WO2018225509A1 - 清掃用シート - Google Patents

清掃用シート Download PDFInfo

- Publication number

- WO2018225509A1 WO2018225509A1 PCT/JP2018/019782 JP2018019782W WO2018225509A1 WO 2018225509 A1 WO2018225509 A1 WO 2018225509A1 JP 2018019782 W JP2018019782 W JP 2018019782W WO 2018225509 A1 WO2018225509 A1 WO 2018225509A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- embossed

- cleaning

- sheet

- cleaning sheet

- bent

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L13/00—Implements for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L13/10—Scrubbing; Scouring; Cleaning; Polishing

- A47L13/16—Cloths; Pads; Sponges

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L13/00—Implements for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L13/10—Scrubbing; Scouring; Cleaning; Polishing

- A47L13/42—Details

-

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47L—DOMESTIC WASHING OR CLEANING; SUCTION CLEANERS IN GENERAL

- A47L13/00—Implements for cleaning floors, carpets, furniture, walls, or wall coverings

- A47L13/10—Scrubbing; Scouring; Cleaning; Polishing

- A47L13/20—Mops

- A47L13/24—Frames for mops; Mop heads

- A47L13/254—Plate frames

- A47L13/256—Plate frames for mops made of cloth

Definitions

- the present invention relates to a cleaning sheet.

- Patent Document 1 describes that irregularities are formed by providing a V-shaped low density region on a sheet fiber.

- An object of the present invention is to provide a cleaning sheet having excellent collection properties while maintaining the strength of the sheet.

- the invention described in claim 1 In the cleaning sheet that is replaceably attached to the flat cleaning tool, Covering the bottom surface of the cleaning tool to form a cleaning surface, bent along the longitudinal edge of the cleaning tool and locked to the upper surface of the cleaning tool, The embossed portion in which the sheet is compressed in the thickness direction and the non-compressed non-embossed portion are alternately arranged along the bent portion bent along the longitudinal edge portion.

- ADVANTAGE OF THE INVENTION According to this invention, the sheet

- the invention according to claim 2 is the cleaning sheet according to claim 1, A plurality of the non-embossed portions are arranged at predetermined intervals along the bent portion. According to the present invention, the collection property can be further improved.

- the invention according to claim 3 is the cleaning sheet according to claim 1 or 2

- Each of the non-embossed portions has a shape having a recess opened to the longitudinal edge portion of the cleaning tool in a state of being mounted on the cleaning tool. According to the present invention, the collection property can be further improved.

- the invention according to claim 4 is the cleaning sheet according to claim 1 or 2

- Each of the non-embossed portions has a shape extending in an oblique direction with respect to the longitudinal edge portion of the cleaning tool when mounted on the cleaning tool. According to the present invention, the collection property can be further improved.

- the invention according to claim 5 is the cleaning sheet according to any one of claims 1 to 4,

- the non-embossed portion disposed along the bent portion corresponding to one of the long edge portions of the cleaning tool, and the bent portion corresponding to the other of the long edge portions of the cleaning tool.

- the non-embossed portion is arranged at a different position in the extending direction of the bent portion. According to the present invention, the collection property can be further improved.

- the invention according to claim 6 is the cleaning sheet according to any one of claims 1 to 5,

- the embossed part is A first protrusion protruding from the surface of the sheet; A second protrusion further protruding from the top of the first protrusion; It is characterized by providing. According to the present invention, the collection property can be further improved.

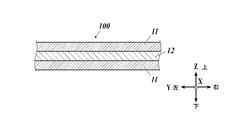

- FIG. 3 is a cross-sectional view taken along line III-III in FIG.

- FIG. 3 is an enlarged view of a portion A in FIG. 2.

- FIG. 5 is a sectional view taken along line VV in FIG. 4.

- It is a figure which shows the modification of a non-embossed part. It is a figure which shows the modification of a non-embossed part. It is a figure which shows the modification of a non-embossed part. It is a figure which shows the modification of a non-embossed part. It is a figure which shows the modification of a non-embossed part. It is a figure which shows the modification of a non-embossed part. It is a figure which shows the modification of a non-embossed part.

