WO2017170199A1 - 二酸化炭素還元電極およびこれを用いた二酸化炭素還元装置 - Google Patents

二酸化炭素還元電極およびこれを用いた二酸化炭素還元装置 Download PDFInfo

- Publication number

- WO2017170199A1 WO2017170199A1 PCT/JP2017/011946 JP2017011946W WO2017170199A1 WO 2017170199 A1 WO2017170199 A1 WO 2017170199A1 JP 2017011946 W JP2017011946 W JP 2017011946W WO 2017170199 A1 WO2017170199 A1 WO 2017170199A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- group

- carbon dioxide

- ionic liquid

- electrode

- carbon atoms

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C25—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES; APPARATUS THEREFOR

- C25B—ELECTROLYTIC OR ELECTROPHORETIC PROCESSES FOR THE PRODUCTION OF COMPOUNDS OR NON-METALS; APPARATUS THEREFOR

- C25B3/00—Electrolytic production of organic compounds

- C25B3/20—Processes

- C25B3/25—Reduction

- C25B3/26—Reduction of carbon dioxide

Definitions

- the present disclosure relates to a carbon dioxide reduction electrode for reducing carbon dioxide and a carbon dioxide reduction apparatus using the same.

- An object of the present disclosure is to provide a carbon dioxide reduction electrode and a carbon dioxide reduction device capable of improving the production efficiency of methanol when electrochemically synthesizing methanol from CO 2 using a mediator.

- the carbon dioxide reducing electrode includes a base material, an ionic liquid, and a nitrogen-containing aromatic compound.

- the base material is composed of a metal or a metal oxide.

- the ionic liquid is represented by the following general formula (1) and forms a monomolecular film on the surface of the substrate.

- the nitrogen-containing aromatic compound is encapsulated between the base material and the ionic liquid.

- M is a P atom or an N atom.

- R 1 to R 4 each independently represents an alkyl group having 1 to 30 carbon atoms, an alkenyl group having 2 to 30 carbon atoms, an alkynyl group having 2 to 30 carbon atoms, or 1 to 30 carbon atoms.

- Alkyl having 1 to 30 carbon atoms, an alkyl group having 1 to 30 carbon atoms, a perfluoroalkyl group having 1 to 30 carbon atoms, an aryl group having 6 to 30 carbon atoms, an aralkyl group having 7 to 30 carbon atoms, or a carbonyl group Represents a group, an alkenyl group, an aryl group or an aralkyl group.

- n is an integer of 1 to 3

- R n and R n + 1 may combine to have a cyclic structure.

- At least one of R 1 to R 4 in the general formula (1) is a —SH group, —SS— group, —S— group, —COOH group, —NH 2 group, silanol group, phosphoric acid group, It has one or more binding functional groups selected from the group consisting of alkenyl groups, alkynyl groups, and azide groups.

- X ⁇ represents a counter anion.

- the nitrogen-containing aromatic compound is formed between the base material and the ionic liquid by forming a monomolecular film of the ionic liquid represented by the general formula (1) on the surface of the base material. It can be included as a mediator.

- the carbon dioxide reduction electrode according to the first aspect of the present disclosure it is possible to reduce the reaction overvoltage and increase the reaction current in the CO 2 reduction reaction. For this reason, the absolute production amount of methanol can be increased.

- the carbon dioxide reduction device includes the carbon dioxide reduction electrode according to the first aspect of the present disclosure, an oxidation electrode, an electrolytic solution, and a carbon dioxide supply unit.

- a carbon dioxide reduction electrode and an oxidation electrode are immersed in the electrolytic solution.

- the carbon dioxide supply unit supplies carbon dioxide to the electrolytic solution.

- the CO 2 reduction device 1 includes a container 10.

- An electrolytic solution 11 is accommodated in the container 10.

- the electrolytic solution 11 is not particularly limited, but an Na 2 SO 4 aqueous solution is used in the present embodiment.

- an oxidation electrode 12, a reduction electrode 13, and a reference electrode 14 are inserted.

- the oxidation electrode 12, the reduction electrode 13 and the reference electrode 14 are immersed in the electrolytic solution 11.

- a platinum electrode can be used.

- the configuration of the reduction electrode 13 will be described later.

- the oxidation electrode 12, the reduction electrode 13 and the reference electrode 14 are connected to a potentiostat 15.

- a CO 2 supply pipe 16 is inserted into the container 10. CO 2 is supplied to the electrolytic solution 11 from the CO 2 supply pipe 16.

