WO2017169575A1 - エネルギー吸収体 - Google Patents

エネルギー吸収体 Download PDFInfo

- Publication number

- WO2017169575A1 WO2017169575A1 PCT/JP2017/009095 JP2017009095W WO2017169575A1 WO 2017169575 A1 WO2017169575 A1 WO 2017169575A1 JP 2017009095 W JP2017009095 W JP 2017009095W WO 2017169575 A1 WO2017169575 A1 WO 2017169575A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- mass

- olefin

- energy absorber

- resin

- polyamide resin

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L23/00—Compositions of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Compositions of derivatives of such polymers

- C08L23/02—Compositions of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Compositions of derivatives of such polymers not modified by chemical after-treatment

- C08L23/10—Homopolymers or copolymers of propene

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R19/00—Wheel guards; Radiator guards, e.g. grilles; Obstruction removers; Fittings damping bouncing force in collisions

- B60R19/02—Bumpers, i.e. impact receiving or absorbing members for protecting vehicles or fending off blows from other vehicles or objects

- B60R19/18—Bumpers, i.e. impact receiving or absorbing members for protecting vehicles or fending off blows from other vehicles or objects characterised by the cross-section; Means within the bumper to absorb impact

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R21/00—Arrangements or fittings on vehicles for protecting or preventing injuries to occupants or pedestrians in case of accidents or other traffic risks

- B60R21/02—Occupant safety arrangements or fittings, e.g. crash pads

- B60R21/04—Padded linings for the vehicle interior ; Energy absorbing structures associated with padded or non-padded linings

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L23/00—Compositions of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Compositions of derivatives of such polymers

- C08L23/02—Compositions of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Compositions of derivatives of such polymers not modified by chemical after-treatment

- C08L23/10—Homopolymers or copolymers of propene

- C08L23/12—Polypropene

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L23/00—Compositions of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Compositions of derivatives of such polymers

- C08L23/02—Compositions of homopolymers or copolymers of unsaturated aliphatic hydrocarbons having only one carbon-to-carbon double bond; Compositions of derivatives of such polymers not modified by chemical after-treatment

- C08L23/18—Homopolymers or copolymers of hydrocarbons having four or more carbon atoms

- C08L23/20—Homopolymers or copolymers of hydrocarbons having four or more carbon atoms having four to nine carbon atoms

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L77/00—Compositions of polyamides obtained by reactions forming a carboxylic amide link in the main chain; Compositions of derivatives of such polymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L77/00—Compositions of polyamides obtained by reactions forming a carboxylic amide link in the main chain; Compositions of derivatives of such polymers

- C08L77/02—Polyamides derived from omega-amino carboxylic acids or from lactams thereof

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L77/00—Compositions of polyamides obtained by reactions forming a carboxylic amide link in the main chain; Compositions of derivatives of such polymers

- C08L77/06—Polyamides derived from polyamines and polycarboxylic acids

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16F—SPRINGS; SHOCK-ABSORBERS; MEANS FOR DAMPING VIBRATION

- F16F7/00—Vibration-dampers; Shock-absorbers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16F—SPRINGS; SHOCK-ABSORBERS; MEANS FOR DAMPING VIBRATION

- F16F7/00—Vibration-dampers; Shock-absorbers

- F16F7/12—Vibration-dampers; Shock-absorbers using plastic deformation of members

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F16—ENGINEERING ELEMENTS AND UNITS; GENERAL MEASURES FOR PRODUCING AND MAINTAINING EFFECTIVE FUNCTIONING OF MACHINES OR INSTALLATIONS; THERMAL INSULATION IN GENERAL

- F16F—SPRINGS; SHOCK-ABSORBERS; MEANS FOR DAMPING VIBRATION

- F16F7/00—Vibration-dampers; Shock-absorbers

- F16F7/12—Vibration-dampers; Shock-absorbers using plastic deformation of members

- F16F7/121—Vibration-dampers; Shock-absorbers using plastic deformation of members the members having a cellular, e.g. honeycomb, structure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R19/00—Wheel guards; Radiator guards, e.g. grilles; Obstruction removers; Fittings damping bouncing force in collisions

- B60R19/02—Bumpers, i.e. impact receiving or absorbing members for protecting vehicles or fending off blows from other vehicles or objects

- B60R19/18—Bumpers, i.e. impact receiving or absorbing members for protecting vehicles or fending off blows from other vehicles or objects characterised by the cross-section; Means within the bumper to absorb impact

- B60R2019/1806—Structural beams therefor, e.g. shock-absorbing

- B60R2019/1833—Structural beams therefor, e.g. shock-absorbing made of plastic material

- B60R2019/184—Blow moulded

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R19/00—Wheel guards; Radiator guards, e.g. grilles; Obstruction removers; Fittings damping bouncing force in collisions

- B60R19/02—Bumpers, i.e. impact receiving or absorbing members for protecting vehicles or fending off blows from other vehicles or objects

- B60R19/18—Bumpers, i.e. impact receiving or absorbing members for protecting vehicles or fending off blows from other vehicles or objects characterised by the cross-section; Means within the bumper to absorb impact

- B60R2019/186—Additional energy absorbing means supported on bumber beams, e.g. cellular structures or material

- B60R2019/1866—Cellular structures

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R21/00—Arrangements or fittings on vehicles for protecting or preventing injuries to occupants or pedestrians in case of accidents or other traffic risks

- B60R21/34—Protecting non-occupants of a vehicle, e.g. pedestrians

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L2205/00—Polymer mixtures characterised by other features

- C08L2205/03—Polymer mixtures characterised by other features containing three or more polymers in a blend

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L2205/00—Polymer mixtures characterised by other features

- C08L2205/08—Polymer mixtures characterised by other features containing additives to improve the compatibility between two polymers

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L2207/00—Properties characterising the ingredient of the composition

- C08L2207/02—Heterophasic composition

Definitions

- the present invention relates to an energy absorber excellent in impact resistance and impact energy absorption.

- an EA (Energy Absorption) material is disposed in a vehicle such as an automobile in order to absorb collision energy at the time of collision.

- an EA material or the like is known which is disposed in a door trim of an automobile and is intended to absorb collision energy at the time of a side collision.

- a hollow EA material produced by blow molding, an EA material having ribs produced by injection molding, and the like are disclosed (see Patent Document 1 and Patent Document 2).

- the present invention has been made in view of the above circumstances, and an object of the present invention is to provide an energy absorber excellent in impact resistance and impact energy absorption.

- the invention according to claim 1 is constituted by an olefin resin composition formed by blending an olefin resin, a polyamide resin, and an elastomer having a reactive group for the polyamide resin.

- the olefin resin composition has a continuous phase containing the olefin resin, and a polyamide resin dispersed phase dispersed in the continuous phase.

- the summary of the polyamide resin-based dispersed phase is that the elastomer is contained in the matrix phase containing the polyamide resin.

- the invention according to claim 2 is the invention according to claim 1, wherein the ratio of the polyamide resin-based dispersed phase is 90% when the total of the continuous phase and the polyamide resin-based dispersed phase is 100% by mass.

- the gist is that it is not more than mass%.

- the gist of the invention described in claim 3 is that, in the invention described in claim 1 or 2, the olefin resin is a polymer containing a structural unit derived from propylene.

- the invention according to claim 4 is the invention according to any one of claims 1 to 3, wherein the elastomer comprises an ⁇ -olefin comprising a structural unit derived from an ⁇ -olefin having 3 to 8 carbon atoms.

- the gist is that it is a copolymer.

- the invention according to claim 5 is summarized in that, in the invention according to any one of claims 1 to 4, the reactive group is an acid anhydride group or a carboxyl group.