- FIGS. 1 to 5 specific modes of the cleaning sheet 100 according to the embodiment of the present invention will be described with reference to FIGS. 1 to 5.

- the technical scope of the present invention is not limited to the illustrated examples.

- the X direction, Y direction, and Z direction, front and rear, left and right, and top and bottom are defined.

- FIG. 1 is a diagram illustrating a state when the cleaning sheet 100 of the present embodiment is in use.

- the cleaning sheet 100 is replaceably mounted on a cleaning tool 200 including, for example, a rectangular flat head portion 201 and a handle portion 202 attached to the upper surface of the head portion 201. Dry sheet.

- the cleaning sheet 100 covers the bottom surface of the head part 201 of the cleaning tool 200 to form a cleaning surface, is bent along the longitudinal edge 201a of the head part 201 of the cleaning tool, and is locked to the upper surface of the head part 201. It will be in the state of wearing.

- the longitudinal edge portion 201 a refers to an edge portion along the longitudinal direction of the head portion 201. That is, the longer edge of the four edges of the rectangular head portion 201 is indicated.

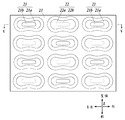

- FIG. 2 is a plan view showing an example of the cleaning sheet 100 of the present embodiment.

- the cleaning sheet 100 has a rectangular shape that is long in the X direction, and is, for example, 250 mm to 300 mm, preferably 260 mm to 290 mm, and Y direction (short direction) in the X direction (longitudinal direction). ) From 180 mm to 230 mm, preferably from 200 mm to 210 mm.

- FIG. 3 is a cross-sectional view taken along line III-III in FIG.

- the cleaning sheet 100 is formed by laminating a plurality of base papers. For example, as shown in FIG. 2, the cleaning sheet 100 is sandwiched between outer layers 11 and 11 that form a surface layer of the cleaning sheet 100 and outer layers 11 and 11. And an inner layer 12.

- the outer layer 11 is mainly formed of hydrophobic fibers.

- hydrophobic fiber a chemical fiber mainly composed of polyethylene terephthalate, polypropylene, polyethylene or the like is applied.

- the outer layer 11 preferably has a blending ratio of polyethylene terephthalate fibers of 80% or more, and the fiber diameter is preferably 3.3 dtex or more. By setting the fiber diameter to 3.3 dtex or more, the rigidity (cushioning property) of the fiber is improved and the operation can be performed with a light force.

- the inner layer 12 may be made of a nonwoven fabric such as polypropylene spunbond, for example, but may be made of the same hydrophobic fiber as that of the outer layer 11, for example, hydrophilic fibers such as pulp, cotton, hemp, rayon, acetate, etc. May be contained as appropriate.

- the above-described sheet structure of the cleaning sheet 100 is merely an example, and the number of layers, fibers that can be contained in each layer, and the like can be appropriately changed.

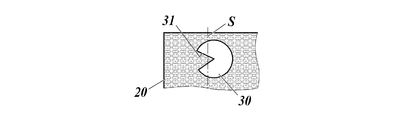

- a portion of the cleaning sheet 100 that is bent along the longitudinal edge portion 201 a of the head portion 201 of the cleaning tool 200 is referred to as a bent portion S.

- the bent portion S has an approximate position set in advance in accordance with the head portion 201 of the prescribed cleaning tool 200. That is, two rows of bent portions S extending in the X direction are set at predetermined positions in the Y direction of the cleaning sheet 100.

- the bending part S may print the straight line corresponding to the bending part S previously on the cleaning sheet 100 so that a user can recognize, for example, or the folding part S may be printed on the cleaning sheet 100. A corresponding polygonal line may be formed.

- a plurality of non-embossed portions 30 are arranged at predetermined intervals in the X direction, and the entire area excluding the region where the non-embossed portions 30 of the cleaning sheet 100 are arranged.

- the embossed portion 20 is disposed. Thereby, the embossed part 20 and the non-embossed part 30 will be alternately arrange

- the embossed portion 20 is a portion of the cleaning sheet 100 where the sheet is compressed in the thickness direction.