- the reduction electrode 13 has a base material 13a, an ionic liquid 13b, and a mediator 13c.

- a monomolecular film of the ionic liquid 13b is formed on the surface of the substrate 13a.

- a nano-order space is formed between the base material 13a and the ionic liquid 13b, and the mediator 13c is included in this space.

- the base material 13a is a metal plate, and is composed of a metal or a metal oxide capable of forming a monomolecular structure on the surface of the ionic liquid 13b.

- the base material 13a for example, any metal of gold, platinum, silver, copper, tin, titanium, or a metal oxide thereof can be used.

- the ionic liquid 13b has a thiol functional group (—SH, —S—, —SS—)

- the ionic liquid 13b having a thiol functional group can form a monomolecular structure as the base material 13a. It is desirable to use any metal of gold, platinum, silver, copper or a metal oxide thereof.

- the ionic liquid 13b is a molecular liquid that is liquid at room temperature.

- the ionic liquid 13b of this embodiment has a branched alkyl chain and has a bulky structure.

- the ionic liquid 13b of the present embodiment is an organic phosphorus type or quaternary amine type ionic liquid containing a structural unit represented by the following general formula (1).

- M is a P atom or an N atom.

- R 1 to R 4 each independently represents an alkyl group having 1 to 30 carbon atoms, an alkenyl group having 2 to 30 carbon atoms, an alkynyl group having 2 to 30 carbon atoms, or 1 to 30 carbon atoms.

- Alkyl having 1 to 30 carbon atoms, an alkyl group having 1 to 30 carbon atoms, a perfluoroalkyl group having 1 to 30 carbon atoms, an aryl group having 6 to 30 carbon atoms, an aralkyl group having 7 to 30 carbon atoms, or a carbonyl group Represents a group, an alkenyl group, an aryl group or an aralkyl group.

- R n and R n + 1 (n is an integer of 1 to 3) may be bonded to each other to have a cyclic structure.

- At least one of R 1 to R 4 in the general formula (1) is at least one binding functional group (—SH group, —SS— group, —S— group, —COOH group, —NH 2 group).

- Silanol group, phosphate group, alkenyl group, alkynyl group, or azido group is at least one binding functional group (—SH group, —SS— group, —S— group, —COOH group, —NH 2 group).

- X ⁇ represents a counter anion.

- the counter anion X ⁇ is an anion having a valence of 1 or more, and various halogen ions, BF 4 ⁇ , PF 6 ⁇ , CF 3 SO 3 ⁇ (abbreviation TfO ⁇ ), (CF 3 SO 2 ). 2 N ⁇ (abbreviation Tf 2 N ⁇ ) and the like are preferably used.

- the ionic liquid 13b in which the surface of the base material 13a is modified with the ionic liquid 13b has a structural unit represented by the general formula (1), so that a spatial gap sufficient to introduce the mediator 13c can be created. .

- the mediator 13c can be introduced into a spatial gap formed by the ionic liquid 13b.

- the ionic liquid 13b is ionic with a functional group such as phosphoric acid or ammonium, the conductivity can be improved and the solubility of CO 2 in the monomolecular film can be improved.

- FIG. 3 has “—SS— group” or “—SH group” at R 1 in the general formula (1).

- an organic compound represented by the following general formula (2) is used as the ionic liquid 13b.

- the organic compound represented by the general formula (2) is an organic compound represented by the general formula (1), in which M is a P atom and R 1 is a — (CH 2 ) 12 S— group having a —S— group as a binding functional group, R 2 to R 4 are C 6 H 13 — groups, and X ⁇ is CF 3 SO 3 ⁇ (TfO ⁇ ).

- the ionic liquid 13b described above can be synthesized by the method described in JP2012-167045A.

- the mediator 13c is a compound that mediates electron transfer through a CO 2 reduction reaction.

- a nitrogen-containing aromatic compound is used as the mediator 13c.

- the aromatic compound is a planar ring having a delocalized ⁇ electron system containing 4n + 2 (n is an integer) ⁇ electrons.

- Aromatic rings can be formed by 5, 6, 7, 8, 9, or 10 or more atoms.

- Aromatic compounds include monocyclic and fused ring polycyclic.

- the nitrogen-containing aromatic compound is a heteroaromatic compound in which one or more constituent atoms of the aromatic ring are N atoms.

