WO2021033708A1 - 蓄電デバイス用外装材の成形工程における品質管理方法、蓄電デバイスの製造方法、蓄電デバイス用外装材、及び蓄電デバイス - Google Patents

蓄電デバイス用外装材の成形工程における品質管理方法、蓄電デバイスの製造方法、蓄電デバイス用外装材、及び蓄電デバイス Download PDFInfo

- Publication number

- WO2021033708A1 WO2021033708A1 PCT/JP2020/031241 JP2020031241W WO2021033708A1 WO 2021033708 A1 WO2021033708 A1 WO 2021033708A1 JP 2020031241 W JP2020031241 W JP 2020031241W WO 2021033708 A1 WO2021033708 A1 WO 2021033708A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- power storage

- storage device

- exterior material

- layer

- base material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/10—Primary casings; Jackets or wrappings

- H01M50/116—Primary casings; Jackets or wrappings characterised by the material

- H01M50/124—Primary casings; Jackets or wrappings characterised by the material having a layered structure

- H01M50/126—Primary casings; Jackets or wrappings characterised by the material having a layered structure comprising three or more layers

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N21/00—Investigating or analysing materials by the use of optical means, i.e. using sub-millimetre waves, infrared, visible or ultraviolet light

- G01N21/17—Systems in which incident light is modified in accordance with the properties of the material investigated

- G01N21/25—Colour; Spectral properties, i.e. comparison of effect of material on the light at two or more different wavelengths or wavelength bands

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G11/00—Hybrid capacitors, i.e. capacitors having different positive and negative electrodes; Electric double-layer [EDL] capacitors; Processes for the manufacture thereof or of parts thereof

- H01G11/78—Cases; Housings; Encapsulations; Mountings

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G11/00—Hybrid capacitors, i.e. capacitors having different positive and negative electrodes; Electric double-layer [EDL] capacitors; Processes for the manufacture thereof or of parts thereof

- H01G11/84—Processes for the manufacture of hybrid or EDL capacitors, or components thereof

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G9/00—Electrolytic capacitors, rectifiers, detectors, switching devices, light-sensitive or temperature-sensitive devices; Processes of their manufacture

- H01G9/004—Details

- H01G9/08—Housing; Encapsulation

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/04—Construction or manufacture in general

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/10—Primary casings; Jackets or wrappings

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/10—Primary casings; Jackets or wrappings

- H01M50/102—Primary casings; Jackets or wrappings characterised by their shape or physical structure

- H01M50/105—Pouches or flexible bags

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M50/00—Constructional details or processes of manufacture of the non-active parts of electrochemical cells other than fuel cells, e.g. hybrid cells

- H01M50/10—Primary casings; Jackets or wrappings

- H01M50/116—Primary casings; Jackets or wrappings characterised by the material

- H01M50/121—Organic material

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P70/00—Climate change mitigation technologies in the production process for final industrial or consumer products

- Y02P70/50—Manufacturing or production processes characterised by the final manufactured product

Definitions

- the present disclosure relates to a quality control method in a molding process of an exterior material for a power storage device, a manufacturing method of a power storage device, an exterior material for a power storage device, and a power storage device.

- an exterior material is an indispensable member for sealing the power storage device elements such as electrodes and electrolytes.

- a metal exterior material has been widely used as an exterior material for a power storage device.

- recesses are generally formed by cold molding, and storage device elements such as electrodes and electrolytic solutions are arranged in the space formed by the recesses to form a thermosetting resin.

- storage device elements such as electrodes and electrolytic solutions are arranged in the space formed by the recesses to form a thermosetting resin.

- a bent portion is formed in the exterior material for the power storage device by forming a recess for accommodating the power storage device element.

- whitening may occur on the surface portion.

- Whitening due to molding of the exterior material for the power storage device leads to poor appearance of the power storage device, and is therefore subject to quality control in the molding of the exterior material for the power storage device. In the quality control, for example, when the exterior material for a power storage device is colored or when the degree of whitening is large, the presence or absence of whitening can be visually confirmed.

- the main purpose of the present disclosure is to provide a new quality control method in the molding process of the exterior material for a power storage device.

- the inventors of the present disclosure have made diligent studies to solve the above problems.

- the exterior material for the power storage device to be tested is extracted from the exterior material for the power storage device in which the recess is formed, and the outer side forming the recess of the exterior material for the power storage device to be tested.

- For the curved and non-curved surfaces of the surface measure the L * value of the reflected light in the L * a * b * color space under the SCI method, the field of view 10 °, and the measurement conditions of the light source F2, respectively, and obtain the L * value.

- the exterior material for a power storage device having a recess formed is a good product based on the magnitude of the difference (that is, the absolute value of the difference in L * values), it is compared with the conventional visual determination. It was found that quality control can be performed with high accuracy.

- the exterior material for a power storage device composed of a laminate including a base material layer, a barrier layer, and a thermosetting resin layer is formed from the thermosetting resin layer side.

- Quality control targets exterior materials for power storage devices, which are molded so as to project toward the base material layer and have recesses on the thermosetting resin layer side for accommodating power storage device elements.

- the exterior material for the power storage device to be tested is extracted from the exterior material for the power storage device in which the recess is formed, and the curved surface portion and the non-curved surface portion of the outer surface forming the recess of the exterior material for the power storage device to be tested are SCI, respectively.

- the L * value of the reflected light in the L * a * b * color space was measured under the method, the field of view of 10 °, and the measurement conditions of the light source F2, and a recess was formed based on the magnitude of the difference in the L * values.

- a determination step for determining whether or not the exterior material for a power storage device is a good product is provided. Quality control method in the molding process of exterior materials for power storage devices.

- the present disclosure it is possible to provide a novel quality control method in the molding process of the exterior material for a power storage device. Further, according to the present disclosure, it is also possible to provide a method for manufacturing an exterior material for a power storage device using the quality control method. Further, according to the present disclosure, it is possible to provide an exterior material for a power storage device determined to be a non-defective product by the quality control method, and further, a power storage device using the exterior material for the power storage device.

- the quality control of the present disclosure is a quality control method in a molding process of an exterior material for a power storage device, and the quality control method includes at least a base material layer, a barrier layer, and a heat-sealing resin layer in order from the outside.

- the exterior material for a power storage device composed of a laminate comprising the above is molded so as to project from the heat-sealing resin layer side to the base material layer side, and the power storage device element is housed on the heat-sealing resin layer side.

- the exterior material for the power storage device in which the recess is formed is subject to quality control, and the exterior material for the power storage device to be tested is extracted from the exterior material for the power storage device in which the recess is formed, and the exterior material for the power storage device to be tested is extracted.

- the exterior material for the power storage device to be tested is extracted from the exterior material for the power storage device in which the recess is formed, and the exterior material for the power storage device to be tested is extracted.

- the present invention is characterized by comprising a determination step of determining whether or not the exterior material for a power storage device having a recess formed is a non-defective product based on the magnitude of the difference in L * values. According to the quality control method of the present disclosure, it is possible to determine whether or not the exterior material for a power storage device having a recess formed is a non-defective product based on the size of the difference in L * values.

- the quality control method the manufacturing method of the power storage device, the exterior material for the power storage device, and the power storage device in the molding process of the exterior material for the power storage device of the present disclosure will be described in detail.

- the numerical range indicated by “-” means “greater than or equal to” and “less than or equal to”.

- the notation of 2 to 15 mm means 2 mm or more and 15 mm or less.

- the quality control method of the present disclosure is a quality control method in the molding process of an exterior material for a power storage device.

