WO2019235560A1 - フィラー含有フィルム - Google Patents

フィラー含有フィルム Download PDFInfo

- Publication number

- WO2019235560A1 WO2019235560A1 PCT/JP2019/022492 JP2019022492W WO2019235560A1 WO 2019235560 A1 WO2019235560 A1 WO 2019235560A1 JP 2019022492 W JP2019022492 W JP 2019022492W WO 2019235560 A1 WO2019235560 A1 WO 2019235560A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- filler

- resin layer

- insulating resin

- containing film

- film

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/30—Adhesives in the form of films or foils characterised by the adhesive composition

- C09J7/35—Heat-activated

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J171/00—Adhesives based on polyethers obtained by reactions forming an ether link in the main chain; Adhesives based on derivatives of such polymers

- C09J171/08—Polyethers derived from hydroxy compounds or from their metallic derivatives

- C09J171/10—Polyethers derived from hydroxy compounds or from their metallic derivatives from phenols

- C09J171/12—Polyphenylene oxides

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K3/00—Use of inorganic substances as compounding ingredients

- C08K3/01—Use of inorganic substances as compounding ingredients characterized by their specific function

- C08K3/013—Fillers, pigments or reinforcing additives

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J11/00—Features of adhesives not provided for in group C09J9/00, e.g. additives

- C09J11/02—Non-macromolecular additives

- C09J11/04—Non-macromolecular additives inorganic

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J163/00—Adhesives based on epoxy resins; Adhesives based on derivatives of epoxy resins

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J201/00—Adhesives based on unspecified macromolecular compounds

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J7/00—Adhesives in the form of films or foils

- C09J7/10—Adhesives in the form of films or foils without carriers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L24/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L24/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L24/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L24/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L24/31—Structure, shape, material or disposition of the layer connectors after the connecting process

- H01L24/32—Structure, shape, material or disposition of the layer connectors after the connecting process of an individual layer connector

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R11/00—Individual connecting elements providing two or more spaced connecting locations for conductive members which are, or may be, thereby interconnected, e.g. end pieces for wires or cables supported by the wire or cable and having means for facilitating electrical connection to some other wire, terminal, or conductive member, blocks of binding posts

- H01R11/01—Individual connecting elements providing two or more spaced connecting locations for conductive members which are, or may be, thereby interconnected, e.g. end pieces for wires or cables supported by the wire or cable and having means for facilitating electrical connection to some other wire, terminal, or conductive member, blocks of binding posts characterised by the form or arrangement of the conductive interconnection between the connecting locations

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R4/00—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation

- H01R4/04—Electrically-conductive connections between two or more conductive members in direct contact, i.e. touching one another; Means for effecting or maintaining such contact; Electrically-conductive connections having two or more spaced connecting locations for conductors and using contact members penetrating insulation using electrically conductive adhesives

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01R—ELECTRICALLY-CONDUCTIVE CONNECTIONS; STRUCTURAL ASSOCIATIONS OF A PLURALITY OF MUTUALLY-INSULATED ELECTRICAL CONNECTING ELEMENTS; COUPLING DEVICES; CURRENT COLLECTORS

- H01R43/00—Apparatus or processes specially adapted for manufacturing, assembling, maintaining, or repairing of line connectors or current collectors or for joining electric conductors

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K2201/00—Specific properties of additives

- C08K2201/001—Conductive additives

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K3/00—Use of inorganic substances as compounding ingredients

- C08K3/34—Silicon-containing compounds

- C08K3/36—Silica

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2463/00—Presence of epoxy resin

-

- C—CHEMISTRY; METALLURGY

- C09—DYES; PAINTS; POLISHES; NATURAL RESINS; ADHESIVES; COMPOSITIONS NOT OTHERWISE PROVIDED FOR; APPLICATIONS OF MATERIALS NOT OTHERWISE PROVIDED FOR

- C09J—ADHESIVES; NON-MECHANICAL ASPECTS OF ADHESIVE PROCESSES IN GENERAL; ADHESIVE PROCESSES NOT PROVIDED FOR ELSEWHERE; USE OF MATERIALS AS ADHESIVES

- C09J2471/00—Presence of polyether

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/27—Manufacturing methods

- H01L2224/271—Manufacture and pre-treatment of the layer connector preform

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29075—Plural core members

- H01L2224/2908—Plural core members being stacked

- H01L2224/29082—Two-layer arrangements

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29075—Plural core members

- H01L2224/2908—Plural core members being stacked

- H01L2224/29083—Three-layer arrangements

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/29186—Material with a principal constituent of the material being a non metallic, non metalloid inorganic material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/2919—Material with a principal constituent of the material being a polymer, e.g. polyester, phenolic based polymer, epoxy

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/29198—Material with a principal constituent of the material being a combination of two or more materials in the form of a matrix with a filler, i.e. being a hybrid material, e.g. segmented structures, foams

- H01L2224/29199—Material of the matrix

- H01L2224/2929—Material of the matrix with a principal constituent of the material being a polymer, e.g. polyester, phenolic based polymer, epoxy

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/29198—Material with a principal constituent of the material being a combination of two or more materials in the form of a matrix with a filler, i.e. being a hybrid material, e.g. segmented structures, foams

- H01L2224/29298—Fillers

- H01L2224/29299—Base material

- H01L2224/293—Base material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/29198—Material with a principal constituent of the material being a combination of two or more materials in the form of a matrix with a filler, i.e. being a hybrid material, e.g. segmented structures, foams

- H01L2224/29298—Fillers

- H01L2224/29299—Base material

- H01L2224/293—Base material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof

