WO2017199590A1 - Procédé de collecte de données de stockage d'objet de stockage et programme - Google Patents

Procédé de collecte de données de stockage d'objet de stockage et programme Download PDFInfo

- Publication number

- WO2017199590A1 WO2017199590A1 PCT/JP2017/012818 JP2017012818W WO2017199590A1 WO 2017199590 A1 WO2017199590 A1 WO 2017199590A1 JP 2017012818 W JP2017012818 W JP 2017012818W WO 2017199590 A1 WO2017199590 A1 WO 2017199590A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- information

- mold

- stored

- registered trademark

- code

- Prior art date

Links

- 238000003860 storage Methods 0.000 title claims abstract description 49

- 238000000034 method Methods 0.000 title claims description 20

- 238000004891 communication Methods 0.000 claims description 26

- 238000004519 manufacturing process Methods 0.000 description 48

- 239000002131 composite material Substances 0.000 description 28

- 239000011247 coating layer Substances 0.000 description 21

- 239000010410 layer Substances 0.000 description 14

- 229910052751 metal Inorganic materials 0.000 description 14

- 239000002184 metal Substances 0.000 description 14

- 238000007689 inspection Methods 0.000 description 9

- 238000000576 coating method Methods 0.000 description 8

- 239000000463 material Substances 0.000 description 8

- 229910052782 aluminium Inorganic materials 0.000 description 7

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 7

- 239000011248 coating agent Substances 0.000 description 6

- 238000013480 data collection Methods 0.000 description 6

- 238000010586 diagram Methods 0.000 description 6

- 238000012423 maintenance Methods 0.000 description 6

- 239000003973 paint Substances 0.000 description 6

- 238000005520 cutting process Methods 0.000 description 4

- 238000005516 engineering process Methods 0.000 description 4

- 230000008569 process Effects 0.000 description 4

- 238000012546 transfer Methods 0.000 description 4

- 238000000465 moulding Methods 0.000 description 3

- 239000011241 protective layer Substances 0.000 description 3

- 230000008439 repair process Effects 0.000 description 3

- 238000013461 design Methods 0.000 description 2

- 238000002347 injection Methods 0.000 description 2

- 239000007924 injection Substances 0.000 description 2

- 238000012986 modification Methods 0.000 description 2

- 230000004048 modification Effects 0.000 description 2

- 238000012545 processing Methods 0.000 description 2

- 229910000831 Steel Inorganic materials 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 238000005266 casting Methods 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000010276 construction Methods 0.000 description 1

- 230000007547 defect Effects 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000010304 firing Methods 0.000 description 1

- 238000005242 forging Methods 0.000 description 1

- 238000005259 measurement Methods 0.000 description 1

- 150000002739 metals Chemical class 0.000 description 1

- 230000004044 response Effects 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 238000012795 verification Methods 0.000 description 1

- 238000011179 visual inspection Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65G—TRANSPORT OR STORAGE DEVICES, e.g. CONVEYORS FOR LOADING OR TIPPING, SHOP CONVEYOR SYSTEMS OR PNEUMATIC TUBE CONVEYORS

- B65G1/00—Storing articles, individually or in orderly arrangement, in warehouses or magazines

- B65G1/02—Storage devices

- B65G1/04—Storage devices mechanical

- B65G1/137—Storage devices mechanical with arrangements or automatic control means for selecting which articles are to be removed

-

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B19/00—Programme-control systems

- G05B19/02—Programme-control systems electric

- G05B19/418—Total factory control, i.e. centrally controlling a plurality of machines, e.g. direct or distributed numerical control [DNC], flexible manufacturing systems [FMS], integrated manufacturing systems [IMS] or computer integrated manufacturing [CIM]

Definitions

- the present invention relates to a storage data collection method and a program for collecting stored items for collecting inventory data of dies and jigs.

- Molds are increasing as product types increase.

- service parts air parts

- service parts are 15 years for automobiles, 7 years for consumer goods, and 30 years for nuclear power. Accordingly, companies that produce parts using molds have a huge number of molds.

- the molds that are held are scattered in each country, and the molds are frequently transferred between countries.

- mold management typically creates a ledger on a computer and relies on humans for data input, but it is very time consuming with work such as actual verification.

- the present inventors give a QR code (registered trademark) to a mold, and further give a QR code (registered trademark) to a mold management shelf, a production facility, a tool management shelf, an operator, etc.

- the technique which manages data similarly is proposed (refer patent document 1).

- a parts manufacturer that delivers parts to a finished product manufacturer may outsource production to a secondary subcontractor.

- the mold owned by the parts manufacturer is lent to the secondary subcontractor.

- the responsible entity that manages the mold and creates the ledger or the like is the component manufacturer.

- the purchasing department of a parts manufacturer manages these, but it has a huge number of dies, and the dies that are held are scattered in each country.

- the transfer is frequently performed, it is not possible to accurately inventory the mold. For this reason, there is a difference between the mold asset ledger and the actual storage, and there is a real difference between the asset and financial problems.