- the embossed portion 20 can be formed by, for example, hot embossing under conditions of a temperature of 80 to 150 ° C. and an embossing pressure of 0.2 to 1.0 MPa.

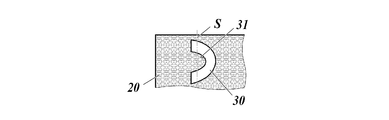

- FIG. 4 is an enlarged view of a region A in FIG.

- FIG. 5 is a cross-sectional view taken along line VV in FIG.

- the embossed portion 20 has a convex emboss 21 that is convex on the upper side (one side of the cleaning sheet 100) and a convex side on the lower side (the other side of the cleaning sheet 100).

- a mold that is, a concave mold on the upper side

- a concave emboss 22 are formed.

- the convex embosses 21 and the concave embosses 22 are alternately arranged so as to be alternately arranged in both the X direction and the Y direction.

- the convex embossing 21 and the concave embossing 22 are regularly arranged alternately so that the dust collecting property can be improved.

- intermediate portions 23 are formed between the convex embosses 21 and the concave embossed portions 22 that are alternately arranged.

- the intermediate portion 23 is a portion where the convex emboss 21 and the concave emboss 22 are not formed. For this reason, the intermediate portion 23 is lower than the convex emboss 21 and higher than the concave emboss 22 in the Z direction.

- the convex emboss 21 or the concave emboss 22 can be provided.

- the convex emboss 21 is formed in a so-called gourd shape having a narrow width in the X direction and a constricted portion in the center in the Y direction in plan view.

- the above shape is preferable from the viewpoint of dust collection, but the shape of the convex emboss 21 is not limited to this, and can be formed in various shapes such as a circle, an ellipse, and a polygon. is there. Moreover, it is good also as what combined each shape.

- the convex emboss 21 is 2 mm to 5 mm in the X direction, preferably 3 mm to 4 mm, 5 mm to 10 mm, preferably 6 mm to 8 mm in the Y direction, and 0.5 mm (height from the intermediate portion 23) in the Z direction. It is formed to 2 mm, preferably 0.7 mm to 1.5 mm.

- the convex emboss 21 is formed in a shape that gradually protrudes upward in a sectional view. That is, in the cross-sectional view, the second convex portion 21b that protrudes further upward is formed at the top of the first convex portion 21a that protrudes from the surface (upper surface) of the sheet. With this configuration, the cushioning property of the cleaning sheet 100 can be improved.

- the concave emboss 22 is formed in a so-called gourd shape having substantially the same shape as the convex emboss 21 in a plan view.

- the shape of the concave emboss 22 is not limited to this, and can be formed in various shapes, and may be different from the convex emboss 21.

- the concave emboss 22 is formed in a shape that is stepwise concave toward the lower side upside down from the convex emboss 21 in a sectional view.

- a second recess 22b that protrudes further downward is formed at the top of the first recess 22a that protrudes from the surface (lower surface) of the sheet.

- the non-embossed portion 30 is a portion of the cleaning sheet 100 in which the sheet is not compressed in the thickness direction and has raised portions, and a plurality of the non-embossed portions 30 are arranged along the row-shaped bent portions S of the cleaning sheet 100.

- the non-embossed portion 30 can be formed by designing the embossing roll forming the embossed portion 20 so as to exclude the shape of the non-embossed portion 30.

- the non-embossed portion 30 is not limited to the case where the compression is not performed at all.

- the non-embossed portion 30 may be lightly compressed as compared with the portion where the embossed portion 20 is compressed to the extent that the raised portions remain.

- the size of the non-embossed portion 30 is 40 mm to 70 mm, preferably 50 mm to 60 mm in the X direction, and 15 mm to 70 mm, preferably 20 mm to 50 mm in the Y direction.

- Each of the non-embossed portions 30 preferably has a shape having a recess 31 that opens to the longitudinal edge portion 201 a of the head portion 201 in a state where the cleaning sheet 100 is mounted on the cleaning tool 200.

- the non-embossed portion 30 has a V-shape in a plan view that opens rightward or leftward, that is, from the central portion of the rectangular cleaning sheet 100 toward the long side. Can be formed.

