WO2021187047A1 - コネクタ - Google Patents

コネクタ Download PDFInfo

- Publication number

- WO2021187047A1 WO2021187047A1 PCT/JP2021/007251 JP2021007251W WO2021187047A1 WO 2021187047 A1 WO2021187047 A1 WO 2021187047A1 JP 2021007251 W JP2021007251 W JP 2021007251W WO 2021187047 A1 WO2021187047 A1 WO 2021187047A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- housing

- rotating member

- guide portion

- peripheral surface

- cam

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/62—Means for facilitating engagement or disengagement of coupling parts or for holding them in engagement

- H01R13/629—Additional means for facilitating engagement or disengagement of coupling parts, e.g. aligning or guiding means, levers, gas pressure electrical locking indicators, manufacturing tolerances

- H01R13/631—Additional means for facilitating engagement or disengagement of coupling parts, e.g. aligning or guiding means, levers, gas pressure electrical locking indicators, manufacturing tolerances for engagement only

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/46—Bases; Cases

- H01R13/516—Means for holding or embracing insulating body, e.g. casing, hoods

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/62—Means for facilitating engagement or disengagement of coupling parts or for holding them in engagement

- H01R13/623—Casing or ring with helicoidal groove

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/62—Means for facilitating engagement or disengagement of coupling parts or for holding them in engagement

- H01R13/629—Additional means for facilitating engagement or disengagement of coupling parts, e.g. aligning or guiding means, levers, gas pressure electrical locking indicators, manufacturing tolerances

- H01R13/62905—Additional means for facilitating engagement or disengagement of coupling parts, e.g. aligning or guiding means, levers, gas pressure electrical locking indicators, manufacturing tolerances comprising a camming member

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/62—Means for facilitating engagement or disengagement of coupling parts or for holding them in engagement

- H01R13/629—Additional means for facilitating engagement or disengagement of coupling parts, e.g. aligning or guiding means, levers, gas pressure electrical locking indicators, manufacturing tolerances

- H01R13/62905—Additional means for facilitating engagement or disengagement of coupling parts, e.g. aligning or guiding means, levers, gas pressure electrical locking indicators, manufacturing tolerances comprising a camming member

- H01R13/62927—Comprising supplementary or additional locking means

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R13/00—Details of coupling devices of the kinds covered by groups H01R12/70 or H01R24/00 - H01R33/00

- H01R13/64—Means for preventing incorrect coupling

Definitions

- This disclosure relates to connectors.

- Patent Document 1 discloses a connector in which the operating force required for mating is reduced.

- This connector is configured by rotatably attaching a lever to the housing.

- a rotational force is applied to the operating portion of the lever with the cam groove of the lever and the cam follower of the mating connector engaged. Then, the operating force to be applied to the lever is reduced by the boosting action based on the lever principle.

- the connector of the present disclosure has been completed based on the above circumstances, and an object thereof is to realize space saving.

- This disclosure is 1st housing and A second housing that can be fitted with the first housing, A guide function unit that enables the first housing and the second housing to approach and separate from each other in a state in which they cannot rotate relative to each other.

- a rotating member that surrounds the first housing and the second housing and is rotatable about an axis parallel to the fitting direction of the first housing and the second housing. As the rotating member rotates relative to the first housing and the second housing, the cam functioning portion that brings the first housing closer to the second housing is provided.

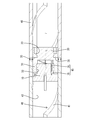

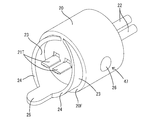

- FIG. 1 is a cross-sectional view showing a state in which the first housing and the second housing have started to be fitted in the connector of the first embodiment.

- FIG. 2 is a cross-sectional view showing a state in which the first housing and the second housing are being fitted.

- FIG. 3 is a cross-sectional view showing a state in which the first housing and the second housing have been fitted.

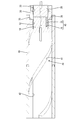

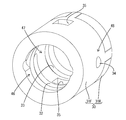

- FIG. 4 is a perspective view of the first housing as viewed obliquely from the rear.