- the current situation is that the person in charge of the parts manufacturer cannot go to the secondary subcontractors in Japan or overseas factories, and the only way to do this is to trust the storage company's report with the management based on the good faith theory.

- an object of the present invention is to provide a storage data collection method and program for collecting inventory data of dies and jigs quickly and accurately without labor. It is to provide.

- a method for collecting stored data of a stored item includes a QR code (registered trademark) including first information for identifying a worker who confirms the stored item. ), A first name plate provided with a QR code (registered trademark) including second information for specifying the stored item is attached to a predetermined position of the stored item, and the storage is performed. A second nameplate provided with a QR code (registered trademark) including third information for specifying a place where an object is stored is attached to a predetermined position, and the operator takes a photographing function and a QR code (registered trademark).

- the QR code (registered trademark) displayed on the display member is photographed, the first information is obtained from the photographed result, and the QR engraved on the first nameplate is obtained.

- Code (registered trademark) The second information is obtained from the photographing result, the QR code (registered trademark) engraved on the second nameplate is photographed, the third information is obtained from the photographing result, and the stored item and the storage.

- the communication terminal transmits the first information, the second information, the third information, and the photographing data of the photographed stored material and the storage state of the stored material to the database.

- the database accumulates the first information, the second information, the third information, and the photographing data transmitted from the communication terminal as storage data of the storage items.

- the stored item is a mold or a tool

- the stored data is used as inventory data

- a mold inventory data collection method includes the following steps.

- the inventory operator is made to have a display member that displays a QR code (registered trademark) including the first information for identifying the inventory operator.

- a first name plate engraved with a QR code (registered trademark) including second information for specifying a mold is attached to a predetermined position of the mold.

- the inventory operator uses a communication terminal having a photographing function and a QR code (registered trademark) recognition function to photograph the QR code (registered trademark) displayed on the display member and obtains the first information from the photographing result.

- the QR code (registered trademark) engraved on the first nameplate is photographed, the second information is acquired from the photographing result, and the QR code (registered trademark) engraved on the second nameplate is obtained. ) And obtaining the third information from the photographing result, photographing the mold and the storage state of the mold, the first information from the communication terminal to the database, the second information, The third information and the photographed mold and the photographing data of the storage state of the mold are transmitted.

- the database stores the first information, the second information, the third information, and the photographing data transmitted from the communication terminal as inventory data of the mold.

- the inventory operator simply needs to take a picture using the communication terminal, and the database stores the inventory operator, the location where the mold is stored, the state of the mold, and the storage of the mold. The state is accumulated in association with it. Therefore, it is possible to quickly and accurately collect the inventory data of the mold without requiring time and effort. Further, by associating the inventory workers in the database, the inventory workers are clarified, and the credibility of the report can be improved even if, for example, it is entrusted to an inventory operator on the secondary subcontractor side. Furthermore, by associating the mold and the storage data of the mold storage state in the database, for example, it is possible to store evidence that the mold exists without going to the secondary subcontractor or overseas from the part manufacturer side.

- the third information specifying the place where the mold is stored includes information specifying the shelf where the mold is stored and information specifying the position in the shelf where the mold is stored,

- An inventory operator uses a communication terminal having a photographing function and a QR code (registered trademark) recognition function to photograph the QR code (registered trademark) engraved on the second nameplate and takes the third result from the photographing result.

- the information for identifying the shelf in which the mold is stored and the information for specifying the position in the shelf in which the mold is stored are acquired as information, and transmitted from the communication terminal to the database.

- information for specifying a shelf in which a mold is stored and information for specifying a position in the shelf in which the mold is stored are stored. Thereby, the storage place of a metal mold

- a program includes a QR code (registered trademark) including first information for specifying an operator who stores a stored item, and a first item for specifying a stored item, from each captured image data.

- the QR code registered trademark

- the QR code including the information 2 and the QR code (registered trademark) including the third information specifying the place where the stored items are stored, and the extracted QR codes ( Acquiring the first information, the second information, and the third information from the registered trademark, and obtaining the acquired first, second, and third information from the stored items and the stored items.

- causing the communication terminal to execute a step of transmitting to the database together with the photographing data obtained by photographing the storage state.

- a program includes a QR code (registered trademark) including first information for identifying an inventory worker, and a second for identifying a mold, from each captured data captured by the program.

- causing the communication terminal to execute a step of transmitting to the database together with the photographed data.

- the inventory data of the mold can be collected quickly and accurately by the communication terminal without any trouble.

- inventory data of dies and jigs can be collected quickly and accurately without requiring labor.

- FIG. 2 It is a figure which shows the structure of the collection system of the inventory data of the metal mold

- FIG. 1 is a diagram showing a configuration of a mold inventory data collection system according to an embodiment of the present invention.

- a mold inventory data collection system 1 includes a database 10 for storing mold inventory data and a tablet possessed by an inventory worker B who performs inventory in an area A in which molds are stored. Terminal 20.