- the non-embossed portion 30 having a V shape in plan view has a V-shaped concave portion 31.

- the non-embossed portions 30 are arranged so that the positions in the X direction are shifted for each column and are staggered. That is, the non-embossed portion 30 along the bent portion S corresponding to one of the long edge portions 201a of the head portion 201 and the non-embossed portion along the bent portion S corresponding to the other of the long edge portions 201a of the head portion 201.

- the part 30 is arranged at a different position in the extending direction of the bent part S. Accordingly, when cleaning is performed by moving the cleaning sheet 100 in the Y direction, that is, in a direction parallel to the short side of the cleaning sheet 100, the trapping properties are complemented to each other, and the floor surface is made without gaps. Since the non-embossed portion 30 passes, it is possible to improve the collection property of garbage.

- the cleaning sheet 100 is attached to the rectangular flat plate head portion 201 of the cleaning tool 200. Specifically, the head portion 201 is mounted on the cleaning sheet 100 such that the longitudinal edge portion 201a of the head portion 201 is aligned with the two rows of bent portions S extending in the X direction of the cleaning sheet 100. Placed. Next, the cleaning sheet 100 is folded along the longitudinal edge 201 a of the head portion 201, and both sides of the folded sheet are locked to the upper surface of the head portion 201. Thereby, for example, as shown in FIG.

- the central portion in the Y direction of the cleaning sheet 100 covers the bottom surface of the head portion 201 of the cleaning tool 200 to form a cleaning surface.

- the embossed portions 20 and the non-embossed portions 30 are alternately arranged along the bent portions S at positions corresponding to the long edge portions 201a.

- the embossed portion 20 can scrape fine dust such as sand dust and house dust, and the non-embossed portion 30.

- coarse dust such as hair and fiber dust can be entangled. More specifically, coarse dust accumulates in the recess 31 of the non-embossed portion 30, and fine dust can be scraped off by the embossed portion 20 between the non-embossed portion 30 and the embossed portion 20 disposed on the cleaning surface.

- the embossed portion 20 gradually collapses with the second convex portion 21b and the first convex portion 21a (or the second concave portion 22b and the first concave portion 22a), and the area of the cleaning surface gradually increases. Therefore, it can be used for a long time.

- the cleaning sheet 100 when forming the embossed part 20 and the non-embossed part 30, the basis weight of the cleaning sheet 100 is not changed in each part, so the strength of the cleaning sheet 100 is not impaired, During the cleaning, the cleaning sheet 100 is not twisted or torn.

- the cleaning sheet 100 is a cleaning sheet 100 that is replaceably attached to the flat head portion 201 of the cleaning tool 200 and covers the bottom surface of the head portion 201 for cleaning.

- a sheet is formed along the bent portion S that is formed along the longitudinal edge 201a of the head portion 201, is bent on the upper surface of the head portion 201, and is bent along the longitudinal edge 201a.

- Embossed portions 20 compressed in the direction and non-embossed portions 30 that are not compressed are alternately arranged. For this reason, since the basis weights of the embossed part 20 and the non-embossed part 30 are the same, the strength of the cleaning sheet 100 is not impaired, and each part collects fine dust and coarse dust, respectively. The collection property can be improved.

- a plurality of non-embossed portions 30 are arranged along the bent portion S at predetermined intervals. For this reason, since the area

- each of the non-embossed portions 30 has a shape having the concave portion 31 opened to the longitudinal edge portion 201 a of the head portion 201 in a state of being mounted on the head portion 201. For this reason, since it becomes easy to accumulate

- the non-embossed portion 30 disposed along the bent portion S corresponding to one of the longitudinal edge portions 201a of the head portion 201 and the other of the longitudinal edge portions 201a of the head portion 201 are provided.

- the non-embossed portions 30 arranged along the corresponding bent portions S are arranged at different positions in the extending direction of the bent portions S. For this reason, when the head part 201 is moved in a direction orthogonal to the extending direction of the bent part S, the non-embossed part 30 arranged in the bent part S corresponding to one of the longitudinal edges 201a of the head part 201. And the non-embossed portion 30 arranged along the bent portion S corresponding to the other of the longitudinal edge portions 201a of the head portion 201 complements each other, thereby improving the collecting property. .