- Invention of Claim 6 is equipped with the impact-absorbing skeleton which has the impact-absorbing skeleton along the surface direction in the direction which receives an impact load in the invention in any one of Claims 1 thru

- the gist of the invention according to claim 7 is that, in the invention according to claim 6, the shock absorbing skeleton has a cylindrical hollow portion formed by being surrounded by the shock absorbing wall.

- the invention according to claim 8 is summarized in that, in the invention according to claim 7, the shock absorbing skeleton has a honeycomb structure having a plurality of the hollow cylindrical portions.

- the gist of the invention according to claim 9 is the energy absorber for vehicles in the invention according to any one of claims 1 to 8.

- the energy absorber of the present invention is made of a specific olefin resin composition, it has excellent impact resistance and impact energy absorbability, and breakage such as cracks hardly occurs. Furthermore, it exhibits excellent spreadability (elongation performance) and repairability (repair performance) when subjected to an impact, and the shape is restored as long as it does not break, so that it has excellent durability. In addition, even when it is cracked due to excessive impact, ductile fracture occurs, so that the influence on the surroundings can be suppressed. Furthermore, since the energy absorber of this invention consists of an olefin resin composition which has the fluidity

- the shock absorbing skeleton when equipped with a shock absorbing skeleton having a shock absorbing wall whose surface direction is parallel to the direction of receiving the shock load, and when the shock absorbing wall is crushed when receiving the shock load, it is configured to absorb the shock

- the impact energy absorbability can be further improved, and breakage such as cracking can be further suppressed.

- the shock absorbing skeleton has a cylindrical hollow part formed by being surrounded by the shock absorbing wall, the impact energy absorption can be further improved, and breakage such as cracking can be further suppressed.

- the impact absorption skeleton has a honeycomb structure having a plurality of cylindrical hollow portions, impact energy absorption can be further improved, and breakage such as cracking can be further suppressed.

- the energy absorber of the present invention comprises an olefin resin (hereinafter referred to as “component (A)”), a polyamide resin (hereinafter referred to as “component (B)”), and an elastomer having a reactive group for the polyamide resin (hereinafter referred to as “component (A)”).

- component (A) olefin resin

- component (B) polyamide resin

- component (C) elastomer having a reactive group for the polyamide resin

- component (C) elastomer having a reactive group for the polyamide resin

- olefin resin composition having a specific structure that is, a continuous phase containing component (A)

- a polyamide resin-based dispersed phase dispersed in the polyamide resin-based dispersed phase by an olefin-based resin composition having a structure containing the component (C) in the matrix containing the component (B). It is a configured energy absorber.

- the olefin resin composition is preferably a thermoplastic resin composition.

- the continuous phase constituting the composition is a phase containing the component (A), and may be a phase composed of the component (A) and another resin (described later) according to the purpose, application, and the like.

- the structure of the said continuous phase is not specifically limited, Either a crosslinked structure and a non-crosslinked structure may be sufficient.

- the component (A) is not particularly limited, and conventionally known polyolefins can be used.

- polyolefins ethylene homopolymer, copolymer of ethylene and unsaturated hydrocarbon having 3 or more carbon atoms (hereinafter referred to as “ ⁇ -olefin”), ⁇ -olefin homopolymer, and ⁇ -olefin

- ⁇ -olefin ethylene homopolymer, copolymer of ethylene and unsaturated hydrocarbon having 3 or more carbon atoms

- ⁇ -olefin copolymer etc. which consist of the above can be used individually or in combination of 2 or more types.

- the ⁇ -olefin include propylene, 1-butene, 1-pentene, 1-hexene, 1-heptene, 3-methyl-1-butene and 4-methyl-1-pentene.

- the above component (A) is preferably an ⁇ -olefin homopolymer or copolymer, such as polypropylene, ethylene / propylene copolymer, ethylene / 1-butene copolymer, ethylene / propylene / 1-butene copolymer. Etc. are more preferable, and a polymer containing a structural unit derived from propylene is particularly preferable.

- the weight average molecular weight (polystyrene conversion) by the gel permeation chromatography (GPC) of the said component (A) is not specifically limited, From a viewpoint that the outstanding impact resistance and impact energy absorptivity are obtained, for example, 10,000 It is preferably from ⁇ 500,000, more preferably from 100,000 to 450,000, still more preferably from 200,000 to 400,000.

- this component (A) is an olefin resin which does not have an affinity with respect to a component (B), and has no reactive group which can react with respect to a component (B). In this respect, it is different from the polyolefin-based component as the component (C) described later.

- the continuous phase may be composed only of the component (A), or may further contain other resins as long as the continuous phase is formed together with the component (A). That is, a co-continuous phase may be formed.

- examples of the other resin include polyamide resin (component (B)).

- the said continuous phase contains a polyamide resin type

- the polyamide resin-based dispersed phase constituting the olefin-based resin composition is a phase containing a modified elastomer in the matrix phase containing the component (B).

- the parent phase may be a phase composed only of the component (B), or may be a phase composed of the component (B) and another resin (described later) in accordance with the purpose and application.

- the component (B) is not particularly limited as long as it has an amide bond (—NH—CO—) in the main chain, and conventionally known methods such as ring-opening polymerization of lactams, dehydration condensation of amino acids. Resins obtained by polycondensation of diamine and dicarboxylic acid, polycondensation of aminocarboxylic acid, and the like can be used alone or in combination of two or more.

- the said component (B) may use each raw material compound independently, and was obtained using two or more It may be.

- the lactams include ⁇ -caprolactam, undecane lactam, and ⁇ -lauryl lactam.

- the amino acid include aminocaproic acid, aminoundecanoic acid, aminododecanoic acid, and paraaminomethylbenzoic acid.

- diamine examples include ethylenediamine, 1,3-diaminopropane, 1,4-diaminobutane, 1,6-diaminohexane, 1,7-diaminoheptane, 1,8-diaminooctane, 1,9-diaminononane, 1, 10-diaminodecane, 1,11-diaminoundecane, 1,12-diaminododecane, 1,13-diaminotridecane, 1,14-diaminotetradecane, 1,15-diaminopentadecane, 1,16-diaminohexadecane, 1, 17-diaminoheptadecane, 1,18-diaminooctadecane, 1,19-diaminononadecane, 1,20-diaminoeicosane, 2-methyl-1,5-diaminopentane, 2-methyl-1

- dicarboxylic acid examples include oxalic acid, malonic acid, succinic acid, glutaric acid, adipic acid, pimelic acid, suberic acid, azelaic acid, sebacic acid, undecanedioic acid, dodecanedioic acid, brassic acid, tetradecanedioic acid, pentadecanedioic acid.

- Examples thereof include aliphatic dicarboxylic acids such as acid and octadecanedioic acid; alicyclic dicarboxylic acids such as cyclohexanedicarboxylic acid; aromatic dicarboxylic acids such as orthophthalic acid, terephthalic acid, isophthalic acid, and naphthalenedicarboxylic acid.

- component (B) examples include polyamide 6, polyamide 66, polyamide 610, polyamide 612, polyamide 614, polyamide 11, polyamide 12, polyamide 6T, polyamide 6I, polyamide 9T, polyamide M5T, polyamide 1010, and polyamide. 1012, polyamide 10T, polyamide MXD6, polyamide 6T / 66, polyamide 6T / 6I, polyamide 6T / 6I / 66, polyamide 6T / 2M-5T, polyamide 9T / 2M-8T, and the like.

- polyamide 11 is particularly preferable, and both the embodiment in which this polyamide 11 is used alone and the embodiment in which this polyamide 11 and another polyamide resin are used in combination are preferable. In the latter case, the upper limit of the content ratio of the other polyamide resin is preferably 40% by mass with respect to the entire component (B).