- FIG. 5 is a cross-sectional view of the first housing.

- FIG. 6 is a perspective view of the second housing as viewed diagonally from the front.

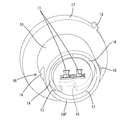

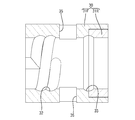

- FIG. 7 is a perspective view of the rotating member as viewed diagonally from the front.

- FIG. 8 is a cross-sectional view of the rotating member.

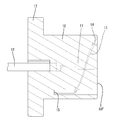

- FIG. 9 is a perspective view of the operating member viewed diagonally from the front.

- the connectors of the present disclosure are (1) A guide function unit that enables the first housing, the second housing that can be fitted to the first housing, and the first housing and the second housing to approach and separate from each other in a state in which they cannot rotate relative to each other.

- a rotating member that surrounds the first housing and the second housing and is rotatable about an axis parallel to the fitting direction of the first housing and the second housing, and the rotating member is the first housing. It also includes a cam functioning unit that brings the first housing closer to the second housing as it rotates relative to the second housing.

- the connector of the present disclosure can realize space saving.

- the guide function portion is configured by fitting the first guide portion formed in the first housing and the second guide portion formed in the second housing. According to this configuration, the number of parts can be reduced as compared with the case where the guide function unit is a separate part from the first housing and the second housing.

- one of the first guide portion and the second guide portion is a protruding guide portion, and the protruding guide portion of the first housing and the second housing is A spiral guide portion is formed in the housing on the non-formed side, and the first guide portion and the second guide portion are brought into contact with each other by sliding the protruding guide portion on the guide portion. It is preferable that the relative rotation is performed so as to have a positional relationship of fitting. According to this configuration, even if the first guide portion and the second guide portion are displaced in the circumferential direction in the process of bringing the first housing and the second housing close to each other, the spiral guide portion causes the first guide portion and the second guide portion to be displaced from each other.

- the second guide portion can be fitted.

- the cam functional unit has a spiral cam groove formed on one of the inner peripheral surface of the rotating member and the outer peripheral surface of the first housing. It is preferable to have a cam follower formed on the inner peripheral surface of the rotating member and the other peripheral surface of the outer peripheral surface of the first housing and sliding along the cam groove. According to this configuration, since the cam function portion is formed by the rotating member and the first housing, the number of parts is increased as compared with the case where the cam function portion is a separate part from the rotating member and the first housing. Can be reduced.

- the rotating member and the second housing are formed with a holding portion that holds the second housing in a state in which the second housing is not displaced relative to the rotating member in a direction away from the first housing. Is preferable. According to this configuration, when the rotating member is displaced relative to the axial direction while rotating relative to the first housing, the second housing is integrally displaced with the rotating member and is displaced in the axial direction. As a result, the second housing fits with the first housing.

- the rotating member is formed with an opening penetrating from the outer peripheral surface to the inner peripheral surface of the rotating member. According to this configuration, the fitted state of the first housing and the second housing can be visually confirmed from the outside of the rotating member.

- a cylindrical operating member that cannot rotate relative to the first housing and the second housing and has a spiral drive groove formed on the inner peripheral surface is provided. It is preferable that a driven projection that slides on the drive groove is formed on the outer peripheral surface of the rotating member. According to this configuration, when the operating member is displaced relative to the rotating member in the axial direction, the rotating member is rotationally driven, and the first housing and the second housing are fitted or separated from each other. Since the moving direction of the operating member is the axial direction, no space is required for operating the operating member on the outer peripheral side of the first housing and the second housing.

- Example 1 embodying the connector of the present disclosure will be described with reference to FIGS. 1 to 9. It should be noted that the present invention is not limited to these examples, and is indicated by the scope of claims, and is intended to include all modifications within the meaning and scope equivalent to the scope of claims.

- the left side in FIGS. 1 to 3, 5, 6, 8 and 9 is defined as the front.

