or the like fastened by riveting

- F16B19/08—Hollow rivets; Multi-part rivets

- F16B19/10—Hollow rivets; Multi-part rivets fastened by expanding mechanically

- F16B19/1027—Multi-part rivets

- F16B19/1036—Blind rivets

- F16B19/1081—Blind rivets fastened by a drive-pin

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16B—DEVICES FOR FASTENING OR SECURING CONSTRUCTIONAL ELEMENTS OR MACHINE PARTS TOGETHER, e.g. NAILS, BOLTS, CIRCLIPS, CLAMPS, CLIPS OR WEDGES; JOINTS OR JOINTING

- F16B19/00—Bolts without screw-thread; Pins, including deformable elements; Rivets

- F16B19/04—Rivets; Spigots or the like fastened by riveting

- F16B19/08—Hollow rivets; Multi-part rivets

- F16B19/10—Hollow rivets; Multi-part rivets fastened by expanding mechanically

Definitions

- the present invention relates to a clip structure and a pin member to be attached to the attached member.

- the bumper retainer (glomet) moves in a direction that deviates from the body due to the load or external force of the bumper, the force acts in the direction of shearing the pin, the pin tilts, and the flange deforms.

- the present invention has been proposed in view of such circumstances. That is, it is an object of the present invention to provide a clip structure and a pin member having a high shearing force.

- a leg portion to be inserted into the attached member is formed on a pedestal portion facing the attached member, and the leg portion is arranged around the pedestal portion.

- It is a clip structure composed of a grommet member having a hole to be inserted and a pin member having a shaft portion inserted into the hole to be inserted and engaging with the leg portion, and the grommet member is the grommet member. It has a protrusion that protrudes toward the side opposite to the leg with respect to the pedestal, and the pin member meets the protrusion in a direction that intersects the shaft on the protrusion side of the pedestal. It is characterized by having a receiving portion to hit.

- the clip structure according to the present invention has a concave groove shape in which the shaft portion and the receiving portion are connected to each other, the flange portion is connected to the receiving portion, and the protrusion portion is inserted between the receiving portion and the flange portion. It is characterized by being formed in.

- the clip structure according to the present invention is characterized in that the flange portion has a thin-walled portion that is pressed against the pedestal portion.

- the clip structure according to the present invention is characterized in that the leg portion has a rib that hits the edge of a hole of the attached member.

- the clip structure according to the present invention is characterized in that the protrusion is formed in an annular shape at the edge of the inserted hole, and the receiving portion is formed in an annular shape on an extension of the shaft portion.

- the pin member according to the present invention is a grommet in which a leg portion to be inserted into the attached member is formed on a pedestal portion facing the attached member and an inserted hole is formed in which the leg portion is arranged around the pin member.

- a pin member that engages with a member and is an extension of the shaft portion that is inserted into the insertion hole and engages with the leg portion and on the side opposite to the leg portion with respect to the pedestal portion.

- An annular concave groove portion that is depressed on the opposite side of the shaft portion and into which a part of the grommet member is inserted, a receiving portion that is connected to the extension of the shaft portion and is a part of the concave groove portion, and the above. It is characterized by having a thin-walled portion connected to the concave groove portion and pressed against the pedestal portion.

- the grommet member has a protrusion that protrudes from the pedestal portion toward the side opposite to the leg portion, and the pin member intersects the shaft portion on the protrusion side of the pedestal portion. It has a receiving part that hits the protrusion in the direction of Even if some force acts on the grommet member in the direction that the grommet member deviates from the mounted member from the direction that intersects the shaft portion of the pin member, the tip of the direction in which the pin member tends to tilt. There is a protrusion of the grommet member, and the receiving portion of the pin member hits the protrusion to prevent the pin member from tilting. That is, it can be said that the present invention has a high shearing force.

- the clip structure according to the present invention is formed in a concave groove shape in which a shaft portion and a receiving portion are connected, a flange portion is connected to the receiving portion, and a protrusion is inserted between the receiving portion and the flange portion. That is, the protrusion of the grommet member is inserted into the concave groove-shaped portion of the pin member. In this state, even if some force acts in the direction in which the grommet member deviates from the attached member, the pin member in which the protrusion of the grommet member is inserted into the concave groove-shaped portion is prevented from tilting. Will be done. That is, it can be said that the present invention has a high shearing force.