- the database 10 is arranged on the part manufacturer side, and the tablet terminal 20 is possessed by the inventory operator B on the secondary subcontractor side.

- the data communication between the database 10 and the tablet terminal 20 is possible via a wireless communication path such as WiFi and a wired communication path.

- the tablet terminal is a form of the communication terminal according to the present invention, and may be another communication terminal such as a smartphone or a PC having a photographing function and a QR code (registered trademark) recognition function.

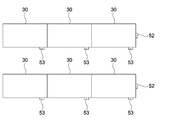

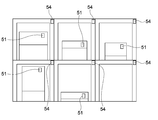

- FIG. 2 is a top view showing an example of the arrangement of the shelves in the region A in which the molds are stored

- FIG. 3 is a view of the shelves as viewed from the front.

- a plurality of shelves 30 are typically arranged in the area A in which the molds are stored.

- the plurality of shelves 30 are typically provided with spaces in which a plurality of molds 40 can be stored.

- a name plate 51 engraved with a QR code (registered trademark) including information for specifying the mold 40 is attached to a predetermined position of each mold 40.

- the information for specifying the mold includes a mold asset number, a mold management number, a product number, product information, and the like.

- the mold asset number is a number for each mold attached to the tubular book.

- the mold management number is a number assigned to each mold on the side where the mold is stored.

- a product number is a number given to a product produced by a mold.

- Product information is information on a product produced by a mold, for example, the name of the product.

- a name plate 52 engraved with a QR code (registered trademark) including information specifying the area of the shelf 30 is attached to a predetermined position of the area where the plurality of shelves 30 are arranged, for example, on the side surface of the shelf 30 on the passage side. Yes.

- Information specifying the area of the shelf 30 typically includes information specifying a company, a factory, and an area.

- a name plate 53 engraved with a QR code (registered trademark) including information specifying the shelf 30 is attached to a predetermined position of each shelf 30.

- the information for specifying the shelf 30 typically includes information for specifying a company, a factory, a rack, and a shelf.

- a name plate 54 engraved with a QR code (registered trademark) including information specifying the position is attached near each position where the mold in the shelf 30 in which the mold 40 is stored is stored. Yes.

- the information for specifying the position typically includes information for specifying a company, a factory, a rack, a shelf, and in-shelf address information.

- the inventory worker B has an employee batch 55 as a display member for displaying a QR code (registered trademark) including information for identifying the inventory worker B.

- the information for specifying the inventory worker B includes information for specifying the country, company, department, and human information (employee number, etc.).

- the inventory worker B possesses the tablet terminal 20 and the employee batch 55 and performs inventory work in the area A.

- the tablet terminal 20 includes a camera 21, a microphone 22, a touch pad display unit 23, a storage unit 24, a control unit 25, and a WiFi communication unit 26.

- the camera 21 is used, for example, to photograph the nameplates 51 to 54, the QR code (registered trademark) of the employee batch 55, the mold 40, the storage state of the mold 40, and the like.

- the microphone 22 is used, for example, for recording the state of the mold 40 by voice.

- the storage unit 24 stores a program according to the present invention, for example.

- the WiFi communication unit 26 is connected to, for example, a WiFi router and performs data communication with the database 10.

- FIG. 4 is a flowchart showing the operation of the tablet terminal 20 during inventory work.

- the tablet terminal 20 displays a screen that prompts the touch pad display unit 23 to shoot the QR code (registered trademark) of the employee batch 55 of the inventory worker (step S1).

- step S3 When the QR code (registered trademark) of the employee batch 55 is photographed and recognized (step S2), information identifying the inventory worker B is extracted from the QR code (registered trademark) (step S3).

- the tablet terminal 20 displays on the touch pad display unit 23 a screen that prompts photographing of the QR code (registered trademark) of the mold 40 to be inventoried (step S4).

- step S5 When the QR code (registered trademark) of the mold 40 is photographed and recognized (step S5), information for specifying the mold 40 is extracted from the QR code (registered trademark) (step S6).

- the tablet terminal 20 displays a screen that prompts the user to shoot the area QR code (registered trademark) on the touch pad display unit 23 (step S7).

- step S8 When the QR code (registered trademark) of the area is photographed and recognized (step S8), information for specifying the area is extracted from the QR code (registered trademark) (step S9).

- the tablet terminal 20 displays a screen for prompting photographing of the QR code (registered trademark) of the shelf 30 on the touch pad display unit 23 (step S10).

- step S11 When the QR code (registered trademark) of the shelf 30 is photographed and recognized (step S11), information specifying the shelf 30 is extracted from the QR code (registered trademark) (step S12).

- the tablet terminal 20 displays a screen for prompting the QR code (registered trademark) at the position where the mold 40 in the shelf 30 is stored on the touch pad display unit 23 (step S13).