- H01L2224/29338—Base material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof the principal constituent melting at a temperature of greater than or equal to 950°C and less than 1550°C

- H01L2224/29339—Silver [Ag] as principal constituent

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/29198—Material with a principal constituent of the material being a combination of two or more materials in the form of a matrix with a filler, i.e. being a hybrid material, e.g. segmented structures, foams

- H01L2224/29298—Fillers

- H01L2224/29299—Base material

- H01L2224/293—Base material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof

- H01L2224/29338—Base material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof the principal constituent melting at a temperature of greater than or equal to 950°C and less than 1550°C

- H01L2224/29344—Gold [Au] as principal constituent

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/29198—Material with a principal constituent of the material being a combination of two or more materials in the form of a matrix with a filler, i.e. being a hybrid material, e.g. segmented structures, foams

- H01L2224/29298—Fillers

- H01L2224/29299—Base material

- H01L2224/293—Base material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof

- H01L2224/29338—Base material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof the principal constituent melting at a temperature of greater than or equal to 950°C and less than 1550°C

- H01L2224/29347—Copper [Cu] as principal constituent

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/29198—Material with a principal constituent of the material being a combination of two or more materials in the form of a matrix with a filler, i.e. being a hybrid material, e.g. segmented structures, foams

- H01L2224/29298—Fillers

- H01L2224/29299—Base material

- H01L2224/293—Base material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof

- H01L2224/29338—Base material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof the principal constituent melting at a temperature of greater than or equal to 950°C and less than 1550°C

- H01L2224/29355—Nickel [Ni] as principal constituent

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/29198—Material with a principal constituent of the material being a combination of two or more materials in the form of a matrix with a filler, i.e. being a hybrid material, e.g. segmented structures, foams

- H01L2224/29298—Fillers

- H01L2224/29299—Base material

- H01L2224/293—Base material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof

- H01L2224/29338—Base material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof the principal constituent melting at a temperature of greater than or equal to 950°C and less than 1550°C

- H01L2224/29357—Cobalt [Co] as principal constituent

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/29198—Material with a principal constituent of the material being a combination of two or more materials in the form of a matrix with a filler, i.e. being a hybrid material, e.g. segmented structures, foams

- H01L2224/29298—Fillers

- H01L2224/29299—Base material

- H01L2224/293—Base material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof

- H01L2224/29363—Base material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof the principal constituent melting at a temperature of greater than 1550°C

- H01L2224/29364—Palladium [Pd] as principal constituent

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/29198—Material with a principal constituent of the material being a combination of two or more materials in the form of a matrix with a filler, i.e. being a hybrid material, e.g. segmented structures, foams

- H01L2224/29298—Fillers

- H01L2224/29299—Base material

- H01L2224/29386—Base material with a principal constituent of the material being a non metallic, non metalloid inorganic material

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/29198—Material with a principal constituent of the material being a combination of two or more materials in the form of a matrix with a filler, i.e. being a hybrid material, e.g. segmented structures, foams

- H01L2224/29298—Fillers

- H01L2224/29299—Base material

- H01L2224/2939—Base material with a principal constituent of the material being a polymer, e.g. polyester, phenolic based polymer, epoxy

- H01L2224/29391—The principal constituent being an elastomer, e.g. silicones, isoprene, neoprene

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/29198—Material with a principal constituent of the material being a combination of two or more materials in the form of a matrix with a filler, i.e. being a hybrid material, e.g. segmented structures, foams

- H01L2224/29298—Fillers

- H01L2224/29399—Coating material

- H01L2224/294—Coating material with a principal constituent of the material being a metal or a metalloid, e.g. boron [B], silicon [Si], germanium [Ge], arsenic [As], antimony [Sb], tellurium [Te] and polonium [Po], and alloys thereof

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/28—Structure, shape, material or disposition of the layer connectors prior to the connecting process

- H01L2224/29—Structure, shape, material or disposition of the layer connectors prior to the connecting process of an individual layer connector

- H01L2224/29001—Core members of the layer connector

- H01L2224/29099—Material

- H01L2224/29198—Material with a principal constituent of the material being a combination of two or more materials in the form of a matrix with a filler, i.e. being a hybrid material, e.g. segmented structures, foams

- H01L2224/29298—Fillers

- H01L2224/29499—Shape or distribution of the fillers

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/31—Structure, shape, material or disposition of the layer connectors after the connecting process

- H01L2224/32—Structure, shape, material or disposition of the layer connectors after the connecting process of an individual layer connector

- H01L2224/325—Material

- H01L2224/32505—Material outside the bonding interface, e.g. in the bulk of the layer connector

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/80—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected

- H01L2224/83—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected using a layer connector

- H01L2224/832—Applying energy for connecting

- H01L2224/83201—Compression bonding

- H01L2224/83203—Thermocompression bonding, e.g. diffusion bonding, pressure joining, thermocompression welding or solid-state welding

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/80—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected

- H01L2224/83—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected using a layer connector

- H01L2224/838—Bonding techniques

- H01L2224/8385—Bonding techniques using a polymer adhesive, e.g. an adhesive based on silicone, epoxy, polyimide, polyester

- H01L2224/83851—Bonding techniques using a polymer adhesive, e.g. an adhesive based on silicone, epoxy, polyimide, polyester being an anisotropic conductive adhesive

Definitions

- the present invention relates to a filler-containing film.

- Filler-containing films in which filler is dispersed in the resin layer are used in a wide variety of applications such as matte films, condenser films, optical films, label films, anti-static films, conductive films, and anisotropic conductive films.