- the clip structure according to the present invention has a thin-walled portion in which the flange portion is pressed against the pedestal portion. That is, since the pin member is prevented from tilting, the flange is not deformed, and the flange portion is pressed against the pedestal portion of the grommet member while covering the protrusion. Therefore, the present invention can realize watertightness.

- the legs have ribs that hit the edges of the holes of the attached member. That is, since the rigidity of the leg portion is increased by the rib, the grommet member is less likely to shift. Further, even when some force acts in the direction in which the grommet member deviates from the attached member, the rib of the leg portion of the grommet member hits the edge of the hole of the attached member, so that the grommet member can be formed. It is hard to shift.

- the protrusion is formed in an annular shape at the edge of the hole to be inserted, and the receiving portion is formed in an annular shape on the extension of the shaft portion.

- the receiving portion of the pin member and the protruding portion of the grommet member are in contact with each other on the entire peripheral surface to be firm, and a high shearing force is realized.

- the protrusion is on the edge of the inserted hole and the receiving portion is on the shaft portion of the pin member, the protrusion and the receiving portion are formed at a position away from the inserted hole and the shaft portion. In comparison, the pin member is prevented from tilting. That is, it can be said that the present invention has a high shearing force.

- the pin member according to the present invention is recessed on the side opposite to the leg portion with respect to the shaft portion inserted into the insertion hole and engaged with the leg portion, and on the side opposite to the shaft portion on the extension of the shaft portion.

- An annular concave groove portion into which a part of the grommet member is inserted, a receiving portion connected to the extension of the shaft portion and a part of the concave groove portion, and a thin wall portion connected to the concave groove portion and pressed against the pedestal portion. Has a part. Therefore, the pin member has the same effect as the clip structure described above.

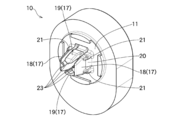

- FIG. 1 is a perspective view of the grommet member in the clip structure according to the embodiment of the present invention as viewed from the side to be inserted.

- FIG. 2 is a perspective view of the grommet member in the clip structure according to the embodiment of the present invention as viewed from the leg side.

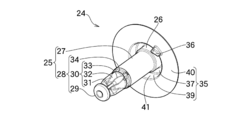

- FIG. 3 is a perspective view of the pin member in the clip structure according to the embodiment of the present invention as viewed from the flange portion side.

- FIG. 4 is a perspective view of the pin member in the clip structure according to the embodiment of the present invention as viewed from the shaft portion side.

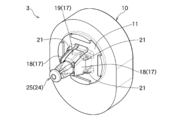

- FIG. 5 is a perspective view seen from the side where the pin member is inserted in the clip structure according to the embodiment of the present invention.

- FIG. 6 is a perspective view seen from the side in which the pin member is inserted in the clip structure according to the embodiment of the present invention.

- FIG. 7 is a rear view showing the side on which the pin member is inserted in the clip structure according to the embodiment of the present invention.

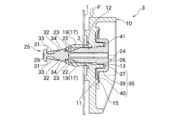

- FIG. 8 is a cross-sectional view taken along the line VIII-VIII in FIG. 7, which is a cross-sectional view of the clip structure according to the embodiment of the present invention.

- FIG. 9 is a cross-sectional view taken along the line IX-IX in FIG. 7, which is a cross-sectional view of the clip structure according to the embodiment of the present invention.

- FIGS. 1 and 2 show the grommet member 10 constituting the clip structure 3

- FIGS. 3 and 4 show the pin member 24 constituting the clip structure 3.

- 5 and 6 show the clip structure 3

- FIGS. 7, 8 and 9 show the appearance and cross section of the clip structure 3 attached to the attached member 1.

- the clip structure 3 has a pin member 24 attached to the grommet member 10, and FIGS. 7, 8 and 6.