- the embossing part 20 further protrudes from the top part of the 1st convex part 21a (1st recessed part 22a) which protruded from the surface of the sheet

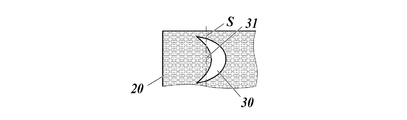

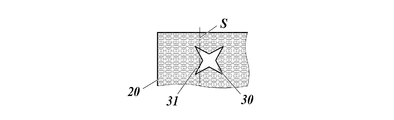

- the V-shaped non-embossed portion 30 has been described as an example.

- the concave portion 31 opened to the longitudinal edge portion 201a of the head portion 201 when mounted on the head portion 201.

- the shape of the non-embossed portion 30 is not limited to this.

- a U-shaped non-embossed portion 30 having a U-shaped recess 31 may be used.

- the shape which formed the V-shaped recessed part 31 in a part of substantially circular non-embossed part 30 may be sufficient, and as shown to FIG. A part of the embossed portion 30 may function as the recessed portion 31.

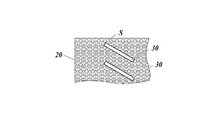

- the shape of the non-embossed portion 30 the shape having the concave portion 31 opened with respect to the longitudinal edge portion 201a of the head portion 201 as described above is most preferable from the viewpoint of the collection property, but FIG. As shown in FIG. 4, the shape may be any shape that extends in an oblique direction with respect to the longitudinal edge portion 201a of the head portion 201. With such a shape, the non-embossed portion 30 is disposed obliquely with respect to the longitudinal edge portion 201a of the head portion 201, and therefore, dust can be collected.

- the non-embossed portion 30 may be formed to have a shape that opens from the central portion of the rectangular cleaning sheet 100 toward the short side.

- the cleaning sheet 100 is bent along the short edge (the edge along the short direction of the head 201) of the head 201, and both ends of the bent sheet are engaged with the upper surface of the head 201. Stopped.

- the cleaning sheet 100 is described as a dry sheet, but a wet sheet to which a chemical solution is applied may be used.

- the inner layer 12 is preferably provided with a water retaining layer such as pulp, for example.

- Example 1 A non-woven fabric composed of 100% hydrophobic fibers containing 80% polyethylene terephthalate as an outer layer and 20% polypropylene and polyethylene core-sheath fibers as binder fibers was prepared. Polyethylene terephthalate fiber with a fineness of 3.3 dtex and binder fiber with a fineness of 1.7 dtex were used. Moreover, a 100% polypropylene spunbond nonwoven fabric was prepared as an inner layer. The above outer layer and inner layer were entangled by the hydroentanglement method to produce a laminated sheet that is a spunlace nonwoven fabric having a three-layer structure. This laminated sheet was embossed at a temperature of 105 ° C.

- the basis weight of the cleaning sheet was 100 gsm

- the long side was 300 mm

- the short side was 200 mm.

- the embossed portion uses a gourd-shaped convex emboss and concave emboss arranged alternately in the long side direction and the short side direction, and the size of each of the convex emboss and concave emboss is 8 mm long and short.

- the side was 3 mm and the height in the protruding direction was 0.8 mm.

- the non-embossed portion has a V-shape in a plan view opened from the central portion of the cleaning sheet toward the long side, and the total length in the long side direction of the non-embossed portion is 45 mm and the total length in the short side direction is 35 mm. It was. Moreover, the length of the longest part of the long side direction of the space formed of the recessed part of a non-embossed part was 20 mm. Moreover, the distance between the non-embossed parts adjacent in the long side direction was 10 mm.

- Example 1 (Comparative Example 1) Except for changing the shape of the non-embossed part, the laminated sheet similar to Example 1 was embossed under the same conditions to produce a dry sheet having an embossed part and a non-embossed part. A cleaning sheet was obtained.