- the polyamide 11 is preferably a resin obtained using 11-aminoundecanoic acid or undecane lactam as a monomer. Since 11-aminoundecanoic acid can be obtained from castor oil, polyamide 11 obtained using this 11-aminoundecanoic acid is desirable from the viewpoint of environmental protection (particularly from the viewpoint of carbon neutral).

- the weight average molecular weight (polystyrene conversion) by the gel permeation chromatography (GPC) of the said component (B) is not specifically limited, From a viewpoint that the outstanding impact resistance and impact energy absorptivity are obtained, for example, 5,000 It is preferably from ⁇ 100,000, more preferably from 7,500 to 50,000, and even more preferably from 10,000 to 50,000.

- the mother phase may further contain another resin as described above.

- the other resin is preferably a resin having compatibility with the component (B).

- the polyamide resin-based dispersed phase is preferably contained in at least the component (A) constituting the continuous phase.

- the component (C) is an elastomer having a reactive group for the polyamide resin. That is, the elastomer is provided with a reactive group capable of reacting with the polyamide resin.

- This component (C) is preferably a component having affinity for the olefin resin. That is, it is preferably a component having a compatibilizing effect on the polyamide resin and the olefin resin. In other words, it is preferably a compatibilizer between a polyamide resin and a polyolefin resin.

- the component (C) according to the present invention is particularly preferably an elastomer having a reactive group for the polyamide resin in the side chain or terminal of the molecule. The amount of modification is not particularly limited.

- the number of reactive groups contained in one molecule of the modified elastomer is preferably 1 or more, more preferably 2 to 50, still more preferably 3 to 30, and particularly preferably. 5-20.

- the said component (C) can be used individually or in combination of 2 or more types.

- Examples of the elastomer before modification include olefin elastomer and styrene elastomer.

- an olefin elastomer is preferable.

- the olefin elastomer is preferably an ⁇ -olefin copolymer containing a structural unit derived from an ⁇ -olefin having 3 to 8 carbon atoms, such as an ethylene / ⁇ -olefin copolymer or ⁇ -olefin.

- It can be a copolymer, an ⁇ -olefin / non-conjugated diene copolymer, or an ethylene / ⁇ -olefin / non-conjugated diene copolymer.

- ethylene / ⁇ -olefin copolymers, ⁇ -olefin copolymers, and ethylene / ⁇ -olefin / non-conjugated diene copolymers are particularly preferred.

- Non-conjugated dienes include linear acyclic diene compounds such as 1,4-pentadiene, 1,4-hexadiene, 1,5-hexadiene, 1,6-hexadiene; 5-methyl-1,4-hexadiene 3,7-dimethyl-1,6-octadiene, 5,7-dimethylocta-1,6-diene, 3,7-dimethyl-1,7-octadiene, 7-methylocta-1,6-diene, dihydromil Branched acyclic diene compounds such as sen; tetrahydroindene, methyltetrahydroindene, dicyclopentadiene, bicyclo [2.2.1] -hepta-2,5-diene, 5-methylene-2-norbornene, 5-ethylidene -2-norbornene, 5-propenyl-2-norbornene, 5-isopropylidene-2-norborn

- the olefin elastomer examples include an ethylene / propylene copolymer, an ethylene / 1-butene copolymer, an ethylene / 1-pentene copolymer, an ethylene / 1-hexene copolymer, and an ethylene / 1-octene copolymer.

- propylene / 1-butene copolymer, propylene / 1-pentene copolymer, propylene / 1-hexene copolymer, and propylene / 1-octene copolymer examples include an ethylene / propylene copolymer, an ethylene / 1-butene copolymer, an ethylene / 1-pentene copolymer, an ethylene / 1-hexene copolymer, and an ethylene / 1-octene copolymer.

- styrene-type elastomer the block copolymer of an aromatic vinyl compound and a conjugated diene compound, and its hydrogenated material are mentioned.

- aromatic vinyl compound include alkyl styrenes such as styrene, ⁇ -methyl styrene, p-methyl styrene, and p-tert-butyl styrene; p-methoxy styrene, vinyl naphthalene, and the like.

- conjugated diene compound examples include butadiene, isoprene, 1,3-pentadiene, methylpentadiene, phenylbutadiene, 3,4-dimethyl-1,3-hexadiene, 4,5-diethyl-1,3-octadiene, and the like. Can be mentioned.

- styrene elastomers include styrene / butadiene / styrene copolymer (SBS), styrene / isoprene / styrene copolymer (SIS), styrene / ethylene / butylene / styrene copolymer (SEBS), styrene / ethylene. / Propylene / styrene copolymer (SEPS).

- SBS styrene / butadiene / styrene copolymer

- SIS isoprene / styrene copolymer

- SEBS styrene / ethylene / butylene / styrene copolymer

- SEPS Propylene / styrene copolymer

- the weight average molecular weight (in terms of polystyrene) of the elastomer by gel permeation chromatography (GPC) is not particularly limited, but from the viewpoint of obtaining excellent impact resistance and impact energy absorption, for example, 10,000 to 500, It is preferably 000, more preferably 20,000 to 500,000, still more preferably 30,000 to 300,000.

- Examples of the reactive group for the polyamide resin include an acid anhydride group, a carboxyl group, an epoxy group, an oxazoline group, and an isocyanate group.

- the method for imparting these reactive groups to the elastomer is not particularly limited, and a known method can be used. Among the above-mentioned reactive groups, an acid anhydride group and a carboxyl group are preferable, and an acid anhydride group is particularly preferable.

- acid anhydride for introducing an acid anhydride group

- a monomer (acid anhydride) for introducing an acid anhydride group for example, maleic anhydride, phthalic anhydride, itaconic anhydride, succinic anhydride, glutaric anhydride, adipic anhydride, citraconic anhydride

- the acid anhydride include tetrahydrophthalic anhydride and butenyl succinic anhydride.

- maleic anhydride, phthalic anhydride, and itaconic anhydride are preferable, and maleic anhydride is particularly preferable.

- Examples of the monomer (carboxylic acid) for introducing a carboxyl group include acrylic acid, methacrylic acid, maleic acid, fumaric acid, itaconic acid, citraconic acid and the like.

- these monomers may be used individually by 1 type, respectively, and may be used in combination of 2 or more type.

- component (C) examples include an acid-modified elastomer to which an acid anhydride group has been added, a carboxylic acid-modified elastomer to which a carboxyl group has been added, an epoxy-modified elastomer to which an epoxy group has been added, and an oxazoline group. And oxazoline-modified elastomers and isocyanate-modified elastomers to which isocyanate groups have been added.

- an elastomer modified with an acid anhydride and an elastomer modified with a carboxylic acid are preferable, and an elastomer modified with maleic anhydride is particularly preferable.

- maleic anhydride modified ethylene / propylene copolymer maleic anhydride modified ethylene / 1-butene copolymer, maleic anhydride modified ethylene / 1-hexene copolymer and maleic anhydride modified ethylene / 1 -Elastomers modified with maleic anhydride, such as octene copolymers, are preferred.

- the polyamide-based resin dispersed phase may contain only the component (C) in the matrix containing the component (B), and may further contain other elastomers.

- elastomers non-modified olefin elastomers can be used.

- the shape and size of the other elastomer in the case where the component (C) contained in the matrix phase of the polyamide resin dispersed phase and other elastomer are included are not particularly limited.

- the average value of the diameter of the phase (finely dispersed phase) containing the modified elastomer (C) is not particularly limited, but is, for example, 5 to 1000 nm from the viewpoint of obtaining excellent impact resistance and impact energy absorption.

- the thickness is preferably 8 to 600 nm, more preferably 10 to 400 nm, and particularly preferably 15 to 350 nm.