- the clip structure 3 is attached to the attached member 1.

- the clip structure 3 is applied to, for example, a bumper retainer or the like used when a bumper is attached to the body of an automobile (the automobile, the body, the bumper and the bumper retainer are not shown). That is, the attached member 1 is formed on, for example, the body of an automobile, and the grommet member 10 is formed on, for example, a bumper retainer or the like. A bumper is attached to the bumper retainer, and in this state, the bumper retainer is attached to the body, so that the bumper is attached to the body.

- the present embodiment has a single clip structure 3, the number of clip structures 3 formed on the bumper retainer is arbitrary.

- the lower side of the insertion direction is the front (Front), the upper side is the rear (Back), and the directions orthogonal to the insertion direction are upward and downward (Up, Down), left and right (Left). Side, Right Side) (see FIGS. 1 and 3).

- the grommet member 10 has a pedestal portion 11 facing the body which is the mounted member 1, and the pedestal portion 11 is formed with an inserted hole 12 into which the pin member 24 is inserted. Has been done.

- a protrusion 13 is formed on the peripheral edge of the insertion hole 12.

- the protrusion 13 has an annular shape or a cylindrical shape centered on the hole 12 to be inserted, and protrudes rearward.

- a wall portion 14 is formed around the protrusion portion 13.

- the wall portion 14 has an annular shape or a cylindrical shape coaxial with the protrusion portion 13 and projects rearward. That is, the pedestal portion 11 is recessed with respect to the height of the wall portion 14.

- a step portion 15 is formed at the connecting portion between the pedestal portion 11 and the wall portion 14.

- the step portion 15 is formed in an annular shape along the wall portion 14.

- a plurality of step pieces 16 are formed between the protrusion portion 13 and the step portion 15.

- the step pieces 16 are formed radially around the protrusions 13 and are arranged at substantially equal intervals in the circumferential direction of the protrusions 13.

- a plurality of leg portions 17 are formed on the peripheral edge of the inserted hole 12.

- the legs 17 are substantially plate-shaped and project forward.

- the leg portions 17 are adjacent to a pair of first leg portions 18 facing each other on the left and right sides with the inserted hole 12 as the center, and are adjacent to the first leg portion 18 and are vertically and vertically centered on the inserted hole 12. It is composed of a pair of second legs 19 facing each other.

- a rib 21 is formed on the outer surface of the base portion 20 which is a portion of the first leg portion 18 connected to the pedestal portion 11.

- the ribs 21 are formed in two places and are arranged at the upper and lower ends of the base 20.

- a raised portion 22 is formed on the inner surface of the second leg portion 19 (see FIG. 8).

- the tip portions of the legs 18 and 19 are formed with a locking piece 23 projecting inward with the legs 18 and 19 facing each other.

- the locking piece 23 of the second leg portion 19 is connected to the raised portion 22.

- the pin member 24 includes a shaft portion 25 inserted into the inserted hole 12 of the grommet member 10 and a receiving portion 26 connected to the extension of the shaft portion 25. It has a flange portion 35 that is connected to the receiving portion 26 and attached to the pedestal portion 11.

- the shaft portion 25 has a substantially hollow cylindrical shape or a columnar shape.

- the shaft portion 25 has an intermediate portion 27 extending forward from the receiving portion 26 and a front end locking portion 28 extending forward from the intermediate portion 27.

- the front end locking portion 28 has a front end portion 29 which is a front end, a temporary fixing portion 30 extending rearward from the front end portion 29, and a locked groove portion 34 connected to the rear of the temporary fixing portion 30. ing.

- the front end portion 29 has a disk shape smaller than the flange portion 35, and the temporary fixing portion 30 is connected to the center thereof.

- the temporary fixing portion 30 is formed with a temporary fixing groove portion 31, an inclined surface 32 that widens toward the side toward the rear, and a plurality of partition portions 33 that project laterally.

- the partition portions 33 extend from the front end portion 29 to the inclined surface 32, and are arranged at substantially equal intervals in the circumferential direction of the shaft portion 25. Therefore, the temporary fixing groove portion 31 and the inclined surface 32 are separated by the partition portion 33.