- the connector of this embodiment includes a first housing 10, a second housing 20, a rotating member 30, and an operating member 40.

- the first housing 10 and the second housing 20 are fitted by approaching each other in the axial direction with the first fitting surface 10F of the first housing 10 and the second fitting surface 20F of the second housing 20 facing each other. Will be done.

- the "fitting direction" of the first housing 10 and the second housing 20 and the "axis direction" of the first housing 10, the second housing 20, the rotating member 30, and the operating member 40 are used interchangeably.

- the first housing 10 is made of synthetic resin and has a cylindrical shape with the axis directed in the front-rear direction as a whole. Inside the first housing 10, a female first terminal fitting 11 connected to the first electric wire 12 is housed. The first electric wire 12 is led out from the front end surface of the first housing 10 to the outside of the first housing 10. The rear end surface of the first housing 10 is a first fitting surface 10F facing the second housing 20.

- a pair of guide portions 13 and one first guide portion 15 are integrally formed in the first housing 10.

- the pair of guide portions 13 have a line-symmetrical shape when the first housing 10 is viewed from the rear.

- Each guide portion 13 has a shape in which a region on the outer peripheral side of the first terminal fitting 11 is recessed in a semicircular groove shape concentric with the first housing 10.

- the inner surfaces of the pair of guide portions 13 function as spiral guide surfaces 14 inclined with respect to the axis of the first housing 10.

- the pair of guide surfaces 14 have spiral directions opposite to each other.

- the first guide portion 15 has a form in which the pair of guide surfaces 14 are recessed from the innermost end to the back (front) in parallel with the axis.

- the first guide unit 15 cooperates with the second guide unit 25 of the second housing 20, which will be described later, to form the guide function unit 45.

- a pair of protruding cam followers 16 separated at a pitch of 180 ° in the circumferential direction are formed on the outer peripheral surface of the first housing 10.

- the cam follower 16 cooperates with the cam groove 32 of the rotating member 30, which will be described later, to form the cam function portion 46.

- a flange portion 17 having a circularly enlarged diameter concentric with the first housing 10 is formed on the outer periphery of the front end portion of the first housing 10.

- a detent projection 18 is formed on the outer periphery of the flange portion 17.

- the second housing 20 is made of synthetic resin and has a cylindrical shape with the axis directed in the front-rear direction as a whole.

- a male second terminal fitting 21 connected to the second electric wire 22 is attached to the inside of the second housing 20.

- the tab 21T at the front end of the second terminal fitting 21 projects forward from the front end surface of the second housing 20.

- the second electric wire 22 is led out from the rear end surface of the second housing 20 to the outside of the second housing 20.

- the front end surface of the second housing 20 is a second fitting surface 20F facing the first housing 10.

- a pair of protruding wall portions 23 and one second guide portion 25 are integrally formed.

- the pair of protruding wall portions 23 have a line-symmetrical shape when the second housing 20 is viewed from the front.

- Each protruding wall portion 23 has a form in which a region on the outer peripheral side of the second terminal fitting 21 is projected in a semicircular shape concentric with the second housing 20.

- the protruding end faces 24 of the pair of protruding wall portions 23 form a spiral shape that is inclined with respect to the axis of the second housing 20.

- the pair of protruding end faces 24 have spiral directions opposite to each other.

- the spiral pitch of the pair of protruding end faces 24 is the same as the spiral pitch of the pair of guiding surfaces 14.

- the second guide portion 25 is in a form of protruding further forward in parallel with the axis from the foremost end portion of the pair of protruding end faces 24.

- the second guide portion 25 is a protruding guide portion.

- a pair of holding protrusions 26 separated at a pitch of 180 ° in the circumferential direction are formed on the outer peripheral surface of the second housing 20.

- the holding protrusion 26 cooperates with the holding groove 33 of the rotating member 30, which will be described later, to form the holding portion 47.