- this average value is an average of 100 granular materials (component (C) and component (C) and the polyamide resin in the randomly selected polyamide resin dispersed phase in an image obtained using an electron microscope. It is the average value of the diameters measured for the phase consisting of the reactants.

- the shape of the said polyamide-type resin dispersion phase can be made into fixed shapes, such as a spherical form and an ellipsoidal shape, or these deformations (indeterminate form), and you may have a recessed part or a convex part on the surface.

- the upper limit of the maximum diameter of the polyamide resin dispersed phase is not particularly limited, but is preferably 20000 nm, more preferably 10,000 nm, and still more preferably from the viewpoint of obtaining excellent impact resistance and impact energy absorption. Is 8000 nm, particularly preferably 4000 nm. However, the lower limit is usually 5 nm (particularly 10 nm, further 15 nm, especially 50 nm).

- the maximum diameter can be a measured value obtained from an electron microscope image.

- the multiple polyamide resin dispersed phases contained in the olefin-based resin composition may be substantially the same in shape and size, or a combination of two or more types having the same maximum diameter. Alternatively, the size may vary within the above range.

- the olefin-based resin composition includes a continuous phase containing the component (A) and a polyamide resin-based dispersed phase dispersed in the continuous phase, and the polyamide resin-based dispersed phase is directly in the continuous phase. It may be included, or may be included in a state having an interface phase at least at a part of the interface between the continuous phase and the polyamide resin-based dispersed phase.

- the interfacial phase may include a modified elastomer and a reaction product of these and a resin component such as component (B).

- the thickness of the interface phase is not particularly limited.

- Additives that can be contained in the continuous phase or the polyamide resin dispersed phase include nucleating agents, antioxidants, thermal stabilizers, weathering agents, light stabilizers, plasticizers, ultraviolet absorbers, antistatic agents, Flame retardants, slip agents, anti-blocking agents, anti-fogging agents, lubricants, pigments, dyes, dispersants, copper damage prevention agents, neutralizing agents, anti-foaming agents, weld strength improvers, natural oils, synthetic oils, waxes, etc. Can be mentioned.

- these additives can be used individually or in combination of 2 or more types.

- nucleating agent and reinforcing filler examples include silicates such as talc, silica, clay, montmorillonite and kaolin; carbonates such as calcium carbonate, lithium carbonate and magnesium carbonate; metal oxides such as alumina, titanium oxide and zinc oxide.

- Metals such as aluminum, iron, silver and copper; hydroxides such as aluminum hydroxide and magnesium hydroxide; sulfides such as barium sulfate; carbides such as charcoal and bamboo charcoal; titanates such as potassium titanate and barium titanate Celluloses such as cellulose microfibril and cellulose acetate; resin fibers such as polyethylene terephthalate fiber, nylon fiber, polyethylene naphthalate fiber, aramid fiber, vinylon fiber, polyarylate fiber; carbons such as fullerene and carbon nanotube .

- Examples of the antioxidant include phenol compounds, organic phosphite compounds, thioether compounds, and the like.

- Examples of the heat stabilizer include hindered amine compounds.

- Examples of the ultraviolet absorber include benzophenone compounds, benzotriazole compounds, and benzoate compounds.

- Examples of the antistatic agent include nonionic compounds, cationic compounds, and anionic compounds.

- Examples of the flame retardant include halogen compounds, phosphorus compounds (nitrogen-containing phosphate compounds, phosphate esters, etc.), nitrogen compounds (guanidine, triazine, melamine, or derivatives thereof), inorganic compounds (metal hydroxides) Etc.), boron compounds, silicone compounds, sulfur compounds, red phosphorus compounds and the like.

- Examples of the flame retardant aid include antimony compounds, zinc compounds, bismuth compounds, magnesium hydroxide, and clay silicates.

- the proportion of the polyamide resin dispersed phase is 90% by mass or less when the total of the continuous phase and the polyamide resin dispersed phase is 100% by mass ( In particular, it can be 2 to 90% by mass).

- This content is preferably 5 to 85% by mass, more preferably 10 to 83% by mass, even more preferably 15 to 80% by mass, still more preferably 20 to 78% by mass, particularly preferably 25 to 75% by mass, 30 to 73% by mass is more particularly preferable, and 35 to 70% by mass is particularly preferable.

- the ratio of the continuous phase can be 10% by mass or more (particularly 10 to 98% by mass), preferably 15 to 95% by mass, more preferably 17 to 90% by mass, and further 20 to 85% by mass.

- 22 to 80% by mass is more preferable, 25 to 75% by mass is particularly preferable, 27 to 70% by mass is more particularly preferable, and 30 to 65% by mass is particularly preferable.

- the content ratio of the polyamide resin-based dispersed phase is within this range, an energy absorber excellent in impact resistance and impact energy absorption can be obtained. In particular, the performance balance of impact resistance, impact energy absorption and moldability can be excellent.

- the content ratio of the component (C) contained in the polyamide resin dispersed phase is such that the component (B) and the component (C) contained in the polyamide resin dispersed phase. ) And 100% by mass, it can be 20 to 90% by mass.

- This ratio is preferably 22 to 88% by mass, more preferably 25 to 86% by mass, still more preferably 27 to 75% by mass, still more preferably 29 to 70% by mass, particularly preferably 32 to 66% by mass, 36 ⁇ 60% by weight is more particularly preferred.

- the content of the component (B) contained in the polyamide-based resin dispersed phase can be 10 to 80% by mass, preferably 12 to 78% by mass, more preferably 14 to 75% by mass, and 25 to 73%. % By mass is more preferable, 30 to 71% by mass is still more preferable, 34 to 68% by mass is particularly preferable, and 40 to 64% by mass is more particularly preferable.

- the components (B) and (C) can be further dispersed as a polyamide-based resin dispersed phase in the continuous phase.

- the specific gravity of the energy absorber which consists of an olefin resin composition can be reduced by reducing the usage-amount of a component (B) with large specific gravity.

- a component (B) with large specific gravity.

- the energy absorber which is excellent in an impact-resistant characteristic and impact energy absorption property can be obtained.

- the content of the component (B) can be reduced, so that the gloss of the surface of the energy absorber made of the olefin resin composition is suppressed and the gloss is low. Appearance can be obtained. Therefore, it can exhibit excellent design properties and can be applied to directly visible exterior materials and interior materials.

- the content ratio of the component (B) when the total of the component (A) and the component (B) is 100% by mass is 1.5 to 88. It can be made into the mass%. This proportion is preferably 3 to 75% by mass, more preferably 5 to 70% by mass, still more preferably 10 to 65% by mass, still more preferably 15 to 60% by mass, particularly preferably 18 to 55% by mass, Is more particularly preferably from 50 to 50% by weight, particularly preferably from 25 to 45% by weight.

- the content of the component (A) can be 12 to 98.5% by mass, preferably 25 to 97% by mass, more preferably 30 to 95% by mass, still more preferably 35 to 90% by mass, More preferably, it is 40 to 85% by mass, particularly preferably 45 to 82% by mass, more particularly preferably 50 to 80% by mass, and particularly preferably 55 to 75% by mass.

- the content ratio of the component (B) is within this range, an energy absorber excellent in impact resistance and impact energy absorption can be obtained. In particular, the performance balance of impact resistance, impact energy absorption and moldability can be excellent.

- the content ratio of the component (A) when the total of the component (A), the component (B) and the component (C) is 100% by mass It can be 2 to 90% by mass.

- This content is preferably 5 to 85% by mass, more preferably 10 to 83% by mass, even more preferably 15 to 80% by mass, still more preferably 20 to 78% by mass, particularly preferably 25 to 75% by mass, 30 to 73% by mass is more particularly preferable, and 35 to 70% by mass is particularly preferable.