- the locked groove portion 34 is recessed toward the center of the shaft portion 25 and is divided at the same interval as the partition portion 33.

- the intermediate portion 27 extending from the rear of the locked groove portion 34 has a cylindrical shape or a cylindrical shape without unevenness, and the receiving portion 26 has an annular shape or a cylindrical shape.

- the flange portion 35 has a top portion 37 which is a circular flat plate, an annular or cylindrical covering portion 39 protruding forward from the peripheral edge of the top portion 37, and an annular shape protruding outward from the front end of the covering portion 39. It has a thin-walled portion 40 of.

- An insertion hole 38 into which a tool or the like (not shown) is inserted is formed on the rear surface of the top portion 37.

- a receiving portion 26 is connected to the center of the front surface of the top portion 37.

- the receiving portion 26 has an annular shape or a cylindrical shape, and is arranged facing the inside of the covering portion 39.

- the receiving portion 26 and the covering portion 39 are concentric circles centered on the shaft portion 25, and a concave groove portion 41 having a concave groove shape is formed in a space surrounded by the receiving portion 26, the covering portion 39, and the top portion 37. ing. That is, the concave groove portion 41 is an annular shape having the receiving portion 26 as a part, and is recessed on the extension of the shaft portion 25 on the side opposite to the direction in which the shaft portion 25 extends.

- the thin-walled portion 40 is thinner than the top portion 37 and the covering portion 39, and easily bends.

- an inclined projecting piece 36 that protrudes forward and is inclined in the circumferential direction of the thin-walled portion 40 is formed in the vicinity of the portion connected to the covering portion 39.

- the inclined projecting pieces 36 are formed at two locations and are arranged laterally with respect to the shaft portion 25. In other words, the inclined projecting piece 36 is located at zero and 180 degrees on the circumference of the thin wall portion 40.

- the grommet member 10 and the pin member 24 are combined.

- the shaft portion 25 of the pin member 24 is inserted into the inserted hole 12 of the grommet member 10 and engages with the leg portions 18 and 19 of the grommet member 10.

- the process of engaging the pin member 24 and the grommet member 10 will be described with reference to the drawings.

- the legs 18 and 19 of the grommet member 10 are inserted into the mounted holes 2 formed in the mounted member 1.

- the rib 21 of the first leg portion 18 hits the edge inside the mounted hole 2.

- the shaft portion 25 of the pin member 24 is inserted into the inserted hole 12 of the grommet member 10.

- the front end portion 29 of the shaft portion 25 that has passed through the insertion hole 12 hits the raised portion 22 of the second leg portion 19 and advances while pushing the second leg portion 19 apart, and the second leg portion 19 bends and opens outward.

- the front end portion 29 that has passed through the raised portion 22 hits the locking piece 23 of the first leg portion 18 and advances while pushing the first leg portion 18 apart, and the first leg portion 18 bends and opens outward.

- the temporary fixing groove portion 31 of the shaft portion 25 faces the raised portion 22, so that the second leg portion 19 returns to the original state and the raised portion 22 returns to the temporary fixing groove portion 31. Is placed in.

- the first leg 18 also returns to its original state.

- the locking piece 23 is arranged in the temporary fixing groove portion 31. In this state, the pin member 24 is temporarily fixed to the grommet member 10.

- the inclined surface 32 of the pin member 24 hits the raised portion 22 and advances while expanding the second leg portion 19, and the second leg portion 19 bends and opens outward.

- the inclined surface 32 rubs against the raised portion 22 and hits the locking piece 23 to move forward while pushing the legs 18 and 19 apart, and the legs 18 and 19 bend and open outward.

- the locked groove portion 34 faces the locking piece 23, so that the legs 18 and 19 return to their original states and the locking piece 23 is locked in the locked groove portion. It is arranged at 34. In this state, the pin member 24 is engaged with the grommet member 10.

- the protrusion 13 of the grommet member 10 is inserted into the concave groove portion 41 of the pin member 24.