- the exterior material for a power storage device subject to quality control is composed of a laminate having at least a base material layer, a barrier layer, and a thermosetting resin layer in this order from the outside. ing. The laminated structure of the exterior material for the power storage device and the details of each layer will be described later.

- the exterior material for a power storage device subject to quality control is molded so as to project from the thermosetting resin layer side to the base material layer side, and has heat fusion properties.

- a recess for accommodating the power storage device element is formed on the resin layer side. That is, the exterior material for the power storage device has a recess formed by molding. As will be described later, the molding can be performed using a mold or the like.

- the shape of the recess formed in the exterior material for the power storage device is not particularly limited as long as a space that can accommodate the power storage device element is formed.

- Specific examples of the shape of the concave portion include a substantially rectangular shape in a plan view and a substantially circular shape in a plan view when observed from the base material layer 1 side.

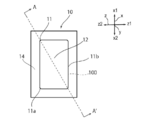

- FIGS. 5 and 6 show a schematic view in which the concave portion 100 having a rectangular shape in a plan view is provided in the exterior material 10 for a power storage device.

- the rectangular shape in a plan view includes not only a case where the corners of the rectangle are right angles, but also a rounded shape as shown in FIGS. 5 and 6.

- the curved surface portion 11 includes a corner portion 11a and a ridge line portion 11b protruding toward the base material layer 1, and the corner portion 11

- the surfaces of the base material layer 1 side of each of the 11a and the ridge line portion 11b have a predetermined radius of curvature R.

- the rectangular recess 100 in a plan view forms a rectangular parallelepiped space, and the power storage device element is housed in the space. If the shape of the recess is circular in a plan view, the recess forms a columnar space, and the power storage device element is housed in the space.

- the size of the recess 100 is not particularly limited, and is appropriately designed according to the size of the power storage device (that is, the size of the power storage device element to be accommodated) and the like.

- the length of the long side of the recess 100 is, for example, about 20 mm or more, preferably about 30 mm when the exterior material 10 for the power storage device is observed from the base material layer 1 side. As mentioned above, it is more preferably about 50 mm or more.

- the length of the long side of the recess 100 is, for example, about 600 mm or less, preferably about 400 mm or less, and more preferably about 200 mm or less.

- the preferred range of the length of the long side of the recess 100 is about 20 to 600 ⁇ m, about 20 to 400 ⁇ m, about 20 to 200 ⁇ m, about 30 to 600 ⁇ m, about 30 to 400 ⁇ m, about 30 to 200 ⁇ m, about 50 to 600 ⁇ m, 50. Examples thereof include about 400 ⁇ m and about 50 to 200 mm.

- the length of the short side of the recess 100 is, for example, about 10 mm or more, preferably about 20 mm or more, and more preferably about 30 mm or more.

- the length of the short side of the recess 100 is, for example, about 300 mm or less, preferably about 200 mm or less, and more preferably about 100 mm or less.

- the preferred range of the length of the short side of the recess 100 is about 10 to 300 ⁇ m, about 10 to 200 ⁇ m, about 10 to 100 ⁇ m, about 20 to 300 ⁇ m, about 20 to 200 ⁇ m, about 20 to 100 ⁇ m, about 30 to 300 ⁇ m, and 30. Examples thereof include about 200 ⁇ m and about 30 to 100 mm.

- the length of the long side of the recess 100 and the length of the short side may be the same (that is, the shape of the recess 100 is square in a plan view).

- the depth D of the recess 100 is not particularly limited, and is appropriately designed according to the size of the power storage device (that is, the size of the power storage device element accommodated) and the like.

- the exterior material 10 for a power storage device having a total thickness described later about 4 to 10 mm can be mentioned.

- the recess 100 included in the exterior material 10 for a power storage device is formed by molding a film-shaped exterior material for a power storage device. Specifically, a mold (female mold) arranged on the base material layer 1 side of the laminate constituting the exterior material for the power storage device and a mold (male mold) arranged on the thermosetting resin layer 4 side. ) To form the laminate (generally cold molding) so that it protrudes from the thermosetting resin layer 4 side to the base material layer 1 side, thereby forming the thermosetting resin layer 4 side. A recess 100 in which the power storage device element is housed can be formed.

- the quality control method of the present disclosure is characterized by including a determination step of determining whether or not the exterior material for a power storage device having a recess formed is a non-defective product.

- the exterior material for the power storage device to be tested is extracted from the exterior material 10 for the power storage device in which the recess 100 is formed, and the curved surface portion 11 on the outer surface forming the recess of the exterior material for the power storage device to be tested.

- the non-curved surface portion 12 the L * value of the reflected light in the L * a * b * color space is measured under the SCI method, the field of view 10 °, and the measurement conditions of the light source F2, respectively, and the magnitude of the difference between the L * values is large.

- the exterior material for the power storage device having the recess formed is a good product.

- the exterior material for the power storage device to be tested may be randomly extracted, or a predetermined ratio (for example, recesses) may be used. It may be extracted as an exterior material for a power storage device to be tested at a ratio of 1 in 1,000 to 10,000 formed exterior materials for a power storage device), or an exterior material for a power storage device having a recess formed therein. All of the above may be extracted as the exterior material for the power storage device to be tested.

- the measurement of L * value and the like is automated and incorporated into the production line in consideration of the production efficiency of the power storage device. Is desirable.

- a bent portion (see curved surfaces 11 and 13 in FIG. 6) is formed in the exterior material for the power storage device.

- whitening may occur on the surface portion.

- Whitening due to molding of the exterior material for the power storage device leads to poor appearance of the power storage device, and is therefore subject to quality control in the molding of the exterior material for the power storage device. In the quality control, for example, when the exterior material for a power storage device is colored or when the degree of whitening is large, the presence or absence of whitening can be visually confirmed.

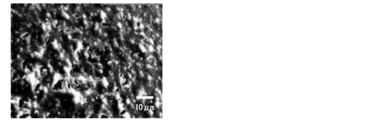

- the bent portion (outer surface of the exterior material for the power storage device) is observed by a scanning electron microscope or the like.

- a scanning electron microscope or the like When observing the curved surface portion of the above, very fine cracks may be formed. Therefore, it is desired to further improve the accuracy of the quality control method in the molding process of the exterior material for the power storage device.

- the curved portion of the recess formed by molding on the basis of the magnitude of the difference in the L * value (i.e. the absolute value of the difference between L * values), fine cracks on the curved surface portion It is possible to suitably detect the quality such as whether or not it is formed. Therefore, if the quality control method of the present disclosure is used for manufacturing a power storage device, an evaluation standard for the magnitude of the difference in L * values is appropriately set according to the quality required for the power storage device, and the exterior material for the power storage device is used. It is possible to preferably suppress the production of defective products in the molding process of.

- the evaluation criteria for the difference in L * values can be appropriately set according to the quality required for the power storage device.

- the evaluation standard is the same as the L * value of the curved surface portion 11.

- the absolute value of the difference between the non-curved surface portion 12 and L * is preferably 2.0 or less, more preferably 1.8 or less, and further preferably 1.5. Below, it is more preferably 1.0 or less, further preferably 0.5 or less, and particularly preferably 0.3 or less.

- the preferred range of the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 is about 0.0 to 2.0 and 0.0 to 1. Examples thereof include about 8, about 0.0 to 1.5, about 0.0 to 1.0, about 0.0 to 0.5, and about 0.0 to 0.3.

- a crack is generated in a layer constituting an exterior material for a power storage device such as a surface coating layer, so that a gap is generated, the gloss of the base is exposed, and the L * value of the curved surface portion is higher than that of the non-curved surface portion.