- the rotating member 30 is made of synthetic resin and has a cylindrical shape with the axis directed in the front-rear direction as a whole. As shown in FIGS. 7 and 8, the rotating member 30 is formed by combining a cylindrical front side component 31F and a cylindrical rear side component 31R coaxially and back and forth. A spiral cam groove 32 is formed on the inner peripheral surface of the front component 31F. The formation range of the cam groove 32 in the axial direction is a region extending from the front end of the rotating member 30 (front component 31F) to a position in front of the rear end of the rotating member 30 (front component 31F).

- the front end of the cam groove 32 is opened on the front end surface of the rotating member 30 as an inlet for allowing the cam follower 16 of the first housing 10 to enter the cam groove 32.

- the spiral pitch of the cam groove 32 is set to a dimension smaller than the spiral pitch of the drive groove 41 of the operating member 40, which will be described later. As shown in FIG. 1, the cam groove 32 cooperates with the cam follower 16 of the first housing 10 described above to form the cam function unit 46.

- a holding groove 33 is formed in a region of the inner peripheral surface of the rotating member 30 behind the cam groove 32.

- the holding groove 33 is not spiral, but forms a perfect circle on a virtual plane orthogonal to the axis.

- the holding groove 33 is composed of a notch having a quarter arc cross section formed on the inner circumference of the rear end portion of the front component 31F and a notch having a quarter arc cross section formed on the inner circumference of the front end portion of the rear component 31R. There is.

- the holding groove 33 cooperates with the holding protrusion 26 of the second housing 20 to form the holding portion 47.

- a pair of driven protrusions 34 separated at a pitch of 180 ° in the circumferential direction are formed on the outer peripheral surface of the rotating member 30.

- the driven protrusion 34 cooperates with the drive groove 41 of the operating member 40 described later to form the rotational force transmission unit 48.

- a pair of openings 35 are formed in the rotating member 30.

- the opening 35 has a form of penetrating from the outer peripheral surface to the inner peripheral surface of the rotating member 30. In the axial direction, the opening 35 is arranged between the cam groove 32 and the holding groove 33.

- the first fitting surface 10F of the first housing 10 and the second fitting surface 20F of the second housing 20 abut between the cam groove 32 and the holding groove 33.

- the operating member 40 has a cylindrical shape with its axis oriented in the front-rear direction as a whole.

- a spiral drive groove 41 is formed on the inner peripheral surface of the operating member 40.

- the spiral pitch of the drive groove 41 is set to a dimension larger than the spiral pitch of the cam groove 32 of the rotating member 30.

- the front end of the drive groove 41 is open to the front end surface of the operating member 40.

- One detent groove 42 is formed on the inner peripheral surface of the operating member 40.

- the front end of the detent groove 42 is open to the front end surface of the operating member 40.

- the detent groove 42 extends in a straight line parallel to the axis.

- the second housing 20 and the rotating member 30 are assembled.

- the front part 31F and the rear part 31R are separated, the front part 31F is fitted from the front to the outer circumference of the first housing 10, and the rear part 31R is rearward to the outer circumference of the first housing 10. Fit out from.

- the holding groove 33 is formed, and at the same time, the holding projection 26 is fitted into the holding groove 33.

- the holding projection 26 is caught in the holding groove 33, so that the relative displacement of the second housing 20 and the rotating member 30 in the axial direction (both front and rear directions) is impossible. become.

- the holding projection 26 and the holding groove 33 are in sliding contact with each other so that the second housing 20 and the rotating member 30 can rotate relatively.

- the first housing 10 and the rotating member 30 are assembled.

- the rear end portion of the first housing 10 is inserted into the rotating member 30 from the front of the rotating member 30.

- the cam follower 16 of the second housing 20 is made to enter the front end portion of the cam groove 32.

- the first housing 10 and the second housing 20 are not fitted, and the first guide portion 15 and the second guide portion 25 are also not fitted.

- the first housing 10, the second housing 20, and the rotating member 30 are assembled.