- one or more hydrogen atoms bonded to the constituent atoms of the aromatic ring may be substituted with a linear or branched lower alkyl group, a hydroxy group, an amino group, or a pyridyl group.

- imidazole, methylimidazole, dimethylimidazole, triazole, pyridine, dimethylaminopyridine are used as the nitrogen-containing aromatic compound constituting the mediator 13c.

- the reduction electrode 13 of the present embodiment can be obtained by introducing the ionic liquid 13b to the surface of the base material 13a to make the ionic liquid modified base material, and introducing the mediator 13c into the ionic liquid modified base material.

- the base material 13a is preferably subjected to surface treatment such as cleaning as necessary before modification with the ionic liquid 13b.

- the surface treatment of the substrate 13a can be performed using concentrated nitric acid, a piranha solution, or hydrofluoric acid.

- the base material 13a is immersed in a solution in which the ionic liquid 13b is dissolved in an organic solvent.

- a method or a method of applying the solution to the surface of the substrate 13a by spray coating or spin coating can be used.

- the substrate 13a may be immersed in the ionic liquid 13b itself, or the ionic liquid 13b may be applied to the surface of the substrate 13a by the above method.

- the time for immersing the base material 13a in the solution of the ionic liquid 13b is not particularly limited as long as the ionic liquid 13b is fixed on the surface of the base material 13a, but preferably 5 minutes to 60 hours, more preferably 1 ⁇ 24 hours. Moreover, you may heat the base material 13a and a solution when immersing or apply

- the organic solvent alcohols, ethers, nitriles, esters, ketones, hydrocarbons, chloroform and the like can be used.

- a method for introducing the mediator 13c into the ionic liquid modified substrate for example, a method in which the ionic liquid modified substrate is immersed in a solution in which the mediator 13c is dissolved in an organic solvent, or a solution is spray coated on the ionic liquid modified substrate.

- coating by spin coating etc. is mentioned.

- the time for immersing the ionic liquid modified base material in the solution of the mediator 13c is not particularly limited as long as the mediator 13b is introduced into the ionic liquid modified base material, but is preferably 5 minutes to 60 hours, more preferably 1 ⁇ 24 hours. Moreover, you may heat an ionic liquid modification base material and a solution when immersing or apply

- the concentration of the target compound is about 0.01 to 100 mmol / L, preferably about 0.1 to 50 mmol / L.

- the organic solvent alcohols, ethers, nitriles, esters, ketones, hydrocarbons, chloroform, water and the like can be used.

- a solution in which the ionic liquid 13b and the mediator 13c coexist is prepared at the time of modifying the ionic liquid on the surface of the base material 13a. It is also possible to modify and fix 13c on the surface of the base material 13a.

- the time for immersing the substrate 13a in the solution is not particularly limited as long as the mediator 13c and the ionic liquid 13b are introduced onto the surface of the substrate 13a, but preferably 5 minutes to 60 hours, more preferably 1 to 24. It's time. Moreover, you may heat a base material and a solution, when immersing as needed.

- the concentration of the mediator 13c is about 0.01 to 100 mmol / L, preferably about 0.1 to 50 mmol / L.

- the organic solvent alcohols, ethers, nitriles, esters, ketones, hydrocarbons, chloroform and the like can be used.

- an electrochemical measurement is performed in an electrolyte solution containing the mediator 13c using an ionic liquid-modified base as an electrode and an electrochemical measurement device, preferably a potentio such as cyclic voltammetry.

- an electrochemical measurement device preferably a potentio such as cyclic voltammetry.

- concentration, temperature, solvent, measurement time, electrolyte to be used, etc. are not particularly limited as long as the mediator 13c is introduced into the ionic liquid modified electrode, but the concentration of the mediator 13c to be introduced is Preferably it is 0.05 to 10 mmol / L, more preferably 0.1 to 5 mmol / L.

- the measurement temperature is preferably ⁇ 10 to 100 ° C., more preferably 0 to 30 ° C.

- organic solvent alcohols, ethers, nitriles, esters, ketones, hydrocarbons, chloroform, water and the like can be used.

- the measurement time is preferably about 1 minute to 2 hours, more preferably about 5 to 30 minutes.

- the electrolyte is not particularly limited as long as it is an electrolyte used for normal electrochemical measurements.

- the solvent is aqueous, lithium perchlorate or sodium perchlorate, and an organic solvent, tetraalkylammonium tetraborate salt. , Hexafluorophosphate, or perchlorate is preferably used.