- the electrolytic solution permeates through the minute cracks, causing the exterior material to peel off. It will be connected.

- the exterior material for the power storage device cannot follow the molding and cracks occur. Therefore, even if it is hard, it is flexible and flexible. It can be adjusted by making it a characteristic. Further, even if the exterior material for a power storage device is hard and supple, if a large amount of additives such as wax and particles are present, the adhesion between the resin and the particles or the boundary between the resin and the wax is weak, and cracks are likely to occur from the boundary. Therefore, it is preferable to adjust the content of the additive to the minimum necessary.

- the electrolytic solution is used as the power storage device exterior in the power storage device manufacturing process depending on the degree of the crack.

- the electrolytic solution may permeate the cracks and peel off between the layers constituting the exterior material for the power storage device. From the viewpoint of quality control so that a power storage device having excellent electrolytic solution resistance is manufactured, the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 in the determination process.

- ABSOR value of the difference determined to be a non-defective product is preferably controlled under stricter conditions than the whitening, preferably 1.5 or less, more preferably 1.0 or less, still more preferably 0.5. Below, it is particularly preferably 0.3 or less.

- the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 is 0.0 or more.

- the preferred range of the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 is about 0.0 to 1.5, about 0.0 to 1.0, and 0.0. Examples thereof include about 0.5 and about 0.0 to 0.3.

- the absolute value of the difference between the a * value of the curved surface portion 11 and the a * value of the non-curved surface portion 12 (that is, the absolute value, which is the absolute value of the difference determined to be a good product).

- a preferable range of is about 0.00 to 0.12.

- the value of ⁇ E * ab is preferably about 1.8 or less, more preferably about 1.0 or less.

- the preferable range of the value of ⁇ E * ab is about 0.0 to 1.8 and about 0.0 to 1.0.

- the determination step can be specifically carried out as follows.

- L * a * b * under the following conditions. Measure the L * value in color space.

- the observation condition of the spectrophotometer (for example, Konica Minolta spectrophotometer (CM-700d)) calibrated with a white calibration cap (for example, CM-A177: manufactured by Konica Minolta) is 10 °, and the observation light source is F2.

- CM-700d Konica Minolta spectrophotometer

- a white calibration cap for example, CM-A177: manufactured by Konica Minolta

- the observation light source is F2.

- SCI mode JIS Z8722-2009.

- the L * value of the outer surface (the surface on the base material layer 1 side) of each of the curved surface portion 11 and the non-curved surface portion 12 to be measured is measured at room temperature and normal humidity.

- the measurement diameter is set to 8 mm ⁇

- the measurement diameter is set to 3 mm ⁇ for measurement.

- the a * value and the b * value of the curved surface portion 11 and the non-curved surface portion 12 can also be measured together with the measurement of

- the curved surface portion 11 for which the L * value is to be measured is the portion of the curved surface portion 11 forming the recess 100 that is most stretched by molding (molding in the formation of the recess 100) (that is, the finest cracks are most generated). The part that is easy to do).

- the most stretched portion is the portion where the difference between the L * values is the largest, and the portion where the L * value of the curved surface portion 11 is the largest.

- the corner portion 11a is the most extended portion of the curved surface portion 11 (rectangular shape in a plan view).

- the part 11a is the target for measuring the L * value.

- the corners 11a are present at four points in the shape of the molding die, but if the shapes of the four corners of the mold forming the corners 11a are the same, the L * value of the corners 11a since it becomes substantially the same, by measuring the L * values for the corners 11a of the one position, the measurement of the L * values for the corners 11a of the other three can be omitted.

- the curved surface portion 11 for measuring the a * value and the b * value is the same as the curved surface portion 11 for measuring the L * value.

- the ridge line portion 11b may be the most extended portion.

- the existing ridge portion 11b can be the most extended portion. In such a case, it is preferable to use the ridge line portion 11b as the measurement target of the L * value.

- the ridgeline portion is the target for measuring the L * value.

- the curved surface portion 13 in FIG. 6 is a curved surface portion that does not protrude toward the base material layer 1, and is generally stretched by molding as compared with the curved surface portion 11 that protrudes toward the base material layer 1. It is small and may or may not be adopted as the curved surface portion 11 for which the L * value is to be measured.

- the L * value of the non-curved surface portion is preferably measured as the non-curved surface portion 12 at a portion that is not substantially stretched by molding.

- the L * value of the non-curved surface portion is usually the same at any position, but for example, when the recess 100 is observed from the base material layer 1 side, the central portion of the recessed portion 100 is defined as the non-curved surface portion 12, and the L * value is L * value. It is preferable to measure.

- L * value and the non-curved portion 12 L * value of the curved surface portion 11 of the outer package 10 for a power storage device that is the object of quality control, respectively is not particularly limited, the As described above, the difference between these L * values may be appropriately managed from the viewpoints of whitening and electrolytic solution resistance.

- the exterior material 10 for a power storage device is colored (specifically, at least one of the layers located closer to the base material layer 1 than the barrier layer 3 of the exterior material 10 for a power storage device (for example,).

- the barrier layer 3 When a color different from the above is visually recognized), whitening or the like on the curved surface portion 11 is likely to be determined as a defective product, and particularly when the appearance of the exterior material 10 for a power storage device is a dark color such as black, the present disclosure is made.

- a quality control method is preferably used.

- the L * value of the non-curved surface portion 12 of the exterior material 10 for a power storage device is preferably, for example, about 60.0 or less, and more preferably about 50.0 or less. Yes, about 40.0 is more preferred, and about 30.0 or less is even more preferred.

- the L * value of the non-curved surface portion 12 is, for example, about 0.0 or more, about 10.0 or more, about 20.0 or more, and the like.

- the preferred range of the L * value of the non-curved surface portion 12 is about 0.0 to 60.0, about 0.0 to 50.0, about 0.0 to 40.0, about 0.0 to 30.0, and so on.

- the a * value of the non-curved surface portion 12 is, for example, about +2.00 or less, preferably about +1.00 or less.

- the a * value of the non-curved surface portion 12 is, for example, about ⁇ 2.00 or more, preferably about ⁇ 1.00 or more.

- the preferred range of the a * value of the non-curved surface portion 12 is about -2.00 to +2.00, about -2.00 to +1.00, about -1.00 to +2.00, and -1.00 to +1. About .00 is mentioned.

- the b * value of the non-curved surface portion 12 is, for example, about +1.00 or less, preferably about +0.00 or less.

- the b * value of the non-curved surface portion 12 is, for example, about ⁇ 3.00 or more, preferably about ⁇ 2.00 or more.

- the preferable range of the b * value of the non-curved surface portion 12 is about -3.00 to +1.00, about -3.00 to +0.00, about -2.00 to +1.00, and -2.00 to +0. About .00 is mentioned.

- the layer located at the outermost layer of the exterior material 10 for the power storage device for example, the base material layer 1 described later, the surface coating.

- the composition and thickness of the layer 6 and the like, the shape and size of the mold, the surface roughness, and the pressing pressure of the mold are adjusted to obtain a predetermined value.

- the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 is adjusted by adjusting the laminating conditions of each layer in the laminating process of the exterior material 10 for the power storage device. You may.

- the mirror glossiness of the non-curved surface portion 12 of the exterior material 10 for a power storage device is preferably, for example, about 5.0 or less, and more preferably about 3.6 or less. Is.

- the mirror glossiness is, for example, about 1.0 or more. Preferred ranges of the mirror glossiness include about 1.0 to 5.0 and about 1.0 to 3.6.