- the shape of the non-embossed portion was a square shape having a length of 10 mm in the long side direction and the short side direction. The distance between the non-embossed portions adjacent in the long side direction was set so that 10 mm and 20 mm were alternately arranged.

- Comparative Example 2 A dry sheet embossed on the entire surface of the same laminated sheet as in Example 1 under the same conditions as in Example 1 was produced, and used as a cleaning sheet in Comparative Example 2.

- Comparative Example 3 A dry sheet which was the same laminated sheet as in Example 1 and was not embossed was prepared as a cleaning sheet of Comparative Example 3.

- the cleaning tool used here was provided with a head portion to which a cleaning sheet was attached as shown in FIG. 1 and a handle portion.

- the head portion is configured by attaching a top surface portion and a bottom surface portion, and the top surface portion is made of ABS resin (acrylonitrile, butadiene, styrene copolymer synthetic resin) and has a rectangular shape with a long side of 240 mm and a short side of 95 mm.

- the bottom portion was made of TPE (thermoplastic elastomer) having a hardness of 70 °, and had a rectangular shape with a long side of 248 mm and a short side of 98 mm.

- the length of the handle portion was 215 mm from the connecting portion with the head portion to the tip of the handle cap.

- the non-embossed portion is 10 mm and the embossed portion is 10 on the bent portion. They were alternately arranged at intervals of ⁇ 20 mm.

- the non-embossed part is 10 mm and the embossed part is 10 to 10 on the bent part. They were arranged at intervals of 20 mm.

- the cleaning sheet of Comparative Example 2 only the embossed portion was disposed on the bent portion, and in the cleaning sheet of Comparative Example 3, only the non-embossed portion was disposed on the folded portion.

- the sheet of Example 1 is easy to be mounted on a jig and has good dust collection.

- the sheet of Comparative Example 1 is better in collecting dust at the bent portion than the samples of Comparative Examples 2 and 3, but the length of the non-embossed portion in the short side direction is shorter, so the jig There is a possibility that the non-embossed portion and the embossed portion are not alternately arranged in the bent portion.

- the collection property in a bending part cannot be improved in the cleaning sheet only of an embossed part like the sheet

- the present invention is suitable for providing a cleaning sheet used for floor cleaning or the like.

Landscapes

- Cleaning Implements For Floors, Carpets, Furniture, Walls, And The Like (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/618,460 US11382482B2 (en) | 2017-06-09 | 2018-05-23 | Cleaning sheet |

| CN201880036823.6A CN110708995A (zh) | 2017-06-09 | 2018-05-23 | 清扫用片材 |

| EP18813157.7A EP3636131B1 (en) | 2017-06-09 | 2018-05-23 | Cleaning sheet |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2017-114688 | 2017-06-09 | ||

| JP2017114688A JP6541718B2 (ja) | 2017-06-09 | 2017-06-09 | 清掃用シート |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2018225509A1 true WO2018225509A1 (ja) | 2018-12-13 |

Family

ID=64566289

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2018/019782 Ceased WO2018225509A1 (ja) | 2017-06-09 | 2018-05-23 | 清掃用シート |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US11382482B2 (enExample) |

| EP (1) | EP3636131B1 (enExample) |

| JP (1) | JP6541718B2 (enExample) |

| CN (1) | CN110708995A (enExample) |

| WO (1) | WO2018225509A1 (enExample) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7391684B2 (ja) * | 2020-01-30 | 2023-12-05 | 大王製紙株式会社 | 清掃用ドライシート及び当該清掃用ドライシートの製造方法 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS559533B2 (enExample) | 1974-06-10 | 1980-03-11 | ||

| JP2000093373A (ja) * | 1998-09-24 | 2000-04-04 | Uni Charm Corp | 清掃用シート |

| JP2004208941A (ja) * | 2002-12-27 | 2004-07-29 | Kao Corp | 清掃用シート |

| JP2007236863A (ja) * | 2006-03-13 | 2007-09-20 | Kuraray Co Ltd | 床用清掃シート |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3559533B2 (ja) * | 2000-04-25 | 2004-09-02 | 大和紡績株式会社 | 絡合不織布とこれを用いた清拭シートおよび湿潤性シート |