- the content ratio of the component (A) is within this range, excellent impact resistance and impact energy absorption are obtained. In particular, the performance balance of impact resistance, impact energy absorption and moldability can be excellent.

- the content ratio of the component (B) when the total of the component (A), the component (B) and the component (C) is 100% by mass can be 1 to 75% by mass.

- This proportion is preferably 3 to 70% by mass, more preferably 5 to 65% by mass, further preferably 7 to 60% by mass, still more preferably 10 to 57% by mass, particularly preferably 13 to 55% by mass, Is more particularly preferably from 50 to 50% by weight, particularly preferably from 20 to 45% by weight.

- the content ratio of the component (B) is within this range, excellent impact resistance and impact energy absorption can be obtained. In particular, the performance balance of impact resistance, impact energy absorption and moldability can be excellent.

- the content ratio of the component (C) when the total of the component (A), the component (B) and the component (C) is 100% by mass It can be 1 to 60% by mass. This ratio is preferably 3 to 55% by mass, more preferably 5 to 50% by mass, still more preferably 7 to 45% by mass, still more preferably 10 to 43% by mass, particularly preferably 10 to 40% by mass, -37% by weight is more particularly preferred, and 15-35% by weight is particularly preferred.

- the content ratio of the component (C) is within this range, excellent impact resistance and impact energy absorption can be obtained. In particular, the performance balance of impact resistance, impact energy absorption and moldability can be excellent.

- the energy absorber of this invention may be comprised only from the said olefin resin composition, and may be comprised from the mixture of the said olefin resin composition and another structural material.

- the other constituent materials include other olefin resins, other thermoplastic resins (excluding resins contained in the olefin resin composition and other olefin resins), reinforcing fillers, flame retardants, and flame retardant aids. , Fillers, colorants, antibacterial agents, antistatic agents and the like. These other constituent materials can be used alone or in combination of two or more.

- olefin resin well-known polyolefin can be used. Specifically, for example, ethylene homopolymer, ethylene and ⁇ -olefin (for example, propylene, 1-butene, 1-pentene, 1-hexene, 1-heptene, 3-methyl-1-butene, 4-methyl- 1-pentene, etc.), ⁇ -olefin homopolymers, copolymers composed of two or more ⁇ -olefins, and the like. These other olefin resins can be used alone or in combination of two or more. Specific examples of the olefin resin include polypropylene.

- the weight average molecular weight (in terms of polystyrene) of the other olefin resin by gel permeation chromatography (GPC) is not particularly limited, but is preferably, for example, 10,000 to 500,000, more preferably 100,000 to 450,000, more preferably 200,000 to 400,000.

- the content of the olefin resin composition is 1 to 4 when the total of the olefin resin composition and the other olefin resin is 100% by mass. It can be 99 mass%. In particular, this proportion is 1 to 99% by mass, further 5 to 95% by mass, further 10 to 90% by mass, further 15 to 85% by mass, further 20 to 80% by mass, further 30 to 70% by mass. Further, it can be 40 to 60% by mass.

- the content of each of the components (A) to (C) It is a value obtained by multiplying the content (%) of the olefin resin composition.

- thermoplastic resins examples include polyester resins (polybutylene terephthalate, polyethylene terephthalate, polycarbonate, polybutylene succinate, polyethylene succinate, polylactic acid) and the like.

- the reinforcing filler examples include resin fibers such as glass fibers, carbon fibers, and organic fibers (for example, polyethylene terephthalate fibers, nylon fibers, aramid fibers (Kevlar, etc.)).

- resin fibers such as glass fibers, carbon fibers, and organic fibers (for example, polyethylene terephthalate fibers, nylon fibers, aramid fibers (Kevlar, etc.)).

- the resin composition (olefin resin composition or mixture of olefin resin composition and other constituent materials) constituting the energy absorber of the present invention has a bar flow length measured by the following method. , 300 mm or more (particularly 350 to 750 mm, further 390 to 700 mm, especially 400 to 650 mm).

- this value is within the above range, since it has a better formability (moldability), an energy absorber having a finer shape can be obtained by injection molding or the like.

- the bar flow length is determined by connecting a bar flow mold (a mold having an angular spiral cavity with an inlet diameter of 10 mm, a width of 20 mm and a thickness of 2 mm) to an injection molding machine, a cylinder temperature of 190 ° C., and a mold temperature of 60 Molding obtained by injection molding under the conditions of °C, injection pressure 150 MPa, injection speed 25-200 mm / sec, weighing value 60 (retracting the screw 60 mm and securing the storage area of 60 mm for the injection object in the cylinder) It is the length of the body.

- a bar flow mold a mold having an angular spiral cavity with an inlet diameter of 10 mm, a width of 20 mm and a thickness of 2 mm

- the resin composition (olefin-based resin composition or a mixture of the olefin resin composition and other constituent materials) constituting the energy absorber of the present invention has a stress at break measured by the following tensile test. 10 MPa or more (especially 12 to 50 MPa, further 15 to 45 MPa, especially 18 to 40 MPa), and elongation at break is 70% or more (especially 80 to 500%, more preferably 100 to 400%, especially 150 to 350%). ). When these are in the said range, it can be set as the energy absorber which is excellent by impact energy absorptivity and is hard to produce destruction, such as a crack.

- the energy absorber of the present invention may be a solid molded body (solid molded body) or a foam molded body.

- a solid molded body is preferable from the viewpoint of obtaining excellent impact absorbability.

- this energy absorber can be manufactured by the method according to the structure, the use, etc.

- the raw material composition is made by injection molding, extrusion molding (sheet extrusion, profile extrusion), T-die molding, blow molding, injection blow molding, inflation molding, hollow molding, vacuum molding, It can be produced by subjecting it to compression molding, press molding, stamping mold molding, transfer molding and the like. These may use only 1 type and may use 2 or more types together.

- an energy absorber when making an energy absorber into a foaming molding, it can manufacture by making a raw material composition carry out chemical foaming or physical foaming.

- known methods such as injection foam molding, press foam molding, extrusion foam molding, stampable foam molding, and heat foam molding can be applied. These may use only 1 type and may use 2 or more types together.

- the olefin resin composition or a mixture of the olefin resin composition and other constituent materials itself may be used as the raw material composition, or a melt containing an olefin resin, a polyamide resin, and a modified elastomer. A kneaded product may be used.

- thermoplastic resin composition containing a melt-kneaded product of an olefin resin, a polyamide resin, and a modified elastomer can be used. Specifically, a first melt-kneading step of melt-kneading a first raw material containing a polyamide resin and a modified elastomer, and a second melt-kneading step of melt-kneading a second raw material containing the obtained first kneaded product and olefin resin.

- melt-kneaded material that is, a thermoplastic resin composition containing a melt-kneaded product of a polyamide resin and a modified elastomer and an olefin resin.

- a thermoplastic resin composition containing a melt-kneaded product of a polyamide resin and a modified elastomer and an olefin resin.

- any of the melt kneading can be performed using a kneading apparatus such as an extruder (single screw extruder, twin screw kneading extruder, etc.), a kneader, a mixer (high speed fluid mixer, paddle mixer, ribbon mixer, etc.). .

- extruder single screw extruder, twin screw kneading extruder, etc.

- a mixer high speed fluid mixer, paddle mixer, ribbon mixer, etc.

- These apparatuses may use only 1 type and may use 2 or more types together. Moreover, when using 2 or more types, you may drive

- the polyamide resin and the modified elastomer may be melt-kneaded all at once, or may be performed while either one is divided and added.