- the mirror glossiness of the non-curved surface portion 12 of the exterior material 10 for a power storage device is specified as follows.

- the mirror glossiness of the non-curved surface portion of the exterior material for the power storage device in which the recess is formed is substantially the mirror glossiness of the outer surface (position of the non-curved surface portion after molding) of the exterior material for the power storage device before molding. (That is, the mirror glossiness does not substantially change due to molding in the non-curved surface portion, but for example, when the recess 100 is observed from the base material layer 1 side, the central portion of the recess 100 is designated as the non-curved surface portion 12. Therefore, it is preferable to measure the mirror surface glossiness.) Therefore, when the exterior material for the power storage device before molding is available, the mirror surface gloss on the outer surface of the exterior material for the power storage device before molding is measured as follows. It may be measured by a method.

- the mirror glossiness of the outer surface of the non-curved surface portion of the exterior material for a power storage device is measured by the following measuring method.

- an incident angle of 60 degrees is used using a gloss measuring device (for example, a gloss measuring device micro-tri-gloss manufactured by Toyo Seiki Seisakusho (measurement area 9 mm x 15 mm)).

- the mirror glossiness of the surface coating layer in the above is measured.

- the power storage device in which the recess is formed is based on the magnitude of the L * value of the curved portion and the non-curved portion forming the recess. It is a new quality control method that includes a judgment process to judge whether the exterior material for use is non-defective, and performs more accurate quality control than the conventional quality control using visual inspection or a camera. Is also possible. Therefore, by utilizing the quality control method of the present disclosure for manufacturing a power storage device, it is possible to more efficiently manufacture a non-defective product of the power storage device.

- the determination step is based on whether or not the exterior material for a power storage device has fine cracks formed in the layer constituting the exterior material for the power storage device, for example, by molding when forming the recess. It can be used as a determination method for evaluating the characteristics (molding characteristics) of the above, and by using this determination method, the characteristics of the exterior material for a power storage device can be easily evaluated without using a scanning electron microscope or the like. be able to.

- the manufacturing method of the power storage device of the present disclosure is composed of a laminate including at least a base material layer 1, a barrier layer 3, and a thermosetting resin layer 4 in this order from the outside.

- the power storage device element is sealed by a package formed by heat-sealing the thermosetting resin layer 4.

- This is a method for manufacturing a power storage device.

- the method for manufacturing the power storage device of the present disclosure uses the quality control method described in the column of "1. Quality control method" for manufacturing the power storage device, and the description of overlapping matters will be omitted as appropriate. Further, as described above, the laminated structure of the exterior material for the power storage device and the details of each layer will be described later.

- the power storage device exterior is formed with a recess for accommodating the power storage device element so as to project from the thermosetting resin layer side to the base material layer side of the power storage device exterior material. It has a process of preparing materials.

- the exterior material for the power storage device in which such a recess is formed is as described in the above section “1. Quality control method”, and the description thereof will be omitted.

- the exterior material for the power storage device to be tested is extracted from the exterior material for the power storage device in which the recess is formed, and the outer side forming the recess of the exterior material for the power storage device to be tested is formed.

- the curved surface and non-curved surface measure the L * value of the reflected light in the L * a * b * color space under the SCI method, the field of view 10 °, and the measurement conditions of the light source F2, respectively, and obtain the L * value. It is provided with a determination step of determining whether or not the exterior material for a power storage device having a recess formed is a good product based on the magnitude of the difference.

- the determination process is also as described in the above section “1. Quality control method”, and the description thereof will be omitted. If, in the determination process of the method for manufacturing the energy storage device of the present disclosure, the exterior material for the energy storage device having the recess formed is determined to be a defective product, the process of laminating the exterior material for the energy storage device or the exterior of the energy storage device The process returns to the material molding process, and the configuration, laminating method, molding conditions, etc. of the exterior material for the power storage device are adjusted until the product is judged to be non-defective in the determination process.

- the method for manufacturing a power storage device of the present disclosure includes a step of manufacturing a power storage device by accommodating a power storage device element in a recess of an exterior material for the power storage device.

- a step of manufacturing a power storage device by accommodating a power storage device element in a recess of an exterior material for the power storage device.

- the exterior material for the power storage device in which the recess is formed is a non-defective product

- it is determined that the formation of the recess is appropriate, and the recess is formed.

- a power storage device element is housed in the storage device to manufacture a power storage device.

- the evaluation criteria for the difference in L * values can be appropriately set according to the quality required for the power storage device.

- the absolute value of the difference between L * values of the non-curved portion 12 is preferably 2.0 or less, more preferably 1.8 or less, further It is preferably 1.5 or less, more preferably 1.0 or less, still more preferably 0.5 or less, and particularly preferably 0.3 or less.

- the preferred range of the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 is about 0.0 to 2.0 and 0.0 to 1. Examples thereof include about 8, about 0.0 to 1.5, about 0.0 to 1.0, about 0.0 to 0.5, and about 0.0 to 0.3.

- the L * value of the curved surface portion 11, of the non-curved portion 12 L * value

- the absolute value of the difference from the above is preferably controlled under stricter conditions than the whitening, preferably 1.5 or less, more preferably 1.0 or less. It is more preferably 0.5 or less, and particularly preferably 0.3 or less.

- the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 is 0.0 or more.

- the preferred range of the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 is about 0.0 to 1.5, about 0.0 to 1.0, and 0.0. Examples thereof include about 0.5 and about 0.0 to 0.3. From the same viewpoint, the absolute value of the difference between the a * value of the curved surface portion 11 and the a * value of the non-curved surface portion 12 (that is, the absolute value, which is the absolute value of the difference determined to be a good product). A preferable range of is about 0.00 to 0.12.

- a known method can be applied to the method of manufacturing the power storage device by accommodating the power storage device element in the recess 100. Specifically, the electrode, the electrolytic solution, and the like constituting the power storage device element are housed in the recess 100, and the heat-sealing resin layers 4 of the exterior material 10 for the power storage device are heat-sealed to form the power storage device element. Seal to obtain a power storage device.

- the inspection method of the present disclosure is an inspection method of an exterior material for a power storage device in which a recess is formed.

- the exterior material for a power storage device composed of a laminate including a base material layer, a barrier layer, and a thermosetting resin layer, in order from the outside, is the thermosetting resin.

- the inspection target is an exterior material for a power storage device, which is formed so as to project from the layer side to the base material layer side and has a recess formed on the heat-sealing resin layer side for accommodating the power storage device element.

- the quality control method of the present disclosure described above can be said to be a quality control method using the inspection method of the present disclosure, and the description of matters overlapping with the matters described in the above-mentioned "1. Quality control method" column will be omitted as appropriate. Further, as described above, the laminated structure of the exterior material for the power storage device and the details of each layer will be described later.

- the exterior material for the power storage device in which the recess to be inspected is formed is as described in the above section "1. Quality control method", and the description thereof will be omitted.

- the curved surface portion and the non-curved surface portion of the outer surface forming the concave portion of the exterior material for the power storage device in which the concave portion is formed are subjected to the SCI method, the field of view 10 °, and the measurement conditions of the light source F2, respectively.

- the determination process is also as described in the above section “1. Quality control method”, and the description thereof will be omitted.

- the evaluation criteria for the difference in L * values can be appropriately set according to the quality required for the power storage device.

- the absolute value of the difference between L * values of the non-curved portion 12 is preferably 2.0 or less, more preferably 1.8 or less, further It is preferably 1.5 or less, more preferably 1.0 or less, still more preferably 0.5 or less, and particularly preferably 0.3 or less.