| AU2003277527A1 (en) * | 2002-12-27 | 2004-07-29 | Kao Corporation | Cleaning sheet |

| JP4827509B2 (ja) * | 2005-12-05 | 2011-11-30 | 花王株式会社 | 嵩高シート |

| JP5718229B2 (ja) | 2009-06-19 | 2015-05-13 | ユニ・チャーム株式会社 | 清掃シートおよび清掃用具 |

| US10441978B2 (en) * | 2014-05-30 | 2019-10-15 | Kikuo Yamada | Fiber sheet |

| EP3305983B1 (en) * | 2015-05-29 | 2020-05-06 | Daio Paper Corporation | Water-disintegrable sheet |

| JP5883190B1 (ja) * | 2015-07-29 | 2016-03-09 | 大王製紙株式会社 | 水解性シート |

-

2017

- 2017-06-09 JP JP2017114688A patent/JP6541718B2/ja active Active

-

2018

- 2018-05-23 CN CN201880036823.6A patent/CN110708995A/zh active Pending

- 2018-05-23 US US16/618,460 patent/US11382482B2/en active Active

- 2018-05-23 WO PCT/JP2018/019782 patent/WO2018225509A1/ja not_active Ceased

- 2018-05-23 EP EP18813157.7A patent/EP3636131B1/en active Active

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS559533B2 (enExample) | 1974-06-10 | 1980-03-11 | ||

| JP2000093373A (ja) * | 1998-09-24 | 2000-04-04 | Uni Charm Corp | 清掃用シート |

| JP2004208941A (ja) * | 2002-12-27 | 2004-07-29 | Kao Corp | 清掃用シート |

| JP2007236863A (ja) * | 2006-03-13 | 2007-09-20 | Kuraray Co Ltd | 床用清掃シート |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3636131A1 (en) | 2020-04-15 |

| US11382482B2 (en) | 2022-07-12 |

| EP3636131B1 (en) | 2023-08-23 |

| CN110708995A (zh) | 2020-01-17 |

| JP2019000129A (ja) | 2019-01-10 |

| EP3636131A4 (en) | 2020-06-17 |

| US20200113401A1 (en) | 2020-04-16 |

| JP6541718B2 (ja) | 2019-07-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN100392166C (zh) | 膨松片材及其制造方法 | |

| US11452427B2 (en) | Cleaning sheet | |

| JP4827509B2 (ja) | 嵩高シート | |

| CN105828770A (zh) | 吸收性物品用无纺布 | |

| JP2008202153A (ja) | ウエットシート用シート基材 | |

| JP5154133B2 (ja) | 吸収体及び該吸収体の製造方法 | |

| WO2007093754A1 (en) | Swab | |

| JP6456898B2 (ja) | 清掃用ドライシートの製造方法 | |

| JP5843494B2 (ja) | 複合シート及びその製造方法 | |

| WO2018225509A1 (ja) | 清掃用シート | |

| JP4836562B2 (ja) | 清掃用ウエットシート | |

| JP2010148732A (ja) | 頭皮ケア用具 | |

| WO2018225505A1 (ja) | 清掃用シート | |

| JP6620127B2 (ja) | 清掃用シート及び清掃用シートの製造方法 | |

| JP5430327B2 (ja) | 産業用ワイプ | |

| WO2018180415A1 (ja) | 清掃用シート及び清掃用シートの製造方法 | |

| JP6061167B1 (ja) | 積層紙、及び積層紙の製造方法 | |

| JP2007020615A (ja) | 清掃用シート | |

| TWI891708B (zh) | 清掃用乾除塵紙及該清掃用乾除塵紙的製造方法 | |

| JP3172308U (ja) | 掃除用具用不織布およびそれを用いた掃除用具 | |

| HK1046937B (en) | Bulky sheet and process for producing the same |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 18813157 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2018813157 Country of ref document: EP |

|

| ENP | Entry into the national phase |

Ref document number: 2018813157 Country of ref document: EP Effective date: 20200109 |