- Patent Literature 1 Patent Literature 2, Patent Literature 3, Patent Literature 4

- the resin forming the filler-containing film is prevented from flowing unnecessarily during thermocompression bonding, and the uneven distribution of the filler is suppressed by optical characteristics, mechanical properties. It is desirable in terms of characteristics or electrical characteristics.

- the conductive resin particles in the insulating resin layer can be used for high-density mounting of electronic components. If the resin is dispersed at a high density, the conductive particles move unnecessarily due to the resin flow at the time of mounting the electronic component and are unevenly distributed between the terminals, causing a short circuit. Therefore, it is desirable to suppress such resin flow. .

- the insulating resin layer is made to contain fine solids such as a melt viscosity modifier and a thixotropic agent (Patent Documents 5 and 6).

- JP 2006-15680 A JP2015-138904A JP2013-103368A JP 2014-183266 A Japanese Patent No. 6187665 Japanese Unexamined Patent Publication No. 2016-031888

- An insulating resin layer containing a fine solid is generally formed by coating and drying an insulating resin layer forming composition in which a fine solid is dispersed.

- an insulating resin layer containing a minute solid in a high concentration by applying and drying the insulating resin layer forming composition

- the dry surface of the insulating resin layer that is, the insulating resin layer forming composition

- the surface of the solvent contained in the composition evaporates), because the roughness derived from the fine solids is formed.

- Temporary pressure bonding at the time is not performed uniformly, and the sticking state becomes unstable.

- thermocompression during the main pressure bonding is not performed uniformly, resulting in disordered arrangement of the conductive particles regularly arranged in the insulating resin layer, improving the trapping property of the conductive particles at the terminals of the electronic component, and short-circuiting.

- the suppression will be adversely affected. This problem is particularly noticeable when the electronic component is small and the terminal size is narrowed.

- the problem of the adhesiveness fall of the filler containing film surface may become remarkable when it thins, compared with the case where it is thick.

- an object of the present invention is to suppress the disorder of the filler arrangement when the filler-containing film is thermocompression bonded to an article.

- the present inventor forms a filler-containing film in which a filler such as conductive particles and a fine solid having a different forming material from the filler are held in an insulating resin layer, and forms an insulating resin layer containing the fine solid. So that the dry surface of the insulating resin layer does not appear on the surface of the filler-containing film when manufacturing by the step of forming the insulating resin layer by coating the composition for use and the step of pressing the filler into the insulating resin layer Then, it discovered that disorder of the arrangement

- the present invention is a filler-containing film in which a filler, a fine solid different from a filler and a forming material are held in an insulating resin layer, and the filler repeats a predetermined arrangement in a plan view,

- a filler-containing film in which the ratio of the repeating pitch of the filler after thermocompression bonding with respect to before thermocompression bonding is within 300%, in particular,

- the insulating resin layer is formed from a laminate of two insulating resin layers, and a low-viscosity resin layer having a minimum melt viscosity in the range of 30 to 200 ° C. lower than that of the insulating resin layer is the insulating resin layer

- stacked is provided.

- this invention apply

- Forming a process A process of pushing the filler from the surface of the insulating resin layer opposite to the peeling substrate, A step of laminating an insulating resin layer into which a filler is pressed, and an insulating resin layer separate from the insulating resin layer, with the release substrate as the outside;

- Providing a method for producing a filler-containing film having As a second production method a step of applying an insulating resin layer forming composition containing a minute solid on a release substrate, and forming an insulating resin layer on the release substrate, A step of forming a laminate of insulating resin layers by laminating two insulating resin layers with their release substrates facing outside, A step of pushing a filler into the laminate of the insulating resin layer, Providing a

- the surface of the filler-containing film is roughened even though a fine solid is contained in the insulating resin layer in an appropriate blending amount in terms of viscosity adjustment and the like. Because it is not formed, the film surface has good adhesion to various articles. Therefore, the filler of the filler-containing film attached to the article by thermocompression bonding can substantially maintain the predetermined arrangement before thermocompression bonding.

- the filler of the filler-containing film of the present invention is conductive particles

- the filler-containing film of the present invention is used for anisotropic conductive connection between electronic parts, temporary pressing can be performed well, However, since the arrangement of the conductive particles is hardly disturbed, the predetermined arrangement before the thermocompression bonding can be substantially maintained. Therefore, even when the electronic components are small and the terminal size is narrowed, the electronic components can be favorably anisotropically connected to each other.

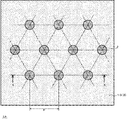

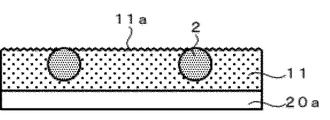

- FIG. 1A is a plan view showing a filler arrangement of a filler-containing film 1A of an example.

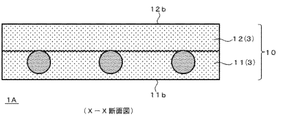

- FIG. 1B is a cross-sectional view of the filler-containing film 1A of the example.

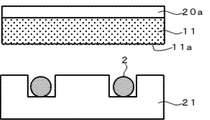

- Drawing 2A is an explanatory view of the manufacturing method of filler content film 1A of an example.

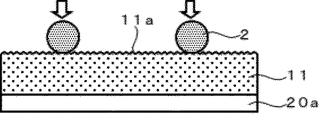

- Drawing 2B is an explanatory view of the manufacturing method of filler content film 1A of an example.

- Drawing 2C is an explanatory view of the manufacturing method of filler content film 1A of an example.

- Drawing 2D is an explanatory view of the manufacturing method of filler content film 1A of an example.