- the front end portion of the operating member 40 is fitted onto the rear end portion of the rotating member 30, and the driven protrusion 34 enters the front end portion of the drive groove 41. Let me. Next, the detent projection 18 of the first housing 10 is fitted to the front end of the detent groove 42. In this state, the relative rotation of the first housing 10 and the second housing 20 with respect to the operating member 40 becomes impossible, but the operating member 40 is relatively displaced forward in the axial direction with respect to the first housing 10 and the second housing 20. Can be done.

- the first housing 10 and the operating member 40 are brought closer to each other in the axial direction without relative rotation.

- the drive groove 41 of the operating member 40 and the driven projection 34 of the rotating member 30 slide, so that the rotating member 30 rotates relative to the first housing 10 and the second housing 20 due to the inclination of the drive groove 41.

- frictional resistance is generated due to the sliding between the cam groove 32 and the cam follower 16, but since the spiral pitch of the drive groove 41 is larger than the spiral pitch of the cam groove 32, it is applied to the operating member 40 in the axial direction. Even if the operating force is small, the rotating member 30 can be reliably rotated.

- the connector of the first embodiment includes a first housing 10, a second housing 20 that can be fitted with the first housing 10, a guide function portion 45, a rotating member 30, and a cam function portion 46.

- the guide function portion 45 is a functional portion that enables the first housing 10 and the second housing 20 to approach and separate from each other in a state in which they cannot rotate relative to each other.

- the rotating member 30 surrounds the first housing 10 and the second housing 20. The rotating member 30 can rotate about an axis parallel to the fitting direction of the first housing 10 and the second housing 20. In short, the rotating member 30 is rotatable about an axis.

- the cam function unit 46 brings the first housing 10 and the second housing 20 closer to each other as the rotating member 30 rotates relative to the first housing 10 and the second housing 20.

- the connector of the present disclosure can realize space saving.

- the guide function portion 45 is configured by fitting the first guide portion 15 formed in the first housing 10 and the second guide portion 25 formed in the second housing 20.

- the first guide portion 15 constituting the guide function portion 45 is integrally formed with the first housing 10

- the second guide portion 25 constituting the guide function portion 45 is integrally formed with the second housing 20. Therefore, as compared with the case where the guide function unit 45 is a separate component from the first housing 10 and the second housing 20, the connector of this embodiment can reduce the number of components.

- the second guide portion 25 is a protruding guide portion.

- a spiral guide portion 13 is formed in the second housing 20 on the side of the first housing 10 and the second housing 20 on which the protruding guide portion (second guide portion 25) is not formed.

- the first guide portion 15 and the second guide portion 25 are brought into sliding contact with the guide portion 13 in a protruding guide portion (second guide portion 25) so as to rotate relative to each other so as to be in a positional relationship of fitting with each other. It has become.

- the front end of the second guide portion 25 is in sliding contact with the spiral guide portion 13. Since the second guide portion 25 is guided to approach the first guide portion 15 by this sliding contact, the first guide portion 15 and the second guide portion 25 can be securely fitted.

- the cam function unit 46 includes a spiral cam groove 32 formed on the inner peripheral surface of the rotating member 30, and a cam follower 16 formed on the outer peripheral surface of the first housing 10.

- the cam follower 16 slides along the cam groove 32 as the rotating member 30 and the first housing 10 rotate relative to each other.

- the cam groove 32 constituting the cam function portion 46 is integrally formed with the rotating member 30, and the cam follower 16 constituting the cam function portion 46 is integrally formed with the first housing 10. Therefore, the number of parts of the connector of this embodiment can be reduced as compared with the case where the cam function portion 46 is a separate component from the rotating member 30 and the first housing 10.

- the rotating member 30 is integrally formed with a holding groove 33 constituting the holding portion 47.

- a holding protrusion 26 forming a holding portion 47 is integrally formed in the second housing 20.