- the kneading temperature at this time is preferably 190 to 350 ° C., more preferably 200 to 330 ° C., still more preferably 205 to 310 ° C.

- the melt-kneading of the first kneaded product and the olefin resin may be performed all at once, or may be performed while either one is divided and added.

- the kneading temperature at this time is preferably 190 to 350 ° C., more preferably 200 to 300 ° C., and still more preferably 205 to 260 ° C.

- the first kneaded product and the second kneaded product may be in a form solidified by pelletization or the like, or may be a melt.

- the olefin resin an ⁇ -olefin homopolymer or copolymer may be used as it is, and polypropylene and ethylene / propylene copolymers are preferable as the raw material resin containing the olefin resin.

- a mixed resin made of polypropylene, polyethylene and ethylene / propylene rubber (non-modified olefin elastomer) known as “type polypropylene” may be used.

- the modified elastomer is preferably an elastomer provided with a reactive group capable of reacting with a polyamide resin, and those described above are applied.

- ⁇ -olefin copolymer “Tuffmer Series” (trade name) manufactured by Mitsui Chemicals, Inc., “AMPLIFY Series” (trade name) manufactured by Dow Chemical Can do.

- the proportions of the olefin resin, the polyamide resin and the modified elastomer used as the main components are as follows, in the order of the olefin resin, the polyamide resin and the modified elastomer when the total of these is 100% by mass. It can be 2 to 90% by mass, 1 to 75% by mass, and 1 to 60% by mass, preferably 5 to 85% by mass, 3 to 70% by mass, and 3 to 55% by mass. -65% by mass and 5-50% by mass are more preferable, 15-80% by mass, 7-60% by mass and 7-45% by mass are more preferable, 20-78% by mass, 10-57% by mass and 10-43%.

- the performance balance of impact resistance, impact energy absorption and moldability can be excellent.

- the performance of the above polyamide resin may vary depending on the type thereof, and preferred amounts for obtaining the effects of the present invention are shown below.

- the amount used is preferably 1 to 50% by mass, more preferably 1 to 40% by mass when the total of the olefin resin, polyamide resin and modified elastomer is 100% by mass. %, More preferably 10 to 35% by mass.

- polyamide 610 is used as the polyamide resin, the amount used is preferably 1 to 40% by mass, more preferably 5 to 40% by mass when the total of the olefin resin, polyamide resin and modified elastomer is 100% by mass. %, More preferably 10 to 40% by mass.

- the amount used is preferably 1 to 55% by mass, more preferably 10 to 55% by mass when the total of the olefin resin, polyamide resin and modified elastomer is 100% by mass. %, More preferably 15 to 55% by mass.

- the amount used is preferably 1 to 35% by mass, more preferably 5 to 35% by mass when the total of the olefin resin, polyamide resin and modified elastomer is 100% by mass. %, More preferably 10 to 35% by mass.

- the amount used is preferably 1 to 55% by mass, more preferably 5 to 55% by mass when the total of the olefin resin, polyamide resin and modified elastomer is 100% by mass. %, More preferably 10 to 55% by mass.

- the amount used is preferably 1 to 45 mass%, more preferably 5 to 45 mass% when the total of the olefin resin, polyamide resin and modified elastomer is 100 mass%. %, More preferably 10 to 45% by mass.

- the amount used is preferably 1 to 40% by mass, more preferably 5 to 40% by mass when the total of the olefin resin, polyamide resin and modified elastomer is 100% by mass. More preferably, it is 10 to 40% by mass.

- the form of the energy absorber of the present invention is not particularly limited, and can be made in accordance with the purpose, application, and the like. Hereinafter, specific embodiments will be described.

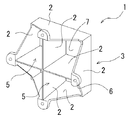

- the energy absorber (1) includes an impact absorbing skeleton (3) having an impact absorbing wall (2) whose surface direction extends along the direction of receiving an impact load.

- the shock absorbing wall (2) is crushed to absorb the shock (see FIGS. 1 and 2).

- impact energy absorptivity can be improved more and destruction, such as a crack, can be suppressed more.

- the surface of the shock absorbing wall (2) is arranged so that its surface direction is along the direction of receiving the impact load [that is, the surface of the shock absorbing wall (2) is substantially the same as the direction of receiving the impact load. It is arranged in parallel] and absorbs impact energy by being crushed along the direction of impact load.

- the “plane direction” means a direction orthogonal to the thickness direction of the shock absorbing wall (2).

- the term “substantially parallel” is not limited to being completely parallel, but the angle between the two is within a range of ⁇ 20 ° (preferably ⁇ 15 °, more preferably ⁇ 10 °). It is a concept that includes the case of leaning to

- the thickness of the shock absorbing wall (2) is not particularly limited and can be appropriately adjusted according to the purpose and application. For example, the thickness can be 10 mm or less (particularly 1 to 8 mm, more preferably 2 to 4 mm).

- the shock absorbing skeleton (3) may have at least the shock absorbing wall (2).

- the shock absorbing skeleton (3) can have a cylindrical hollow portion (5) formed by being surrounded by the shock absorbing wall (2).

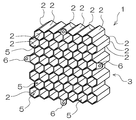

- the cross-sectional shape of the hollow part (5) is not limited to a quadrangle (see FIG. 1), but may be another polygonal shape such as a circular shape, an elliptical shape, a triangle or a hexagon (see FIG. 2).

- the number of hollow portions (5) is not particularly limited. In particular, it can be configured to have a plurality of hollow portions (5) (see FIG. 2).

- honeycomb structure As the impact-absorbing skeleton (3) in which a plurality of hollow portions (5) are formed, a honeycomb structure is particularly exemplified (see FIG. 2).

- the shock absorbing skeleton (3) is in the form of a honeycomb structure, the impact energy absorbability can be further improved, and breakage such as cracking can be further suppressed.

- the “honeycomb structure” is not limited to the case where the cross-sectional shape of the hollow portion (5) is a regular hexagon, but is a single polygon (see FIG. 1) or two or more polygons. This is a concept including a combination of the above.

- the shock absorbing skeleton (3) may be provided with an attachment site (6), another wall (7) (see FIGS. 1 and 2), a reinforcing rib, and the like.

- the energy absorber (1) may be composed of only the shock absorbing skeleton (3) as shown in FIGS. 1 and 2, or the shock absorbing skeleton (3) as in the embodiment described later.

- other constituent members may be provided.

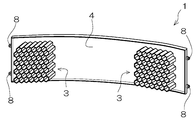

- an exterior part (4) and one or more shock absorbing skeletons (3) connected to the exterior part (4) are provided. What is provided can be mentioned (see FIG. 3). The above description can be applied to the shock absorbing skeleton (3) as it is.

- the exterior part (4) is not particularly limited as long as it is connected to the shock absorbing skeleton (3), and the shape thereof is appropriately adjusted according to the shape of the location where the energy absorber (1) is disposed. . Moreover, an attachment site

- the energy absorber (1) according to these embodiments can be integrally formed by using the above-described raw material composition.

- the energy absorber of the present invention is excellent in impact resistance and impact energy absorption, breakage such as cracking is unlikely to occur. Furthermore, it exhibits excellent spreadability (elongation performance) and repairability (repair performance) when subjected to an impact, and the shape is restored as long as it does not break, so that it has excellent durability. Moreover, even if it is cracked due to excessive impact, it is highly safe because it is ductile. Therefore, parts for vehicles (for automobiles, bicycles), parts for ships, parts for aviation, industrial materials, office parts, daily necessities, toys, sports equipment, building materials parts, structures, medical supplies, parts for agriculture, forestry and fisheries, etc. It is suitable for. For example, in a vehicle part, a ship part, or an aircraft part, it is suitable as an exterior part, an interior part, or a base material thereof.