- FIG. 2E is an explanatory diagram of a method for producing the filler-containing film 1A of the example.

- FIG. 1A is a plan view showing a filler arrangement of a filler-containing film 1A of an example.

- FIG. 1B is a cross-sectional view of the filler-containing film 1A of the example.

- Drawing 2A is

- FIG. 2F is an explanatory diagram of a method for producing the filler-containing film 1A of the example.

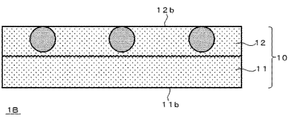

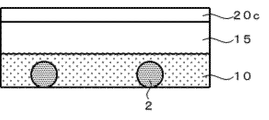

- FIG. 3 is a cross-sectional view of the filler-containing film 1B of the example.

- Drawing 4A is an explanatory view of the manufacturing method of filler content film 1B of an example.

- Drawing 4B is an explanatory view of the manufacturing method of filler content film 1B of an example.

- Drawing 4C is an explanatory view of the manufacturing method of filler content film 1B of an example.

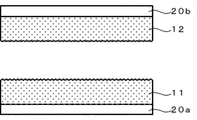

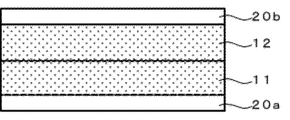

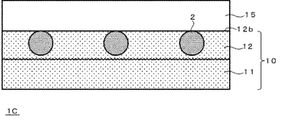

- FIG. 5 is a cross-sectional view of the filler-containing film 1C of the example.

- Drawing 6 is an explanatory view of the manufacturing method of filler content film 1C of an example.

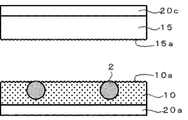

- FIG. 7 is a cross-sectional view of the filler-containing film 1D of the example.

- Drawing 8A is an explanatory view of the manufacturing method of filler content film 1D of an example.

- Drawing 8B is an explanatory view of the manufacturing method of filler content film 1D of an example.

- Drawing 8C is an explanatory view of the manufacturing method of filler content film 1D of an example.

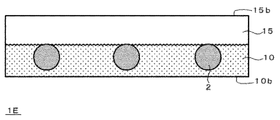

- FIG. 9 is a cross-sectional view of the filler-containing film 1E of the example.

- FIG. 10A is an explanatory diagram of a method for producing the filler-containing film 1E of the example.

- Drawing 10B is an explanatory view of the manufacturing method of filler content film 1E of an example.

- FIG. 10C is an explanatory diagram of a method for producing the filler-containing film 1E of the example.

- FIG. 11 is a perspective view of a sample for an adhesive strength test.

- FIG. 12 is an explanatory diagram of an adhesive strength test method.

- FIG. 1A is a plan view showing the filler arrangement of the filler-containing film 1A of the example, and FIG. 1B is an XX cross-sectional view thereof.

- This filler-containing film 1A contains conductive particles as the filler 2 and is used as an anisotropic conductive film. The conductive particles are held in the insulating resin layer 10 in a regular arrangement in which a predetermined arrangement is repeated. .

- the insulating resin layer 10 contains a fine solid 3 in addition to the filler 2.

- the regular filler arrangement before thermocompression spreads after thermocompression, and the repeated pitch of the array becomes wider than before thermocompression-bonding.

- the variation in the repeat pitch also increases, and the filler arrangement is disturbed.

- the filler movement amount and the array are less disturbed, and the filler repeat pitch after the thermocompression before the thermocompression is reduced.

- the ratio is within 300%, preferably within 250%, more preferably within 200%.

- the relative positional relationship of the filler arrangement is maintained before and after thermocompression, so that the distance between the centers of the nearest fillers before thermocompression is the closest after thermocompression.

- the distance between the centers of the fillers can be within 3 times, within 2.5 times, and within 2 times.

- the filler-containing film of the present invention has a thermocompression bonding condition in which the ratio of repeated pitches before and after thermocompression bonding is equal to or less than the above numerical value. This is because, according to the method for producing a filler-containing film of the present invention, since the surface of the filler-containing film 1A becomes a release surface from the release substrate, the insulating resin layer 10 contains a large amount of fine solids 3. However, the surface of the filler-containing film 1A does not become rough and becomes a smooth surface. When the smooth surface is attached to an article and heated and pressurized, the filler-containing film is uniformly pressed and regularly arranged in the film.

- the solid solids do not interfere with the pressing force being applied uniformly to the filler, and the filler arrangement is prevented from being disturbed unevenly, and the filler arrangement after heating and pressurization has expanded the original arrangement uniformly. This is considered to be because the portion where the ratio of the filler repeat pitch before and after thermocompression bonding is locally increased is reduced.

- thermocompression bonding is not performed on a smooth surface, nonuniformity occurs in the amount of filler movement and disorder of the thermocompression bonding. Therefore, when the filler-containing film is configured as an anisotropic conductive film, if the fine pitch bump array is thermocompression bonded with the anisotropic conductive film, the disorder of the filler array may be relatively large.

- the filler 2 depending on the use of the filler-containing film, known inorganic fillers (metal particles, metal oxide particles, metal nitride particles, etc.), organic fillers (resin particles, rubber particles, etc.), Filler in which organic and inorganic materials are mixed (for example, particles whose core is formed of a resin material and metal-plated on the surface (metal-coated resin particles), and in which insulating fine particles are attached to the surface of conductive particles The surface of the conductive particles is subjected to insulation treatment, etc.) according to the performance required for applications such as hardness and optical performance.

- inorganic fillers metal particles, metal oxide particles, metal nitride particles, etc.