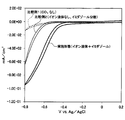

- FIG. 4 shows the result of CV measurement performed by the CO 2 reduction device 1 of the present embodiment. Imidazole was used as the mediator 13c.

- the CV measurement result when not supplying CO 2 to the electrolytic solution 11 is shown as the comparative example 1, and the electrolytic solution is formed as the comparative example 2 without forming a monomolecular film of the ionic liquid 13b on the surface of the base material 13a.

- 11 shows the results of CV measurement when imidazole is dispersed in No. 11.

- Comparative Example 1 in which CO 2 is not supplied to the electrolyte solution 11, the current is kept near zero.

- Comparative Example 2 in which the ionic liquid 13b is not used the current changes from zero to minus around ⁇ 0.6V.

- the current changes from zero to minus around ⁇ 0.4V.

- the current density is increased as compared with Comparative Example 2. That is, in this embodiment, by using the ionic liquid 13b, the reaction overvoltage in the CO 2 reduction reaction is reduced and the reaction current is increased.

- the ionic liquid 13b and the mediator 13c are a combination having a high interaction, and the diffusion of the reductant on the outermost surface of the reduction electrode 13 is reduced.

- the charge transfer in the CO 2 reduction reaction is efficient, the reaction overvoltage is reduced, and the reaction current is increased.

- the CO 2 reduction reaction is a multistage reaction that changes in the order of CO 2 ⁇ formic acid (HCOOH) ⁇ methanol (CH 3 OH).

- HCOOH formic acid

- CH 3 OH methanol

- a monomolecular film of the ionic liquid 13b having high conductivity and high inclusion of the mediator 13c and the reductant (reactant) is formed on the surface of the base material 13a, thereby reducing the reductant. Can be prevented from diffusing from the electrode surface at the formic acid stage, and the above multi-stage reaction is considered to proceed smoothly.

- FIG. 5 shows the current density and methanol production efficiency of an example in which CO 2 was reduced by changing the combination of the base material 13a, the ionic liquid 13b, and the mediator 13c in the CO 2 reduction apparatus 1 of the present embodiment. Yes.

- FIG. 5 also shows a comparative example in which CO 2 is reduced without using the ionic liquid 13b or the mediator 13b.

- the cathode potential was ⁇ 0.8 V / Ag / AgCl.

- the base material 13a gold was used in Examples 1 to 7 and Comparative Examples 1, 3, and 4, platinum was used in Example 8, and copper was used in Examples 9 and 2.

- the ionic liquid 13b in Examples 1 to 9 and Comparative Example 4, a phosphoric acid ionic liquid 13b containing P atoms was used. In Comparative Examples 1 to 3, the ionic liquid 13b was not used.

- the mediator 13c uses imidazole in Examples 1, 8, and 9, Comparative Examples 1 and 2, pyridine in Examples 2 and 3, and 3,5-diamino-1,2,4- in Example 3. Triazole was used, 1-methylimidazole was used in Example 4, 2-methylimidazole was used in Example 5, 1,2-dimethylimidazole was used in Example 6, and 4-dimethylimidazole was used in Example 7. In Comparative Example 4, the mediator 13c was not used.

- the methanol production efficiency was 13% to 28%.

- the methanol production efficiency was 1 to 6%.

- Comparative Example 4 in which the ionic liquid 13b was used and the mediator 13c was not used, the methanol production efficiency was 0%. That is, in this embodiment, methanol production efficiency higher than that of the comparative example is obtained.

- Examples 1 to 9 when gold is used as the substrate 12a, methanol production efficiency is higher than other metals. In Examples 1 to 9, the methanol production efficiency is highest when gold is used as the substrate 12a and imidazole is used as the mediator 13c.

- the kind of metal used as the base material 13a can be determined by elemental analysis by XPS, for example.

- the presence / absence of the monomolecular film of the ionic liquid 13b on the surface of the base material 13a can be determined by, for example, an electrochemical reduction method (that is, electrical desorption of the monomolecular film).

- the type of the monomolecular film of the ionic liquid 13b can be determined by elemental analysis using, for example, XRS or EDX.

- the type of mediator 13c can be analyzed by, for example, XPS, EDS, gas chromatography, or the like.

- a monomolecular film of the ionic liquid 13b is formed on the surface of the base material 13a, and the mediator 13c is included between the base material 13a and the ionic liquid 13b to perform the CO 2 reduction reaction.