- the preferred range of the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 is about 0.0 to 2.0 and 0.0 to 1. Examples thereof include about 8, about 0.0 to 1.5, about 0.0 to 1.0, about 0.0 to 0.5, and about 0.0 to 0.3.

- the L * value of the curved surface portion 11, of the non-curved portion 12 L * value

- the absolute value of the difference from the above is preferably controlled under stricter conditions than the whitening, preferably 1.5 or less, more preferably 1.0 or less. It is more preferably 0.5 or less, and particularly preferably 0.3 or less.

- the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 is 0.0 or more.

- the preferred range of the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 is about 0.0 to 1.5, about 0.0 to 1.0, and 0.0. Examples thereof include about 0.5 and about 0.0 to 0.3. From the same viewpoint, the absolute value of the difference between the a * value of the curved surface portion 11 and the a * value of the non-curved surface portion 12 (that is, the absolute value, which is the absolute value of the difference determined to be a good product). A preferable range of is about 0.00 to 0.12.

- Exterior material for power storage device is composed of a laminated body including a base material layer 1, a barrier layer 3, and a thermosetting resin layer 4, at least in this order from the outside. It is an exterior material for devices.

- the exterior material 10 for a power storage device is formed so as to project from the thermosetting resin layer 4 side to the base material layer 1 side, and the recess 100 in which the power storage device element is housed on the heat fusion resin layer 4 side. It has.

- the reflected light L * a * b * is obtained under the SCI method, the field of view 10 °, and the measurement conditions of the light source F2, respectively.

- the absolute value of the difference between the L * value of the curved surface portion 11, of the non-curved portion 12 and the L * is characterized by more than 1.5. That is, the case 10 for a power storage device of the present disclosure, one of the "1.

- the electrolytic solution may be used as the exterior material for the power storage device in the manufacturing process of the power storage device depending on the degree of the cracks. When it adheres to the surface, the electrolytic solution may permeate into the cracks and the layers constituting the exterior material for the power storage device may be peeled off. Therefore, the absolute value of the difference between the L * value of the curved surface portion 11 of the exterior material 10 for the power storage device in which the recess is formed and the L * value of the non-curved surface portion 12 should be managed under stricter conditions than the whitening. Is desirable.

- the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 is particularly low, 1.5 or less. It is set to a value.

- the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 is preferably 1.0 or less, more preferably 0.5 or less. , Especially preferably 0.3 or less.

- the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 is 0.0 or more.

- the preferred range of the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 is about 0.0 to 1.5, about 0.0 to 1.0, and 0.0. Examples thereof include about 0.5 and about 0.0 to 0.3. From the same viewpoint, a preferable range of the absolute value of the difference between the a * value of the curved surface portion 11 and the a * value of the non-curved surface portion 12 is about 0.00 to 0.12. From the same viewpoint, a preferable range of the absolute value of the difference between the b * value of the curved surface portion and the b * value of the non-curved surface portion is about 0.00 to 0.60.

- the preferable L * value, a * value, and b * value of the curved surface portion 11 and the non-curved surface portion 12, the measurement method thereof, and the details of the measurement location are as described in "1. Quality control method" above.

- the exterior material 10 for a power storage device before forming the recess 100 is described below so that the exterior material for the power storage device protrudes from the thermosetting resin layer 4 side to the base material layer 1 side.

- the curved surface portion 11 and the non-curved surface portion 12 on the outer surface which are molded under the molding conditions to form a recess on the thermosetting resin layer 4 side in which the power storage device element is housed to form the recess of the exterior material 10 for the power storage device.

- the non-curved portion It is preferable that the absolute value of the difference between 12 and L * is 1.5 or less.

- the electric storage device for the exterior material 10 is not formed a recess as described above, to form a recess at a predetermined molding condition, and the L * value of the curved surface portion 11, the absolute of the difference between the non-curved portion 12 L * The value is 1.5 or less.

- the exterior material for the power storage device is placed between the molding die (female mold) having a diameter of 54.5 mm (TD) x 31.6 mm (MD) and the corresponding molding die (male mold) on the female mold side. It is arranged so as to be on the base material layer side, the pressing pressure (surface pressure) is 0.25 MPa, and cold molding is performed at a molding depth of 3.0 mm to form a concave portion having a rectangular shape in a plan view.

- the clearance between the female type and the male type is 0.5 mm.

- the surface of the female mold has a maximum height roughness (nominal value of Rz) of 0.8 ⁇ m specified in Table 2 of the comparative surface roughness standard piece in JIS B 0659-1: 2002 Annex 1 (reference). ..

- the female corner R is 2.0 mm and the ridge R is 2.5 mm.

- the male surface has a maximum height roughness (nominal value of Rz) of 3.2 ⁇ m specified in Table 2 of the comparative surface roughness standard piece in JIS B 0659-1: 2002 Annex 1 (reference). ..

- the male corner R is 2.0 mm and the ridge R is 2.0 mm.

- the male-shaped corner R and ridge line R have a maximum height roughness (nominal value of Rz) of 1 as specified in Table 2 of the comparative surface roughness standard piece in JIS B 0659-1: 2002 Annex 1 (reference). It is 0.6 ⁇ m.

- the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 after the recess is formed under the above-mentioned molding conditions. Is preferably 1.0 or less, more preferably 0.5 or less, and particularly preferably 0.3 or less. As described above, the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 is 0.0 or more. The preferred range of the absolute value of the difference between the L * value of the curved surface portion 11 and the L * value of the non-curved surface portion 12 is about 0.0 to 1.5, about 0.0 to 1.0, and 0.0.

- Examples thereof include about 0.5 and about 0.0 to 0.3. From the same viewpoint, a preferable range of the absolute value of the difference between the a * value of the curved surface portion 11 and the a * value of the non-curved surface portion 12 is about 0.00 to 0.12. From the same viewpoint, a preferable range of the absolute value of the difference between the b * value of the curved surface portion and the b * value of the non-curved surface portion is about 0.00 to 0.60. Further, the preferable L * value, a * value, and b * value of the curved surface portion 11 and the non-curved surface portion 12, the measurement method thereof, and the details of the measurement location are as described in "1. Quality control method" above. is there.

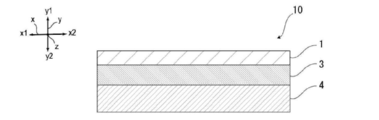

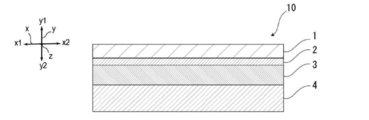

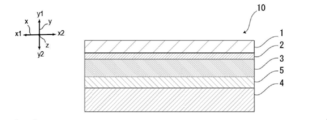

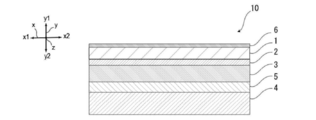

- the exterior material 10 for power storage device is composed of a laminate having at least a base material layer 1, a barrier layer 3, and a thermosetting resin layer 4 in this order. It is configured.

- the base material layer 1 is on the outermost layer side

- the thermosetting resin layer 4 is on the innermost layer.

- the peripheral portion 14 is heat-sealed with the thermosetting resin layers 4 of the power storage device exterior material 10 facing each other. The energy storage device element is housed in the space formed by this.

- the heat-sealing resin layer 4 side is inside the barrier layer 3 and the base material layer 1 side is more than the barrier layer 3 with the barrier layer 3 as a reference. It is the outside.