- the receiving portion 26 faces the protrusion 13 at the rear side of the pedestal portion 11 on the protrusion 13 side and in the direction intersecting the shaft portion 25.

- the flange portion 35 covers the protrusion portion 13. That is, the receiving portion 26, the covering portion 39, and the top portion 37 cover the protruding portion 13, and the tip of the thin-walled portion 40 is pressed against the stepped portion 15 of the grommet member 10 and bends, whereby the thin-walled portion 40 is formed. It is pressed against the pedestal portion 11 and the rear surface side of the pedestal portion 11 becomes watertight.

- the inclined projecting piece 36 of the flange portion 35 is arranged between the step pieces 16 in the grommet member 10.

- the peripheral edge of the inserted hole 12 of the grommet member 10 is an annular or cylindrical shape centered on the inserted hole 12 from the side opposite to the legs 18 and 19 with respect to the pedestal portion 11.

- the protrusion 13 is protruding.

- the pin member 24 is an extension of the shaft portion 25, and an annular or cylindrical receiving portion 26 is connected between the intermediate portion 27 of the shaft portion 25 and the flange portion 35, and this receiving portion is connected. It has an annular recessed groove 41 having 26 as a part.

- the protrusion 13 is inserted into the concave groove portion 41 behind the pedestal portion 11, and in the concave groove portion 41, the receiving portion 26 is the pedestal portion. Behind the eleven, the side surface faces the protrusion 13.

- the hole 12 to be inserted becomes a cylindrical hole that is pseudo-extended rearward from the pedestal portion 11 by the protrusion 13, and the cover of this cylinder.

- the shaft portion 25 and the receiving portion 26 of the pin member 24 are inserted into the insertion hole 12.

- annular or cylindrical receiving portion 26 and the annular or cylindrical protrusion 13 are in contact with each other on the entire peripheral surface and are firm, and a high shearing force is realized.

- the flange portion 35 of the pin member 24 includes a top portion 37 which is a circular flat plate connected to the receiving portion 26, and an annular or cylindrical covering portion 39 protruding forward from the peripheral edge of the top portion 37. It has an annular thin-walled portion 40 that protrudes outward from the front end of the covering portion 39.

- the flange portion 35 covers the protrusion 13 and the tip of the thin-walled portion 40 is pressed against the step portion 15 of the grommet member 10 to bend.

- the thin portion 40 is pressed against the pedestal portion 11. Therefore, watertightness can be realized on the rear surface side of the pedestal portion 11. Further, since the pin member 24 is prevented from being tilted, the flange portion 35 is not deformed and the watertightness can be maintained.

- the base 20 of the first leg 18 has ribs 21 formed on the outer surface thereof. That is, since the rigidity of the first leg portion 18 is increased by the rib 21, the grommet member 10 is less likely to shift. Further, when the legs 18 and 19 of the grommet member 10 are inserted into the mounted holes 2 of the mounted member 1, the ribs 21 hit the edges inside the mounted holes 2. With this configuration, even when some force F acts on the grommet member 10 from the side in the direction in which the grommet member 10 deviates from the mounted member 1, the rib is formed at the edge of the mounted hole 2. By hitting 21, the grommet member 10 is hard to shift. That is, it can be said that this embodiment has a high shearing force.

- the ribs are formed only at the base of the second leg. In another embodiment, ribs are formed at the base of the first leg and the base of the second leg, respectively. In other embodiments, the shape, number, and position of the ribs are arbitrary at the base.

- the protrusion is not a continuous ring, but a plurality of protrusions arranged in a ring. In another embodiment, the protrusion of the grommet member and the receiving portion of the pin member are formed at positions laterally separated from the insertion hole of the grommet member and the shaft portion of the pin member. In other embodiments, the pin member does not have a flange portion.

- the present invention is not limited to the above-described embodiments.

- the present invention can be modified in various ways as long as it does not deviate from the matters described in the claims.

- the present invention is also used, for example, in vehicles such as automobiles, aircraft, and ships.