- QR code registered trademark

- step S14 When the QR code (registered trademark) at the position where the mold 40 is stored is photographed and recognized (step S14), information specifying the position is extracted from the QR code (registered trademark) (step S15). .

- the tablet terminal 20 displays a screen for prompting photographing of the mold on the touch pad display unit 23 (step S16).

- the tablet terminal 20 displays a screen for prompting photographing of the storage state of the mold on the touch pad display unit 23 (step S18).

- the tablet terminal 20 displays an inventory inspection result sheet on the touch pad display unit 23 (step S20). Thereafter, when a predetermined button of the touch pad display unit 23 is touched (step S21), the tablet terminal 20 transmits the data of the inventory inspection result sheet to the database 10 (step S22).

- FIG. 5 is a diagram showing a typical example of an inventory inspection result sheet displayed on the touch pad display unit 23.

- the inventory inspection result sheet 60 is automatically described when the QR code (registered trademark) is recognized and information is extracted in the tablet terminal 20 as described above.

- the inventory inspection result sheet 60 includes an inventory date display field 61, an inventory manager display field 62, an inventory mold display field 63, a mold management area display field 64a, and a mold management.

- a shelf number display column 64b, a mold shelf address number display column 64c, a mold photo display column 65, and a mold shelf photo display column 66 are provided.

- the date of entry is displayed in the inventory date display field 61.

- the inventory manager display field 62 information on the inventory operator is displayed based on the information extracted in step S3.

- step S6 information for specifying a mold based on the information extracted in step S6 is displayed.

- the molds inventoried based on the information extracted in the above steps S9, S12, and S15 are displayed. Storage location information is displayed.

- the mold photo display column 65 displays a photo of the mold taken in step S17

- the mold shelf photo display column 67 displays a photo of the mold management state taken in step S19. The Thus, the location of the mold can be determined by attaching the mold photo and the status photograph of the mold management shelf.

- the database 10 receives the data of the inventory inspection result sheet transmitted from the tablet terminal 20 and accumulates these data as mold inventory data.

- the inventory data is described in the management ledger of the mold itself and stored as a mold history (medical record).

- the inventory worker B simply performs an operation of photographing a QR code (registered trademark) using the tablet terminal 20, and the inventory worker B and the mold 40 are stored in the database 10.

- the location (area, shelf, position in the shelf), the state of the mold 40, and the storage state of the mold 40 are accumulated in association with each other. Therefore, it is possible to collect the inventory data of the mold 40 quickly and accurately without requiring labor.

- the inventory worker B is clarified, and the credibility of the report can be improved even if the inventory worker B is outsourced to the secondary subcontractor side, for example.

- the mold 40 and the photographic data of the storage state of the mold 40 in the database 10 for example, the evidence that the mold 40 exists without going to the secondary subcontractor side or overseas from the part manufacturer side is stored. Can do.

- the mold inventory data stored in the database 10 according to the present invention can be used in the purchasing department, the accounting department, the manufacturing department, the mold production engineering department, and the like.

- FIG. 6 is a diagram showing a typical example of the mold inventory record of the purchasing department created based on the mold inventory data.

- the mold inventory record 70 typically includes a mold photo display field 71, a mold inventory date display field 72, a mold record manager display field 73, and a mold asset number.

- the display column 71 for the mold photo the display column 72 for the mold inventory date, the display column 73 for the person responsible for recording the mold, the display column 74 for the mold asset number, the display column 75 for the mold management number, the mold

- the data in the location management area display column 76 and the mold storage area photo display column 77 are created based on the mold inventory data stored in the database 10.

- the production approval check column 78b, the manufacturing approval check column 78c, and the accounting approval check column 78d are checked by each department.

- the mold inventory record 70 is updated with the data of the inventory inspection result sheet transmitted from the tablet terminal 20.

- the mold inventory record 70 is used for asset / location management of the entire company with the approval of each related department.

- FIG. 7 is a diagram showing a typical example of the inventory management sheet for the accounting department created based on the inventory data of the mold.

- the inventory management sheet 80 includes a mold QR sheet display field 81, an account item display field 82, a name display field 83, a mold asset management number display field 84, and an ownership display.

- Column 85 mold control number display column 86, mold start date display column 87, settlement date display column 88, acquisition amount display column 89, amortization method display column 90, useful life display column 91, current period It has a display column 92 for depreciation expenses, a display column 93 for discontinuation dates, a display column 94 for repair items, and a display column 95 for disposal dates.

- the data in the mold QR code (registered trademark) display field 81, the mold asset management number display field 84, and the mold management number display field 86 are the inventory data of the molds stored in the database 10. Created based on.

- FIG. 8 is a diagram showing a typical example of the production facility management sheet of the manufacturing department created based on the mold inventory data.

- the production facility management sheet 100 includes a mold display column 101, a processing machine display column 102, a production location display column 103, a production transfer display column 104, and a mold management number display column 105.