- the methanol production efficiency can be improved.

- the reaction overvoltage decreases and the reaction current increases. For this reason, the absolute production amount of methanol can be increased.

- the mediator 13c is not limited to the nitrogen-containing aromatic compound exemplified in the above embodiment, but when the organic compound represented by the general formula (2) is used as the ionic liquid 13b, the reaction potential of the nitrogen-containing aromatic compound is used. Is desirably smaller than ⁇ 1.0 V / Ag / AgCl on the positive side. That is, when the organic compound represented by the general formula (2) is used as the ionic liquid 13b, the monomolecular film of the ionic liquid 13b is reduced and desorbed from the substrate 13a at a potential of about ⁇ 1.0 V / Ag / AgCl. There is a risk of separation.

- the monomolecular film of the ionic liquid 13b is removed from the substrate 13a during the CO 2 reduction reaction. Reductive desorption can be avoided.

Landscapes

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- Materials Engineering (AREA)

- Metallurgy (AREA)

- Electrolytic Production Of Non-Metals, Compounds, Apparatuses Therefor (AREA)

- Electrodes For Compound Or Non-Metal Manufacture (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016070181A JP6590459B2 (ja) | 2016-03-31 | 2016-03-31 | 二酸化炭素還元電極およびこれを用いた二酸化炭素還元装置 |

| JP2016-070181 | 2016-03-31 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2017170199A1 true WO2017170199A1 (ja) | 2017-10-05 |

Family

ID=59965598

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2017/011946 Ceased WO2017170199A1 (ja) | 2016-03-31 | 2017-03-24 | 二酸化炭素還元電極およびこれを用いた二酸化炭素還元装置 |

Country Status (2)

| Country | Link |

|---|---|

| JP (1) | JP6590459B2 (enExample) |

| WO (1) | WO2017170199A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2021014629A (ja) * | 2019-07-16 | 2021-02-12 | 株式会社豊田中央研究所 | 還元反応用電極、およびそれを用いた反応デバイス |

| WO2024248073A1 (ja) * | 2023-05-30 | 2024-12-05 | 古河電気工業株式会社 | カソード電極、カソード電極と基材との複合体、カソード電極を備えた電解還元装置及びカソード電極と基材との複合体の製造方法 |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP7062939B2 (ja) * | 2017-12-18 | 2022-05-09 | 株式会社デンソー | 二酸化炭素還元電極およびこれを用いた二酸化炭素還元装置 |

| CN110699704B (zh) * | 2019-10-21 | 2021-05-11 | 昆明理工大学 | 一种自支撑型硫化银催化二氧化碳还原电极材料的制备方法、产品及应用 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012167045A (ja) * | 2011-02-14 | 2012-09-06 | Nagoya Institute Of Technology | イオン液体およびイオン液体修飾基材 |

| JP2012184132A (ja) * | 2011-03-04 | 2012-09-27 | Nagoya Institute Of Technology | アンモニア製造方法 |

| JP2015513616A (ja) * | 2012-03-06 | 2015-05-14 | リキッド・ライト・インコーポレーテッドLiquid Light Incorporated | 二酸化炭素の生成物への還元 |

| WO2015133127A1 (ja) * | 2014-03-04 | 2015-09-11 | 株式会社デンソー | 二酸化炭素還元電極及びこれを用いた二酸化炭素還元装置 |

| WO2015136776A1 (ja) * | 2014-03-14 | 2015-09-17 | 株式会社 東芝 | 酸化電極および光電気化学装置 |

-

2016

- 2016-03-31 JP JP2016070181A patent/JP6590459B2/ja active Active

-

2017

- 2017-03-24 WO PCT/JP2017/011946 patent/WO2017170199A1/ja not_active Ceased

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2012167045A (ja) * | 2011-02-14 | 2012-09-06 | Nagoya Institute Of Technology | イオン液体およびイオン液体修飾基材 |

| JP2012184132A (ja) * | 2011-03-04 | 2012-09-27 | Nagoya Institute Of Technology | アンモニア製造方法 |

| JP2015513616A (ja) * | 2012-03-06 | 2015-05-14 | リキッド・ライト・インコーポレーテッドLiquid Light Incorporated | 二酸化炭素の生成物への還元 |

| WO2015133127A1 (ja) * | 2014-03-04 | 2015-09-11 | 株式会社デンソー | 二酸化炭素還元電極及びこれを用いた二酸化炭素還元装置 |