- Attached member 1 Attached member 2 Attached hole 3 Clip structure 10 Grommet member 11 Pedestal 12 Inserted hole 13 Protrusion 14 Wall 15 Step 16 Step piece 17 Leg 18 First leg 19 Second leg 20 Base 21 Rib 22 Raised part 23 Locking piece 24 Pin member 25 Shaft part 26 Receiving part 27 Intermediate part 28 Front end locking part 29 Front end part 30 Temporary fixing part 31 Temporary fixing groove part 32 Inclined surface 33 Partition part 34 Locked groove part 35 Flange part 36 Inclined projectile 37 Top 38 Insertion hole 39 Cover 40 Thin wall 41 Concave groove F force

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Insertion Pins And Rivets (AREA)

- Snaps, Bayonet Connections, Set Pins, And Snap Rings (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US18/004,204 US20240280129A1 (en) | 2020-07-08 | 2021-03-29 | Clip structure and pin member |

| MX2023000408A MX2023000408A (es) | 2020-07-08 | 2021-03-29 | Estructura de clip y miembro de pasador. |

| CN202180056743.9A CN116034223B (zh) | 2020-07-08 | 2021-03-29 | 夹具构造以及销构件 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020117576A JP7350695B2 (ja) | 2020-07-08 | 2020-07-08 | クリップ構造及びピン部材 |

| JP2020-117576 | 2020-07-08 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2022009487A1 true WO2022009487A1 (ja) | 2022-01-13 |

Family

ID=79552858

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2021/013253 Ceased WO2022009487A1 (ja) | 2020-07-08 | 2021-03-29 | クリップ構造及びピン部材 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US20240280129A1 (enExample) |

| JP (1) | JP7350695B2 (enExample) |

| CN (1) | CN116034223B (enExample) |

| MX (1) | MX2023000408A (enExample) |

| WO (1) | WO2022009487A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2024116687A1 (ja) * | 2022-12-01 | 2024-06-06 | 株式会社ニフコ | 留め具及び取付構造 |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2025081993A (ja) | 2023-11-16 | 2025-05-28 | 株式会社ニフコ | クリップ |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0814231A (ja) * | 1994-06-28 | 1996-01-16 | Piolax Inc | 止め具 |

| JP2007315556A (ja) * | 2006-05-29 | 2007-12-06 | Toyota Motor Corp | 締結具 |

| JP2016166650A (ja) * | 2015-03-10 | 2016-09-15 | ポップリベット・ファスナー株式会社 | 留め具及び締結構造 |

| JP2020034024A (ja) * | 2018-08-27 | 2020-03-05 | 株式会社パイオラックス | 留め具 |

| WO2020059680A1 (ja) * | 2018-09-18 | 2020-03-26 | 株式会社パイオラックス | 留め具 |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4085651A (en) * | 1977-02-14 | 1978-04-25 | Illinois Tool Works Inc. | Plastic fastener |

| US4391559A (en) * | 1980-07-28 | 1983-07-05 | Nifco Inc. | Plastic fastener |

| US4405272A (en) * | 1981-03-11 | 1983-09-20 | Phillips Plastics Corporation | Two-piece fastener with front shoulder |

| JP3290292B2 (ja) * | 1994-03-29 | 2002-06-10 | 株式会社ニフコ | 留め具 |

| FR2776345B1 (fr) * | 1998-03-17 | 2000-06-30 | Itw De France | Dispositif a monter en aveugle |

| JP2003232318A (ja) * | 2002-02-08 | 2003-08-22 | Zen Kenchiku Sekkei Jimusho:Kk | ファスナー |

| JP2005249111A (ja) * | 2004-03-05 | 2005-09-15 | Nifco Inc | 連結軸具、および、電子機器 |

| JP5360480B2 (ja) * | 2009-06-22 | 2013-12-04 | 株式会社ニフコ | 留め具 |

| EP2827006A1 (de) * | 2013-05-13 | 2015-01-21 | Schaeffler Technologies GmbH & Co. KG | Blindnietsystem |

| US9631653B2 (en) * | 2013-06-20 | 2017-04-25 | Illinois Tool Works Inc | Push-in fastener |