- Mold manufacturer display column 106 auxiliary equipment display column 107, production facility display column 108, facility management number display column 109, injection pressure display column 110, molding time display column 111, pack pressure display column It has a display column 112, a holding pressure display column 113, a temperature display column 114, a filling time display column 115, a production history display column 116, a production number display column 117, and a defect number display column 118.

- the data in the mold display column 101, the production location display column 103, the production transfer display column 104, and the mold management number display column 105 are created based on the mold inventory data stored in the database 10. Is done.

- Assets and production management are performed based on the above inventory management sheet 80 and production equipment management sheet 100.

- FIG. 9 is a diagram showing a typical example of a mold management sheet for a mold production engineering department created based on mold inventory data.

- the mold management sheet 120 includes a QR sheet display field 121, a mold management number display field 122, an asset management number display field 123, a mold manufacturer display field 124, a mold period.

- the data in the QR sheet display field 121, the mold management number display field 122, and the asset management number display field 123 is created based on the inventory data of the molds stored in the database 10.

- the data on this mold management sheet is linked to the product number and combined with the diverted parts management and mold maintenance data of the mold chart to create a chart (history) for the entire life of the mold from construction to disposal. It can also be used for the next mold design from the weak points of the mold.

- diverted parts management is to manage these data using a design database that accumulates historical data indicating that parts used for a given product have been diverted to parts of other products.

- the mold maintenance data of the mold chart is data stored in a mold maintenance database that stores a repair history of a mold corresponding to a mold number.

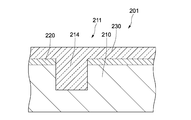

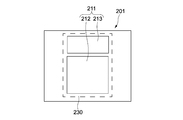

- FIG. 10 is a top view showing a configuration of a mold identification plate as a name plate engraved with a QR code (registered trademark).

- FIG. 11 is a partial longitudinal sectional view thereof.

- the mold identification plate 201 is a mold identification plate (name plate engraved with a QR code (registered trademark)) attached to the mold 40.

- the mold includes not only the mold itself but also mold parts constituting the mold. In some cases, each mold part is managed with a mold identification plate 201 attached thereto.

- the mold 40 includes various types such as a press mold, a forging mold, a casting mold, and an injection mold.

- the mold identification plate 201 includes a mold identification plate main body 210, an alumite layer 220, and an inorganic / organic composite coating layer 230.

- the mold identification plate body 210 is made of aluminum, for example, a rectangular plate-shaped member.

- the plate thickness of the mold identification plate body 210 is, for example, 1 to 1.5 mm, and may be other metals such as stainless steel in addition to aluminum.

- the mold identification plate main body 210 has a display area 211 at substantially the center thereof.

- the display area 211 includes a first display area 212 provided with a recess 214 corresponding to a QR code (registered trademark) as a two-dimensional code corresponding to information on the mold 40, and a company name, a serial number, etc. directly by visual inspection. And a second display area 213 provided with a recess 214 corresponding to information that can be confirmed. These recesses 214 are provided by, for example, cutting.

- the information about the mold 40 is as described in the above embodiment, but as another example, a server (not shown) that stores production technology information, production / facility information, and management information is accessed. This is information for accessing the production technology information, production / facility information, and management information of the individual mold among the mold information stored in the server.

- the information stored in the server may be stored in one server, or may be distributed and stored in a plurality of servers.

- the information on the mold may include, for example, information on the second display area 213 and other information in addition to the information for access described above.

- the production technology information includes, for example, a mold manufacturer, mold data, the number of production shots, mold maintenance information, and location.

- the production / equipment information includes, for example, production condition data such as molding conditions, production machine / tool specification, production line data, maintenance information such as equipment, quality information, and production environment information such as power supply / temperature / humidity.

- the management information includes, for example, a QC process chart, a work manual, and an inspection standard document.

- the depth of the recess 214 is preferably in the range of 0.1 mm to 0.2 mm, and more preferably 0.15 mm. If it is shallower than 0.1 mm, the inner side surface of the concave portion 214 may not be recognized as the concave portion 214 when it becomes a slope during processing, for example. It becomes easy and may not be recognized as the recess 214. If the depth of the concave portion 214 is around 0.15 mm, these are prevented and the QR code (registered trademark) is correctly recognized.

- the alumite layer 220 is provided on the surface of the mold identification plate main body 210 including the surface of the display area 211 so as to avoid the recess 214.

- the alumite layer 220 is provided by an alumite process described later.

- the region where the alumite layer 220 is provided is black, and the concave portion 214 is the color of the gloss of aluminum itself.

- the present invention includes any layer that makes the color difference between the surface and the recess clear.

- the anodized layer 220 is preferable. This is because the alumite layer 220 can be easily formed by an alumite treatment, and the color difference from the concave portion becomes black.

- the inorganic / organic composite coating layer 230 is made of a transparent and heat-resistant two-component room temperature curable inorganic / organic hybrid coating (for example, “FOC700 (trade name)” manufactured by FECT).

- the heat resistance is preferably in the range of 70 ° to 200 °.