- organic fillers resin particles, rubber particles, etc.

- Filler in which organic and inorganic materials are mixed for example, particles whose core is formed of a resin material and metal-plated on the surface (metal-coated resin particles), and in which insulating fine particles are attached to the surface of conductive particles

- a silica filler for example, in an optical film or a matte film, a silica filler, a titanium oxide filler, a styrene filler, an acrylic filler, a melamine filler, various titanates, and the like can be used.

- titanium oxide, magnesium titanate, zinc titanate, bismuth titanate, lanthanum oxide, calcium titanate, strontium titanate, barium titanate, barium zirconate titanate, lead zirconate titanate and mixtures thereof Etc. can be used.

- the adhesive film can contain polymer rubber particles, silicone rubber particles, and the like. In the conductive film and the anisotropic conductive film, conductive particles are contained.

- the conductive particles include metal particles such as nickel, cobalt, silver, copper, gold, and palladium, alloy particles such as solder, metal-coated resin particles, and metal-coated resin particles having insulating fine particles attached to the surface. . Two or more kinds can be used in combination. Among these, the metal-coated resin particles are preferable in that the resin particles repel after being connected, so that the contact with the terminal is easily maintained and the conduction performance is stabilized. In addition, the surface of the conductive particles may be subjected to an insulation treatment that does not hinder the conduction characteristics by a known technique.

- the particle diameter of the filler 2 can be determined according to the use of the filler-containing film.

- the particle diameter of the filler 2 in order to improve the indentation precision of the filler at the time of manufacture of a filler containing film, Preferably it is 1 micrometer or more, More preferably, it is 2.5 micrometers or more.

- the particle diameter in order to suppress the influence of the position shift of the filler at the time of manufacture of a filler containing film, Preferably it is 200 micrometers or less, More preferably, it is 50 micrometers or less.

- the particle diameter means an average particle diameter.

- the average particle diameter of the filler in the filler-containing film can be determined from a planar image or a cross-sectional image.

- the average particle size of the filler as raw material particles before being contained in the filler-containing film can be determined using a wet flow type particle size / shape analyzer FPIA-3000 (Malvern). When fine particles such as insulating fine particles are attached to the filler, the diameter not including the fine particles is defined as the particle size.

- CV value standard deviation / average

- the filler-containing film is easily pressed evenly when the filler-containing film is pressed onto the article, and the pressing force can be prevented from being concentrated locally. Therefore, when the filler-containing film is configured as an anisotropic conductive film, the stability of the connection is improved, and after the connection, the connection state can be accurately evaluated by observing the indentation or the sandwiched state of the filler. .

- the terminal size is relatively large (FOB etc.) or relatively small (COG etc.) It is possible to accurately confirm the connection state by observing the indentation and the state of sandwiching the conductive particles. Therefore, inspection after anisotropic connection becomes easy, and it can be expected to improve the productivity of the connection process.

- the filler has a regular arrangement in which a predetermined arrangement is repeated.

- the arrangement of the filler 2 is a hexagonal lattice arrangement. It has become.

- examples of the regular arrangement of the filler include a lattice arrangement such as a square lattice, a rectangular lattice, and an orthorhombic lattice. A plurality of grids having different shapes may be combined. Particle rows in which fillers are linearly arranged at predetermined intervals may be arranged in parallel at predetermined intervals.

- the region where the fillers are densely arranged and the region where the fillers are sparsely arranged may be regularly repeated.

- the unit which the fillers are contacting may comprise the regular repeating unit of a filler.

- the filler-containing film is an anisotropic conductive film, it is more preferable to arrange the conductive particles in a non-contact regular arrangement in order to achieve both capture stability and short-circuit suppression at the terminal.

- Whether or not the fillers are regularly arranged is, for example, whether or not a predetermined arrangement of the fillers is repeated in the longitudinal direction of the film (winding direction when the filler-containing film is used as a wound body). Can be determined by observing.

- the lattice axis or the arrangement axis of the arrangement may be parallel to or crossing at least one of the longitudinal direction of the filler-containing film and the direction perpendicular to the longitudinal direction, It can be determined according to the article to which the filler-containing film is pressure-bonded.

- the distance between the fillers can be determined according to the article to be connected and the use, and the number density of the fillers is usually 10 pieces / mm 2 or more and 100,000 pieces / mm 2 or less, preferably 30 pieces / mm 2. As described above, it can be appropriately determined within the range of 70000 pieces / mm 2 or less.

- the filler-containing film is an anisotropic conductive film

- the interparticle distance of the conductive particles used as the filler 2 is appropriately determined according to the size, shape, and terminal pitch of the terminals connected by the anisotropic conductive film. Can be determined.

- the number density of the conductive particles may be 30 / mm 2 or more, and preferably 150 to 70000 / mm 2 . Particularly in the case of fine pitch use, it is preferably 6000 to 42000 pieces / mm 2 , more preferably 10,000 to 40000 pieces / mm 2 , and still more preferably 15000 to 35000 pieces / mm 2 .

- the particle diameter of the conductive particles is 10 ⁇ m or more, the number density of the conductive particles is preferably 30 to 6000 / mm 2 .

- the filler area occupancy calculated by the following formula is 0.3% or more from the viewpoint of expressing the filler-containing effect.

- the area occupancy of the filler is 35% or less and more preferably 30% or less from the viewpoint of suppressing the thrust required for the pressing jig to press the filler-containing film to the article.

- Filler area occupancy (%) [number density of filler in plan view] ⁇ [average of plan view area of one filler] ⁇ 100

- the number density of the filler is obtained by observing with a metal microscope, and is also observed with image analysis software (for example, WinROOF (Mitani Corporation), A Image-kun (registered trademark) (Asahi Kasei Engineering Corporation), etc.). May be obtained by measuring.