- the holding groove 33 and the holding protrusion 26 hold the second housing 20 in a state in which the second housing 20 is not displaced relative to the rotating member 30 in the direction away from the first housing 10. According to this configuration, when the rotating member 30 is relatively displaced forward in the axial direction while rotating relative to the first housing 10, the second housing 20 is integrally displaced forward in the axial direction together with the rotating member 30. .. As a result, the second housing 20 fits into the first housing 10.

- the rotating member 30 is formed with an opening 35 penetrating from the outer peripheral surface to the inner peripheral surface of the rotating member 30. According to this configuration, the fitted state of the first housing 10 and the second housing 20 can be visually confirmed from the outside of the rotating member 30.

- the connector of this embodiment is non-rotatable relative to the first housing 10 and the second housing 20, and includes a cylindrical operating member 40 having a spiral drive groove 41 formed on the inner peripheral surface.

- a driven projection 34 that slides on the drive groove 41 is formed on the outer peripheral surface of the rotating member 30.

- the present invention is not limited to the examples described in the above description and drawings, but is shown by the scope of claims.

- the present invention includes the meaning equivalent to the scope of claims and all modifications within the scope of claims, and is intended to include the following embodiments.

- the first guide portion has a concave shape and the second guide portion has a protruding shape, but the first guide portion may have a protruding shape and the second guide portion may have a concave shape.

- the guide function unit is formed in the first housing and the second housing, but the guide function unit may be a separate component from the first housing and the second housing.

- the spiral guide portion is formed in the first housing and the second housing, but the form may not have the spiral guide portion.

- the cam function portion is formed of the rotating member and the first housing, but the cam function portion may be a separate component from the rotating member and the first housing.

- the cam groove is formed on the inner peripheral surface of the rotating member and the cam follower is formed on the outer peripheral surface of the first housing.

- the cam groove is formed on the outer peripheral surface of the first housing and the cam follower is formed on the inner peripheral surface of the rotating member. It may be formed on the peripheral surface.

- the holding portion is composed of a holding groove formed on the inner peripheral surface of the rotating member and a holding protrusion formed on the outer peripheral surface of the second housing.

- the holding portion is formed on the outer peripheral surface of the second housing.

- the rotating member may be composed of a holding groove formed on the surface and a holding protrusion formed on the inner peripheral surface of the rotating member.

- the rotating member has an opening, but the rotating member may have no opening.

- the rotating member is rotated by using the operating member, but the rotating member may be directly rotated without using the operating member.

- the operating member and the first housing are fitted as a means for making the operating member relatively non-rotatable with respect to the first housing and the second housing, but the operating member and the second housing are fitted. You may let me.

- the first housing has a female terminal fitting and the second housing has a male terminal fitting, but the first housing has a male terminal fitting and the second housing has a female terminal fitting. May be good.

Landscapes

- Details Of Connecting Devices For Male And Female Coupling (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US17/911,532 US20230134481A1 (en) | 2020-03-19 | 2021-02-26 | Connector |

| CN202180021189.0A CN115298910A (zh) | 2020-03-19 | 2021-02-26 | 连接器 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2020-048624 | 2020-03-19 | ||

| JP2020048624A JP7377440B2 (ja) | 2020-03-19 | 2020-03-19 | コネクタ |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2021187047A1 true WO2021187047A1 (ja) | 2021-09-23 |

Family

ID=77771851

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2021/007251 Ceased WO2021187047A1 (ja) | 2020-03-19 | 2021-02-26 | コネクタ |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20230134481A1 (enExample) |

| JP (1) | JP7377440B2 (enExample) |

| CN (1) | CN115298910A (enExample) |

| WO (1) | WO2021187047A1 (enExample) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN219801372U (zh) * | 2023-03-30 | 2023-10-03 | 深圳市拾力信息技术有限公司 | 一种电源插头旋转收缩结构 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11339890A (ja) * | 1998-05-29 | 1999-12-10 | Hosiden Corp | ロック機構付きコネクタ |