- automotive parts include exterior parts such as roof rails, fenders, garnishes, bumpers, door panels, roof panels, hood panels, trunk lids, spoilers, cowls; door trims, pockets, armrests, decorative panels, ornaments Panel, energy absorber (impact absorber) [specifically, for example, bumper energy absorber, pedestrian protection energy absorber, pedestrian protection system, pedestrian protection system, etc.

- Pedestrian-protection beam frontal collision protection system

- Frontal collision protection system Front end Pedestrian-protection System, Crash Can, Instrument Panel Support (Fascia Supports), Corner Impact Protection (Corner Impact Protection System), Shock Absorber (Energy Absorber System) ), Crash box (Crash Box), honeycomb structure impact absorber (Honeycomb Structure Energy Absorber), etc.

- speaker grille quarter trim, pillar garnish, cowl side garnish, shield, back of back Board, dynamic damper, rhino Airbag peripheral parts, instrument panel, airbag peripheral parts, center console, overhead console, sun visor, package tray, high-mount stop lamp cover, seat side garnish, assist grip, safety belt parts, interior parts such as lamp housing, Electric parts such as a cleaner case and a filter case are listed.

- Industrial materials include transport containers, trays, trolleys, pylons, center poles, and construction equipment.

- household goods include food trays, helmets, shoes, book stands, tableware, and cleaning tools.

- sports equipment include protectors (baseball, soccer, motor sports), outdoor equipment, and mountaineering equipment.

- Examples of building material parts include heat insulating materials.

- Examples of the structure include road signs.

- Examples of medical supplies include a mouthpiece, a medical device, and a pharmaceutical container.

- Agricultural, forestry and fishery-related parts include floats, flower pots (planters), aquaculture equipment, and the like.

- the energy absorber of the present invention is preferably used as an energy absorber (EA material) in automobile-related parts.

- EA material energy absorber

- it can be suitably used as an EA material that absorbs impact energy by crushing at least a part of the absorber by impact load at the time of collision (front collision, rear collision, side collision).

- Example 1 Production of molded article for evaluation ⁇ Example 1> Olefin-based resin composition containing 55% by mass of olefin, 25% by mass of polyamide resin, and 20% by mass of modified elastomer when the entire olefin-based resin composition (energy absorber) is 100% by mass.

- a molded article for evaluation of Example 1 constituted by the following steps was prepared by the following procedure.

- thermoplastic resin composition of Example 1 was melt kneaded under the conditions of ° C., extrusion speed of 150 kg / hour and screw rotation speed of 500 revolutions / minute, and further cut out the extruded thermoplastic resin composition using a pelletizer. A pellet was prepared. Thereafter, the obtained pellets of the thermoplastic resin composition of Example 1 were put into a hopper of an injection molding machine (manufactured by Nissei Plastic Industry Co., Ltd., 40 ton injection molding machine), a set temperature of 210 ° C., and a mold temperature of 40 A molded article for evaluation (test piece for measuring physical properties) used for each measurement and evaluation described below under injection conditions at 0 ° C. was injection molded.

- an injection molding machine manufactured by Nissei Plastic Industry Co., Ltd., 40 ton injection molding machine

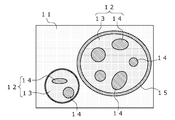

- the phase structure of the olefin resin composition which comprises this molded object was confirmed as follows. A sample cut out from the molded article for evaluation was embedded in a resin, then trimmed and cross-sectioned with an ultramicrotome equipped with a diamond knife, and vapor-stained with a metal oxide. The phase structure was confirmed by observing an ultrathin section sample collected from the obtained cross-section after staining using a transmission electron microscope (TEM, manufactured by Hitachi High-Technologies Corporation, model “HT7700”). As a result, as shown in the schematic diagram of FIG.

- TEM transmission electron microscope

- the fine dispersed phase 14 containing the modified elastomer dispersed in the matrix phase 13 containing the polyamide resin in the system dispersed phase 12 exists between the continuous phase 11 and the polyamide resin dispersed phase 12, and contains the modified elastomer.

- Interfacial phase 15 was observed.

- Example 2 In the same procedure as in Example 1 above, when the total amount of the olefin resin composition (energy absorber) is 100% by mass, the olefin is 30% by mass, the polyamide resin is 60% by mass, and the modified elastomer is 10%.

- Example 2 the phase structure of the olefin resin composition which comprises a molded object was confirmed similarly to the above-mentioned Example 1.

- a co-continuous phase containing an olefin resin and a polyamide a polyamide resin-based dispersed phase containing a polyamide resin and a modified elastomer dispersed in a continuous phase comprising the olefin resin, and a polyamide resin in the polyamide resin-based dispersed phase

- This bending elastic modulus is measured at a speed of 2 mm from an action point (curvature radius 5 mm) arranged at the center between the fulcrums while supporting each test piece at two fulcrums (curvature radius 5 mm) with a distance (L) between the fulcrums of 64 mm.

- the measurement was performed by applying a load at / min.

- the mold 9) is connected, the cylinder temperature is 190 ° C., the mold temperature is 60 ° C., the injection pressure is 150 MPa, the injection speed is 25 to 200 mm / sec (25 mm / sec, 50 mm / sec, 100 mm / sec, 200 mm / sec), and the measurement value is 60 ( The length of the molded body obtained by injection molding under the conditions of retreating the screw by 60 mm and ensuring the storage area of the object to be injected for 60 mm in the cylinder was measured as the bar flow length.

- the resin compositions in Examples 1 and 2 have lower stress until the start of plastic deformation than Comparative Examples 1 to 4, and It was confirmed that the elongation until breakage was high, and when it received an impact load, it exhibited excellent impact absorbability and reduced the reaction force toward the impact load. From the above, it is considered that the resin composition of this example can provide an energy absorber excellent in impact resistance and impact energy absorption.

- the elongation at break is high, it is considered that an energy absorber that exhibits good spreadability (elongation performance) and repairability (repair performance) when subjected to an impact and hardly breaks or breaks can be obtained.

- even when it is cracked due to excessive impact it is considered that the influence on the surroundings can be suppressed because of ductile fracture.

- the bar flow lengths of the resin compositions in Comparative Examples 2 to 4 were 145 to 381 mm at an injection speed of 50 to 100 mm / sec.

- the bar flow length of the resin composition in Examples 1 and 2 is 504 to 620 mm at an injection speed of 25 to 200 mm / sec, which is about 1.3 to 4.4 as a result of Comparative Examples 2 to 4.

- the value was 3 times. From the above, it was confirmed that the resin compositions in Examples 1 and 2 were excellent in fluidity and had excellent shapeability (moldability). Therefore, it is considered that an energy absorber having a fine shape can be obtained by the resin composition of this example.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Mechanical Engineering (AREA)

- Compositions Of Macromolecular Compounds (AREA)

- Vibration Dampers (AREA)

- Injection Moulding Of Plastics Or The Like (AREA)

Priority Applications (7)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US16/087,344 US11014516B2 (en) | 2016-03-31 | 2017-03-07 | Energy absorber |

| CN201780019667.8A CN108884279B (zh) | 2016-03-31 | 2017-03-07 | 能量吸收体 |

| RU2018136244A RU2744290C2 (ru) | 2016-03-31 | 2017-03-07 | Амортизатор |

| BR112018068375A BR112018068375A2 (pt) | 2016-03-31 | 2017-03-07 | absorvente de energia |

| EP17774120.4A EP3438180B1 (en) | 2016-03-31 | 2017-03-07 | Energy absorber |

| SG11201806523UA SG11201806523UA (en) | 2016-03-31 | 2017-03-07 | Energy absorber |

| KR1020187030603A KR102116918B1 (ko) | 2016-03-31 | 2017-03-07 | 에너지 흡수체 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2016071735A JP6384507B2 (ja) | 2016-03-31 | 2016-03-31 | エネルギー吸収体 |

| JP2016-071735 | 2016-03-31 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2017169575A1 true WO2017169575A1 (ja) | 2017-10-05 |