- image analysis software for example, WinROOF (Mitani Corporation), A Image-kun (registered trademark) (Asahi Kasei Engineering Corporation), etc.

- the observation method and the measurement method are not limited to the above.

- the vertices of the fillers in the film thickness direction are flush with the surface of the insulating resin layer 10 or a plane parallel to the surface. Preferably it is. Thereby, it becomes easy to make the filler-containing film uniformly press-bonded to the article.

- Insulating resin layer 10 can contain various fine solids 3 having different formation materials from filler 2 in order to impart functions different from filler 2 to filler-containing film 1A.

- the fine solid 3 can contain a viscosity modifier, a thixotropic agent, a polymerization initiator, a coupling agent, a flame retardant, and the like. More specifically, examples of the viscosity modifier include silica powder and alumina powder.

- the filler 2 and the fine solid 3 when conductive particles are used as the filler 2 and the filler-containing film is an anisotropic conductive film, the fine solid as described in Patent Document 5 is used.

- the conductive particles are held in the insulating resin layer by kneading into the insulating resin layer and pushing the conductive particles into the insulating resin layer, the conductive particles and the fine solids are both distributed in the insulating resin layer. Can be easily distinguished by the state.

- the particle size of the fine solid 3 is preferably smaller than the particle size of the filler 2.

- the fine solid contained as a viscosity modifier preferably has an average particle size. Can be less than 1 ⁇ m, more preferably 5 nm to 0.3 ⁇ m, or preferably 1/3 to 1/2 of the average particle diameter of the conductive particles contained as filler.

- the fine solids are kneaded into the insulating resin layer and the conductive particles are pushed into the insulating resin layer.

- the anisotropic conductive film is manufactured by this, there is no particular limitation as long as the indentation of the conductive particles is not hindered.

- the fine solid is 3% by mass or more.

- the amount is 5% by mass or more, and the fine solid 3 is formed in the insulating resin layer 10 at a high concentration so that it is necessary to push in anisotropic conductive connection in two stages. It can be included.

- the content of the fine solid 3 is preferably 50% by mass or less, and 40% by mass or less with respect to the insulating resin layer 10 from the viewpoint of securing the fluidity necessary for the film for connecting electronic components. More preferred is 35% by mass or less.

- the insulating resin layer may be comprised from the single insulating resin layer, and may be comprised from the laminated body of the several insulating resin layer.

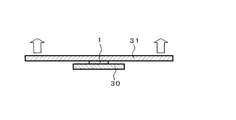

- the insulating resin layer 10 of the filler-containing film 1A shown in FIGS. 1A and 1B is obtained by applying the same insulating resin layer-forming composition onto a smooth release substrate by a method for producing a filler-containing film described later.

- the insulating resin layers 11 and 12 formed by drying are laminated with their dry surfaces on the inside and the surface on the peeling substrate side on the outside. In the filler-containing film 1A, the interface between the two insulating resin layers 11 and 12 can be observed.

- Roughness derived from fine solids contained in the composition is likely to appear on the surface coated with the insulating resin layer-forming composition and dried, but as shown in FIG. 1B, the insulating resin layer 11, When the coating and drying surface in No. 12 is overlapped, the surface of the filler-containing film becomes the surface to which the smooth surface of the release substrate is transferred, so that it is easy to thermocompression-bond the filler-containing film to the article uniformly. It is done.

- the resin composition forming the insulating resin layer 10 is appropriately selected according to the use of the filler-containing film, and can be formed from a thermoplastic resin composition, a high-viscosity adhesive resin composition, and a curable resin composition.

- the filler-containing film is an anisotropic conductive film, it is formed from a polymerizable compound and a polymerization initiator in the same manner as the resin composition forming the insulating resin layer of the anisotropic conductive film described in Patent Document 5.

- the curable resin composition to be used can be used.

- a thermal polymerization initiator may be used, a photopolymerization initiator may be used, or they may be used in combination.

- a cationic polymerization initiator is used as the thermal polymerization initiator

- an epoxy resin is used as the thermopolymerizable compound

- a radical photopolymerization initiator is used as the photopolymerization initiator

- an acrylate compound is used as the photopolymerizable compound.

- a thermal anionic polymerization initiator may be used as the thermal polymerization initiator.

- the thermal anionic polymerization initiator it is preferable to use a microcapsule-type latent curing agent formed by coating an imidazole-modified product as a nucleus and the surface thereof with polyurethane.

- the minimum melt viscosity of the insulating resin layer 10 is not particularly limited as long as the filler is pushed into the insulating resin layer, but in order to suppress unnecessary flow of the filler 2 when the filler-containing film 1A is thermocompression bonded to an article, It is preferably 1500 Pa ⁇ s or more, more preferably 2000 Pa ⁇ s or more, further preferably 3000 to 15000 Pa ⁇ s, and particularly preferably 3000 to 10000 Pa ⁇ s.

- This minimum melt viscosity can be determined by using a rotary rheometer (manufactured by TA instruments) as an example, and is kept constant at a measurement pressure of 5 g and using a measurement plate having a diameter of 8 mm. In a range of 30 to 200 ° C., the temperature can be obtained by setting the temperature rising rate to 10 ° C./min, the measurement frequency to 10 Hz, and the load fluctuation to the measurement plate of 5 g.

- the minimum melt viscosity can be adjusted by changing the kind and blending amount of the fine solids contained as the melt viscosity modifier, the adjustment conditions of the resin composition, and the like.