- the inorganic / organic composite coating layer 230 is provided with a concave portion 214 corresponding to a QR code (registered trademark) as a two-dimensional code corresponding to information on the mold on the surface of the mold identification plate main body 210. Cover and fill the recess 214.

- the surface of the inorganic / organic composite coating layer 230 is substantially flat including the position corresponding to the recess 214.

- the inorganic / organic composite coating layer 230 preferably has a thickness of 0.1 mm to 0.2 mm as a height from the surface of the mold identification plate body 210. When the thickness is smaller than 0.1 mm, the display area 211 is not sufficiently protected by the inorganic / organic composite coating layer 230.

- the thickness is up to 0.2 mm, and the above protection is sufficient. If the thickness is larger than 0.2 mm, the coating material is wasted.

- the inorganic / organic composite coating layer 230 does not need to cover the entire area of the surface of the mold identification plate main body 210 as shown in FIG. That is, the inorganic / organic composite coating layer 230 only needs to cover at least the surface of the display region 211, and a step of applying an inorganic / organic composite coating to be described later by covering a certain area including the surface of the display region 211. This eliminates the need for strict accuracy and saves coating materials.

- the mold identification plate 201 information about the mold 40 is displayed by providing a recess 214 corresponding to a QR code (registered trademark) as a two-dimensional code in the display area 211, and the surface of the display area 211 is inorganic. Since the organic composite paint layer 230 is provided, a QR code (registered trademark) as a two-dimensional code for each individual can be attached in a simple process and can be produced in a short time.

- a QR code registered trademark

- the transparent and heat-resistant inorganic / organic composite coating layer 230 is provided with a recess 214 corresponding to the two-dimensional code so as to cover the surface of the display area 211 and fill the recess 214. Oil does not accumulate, and the recognition rate of the QR code (registered trademark) as a two-dimensional code does not decrease over a long period of time.

- the inorganic / organic composite coating layer 230 fills the recess 214, the adhesion between the inorganic / organic composite coating layer 230 and the display region 211 is increased, and durability can be maintained for a long time.

- the adhesion between the inorganic / organic composite coating layer 230 and the display region 211 is poor, gas or the like may accumulate in the concave portion 214 at the time of creation. There is a possibility that the recognition rate of the QR code (registered trademark) as a two-dimensional code is lowered. Further, if the non-attachability is poor, the inorganic / organic composite coating layer 230 may be peeled off from the display area 211 and the display area 211 may be exposed.

- This mold identification plate 201 is typically manufactured by the following method.

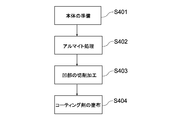

- FIG. 13 is a flowchart showing a configuration of a method for manufacturing the mold identification plate 201.

- a mold identification plate main body 210 having a plate thickness of, for example, 1 to 1.5 mm and made of rectangular and plate-shaped aluminum is prepared (step 401).

- an alumite treatment is performed on the entire surface of one side of the mold identification plate body 210 (step 402) to form an alumite layer 220.

- a recess 214 is formed by cutting to a depth of about 0.1 mm to 0.2 mm in the center of the anodized surface (surface) of the mold identification plate body 210 (step 403).

- the display area 211 is formed.

- the display area 211 includes a first display area 212 provided with a recess 214 corresponding to a QR code (registered trademark) as a two-dimensional code corresponding to information on a mold, a company name, and a serial number.

- a second display region 213 provided with a recess 214 corresponding to information that can be directly confirmed visually.

- an inorganic / organic composite paint is applied to the surface of the mold identification plate main body 210 so as to cover a certain area including the surface of the display area 211 (step 404).

- An inorganic-organic composite coating layer 230 having a thickness of about 1 mm to 0.2 mm is formed.

- the layer 230 that protects the concave portion 214 is provided, and the layer 230 is an inorganic-organic composite coating layer that is formed of an inorganic organic composite coating, so that the layer that protects the concave portion 214 is formed by a simple coating process.

- the heat resistance, durability and the like are very excellent, and the recognition rate of the two-dimensional code can be maintained for a long time.

- bubbles and the like in the recess 214 do not float on the surface and remain in the recess 214 at the time of application, and the adhesion is extremely high.

- the protective layer 230 can be formed by a simple coating process, and thus the protective layer 230 has extremely high adhesion in a simple and short process. Can be formed. Furthermore, by using a two-component room temperature curing type inorganic organic hybrid paint (for example, “FOC700 (trade name)” manufactured by FECT), transparency can be maintained over a long period of time, so that the recognition rate of a two-dimensional code is maintained over a long period of time. can do.

- a two-component room temperature curing type inorganic organic hybrid paint for example, “FOC700 (trade name)” manufactured by FECT

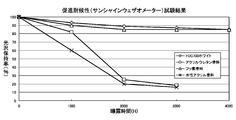

- Fig. 14 shows data disclosed by FECT regarding transparency.