| JP2006228463A (ja) * | 2005-02-15 | 2006-08-31 | Auto Network Gijutsu Kenkyusho:Kk | シールドコネクタ |

| JP2010118224A (ja) * | 2008-11-12 | 2010-05-27 | Hirose Electric Co Ltd | 誤挿入防止機能を有するコネクタ |

| WO2014103651A1 (ja) * | 2012-12-25 | 2014-07-03 | 矢崎総業株式会社 | コネクタ |

| WO2019155534A1 (ja) * | 2018-02-06 | 2019-08-15 | ウイトコオブジュピター電通株式会社 | コネクタ |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5662488A (en) * | 1996-10-31 | 1997-09-02 | Alden; Peter H. | Quick connect coupling system for rapidly joining connectors and/or other elongated bodies |

| US6666701B1 (en) * | 2002-07-22 | 2003-12-23 | Signet Scientific Company | Bayonet-type electrical connector assembly |

-

2020

- 2020-03-19 JP JP2020048624A patent/JP7377440B2/ja active Active

-

2021

- 2021-02-26 US US17/911,532 patent/US20230134481A1/en not_active Abandoned

- 2021-02-26 CN CN202180021189.0A patent/CN115298910A/zh active Pending

- 2021-02-26 WO PCT/JP2021/007251 patent/WO2021187047A1/ja not_active Ceased

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11339890A (ja) * | 1998-05-29 | 1999-12-10 | Hosiden Corp | ロック機構付きコネクタ |

| JP2006228463A (ja) * | 2005-02-15 | 2006-08-31 | Auto Network Gijutsu Kenkyusho:Kk | シールドコネクタ |

| JP2010118224A (ja) * | 2008-11-12 | 2010-05-27 | Hirose Electric Co Ltd | 誤挿入防止機能を有するコネクタ |

| WO2014103651A1 (ja) * | 2012-12-25 | 2014-07-03 | 矢崎総業株式会社 | コネクタ |

| WO2019155534A1 (ja) * | 2018-02-06 | 2019-08-15 | ウイトコオブジュピター電通株式会社 | コネクタ |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2021150163A (ja) | 2021-09-27 |

| JP7377440B2 (ja) | 2023-11-10 |

| CN115298910A (zh) | 2022-11-04 |

| US20230134481A1 (en) | 2023-05-04 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6820293B2 (ja) | コネクタ | |

| JP5370261B2 (ja) | コネクタ | |

| JP2011253655A (ja) | コネクタ | |

| EP3726664B1 (en) | Rotary connector | |

| JP2009158151A (ja) | コネクタ | |

| WO2021187047A1 (ja) | コネクタ | |

| US9929505B2 (en) | Connector | |

| JP6222588B1 (ja) | レバー式コネクタ | |

| JP2019129078A (ja) | レバー式コネクタ | |

| JP2021015706A (ja) | レバー式コネクタ | |

| JP4904094B2 (ja) | コネクタ | |

| WO2012176480A1 (ja) | レバー式コネクタ | |

| JP5747809B2 (ja) | レバー式コネクタ | |

| CN108136813B (zh) | 复合书写用具 | |

| WO2021075149A1 (ja) | レバー式コネクタ | |

| JP2004303452A (ja) | レバー式コネクタ | |

| JP6032169B2 (ja) | コネクタの取付構造およびコネクタ | |

| JP3659568B2 (ja) | コネクタ | |

| JP4966090B2 (ja) | ランプソケット及び照明器具 | |

| JP2598587Y2 (ja) | レバー嵌合式コネクタ | |

| JP2021103652A (ja) | レバー式コネクタ | |

| JP4805103B2 (ja) | 回転嵌合式コネクタにおける回動部材側コネクタ | |

| JP2012234635A (ja) | コネクタ | |

| US20240079836A1 (en) | Extension cord socket | |

| JP5118561B2 (ja) | ランプソケット及び照明器具 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 21769875 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 21769875 Country of ref document: EP Kind code of ref document: A1 |