- the insulating resin layer may be composed of a single insulating resin layer, or may be composed of a laminate of a plurality of insulating resin layers.

- the thickness of the insulating resin layer is preferably relative to the particle diameter of the filler 2 so that the filler can be pushed in stably. 0.3 times or more, more preferably 0.6 times or more, further preferably 0.8 times or more, and particularly preferably 1 time or more.

- the upper limit of the thickness of the insulating resin layer is not particularly limited, and the layer thickness of the insulating resin layer may be appropriately adjusted according to the article to which the filler-containing film is thermocompression bonded. If the thickness is too thick, the filler 2 will be unnecessarily susceptible to the influence of the resin flow when the filler-containing film is thermocompression bonded to the article, and the absolute amount of fine solids contained in the insulating resin layer is large. As a result, the thermocompression bonding of the article may be hindered. Therefore, the layer thickness of the insulating resin layer is preferably 20 times or less, more preferably 15 times or less the particle diameter of the filler 2.

- the layer thickness of the low-viscosity resin layer depends on the use of the filler-containing film.

- the thickness of the filler 2 is preferably 0.2 times or more, more preferably 1 time or more, since the dispersion of the layer thickness becomes relatively large when the thickness is too thin.

- the particle diameter of the filler 2 is preferably 50 times or less, more preferably 15 times. Hereinafter, it is more preferably 8 times or less.

- the total thickness of these resin layers is the filler when the filler-containing film is thermocompression bonded to an article. From the point of suppression of unnecessary flow of 2, the point of suppression of protrusion and blocking of resin when winding a filler-containing film, the point of increasing the film length per unit weight of the filler-containing film, etc.

- the total thickness of the resin layer is preferably thinner. However, when it becomes too thin, the handleability of a filler containing film will be inferior. In addition, it may be difficult to stick the filler-containing film to the article.

- the total thickness of the resin layer in the filler-containing film is preferably 0.6 times or more, more preferably 0.8 times or more, further preferably 1 time or more, particularly preferably 1.times. 2 times or more.

- the upper limit of the total thickness of the resin layer including the insulating resin layer and the low-viscosity resin layer is not particularly limited, and may be appropriately adjusted according to the article to be thermocompression-bonded with the filler-containing film. If the total thickness becomes too thick, the filler 2 is easily affected by the resin flow when the filler-containing film is thermocompression bonded to the article, and the absolute amount of fine solids contained in the resin layer increases. Therefore, the total thickness of the resin layer is preferably 50 times or less, more preferably 15 times or less, and even more preferably 8 times or less the particle diameter of the filler 2. . It is considered that the influence of the resin flow on the filler arrangement can be minimized by making it 4 times or less, preferably 3 times or less.

- the conductive particles may be embedded in the insulating resin layer or exposed.

- the filler-containing film is configured as an anisotropic conductive film and the insulating resin layer and the low-viscosity resin layer are provided as the resin layer, the total thickness of the resin layer can be in the above range, but the electronic component to be connected In order to cope with the low profile of the bump, it is preferable to make the total thickness of the resin layer thinner than the above. In addition, by making the resin layer thin, the contact between the conductive particles and the bumps is facilitated.

- the lower limit of the total thickness of the resin layer is preferably 0.6 times or more, more preferably 0.8 times or more, and further preferably 1 time or more of the conductive particle diameter.

- the upper limit if it is too high, the thrust required at the time of indentation becomes too high, so that it can be 4 times or less the conductive particle diameter, preferably 3 times or less, more preferably 2 times or less, and still more preferably 1.8. It is not more than twice, particularly preferably not more than 1.5 times. What is necessary is just to adjust suitably about the ratio of the thickness of an insulating resin layer and a low-viscosity resin layer from relationships, such as an electroconductive particle diameter, bump height, and the adhesive force calculated

- the insulating resin layer has an adhesive force that enables temporary compression before thermocompression bonding to an article to be thermocompression bonded to the filler-containing film.

- the adhesive strength of the filler-containing film can be measured according to JIS Z 0237, and can also be measured as a tack force by a probe method according to JIS Z 3284-3 or ASTM D 2979-01.

- the tack force by the probe method on the front and back surfaces of the filler-containing film is, for example, When the pressing speed is 30 mm / min, the applied pressure is 196.25 gf, the pressing time is 1.0 sec, the peeling speed is 120 mm / min, and the measurement temperature is 23 ° C. ⁇ 5 ° C., at least one of the front and back surfaces is removed.

- 1.0kPa be a (0.1N / cm 2) or more, preferably to 1.5kPa (0.15N / cm 2) or more, and more to be higher than 3kPa (0.3N / cm 2) preferable.

- the tack force of the other surface may be measured by sticking one surface of the filler-containing film to the raw glass. Measurement may be performed by attaching to a flexible thermoplastic resin film (for example, a PET film having a thickness of 20 ⁇ m or less and not subjected to a release treatment, silicon rubber, etc.) instead of the raw glass. By reversing the surface to which the filler-containing film is attached, the tack force on the front and back surfaces of the filler-containing film can be measured under the same conditions.

- a flexible thermoplastic resin film for example, a PET film having a thickness of 20 ⁇ m or less and not subjected to a release treatment, silicon rubber, etc.

- the filler-containing film has release substrates on both front and back surfaces

- the filler-containing film has a release substrate on one side thereof, such as a filler-containing film formed into a wound body

- the surface on the release substrate side preferably exhibits the above-described tack force.

- a filler containing film has an insulating resin layer and a low-viscosity resin layer

- it is preferable that the surface of a low-viscosity resin layer has the above-mentioned tack force.