| WO2015136776A1 (ja) * | 2014-03-14 | 2015-09-17 | 株式会社 東芝 | 酸化電極および光電気化学装置 |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2021014629A (ja) * | 2019-07-16 | 2021-02-12 | 株式会社豊田中央研究所 | 還元反応用電極、およびそれを用いた反応デバイス |

| JP7342474B2 (ja) | 2019-07-16 | 2023-09-12 | 株式会社豊田中央研究所 | 二酸化炭素還元反応用電極、およびそれを用いた二酸化炭素還元装置 |

| WO2024248073A1 (ja) * | 2023-05-30 | 2024-12-05 | 古河電気工業株式会社 | カソード電極、カソード電極と基材との複合体、カソード電極を備えた電解還元装置及びカソード電極と基材との複合体の製造方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2017179514A (ja) | 2017-10-05 |

| JP6590459B2 (ja) | 2019-10-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Zhang et al. | Electrochemical oxidation of gold and thiourea in acidic thiourea solutions | |

| Tan et al. | Bottom-up electrosynthesis of highly active tungsten sulfide (WS3–x) films for hydrogen evolution | |

| CN102971451B (zh) | 催化剂混合物 | |

| Andrews et al. | Electrocatalytic reduction of CO2 at Au nanoparticle electrodes: effects of interfacial chemistry on reduction behavior | |

| JP6590459B2 (ja) | 二酸化炭素還元電極およびこれを用いた二酸化炭素還元装置 | |

| Benn et al. | Characterization of nanoporous metal-ionic liquid composites for the electrochemical oxygen reduction reaction | |

| JP6636885B2 (ja) | 還元触媒および還元反応装置 | |

| Uzunoglu et al. | A sensitive electrochemical H2O2 sensor based on PdAg-decorated reduced graphene oxide nanocomposites | |

| Basova et al. | Hybrid materials based on phthalocyanines and metal nanoparticles for chemiresistive and electrochemical sensors: A mini-review | |

| Liu et al. | An electrochemical chiral sensor based on the synergy of chiral ionic liquid and 3D-NGMWCNT for tryptophan enantioselective recognition | |

| Xie et al. | Voltammetric study and electrodeposition of Cu from CuO in deep eutectic solvents | |

| Vanderaspoilden et al. | Contrasted electrochemical behaviour of Cu (I) and Cu (II) ions in 1-butyl-3-methylimidazolium dicyanamide | |

| Huang et al. | Tunable Ag micromorphologies show high activities for electrochemical H2 evolution and CO2 electrochemical reduction | |

| Qi et al. | Electrochemical sensor for Cd2+ detection based on carbon fiber paper sequentially modified with CoMOF, AuNPs, and glutathione | |

| Schaltin et al. | Electrodeposition from cationic cuprous organic complexes: ionic liquids for high current density electroplating | |

| Mironov et al. | On Gold (I) Complexes and Anodic Gold Dissolution in Sulfite–Thiourea Solutions | |

| Pašti et al. | Adsorption of acetonitrile on platinum and its effects on oxygen reduction reaction in acidic aqueous solutions—combined theoretical and experimental study | |

| Jin et al. | Novel and green chemical compound of HAu (Cys) 2: toward a simple and sustainable electrolyte recipe for cyanide-free gold electrodeposition | |

| Huang et al. | Electrochemical study of Pt and Fe and electrodeposition of PtFe alloys from air-and water-stable room temperature ionic liquids | |

| Melamed et al. | Electroplating of pure aluminum from [hmim][TFSI]–AlCl3 room-temperature ionic liquid | |

| Yaqub et al. | Organic–Inorganic Hybrid Films of the Sulfate Dawson Polyoxometalate,[S2W18O62] 4–, and Polypyrrole for Iodate Electrocatalysis | |

| Jin et al. | Electrochemistry and coordination behaviors of hypoxanthine-Au (III) ion in the cyanide-free gold electrodeposition | |

| JP2017179514A5 (enExample) | ||

| Huang et al. | Voltammetric behavior of Pd (II) and Ni (II) ions and electrodeposition of PdNi bimetal in N-butyl-N-methylpyrrolidinium dicyanamide ionic liquid | |

| JP2017101285A (ja) | 還元反応用電極及びそれを用いた反応デバイス |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 17774736 Country of ref document: EP Kind code of ref document: A1 |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 17774736 Country of ref document: EP Kind code of ref document: A1 |