- Bonde steel plate (150 x 50 x 0.3 mm) as a material as a material

- film thickness as a film thickness: 25 to 30 ⁇ m 25 to 30 ⁇ m

- curing conditions as drying at 80 ° C for 30 minutes, room temperature for 2 weeks It was served after being left.

- the material for the above-mentioned inorganic / organic composite coating layer is not limited to the illustrated material, and any material having the same function can be used in the same manner.

- the cutting of the recess in the display area is not limited to the above embodiment, and other cutting may be used.

- the above identification board can be grasped as the following technology

- An identification plate attached to an object A metal identification board body, On the surface of the identification plate main body, a recess is provided according to a two-dimensional code corresponding to information on the object, and a display area;

- An identification comprising: a transparent and heat-resistant inorganic-organic composite coating layer that covers the surface of the display area and fills the recess.

- the identification plate according to (1) The inorganic / organic composite coating layer has a heat resistance of 70 ° to 200 °.

- a method of manufacturing an identification plate attached to an object On the surface of the display area of the metal identification plate main body, a recess according to the two-dimensional code corresponding to the information on the object is provided, A transparent and heat-resistant inorganic / organic composite coating is applied to the surface of the display area provided with the recess so as to cover the surface and fill the recess.

- the inorganic-organic composite paint has a heat resistance of 70 ° to 200 °.

- the identification plate body is made of aluminum

- the method is A method for manufacturing an identification plate, wherein an alumite treatment is performed on the surface of the identification plate main body before providing a recess according to a two-dimensional code corresponding to information on the object.

- a mold is used as an example of stored items.

- inventory data of other stored items such as jigs and tools may be collected. Further, for example, when storing dies and jigs together, these storage data may be collected as inventory data.

- the jigs and tools there are typically a measurement jig and an assembly jig used in a production line.

- the storage data may be collected not only as inventory data but also for other purposes.

- the QR code (registered trademark) is engraved on the metal plate as the name plate.

- a seal-like name plate on which the QR code (registered trademark) is printed may be used.

- Mold inventory data collection system 10 Database 20 Tablet terminal 30 Shelf 40 Mold 51-54 Name plate 55 engraved with QR code (registered trademark) Employee batch

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Quality & Reliability (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Automation & Control Theory (AREA)

- General Factory Administration (AREA)

- Management, Administration, Business Operations System, And Electronic Commerce (AREA)

Abstract

Afin de collecter rapidement et correctement des données d'inventaire de matrices sans qu'il soit nécessaire d'augmenter le temps ni l'effort, un opérateur d'inventaire (B) est équipé d'un badge d'employé (55) permettant d'afficher un code QR (marque déposée) comprenant des premières informations permettant de spécifier l'opérateur d'inventaire (B). Une première plaque signalétique (51) gravée à l'aide d'un code QR (marque déposée) comprenant des deuxièmes informations permettant de spécifier une matrice (40) est fixée à la matrice (40) dans une position prédéterminée. Une seconde plaque signalétique (52-54) gravée à l'aide d'un code QR (marque déposée) comprenant des troisièmes informations permettant de spécifier un emplacement de stockage de la matrice (40) est fixée dans une position prédéterminée. L'opérateur d'inventaire (B) utilise un terminal de tablette (20) permettant d'acquérir les informations à partir des codes QR (marque déposée), récupère une image de la matrice (40) et un état de stockage de la matrice (40) et accumule les données en tant que données d'inventaire de la matrice (40) dans une base de données (10).

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201780030404.7A CN109313433B (zh) | 2016-05-19 | 2017-03-29 | 保管物的保管数据的收集方法及程序 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016-100383 | 2016-05-19 | ||

| JP2016100383A JP6881897B2 (ja) | 2016-05-19 | 2016-05-19 | 保管物の保管データの収集方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2017199590A1 true WO2017199590A1 (fr) | 2017-11-23 |

Family

ID=60325894

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2017/012818 WO2017199590A1 (fr) | 2016-05-19 | 2017-03-29 | Procédé de collecte de données de stockage d'objet de stockage et programme |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP6881897B2 (fr) |

| CN (1) | CN109313433B (fr) |

| WO (1) | WO2017199590A1 (fr) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113800184A (zh) * | 2021-08-05 | 2021-12-17 | 深圳市鼎立特科技有限公司 | 一种基于工业互联网平台的立体库标识采集系统 |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7186035B2 (ja) * | 2018-08-09 | 2022-12-08 | 株式会社日立システムズ | 資産管理システム、資産管理方法 |

| JP7424614B2 (ja) * | 2019-12-24 | 2024-01-30 | 株式会社Kmc | 管理システム及び管理方法 |

| KR102576107B1 (ko) * | 2020-03-10 | 2023-09-08 | 주식회사 아모센스 | 데이터 로거 장치 |

| JP6987934B1 (ja) * | 2020-07-28 | 2022-01-05 | 株式会社日本製鋼所 | 成形条件の管理機能を備えた射出成形機システム |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002029612A (ja) * | 2000-07-12 | 2002-01-29 | Tsubakimoto Chain Co | 物品保管棚及び物品の入出庫管理方法 |