- the filler-containing film has a release substrate on both front and back surfaces, the surface pasted on the electronic component, or the surface on the side without the release substrate when the filler-containing film has a release substrate on one side,

- the surface on the insulating resin layer side when the filler-containing film has the insulating resin layer and the low-viscosity resin layer does not necessarily have the above-described tack force, but it is desirable to have it.

- the reason why the preferable tack force is different between the front and back surfaces of the filler-containing film is as follows.

- the anisotropic conductive film is generally attached to the second electronic component such as a substrate on the side opposite to the peeling substrate and then peeled off.

- the substrate is peeled, and the first electronic component is mounted on the surface from which the peeling substrate is peeled (that is, the surface on the peeling substrate side). This is because it is necessary to ensure adhesive performance that can accurately fix the mounted component at this time.

- the necessary adhesive force may be determined according to the mounted component.

- the adhesive strength of the filler-containing film can also be determined according to the adhesive strength test described in JP-A-2017-48358. In this adhesive strength test, for example, when a filler-containing film is sandwiched between two glass plates, one glass plate is fixed, and the other glass plate is peeled off at a peeling speed of 10 mm / min and a test temperature of 50 ° C. In addition, by strengthening the adhesive state between the glass plate to be fixed and the filler-containing film, the adhesive force between the glass plate to be peeled off and the surface of the filler-containing film bonded to the glass plate is measured. Is possible.

- the adhesive force measured in this way can be preferably 1 N / cm 2 (10 kPa) or more, more preferably 10 N / cm 2 (100 kPa) or more.

- the adhesive strength of the filler-containing film can also be determined by a test in which the test piece is peeled off by aligning and bonding one end of the test piece and pulling up the other end.

- the adhesive force measured by this test method may be equivalent to the above-described adhesive strength test (1 N / cm 2 (10 kPa) or more).

- the adhesive strength in this test method can be 10% or more of the adhesive strength by the above-mentioned adhesive strength test. .

- the filler-containing film has the above-mentioned adhesive force, even if the article to be thermocompression bonded is, for example, an electronic component having a maximum dimension of less than 0.8 mm smaller than a general IC chip, the problem of misalignment in provisional pressure bonding is eliminated. Adhesion can be stabilized even with an electronic component having a maximum size of about 450 cm, which is the same as that of a large TV.

- Such adhesiveness adjusts the resin composition which comprises an insulating resin layer suitably, and improves the smoothness of the insulating resin layer which makes the outer surface of a filler containing film with the manufacturing method of the filler containing film mentioned later. By making it, it can provide to an insulating resin layer.

- the filler-containing film 1A can be manufactured as follows. First, the step of forming the insulating resin layer 11 by applying the above-described composition for forming an insulating resin layer containing a fine solid to a release substrate 20a having a smooth surface such as a PET film and drying it. Perform (FIG. 2A).

- the concave portion of the mold 21 in which the concave portion is formed corresponding to the regular arrangement of the filler 2 is filled with the filler 2 (FIG. 2B), transferring to the dry surface (surface opposite to the peeling substrate 20a) 11a of the insulating resin layer 11 (FIG. 2C), and performing a step of pushing the filler 2 into the insulating resin layer 11 (FIG. 2D). ).

- the insulating resin layer 12 is formed on the peeling base material 20b in the same manner as the insulating resin layer 11, and the insulating resin layer 12 and the insulating resin layer 11 into which the above-mentioned filler is pressed are used.

- the peeling base materials 20a and 20b are opposed to each other (FIG. 2E), and a step of laminating them is performed (FIG. 2F).

- a filler-containing film 1A can be obtained (FIG. 1A).

- the filler 2 flows non-uniformly by thermocompression bonding, and the arrangement of the filler 2 after thermocompression bonding is an expansion of the original regular arrangement uniformly. Therefore, when the filler-containing film 1A is sandwiched between smooth surfaces and the area is subjected to thermocompression bonding under a predetermined heating and pressing condition according to the composition of the insulating resin layer, the repetition pitch of the filler after thermocompression bonding before thermocompression bonding The ratio is within 300%, which is significantly smaller than when the dry surfaces 11a and 12a of the insulating resin layer constitute the surface of the filler-containing film.

- thermocompression bonding conditions in which the ratio of the repetition pitch of the filler is within 300%, the temperature, pressure, and time can be easily selected because they can be appropriately selected from normal heating and pressing conditions in the insulating resin layer. Can do.

- a glass plate or the like As a smooth surface for sandwiching the filler-containing film when examining the ratio of the filler repeated pitch before and after thermocompression bonding, a glass plate or the like can be used, but the smooth surface of the article to be subjected to thermocompression bonding of the filler-containing film is used. May be.

- the filler-containing film is configured as an anisotropic conductive film

- smooth surfaces such as electrodes and bumps to be connected can be used. Thereby, the ratio of the repetition pitch of the conductive particles before and after thermocompression bonding in the electronic component to be connected can be evaluated.

- the area of the smooth surface when examining the ratio of the repeated pitches of the filler before and after thermocompression may be an area where the filler arrangement can be confirmed.

- the area can be an area in which at least one unit lattice or a repeating unit of a specific shape exists.

- the area where the unit cell is preferably 3 or more, more preferably 5 or more, and even more preferably 10 or more in the arrangement axis with the smallest filler pitch.

- the distance between the repeating units existing at the center is measured as the repetition pitch.

- the number of fillers is preferably 1000 or less, more preferably 500 or less, still more preferably 200 or less, and particularly preferably 50 or less. The area included in.