| WO2016006328A1 (ja) * | 2014-07-08 | 2016-01-14 | 株式会社パイオラックス | 止め具 |

| TWI625471B (zh) * | 2017-05-22 | 2018-06-01 | 技嘉科技股份有限公司 | 卡扣及使用其之組合件 |

| EP4012199A4 (en) * | 2019-09-12 | 2023-10-18 | Nifco Inc. | BRACKET AND BRACKET MOUNTING STRUCTURE |

-

2020

- 2020-07-08 JP JP2020117576A patent/JP7350695B2/ja active Active

-

2021

- 2021-03-29 CN CN202180056743.9A patent/CN116034223B/zh active Active

- 2021-03-29 US US18/004,204 patent/US20240280129A1/en active Pending

- 2021-03-29 WO PCT/JP2021/013253 patent/WO2022009487A1/ja not_active Ceased

- 2021-03-29 MX MX2023000408A patent/MX2023000408A/es unknown

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0814231A (ja) * | 1994-06-28 | 1996-01-16 | Piolax Inc | 止め具 |

| JP2007315556A (ja) * | 2006-05-29 | 2007-12-06 | Toyota Motor Corp | 締結具 |

| JP2016166650A (ja) * | 2015-03-10 | 2016-09-15 | ポップリベット・ファスナー株式会社 | 留め具及び締結構造 |

| JP2020034024A (ja) * | 2018-08-27 | 2020-03-05 | 株式会社パイオラックス | 留め具 |

| WO2020059680A1 (ja) * | 2018-09-18 | 2020-03-26 | 株式会社パイオラックス | 留め具 |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2024116687A1 (ja) * | 2022-12-01 | 2024-06-06 | 株式会社ニフコ | 留め具及び取付構造 |

| JP2024080109A (ja) * | 2022-12-01 | 2024-06-13 | 株式会社ニフコ | 留め具及び取付構造 |

| JP7704729B2 (ja) | 2022-12-01 | 2025-07-08 | 株式会社ニフコ | 留め具及び取付構造 |

Also Published As

| Publication number | Publication date |

|---|---|

| US20240280129A1 (en) | 2024-08-22 |

| CN116034223A (zh) | 2023-04-28 |

| CN116034223B (zh) | 2025-08-05 |

| MX2023000408A (es) | 2023-04-10 |

| JP2022015002A (ja) | 2022-01-21 |

| JP7350695B2 (ja) | 2023-09-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5627940B2 (ja) | グロメット | |

| JP4485281B2 (ja) | 留め具 | |

| WO2022009487A1 (ja) | クリップ構造及びピン部材 | |

| JP5128546B2 (ja) | 締結具 | |

| WO2011136105A1 (ja) | 部材締結構造及び部材締結用のクリップ | |

| JP2016166650A (ja) | 留め具及び締結構造 | |

| WO2015041103A1 (ja) | クリップ | |

| US7640707B2 (en) | Fastening clip | |

| JP6843098B2 (ja) | グロメット | |

| WO2014050047A1 (ja) | クリップ | |

| JP5911023B2 (ja) | 樹脂部材取付構造 | |

| JP2014173643A (ja) | クリップ | |

| JP7211882B2 (ja) | 取付構造 | |

| JP2006022898A (ja) | Ea材及びその取付構造 | |

| JP7530972B2 (ja) | ボールジョイント | |

| JP4408081B2 (ja) | フォグランプフィニッシャ構造 | |

| JP5850785B2 (ja) | クリップ | |

| JP7191483B2 (ja) | 留め具 | |

| JP2011020533A (ja) | フロントグリルの取り付け構造 | |

| JP6694273B2 (ja) | クッションクリップ | |

| WO2024135394A1 (ja) | 出没式筆記具 | |

| WO2014050120A1 (ja) | クリップ | |

| JP2001200965A (ja) | 押 輪 | |

| JP2008019938A (ja) | クリップ | |

| JP2020063831A (ja) | 取付具 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 21837585 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 21837585 Country of ref document: EP Kind code of ref document: A1 |

|

| WWG | Wipo information: grant in national office |

Ref document number: 202180056743.9 Country of ref document: CN |