| JP2014002705A (ja) * | 2012-05-23 | 2014-01-09 | Mitsubishi Heavy Ind Ltd | 生産管理システム及び方法 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007241377A (ja) * | 2006-03-06 | 2007-09-20 | Sony Corp | 検索システム、撮像装置、データ保存装置、情報処理装置、撮像画像処理方法、情報処理方法、プログラム |

| WO2015015594A1 (fr) * | 2013-07-31 | 2015-02-05 | 株式会社日立システムズ | Système de gestion d'objets gérés |

| JP6425198B2 (ja) * | 2014-03-19 | 2018-11-21 | 株式会社Kmc | 金型電子カルテシステムを使った金型の管理方法 |

| CN105631592A (zh) * | 2015-12-28 | 2016-06-01 | 海南华人智慧科技有限公司 | 一种基于物联网的rfid资产监管系统 |

-

2016

- 2016-05-19 JP JP2016100383A patent/JP6881897B2/ja active Active

-

2017

- 2017-03-29 WO PCT/JP2017/012818 patent/WO2017199590A1/fr active Application Filing

- 2017-03-29 CN CN201780030404.7A patent/CN109313433B/zh not_active Expired - Fee Related

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2002029612A (ja) * | 2000-07-12 | 2002-01-29 | Tsubakimoto Chain Co | 物品保管棚及び物品の入出庫管理方法 |

| JP2014002705A (ja) * | 2012-05-23 | 2014-01-09 | Mitsubishi Heavy Ind Ltd | 生産管理システム及び方法 |

Non-Patent Citations (1)

| Title |

|---|

| SEIKI SATO ET AL.: "Nipponban IoT System/Denshi Karute no Shinka to Kotai Ninshiki Gijutsu ni yoru Johoka Senryaku no Shishin Kanagata Kanri Kino to QR Sessaku System no Kaihatsu", GEKKAN JIDO NINSHIKI, vol. 28, no. 12, 10 November 2015 (2015-11-10), pages 14 - 21, ISSN: 0915-1060 * |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113800184A (zh) * | 2021-08-05 | 2021-12-17 | 深圳市鼎立特科技有限公司 | 一种基于工业互联网平台的立体库标识采集系统 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP6881897B2 (ja) | 2021-06-02 |

| CN109313433B (zh) | 2021-10-01 |

| JP2017207950A (ja) | 2017-11-24 |

| CN109313433A (zh) | 2019-02-05 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2017199590A1 (fr) | Procédé de collecte de données de stockage d'objet de stockage et programme | |

| JP6004831B2 (ja) | トレーサビリティ管理システム及び方法 | |

| US11868843B2 (en) | Tooling system | |

| WO2018107290A1 (fr) | Système de collaboration pour la gestion de construction utilisant des plates-formes informatiques partagées | |

| JP2016144846A (ja) | 組立ナビゲーションシステム及び組立ナビゲーション方法 | |

| US9740790B2 (en) | Tooling system | |

| JP6763579B2 (ja) | 取引支援システム、方法、及びプログラム | |

| JP4657333B2 (ja) | エレベータの部品材料管理装置及びその材料管理方法 | |

| KR101011144B1 (ko) | 온라인을 통한 금형 제작 정보 제공방법 및 그 시스템 | |

| JP2019102065A (ja) | 製造委託支援装置、製造委託支援方法、及びそのためのプログラム | |

| JP6420086B2 (ja) | 報告書作成システム | |

| US20080228815A1 (en) | Methods and systems for managing risk | |

| US20140237334A1 (en) | Systems and methods for use in populating information into a document | |

| JP6401962B2 (ja) | 品質関連情報の蓄積方法 | |

| JP2022175058A (ja) | 型管理システム、型管理方法及び型管理プログラム | |

| KR20090105088A (ko) | 금형 통합관리 시스템 | |

| JP6672110B2 (ja) | 管理システムおよび管理方法 | |

| Bildsten | A project-based purchasing portfolio matrix applied to the Australian construction industry | |

| JP2019185272A (ja) | 業種業態毎の業務処理形態から推定される問題点と業務フローチャートとが組み合わされた業務フローチャート作成方法およびその作成システム | |

| TWI702561B (zh) | 線上簽約裝置與方法 | |

| US20210312581A1 (en) | Compliance hub | |

| US20220004996A1 (en) | Temporary Employment Assistance System | |

| Current | Metalcasting Industry Research | |

| IT202100007811A1 (it) | Apparecchiatura e metodo per l’espletamento di attività di prenotazione e/o acquisto di servizi e di elaborazione e pubblicazione di dati inerenti i servizi stessi | |

| JP2013008269A (ja) | 基準在庫設定装置及び基準在庫設定方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 17799024 Country of ref document: EP Kind code of ref document: A1 |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 17799024 Country of ref document: EP Kind code of ref document: A1 |