- the exterior material 10 for a power storage device is used as necessary for the purpose of enhancing the adhesiveness between the base material layer 1 and the barrier layer 3 and the like. It may have an adhesive layer 2. Further, for example, as shown in FIGS. 3 and 4, the adhesive layer 5 is required between the barrier layer 3 and the thermosetting resin layer 4 for the purpose of enhancing the adhesiveness between the layers. May have. Further, as shown in FIG. 4, a surface coating layer 6 or the like may be provided on the outside of the base material layer 1 (the side opposite to the thermosetting resin layer 4 side), if necessary.

- the thickness of the laminate constituting the exterior material 10 for the power storage device is not particularly limited, but is preferably about 180 ⁇ m or less, about 155 ⁇ m or less, and about 120 ⁇ m or less from the viewpoint of cost reduction, energy density improvement, and the like. Further, the thickness of the laminate constituting the exterior material 10 for the power storage device is preferably about 35 ⁇ m or more, about 45 ⁇ m or more, and about from the viewpoint of maintaining the function of the exterior material for the power storage device of protecting the power storage device element. 60 ⁇ m or more can be mentioned.

- the preferred range of the laminate constituting the exterior material 10 for the power storage device is, for example, about 35 to 180 ⁇ m, about 35 to 155 ⁇ m, about 35 to 120 ⁇ m, about 45 to 180 ⁇ m, about 45 to 155 ⁇ m, about 45 to 120 ⁇ m. , About 60 to 180 ⁇ m, about 60 to 155 ⁇ m, about 60 to 120 ⁇ m, and particularly preferably about 60 to 155 ⁇ m.

- the ratio of the total thickness of the adhesive layer 5, the thermosetting resin layer 4, and the surface coating layer 6 provided as needed is preferably 90% or more, more preferably 95% or more. More preferably, it is 98% or more.

- the exterior material 10 for a power storage device of the present disclosure includes a base material layer 1, an adhesive layer 2, a barrier layer 3, an adhesive layer 5, and a thermosetting resin layer 4, the exterior for the power storage device

- the ratio of the total thickness of each of these layers to the thickness (total thickness) of the laminate constituting the material 10 is preferably 90% or more, more preferably 95% or more, and further preferably 98% or more.

- the exterior material 10 for a power storage device of the present disclosure is a laminated body including a base material layer 1, an adhesive layer 2, a barrier layer 3, and a thermosetting resin layer 4, the exterior material for a power storage device is also used.

- the ratio of the total thickness of each of these layers to the thickness (total thickness) of the laminate constituting 10 is, for example, 80% or more, preferably 90% or more, more preferably 95% or more, and further preferably 98% or more. Can be done.

- the base material layer 1 is a layer provided for the purpose of exerting a function as a base material of an exterior material for a power storage device.

- the base material layer 1 is located on the outer layer side of the exterior material for the power storage device.

- the material forming the base material layer 1 is not particularly limited as long as it has a function as a base material, that is, at least an insulating property.

- the base material layer 1 can be formed using, for example, a resin, and the resin may contain an additive described later.

- the base material layer 1 may be, for example, a resin film formed of resin or may be formed by applying a resin.

- the resin film may be an unstretched film or a stretched film.

- the stretched film include a uniaxially stretched film and a biaxially stretched film, and a biaxially stretched film is preferable.

- the stretching method for forming the biaxially stretched film include a sequential biaxial stretching method, an inflation method, and a simultaneous biaxial stretching method.

- the method for applying the resin include a roll coating method, a gravure coating method, and an extrusion coating method.

- the resin forming the base material layer 1 examples include resins such as polyester, polyamide, polyolefin, epoxy resin, acrylic resin, fluororesin, polyurethane, silicon resin, and phenol resin, and modified products of these resins. Further, the resin forming the base material layer 1 may be a copolymer of these resins, or may be a modified product of the copolymer. Further, it may be a mixture of these resins.

- the resin forming the base material layer 1 include polyester and polyamide.

- polyester examples include polyethylene terephthalate, polybutylene terephthalate, polyethylene naphthalate, polybutylene naphthalate, polyethylene isophthalate, and copolymerized polyester.

- copolymerized polyester examples include a copolymerized polyester containing ethylene terephthalate as a repeating unit.

- a copolymer polyester hereinafter abbreviated after polyethylene (terephthalate / isophthalate)

- polyethylene (terephthalate / adipate) polyethylene (terephthalate / terephthalate /)

- polyethylene (terephthalate / terephthalate /) which polymerizes with ethylene isophthalate using ethylene terephthalate as a repeating unit as a main component.

- polyesters (Sodium sulfoisophthalate), polyethylene (terephthalate / sodium isophthalate), polyethylene (terephthalate / phenyl-dicarboxylate), polyethylene (terephthalate / decandicarboxylate) and the like. These polyesters may be used alone or in combination of two or more.

- polyamide specifically, an aliphatic polyamide such as nylon 6, nylon 66, nylon 610, nylon 12, nylon 46, a copolymer of nylon 6 and nylon 66; terephthalic acid and / or isophthalic acid.

- Hexamethylenediamine-isophthalic acid-terephthalic acid copolymerized polyamide such as nylon 6I, nylon 6T, nylon 6IT, nylon 6I6T (I stands for isophthalic acid, T stands for terephthalic acid), polyamide MXD6 (polymethaki) containing the derived structural units.

- Polyamide containing aromatics such as silylene adipamide); Alicyclic polyamide such as polyamide PACM6 (polybis (4-aminocyclohexyl) methaneadipamide); Further, lactam component and isocyanate component such as 4,4'-diphenylmethane-diisocyanate Examples thereof include a copolymerized polyamide, a polyesteramide copolymer or a polyether esteramide copolymer which is a copolymer of a copolymerized polyamide and a polyester or a polyalkylene ether glycol; and a polyamide such as these copolymers. These polyamides may be used alone or in combination of two or more.

- the base material layer 1 preferably contains at least one of a polyester film, a polyamide film, and a polyolefin film, and preferably contains at least one of a stretched polyester film, a stretched polypropylene film, and a stretched polyolefin film. It is more preferable to contain at least one of a stretched polyethylene terephthalate film, a stretched polybutylene terephthalate film, a stretched nylon film, and a stretched polypropylene film, preferably a biaxially stretched polyethylene terephthalate film, a biaxially stretched polybutylene terephthalate film, and a biaxially stretched nylon film. , It is more preferable to contain at least one of the biaxially stretched polypropylene films.

- the base material layer 1 may be a single layer or may be composed of two or more layers.

- the base material layer 1 may be a laminated body in which a resin film is laminated with an adhesive or the like, or the resin is co-extruded to form two or more layers. It may be a laminated body of the resin film. Further, the laminated body of the resin film obtained by co-extruding the resin into two or more layers may be used as the base material layer 1 without being stretched, or may be uniaxially stretched or biaxially stretched as the base material layer 1.

- the laminate of two or more layers of resin film in the base material layer 1 include a laminate of a polyester film and a nylon film, a laminate of two or more layers of nylon film, and a laminate of two or more layers of polyester film. And the like, preferably, a laminate of a stretched nylon film and a stretched polyester film, a laminate of two or more layers of stretched nylon film, and a laminate of two or more layers of stretched polyester film are preferable.

- the base material layer 1 is a laminate of two layers of resin film, a laminate of polyester resin film and polyester resin film, a laminate of polyamide resin film and polyamide resin film, or a laminate of polyester resin film and polyamide resin film.

- a laminate is preferable, and a laminate of a polyethylene terephthalate film and a polyethylene terephthalate film, a laminate of a nylon film and a nylon film, or a laminate of a polyethylene terephthalate film and a nylon film is more preferable.

- the polyester resin is difficult to discolor when the electrolytic solution adheres to the surface, for example, when the base material layer 1 is a laminate of two or more resin films, the polyester resin film is the base material layer 1. It is preferably located in the outermost layer.

- the two or more layers of resin films may be laminated via an adhesive.

- Preferred adhesives include those similar to the adhesives exemplified in the adhesive layer 2 described later.

- the method of laminating two or more layers of resin films is not particularly limited, and known methods can be adopted. Examples thereof include a dry laminating method, a sandwich laminating method, an extrusion laminating method, and a thermal laminating method, and a dry laminating method is preferable.

- the laminating method can be mentioned.

- the thickness of the adhesive is, for example, about 2 to 5 ⁇ m.

- an anchor coat layer may be formed on the resin film and laminated. Examples of the anchor coat layer include the same adhesives as those exemplified in the adhesive layer 2 described later. At this time, the thickness of the anchor coat layer is, for example, about 0.01 to 1.0 ⁇ m.

- additives such as a lubricant, a flame retardant, an antiblocking agent, an antioxidant, a light stabilizer, a tackifier, and an antistatic agent are present on at least one of the surface and the inside of the base material layer 1. Good. Only one type of additive may be used, or two or more types may be mixed and used.

- the lubricant is present on the surface of the base material layer 1.

- the lubricant is not particularly limited, but an amide-based lubricant is preferable.

- Specific examples of the amide-based lubricant include saturated fatty acid amides, unsaturated fatty acid amides, substituted amides, methylol amides, saturated fatty acid bisamides, unsaturated fatty acid bisamides, fatty acid ester amides, and aromatic bisamides.

- saturated fatty acid amide examples include lauric acid amide, palmitic acid amide, stearic acid amide, bechenic acid amide, hydroxystearic acid amide and the like.

- unsaturated fatty acid amide examples include oleic acid amide and erucic acid amide.

- substituted amide examples include N-oleyl palmitic acid amide, N-stearyl stearic acid amide, N-stearyl oleic acid amide, N-oleyl stearic acid amide, N-stearyl erucate amide and the like.

- methylolamide examples include methylolstearic acid amide.

- saturated fatty acid bisamide examples include methylene bisstearic acid amide, ethylene biscapric acid amide, ethylene bislauric acid amide, ethylene bisstearic acid amide, ethylene bishydroxystearic acid amide, ethylene bisbechenic acid amide, and hexamethylene bisstearate.

- saturated fatty acid bisamide examples include acid amides, hexamethylene bisbechenic acid amides, hexamethylene hydroxystearic acid amides, N, N'-distearyl adipate amides, and N, N'-distealyl sebasic acid amides.

- unsaturated fatty acid bisamides include ethylene bisoleic acid amide, ethylene biserucic acid amide, hexamethylene bisoleic acid amide, N, N'-diorail adipate amide, and N, N'-diorail sebacic acid amide. And so on.

- Specific examples of the fatty acid ester amide include stearoamide ethyl stearate and the like.

- Specific examples of the aromatic bisamide include m-xylylene bisstearic acid amide, m-xylylene bishydroxystearic acid amide, and N, N'-distearyl isophthalic acid amide.

- One type of lubricant may be used alone, or two or more types may be used in combination.

- the abundance thereof is not particularly limited, but is preferably about 3 mg / m 2 or more, more preferably about 4 to 15 mg / m 2 , and further preferably 5 to 14 mg. / M 2 is mentioned.

- the lubricant existing on the surface of the base material layer 1 may be one in which the lubricant contained in the resin constituting the base material layer 1 is exuded, or one in which the lubricant is applied to the surface of the base material layer 1. You may.

- the thickness of the base material layer 1 is not particularly limited as long as it functions as a base material, and examples thereof include about 3 to 50 ⁇ m, preferably about 10 to 35 ⁇ m.

- the thickness of the resin films constituting each layer is preferably about 2 to 25 ⁇ m, respectively.

- the adhesive layer 2 is a layer provided between the base material layer 1 and the barrier layer 3 as necessary for the purpose of enhancing the adhesiveness.

- the adhesive layer 2 is formed by an adhesive capable of adhering the base material layer 1 and the barrier layer 3.

- the adhesive used for forming the adhesive layer 2 is not limited, but may be any of a chemical reaction type, a solvent volatile type, a heat melting type, a hot pressure type and the like. Further, it may be a two-component curable adhesive (two-component adhesive), a one-component curable adhesive (one-component adhesive), or a resin that does not involve a curing reaction. Further, the adhesive layer 2 may be a single layer or a multilayer.

- the adhesive component contained in the adhesive include polyesters such as polyethylene terephthalate, polybutylene terephthalate, polyethylene naphthalate, polybutylene naphthalate, polyethylene isophthalate, and copolymerized polyester; polyether; polyurethane; epoxy resin; Phenolic resin; Polyethylene such as nylon 6, nylon 66, nylon 12, copolymerized polyamide; Polyethylene resin such as polyolefin, cyclic polyolefin, acid-modified polyolefin, acid-modified cyclic polyolefin; Polyvinyl acetate; Cellulose; (Meta) acrylic resin; Polyethylene; polycarbonate; amino resin such as urea resin and melamine resin; rubber such as chloroprene rubber, nitrile rubber and styrene-butadiene rubber; silicone resin and the like.

- polyesters such as polyethylene terephthalate, polybutylene terephthalate, polyethylene naphthalate, polybutylene

- adhesive components may be used alone or in combination of two or more.

- a polyurethane adhesive is preferable.

- the resins used as these adhesive components can be used in combination with an appropriate curing agent to increase the adhesive strength.

- An appropriate curing agent is selected from polyisocyanate, polyfunctional epoxy resin, oxazoline group-containing polymer, polyamine resin, acid anhydride and the like, depending on the functional group of the adhesive component.

- polyurethane adhesive examples include a polyurethane adhesive containing a main agent containing a polyol compound and a curing agent containing an isocyanate compound.

- a polyol such as a polyester polyol, a polyether polyol, and an acrylic polyol is used as a main component, and an aromatic or aliphatic polyisocyanate is used as a curing agent.

- the polyol compound it is preferable to use a polyester polyol having a hydroxyl group in the side chain in addition to the hydroxyl group at the end of the repeating unit.

- Examples of the curing agent include aliphatic, alicyclic, aromatic, and aromatic aliphatic isocyanate compounds.

- Examples of the isocyanate-based compound include hexamethylene diisocyanate (HDI) xylylene diisocyanate (XDI), isophorone diisocyanate (IPDI), hydrogenated XDI (H6XDI), hydrogenated MDI (H12MDI), tolylene diisocyanate (TDI), and diphenylmethane diisocyanate ( MDI), naphthalenediocyanate (NDI) and the like.

- HDI hexamethylene diisocyanate

- XDI xylylene diisocyanate

- IPDI isophorone diisocyanate

- H6XDI hydrogenated XDI

- H12MDI hydrogenated MDI

- TDI tolylene diisocyanate

- MDI diphenylmethane diisocyanate

- a multimer for example, a trimer

- a multimer include an adduct body, a biuret body, a nurate body and the like. Since the adhesive layer 2 is formed of a polyurethane adhesive, excellent electrolyte resistance is imparted to the exterior material for the power storage device, and even if the electrolyte adheres to the side surface, the base material layer 1 is suppressed from peeling off. ..

- the adhesive layer 2 may contain a colorant, a thermoplastic elastomer, a tackifier, a filler (including particles) and the like, as long as the adhesiveness is not impaired. Since the adhesive layer 2 contains a colorant, the exterior material for the power storage device can be colored. As the colorant, known pigments, dyes and the like can be used. Further, only one type of colorant may be used, or two or more types may be mixed and used.

- the exterior material 10 for the power storage device is colored (specifically, at least one of the layers located closer to the base material layer 1 than the barrier layer 3 of the exterior material 10 for the power storage device 10).

- the exterior material 10 for a power storage device is observed from the base material layer 1 side by coloring the layers (for example, the base material layer 1, the adhesive layer 2, the coloring layer, the surface coating layer 6, etc., which will be described later).

- the layers for example, the base material layer 1, the adhesive layer 2, the coloring layer, the surface coating layer 6, etc., which will be described later.

- whitening on the curved surface portion 11 is likely to be determined as a defective product, and particularly when the appearance of the exterior material 10 for a power storage device is a dark color such as black.

- the quality control method of the present disclosure becomes effective. Therefore, it is preferable that the adhesive layer 2 of the exterior material 10 for the power storage device is colored.

- the type of pigment is not particularly limited as long as it does not impair the adhesiveness of the adhesive layer 2.

- organic pigments include azo-based, phthalocyanine-based, quinacridone-based, anthracinone-based, dioxazine-based, indigothioindigo-based, perinone-perylene-based, isowearnine-based, and benzimidazolone-based pigments, which are inorganic.

- the pigment include carbon black-based, titanium oxide-based, cadmium-based, lead-based, chromium oxide-based, and iron-based pigments, and other examples include fine powder of mica (mica) and fish scale foil.

- colorants for example, carbon black is preferable in order to make the appearance of the exterior material for a power storage device black.

- the average particle size of the pigment is not particularly limited, and examples thereof include about 0.05 to 5 ⁇ m, preferably about 0.08 to 2 ⁇ m.

- the average particle size of the pigment is the median size measured by a laser diffraction / scattering type particle size distribution measuring device.

- the content of the pigment in the adhesive layer 2 is not particularly limited as long as the exterior material for the power storage device is colored, and examples thereof include about 5 to 60% by mass, preferably 10 to 40% by mass.

- the thickness of the adhesive layer 2 is not particularly limited as long as the base material layer 1 and the barrier layer 3 can be adhered to each other, but is, for example, about 1 ⁇ m or more and about 2 ⁇ m or more.

- the thickness of the adhesive layer 2 is, for example, about 10 ⁇ m or less and about 5 ⁇ m or less.

- the preferable range of the thickness of the adhesive layer 2 is about 1 to 10 ⁇ m, about 1 to 5 ⁇ m, about 2 to 10 ⁇ m, and about 2 to 5 ⁇ m.

- the colored layer is a layer provided between the base material layer 1 and the barrier layer 3 as needed (not shown).

- a colored layer may be provided between the base material layer 1 and the adhesive layer 2 and between the adhesive layer 2 and the barrier layer 3. Further, a colored layer may be provided on the outside of the base material layer 1. By providing the coloring layer, the exterior material for the power storage device can be colored.

- a colored adhesive layer 2 and a colored layer may be provided between the base material layer 1 and the barrier layer 3.

- the colored layer can be formed, for example, by applying an ink containing a colorant to the surface of the base material layer 1 or the surface of the barrier layer 3.

- a colorant known pigments, dyes and the like can be used. Further, only one type of colorant may be used, or two or more types may be mixed and used.

- colorant contained in the colored layer include the same as those exemplified in the column of [Adhesive layer 2].

- the barrier layer 3 is at least a layer that suppresses the infiltration of water.

- Examples of the barrier layer 3 include a metal foil having a barrier property, a thin-film deposition film, a resin layer, and the like.

- Examples of the vapor deposition film include a metal vapor deposition film, an inorganic oxide vapor deposition film, a carbon-containing inorganic oxide vapor deposition film, and the like

- examples of the resin layer include polymers and tetras mainly composed of polyvinylidene chloride and chlorotrifluoroethylene (CTFE). Examples thereof include polymers containing fluoroethylene (TFE) as a main component, polymers having a fluoroalkyl group, fluorine-containing resins such as polymers containing fluoroalkyl units as a main component, and ethylene vinyl alcohol copolymers.

- examples of the barrier layer 3 include a resin film provided with at least one of these vapor-deposited films and a resin layer.

- a plurality of barrier layers 3 may be provided.

- the barrier layer 3 preferably includes a layer made of a metal material.

- Specific examples of the metal material constituting the barrier layer 3 include an aluminum alloy, stainless steel, titanium steel, and a steel plate.

- the metal material includes at least one of an aluminum alloy foil and a stainless steel foil. Is preferable.

- the aluminum alloy foil is more preferably a soft aluminum alloy foil composed of, for example, an annealed aluminum alloy, and the viewpoint of further improving the moldability. Therefore, it is preferable that the aluminum alloy foil contains iron.

- the iron-containing aluminum alloy foil (100% by mass) the iron content is preferably 0.1 to 9.0% by mass, more preferably 0.5 to 2.0% by mass.

- the iron content is 0.1% by mass or more, an exterior material for a power storage device having more excellent moldability can be obtained.

- the iron content is 9.0% by mass or less, a more flexible exterior material for a power storage device can be obtained.

- the soft aluminum alloy foil for example, an aluminum alloy having a composition specified by JIS H4160: 1994 A8021HO, JIS H4160: 1994 A8079HO, JIS H4000: 2014 A8021PO, or JIS H4000: 2014 A8077P-O. Foil is mentioned. Further, if necessary, silicon, magnesium, copper, manganese and the like may be added. Further, softening can be performed by annealing or the like.

- stainless steel foils examples include austenite-based, ferrite-based, austenite-ferritic-based, martensitic-based, and precipitation-hardened stainless steel foils. Further, from the viewpoint of providing an exterior material for a power storage device having excellent moldability, the stainless steel foil is preferably made of austenitic stainless steel.

- austenitic stainless steel constituting the stainless steel foil include SUS304, SUS301, and SUS316L, and among these, SUS301 or SUS304 is particularly preferable.

- the thickness of the barrier layer 3 may at least exhibit a function as a barrier layer that suppresses the infiltration of water, and is, for example, about 9 to 200 ⁇ m.

- the thickness of the barrier layer 3 is preferably about 85 ⁇ m or less, more preferably about 50 ⁇ m or less, still more preferably about 40 ⁇ m or less, and particularly preferably about 35 ⁇ m or less.

- the thickness of the barrier layer 3 is preferably about 10 ⁇ m or more, more preferably about 20 ⁇ m or more, and more preferably about 25 ⁇ m or more.

- the preferred range of the thickness of the barrier layer 3 is about 10 to 85 ⁇ m, about 10 to 50 ⁇ m, about 10 to 40 ⁇ m, about 10 to 35 ⁇ m, about 20 to 85 ⁇ m, about 20 to 50 ⁇ m, about 20 to 40 ⁇ m, and about 20 to. Examples thereof include about 35 ⁇ m, about 25 to 85 ⁇ m, about 25 to 50 ⁇ m, about 25 to 40 ⁇ m, and about 25 to 35 ⁇ m.

- the barrier layer 3 is made of an aluminum alloy foil, the above range is particularly preferable.

- the thickness of the stainless steel foil is preferably about 60 ⁇ m or less, more preferably about 50 ⁇ m or less, still more preferably about 40 ⁇ m or less, still more preferably about 30 ⁇ m. Below, it is particularly preferably about 25 ⁇ m or less.