Family

ID=59964078

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2017/009095 Ceased WO2017169575A1 (ja) | 2016-03-31 | 2017-03-07 | エネルギー吸収体 |

Country Status (9)

| Country | Link |

|---|---|

| US (1) | US11014516B2 (enExample) |

| EP (1) | EP3438180B1 (enExample) |

| JP (1) | JP6384507B2 (enExample) |

| KR (1) | KR102116918B1 (enExample) |

| CN (1) | CN108884279B (enExample) |

| BR (1) | BR112018068375A2 (enExample) |

| RU (1) | RU2744290C2 (enExample) |

| SG (1) | SG11201806523UA (enExample) |

| WO (1) | WO2017169575A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11643532B2 (en) * | 2017-04-19 | 2023-05-09 | Toyota Boshoku Kabushiki Kaisha | Thermoplastic resin composition, molded object, and production methods therefor |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110177826A (zh) * | 2017-01-30 | 2019-08-27 | 丰田纺织株式会社 | 改性剂和其使用方法、改性剂的制造方法以及添加材料用载体 |

| CN110392714B (zh) | 2017-03-16 | 2021-03-12 | 丰田纺织株式会社 | 热塑性树脂片、层叠片和成型体 |

| IT201700103763A1 (it) * | 2017-09-15 | 2019-03-15 | Srt S R L | Elemento ad assorbimento d’urto polimerico per un veicolo e struttura paraurti |

| CN109188012B (zh) * | 2018-11-15 | 2024-02-02 | 中国兵器工业集团第二一四研究所苏州研发中心 | 一种蜂窝状微止挡结构 |

| JP7136740B2 (ja) * | 2019-04-18 | 2022-09-13 | トヨタ自動車株式会社 | 車両構造及び車両の製造方法 |

| US11207958B2 (en) * | 2019-07-30 | 2021-12-28 | Ford Global Technologies, Llc | Vehicle door arrangement configured to prevent overlap |

| JP7677996B2 (ja) * | 2020-12-22 | 2025-05-15 | 三井化学株式会社 | 熱可塑性樹脂組成物およびその製造方法 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013147646A (ja) * | 2011-12-22 | 2013-08-01 | Toyota Boshoku Corp | 植物由来ポリアミド樹脂を用いた熱可塑性樹脂組成物及び成形体 |

| JP2013147647A (ja) * | 2011-12-22 | 2013-08-01 | Toyota Boshoku Corp | 熱可塑性樹脂組成物及びその製造方法 |

| JP2013147648A (ja) * | 2011-12-22 | 2013-08-01 | Toyota Boshoku Corp | 熱可塑性樹脂組成物の製造方法 |

| JP2014025060A (ja) * | 2012-06-22 | 2014-02-06 | Toyota Central R&D Labs Inc | 樹脂組成物 |

| JP2016027178A (ja) * | 2011-12-22 | 2016-02-18 | トヨタ紡織株式会社 | 熱可塑性樹脂組成物及びその製造方法 |

Family Cites Families (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6670421B1 (en) * | 2001-08-03 | 2003-12-30 | Aci Technologies, Llc | Olefin-polyamide thermoplastic alloy and process for making the same |

| CN1863861B (zh) | 2003-10-10 | 2011-03-30 | 埃克森美孚化学专利公司 | 聚丙烯和聚酰胺的组合物 |

| JP2009029296A (ja) * | 2007-07-27 | 2009-02-12 | Tokai Rubber Ind Ltd | 衝撃吸収部材 |

| JP5125704B2 (ja) | 2008-04-08 | 2013-01-23 | トヨタ紡織株式会社 | 側突用樹脂衝撃吸収体 |

| JP5552016B2 (ja) | 2010-09-30 | 2014-07-16 | トヨタ紡織株式会社 | 衝撃吸収体 |

| US8336933B2 (en) * | 2010-11-04 | 2012-12-25 | Sabic Innovative Plastics Ip B.V. | Energy absorbing device and methods of making and using the same |

| US9586355B2 (en) | 2011-03-11 | 2017-03-07 | Exxonmobil Chemical Patents Inc. | Dynamically vulcanized thermoplastic elastomer film |

| US20150065625A1 (en) | 2011-03-11 | 2015-03-05 | Exxonmobil Chemical Patents Inc. | Method of Forming Dynamically Vulcanized Thermoplastic Elastomer Films and Films Formed Therefrom |

| JP2012222846A (ja) | 2011-04-04 | 2012-11-12 | Hitachi Ltd | ディジタル保護制御装置 |

| EP2796497B1 (en) | 2011-12-22 | 2024-09-04 | Toyota Boshoku Kabushiki Kaisha | Thermoplastic resin composition, method for producing same, and molded body |

| EP2796496B1 (en) * | 2011-12-22 | 2018-11-07 | Toyota Boshoku Kabushiki Kaisha | Thermoplastic resin composition and method for producing same |

| JP5882730B2 (ja) * | 2011-12-28 | 2016-03-09 | 株式会社ブリヂストン | 外観検査装置及び外観検査方法 |

| US20130175128A1 (en) * | 2012-01-05 | 2013-07-11 | Sabic Innovative Plastics Ip B.V. | Multi-stage energy absorber and method of making and using the same |

| US8876179B2 (en) * | 2012-02-01 | 2014-11-04 | Sabic Global Technologies B.V. | Energy absorbing assembly and methods of making and using the same |

| JP2013237242A (ja) | 2012-05-17 | 2013-11-28 | Toray Ind Inc | ハニカム構造体およびサンドイッチ構造体 |

| KR102166745B1 (ko) | 2013-06-12 | 2020-10-16 | 킴벌리-클라크 월드와이드, 인크. | 에너지 흡수 부재 |

| JP6177834B2 (ja) * | 2014-06-26 | 2017-08-09 | 三洋化成工業株式会社 | シリコーン粘着剤用帯電防止剤及び帯電防止性シリコーン粘着剤 |

-

2016

- 2016-03-31 JP JP2016071735A patent/JP6384507B2/ja active Active

-

2017

- 2017-03-07 EP EP17774120.4A patent/EP3438180B1/en active Active

- 2017-03-07 US US16/087,344 patent/US11014516B2/en active Active

- 2017-03-07 CN CN201780019667.8A patent/CN108884279B/zh active Active

- 2017-03-07 SG SG11201806523UA patent/SG11201806523UA/en unknown

- 2017-03-07 BR BR112018068375A patent/BR112018068375A2/pt not_active Application Discontinuation

- 2017-03-07 KR KR1020187030603A patent/KR102116918B1/ko active Active

- 2017-03-07 RU RU2018136244A patent/RU2744290C2/ru active

- 2017-03-07 WO PCT/JP2017/009095 patent/WO2017169575A1/ja not_active Ceased

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2013147646A (ja) * | 2011-12-22 | 2013-08-01 | Toyota Boshoku Corp | 植物由来ポリアミド樹脂を用いた熱可塑性樹脂組成物及び成形体 |

| JP2013147647A (ja) * | 2011-12-22 | 2013-08-01 | Toyota Boshoku Corp | 熱可塑性樹脂組成物及びその製造方法 |

| JP2013147648A (ja) * | 2011-12-22 | 2013-08-01 | Toyota Boshoku Corp | 熱可塑性樹脂組成物の製造方法 |

| JP2016027178A (ja) * | 2011-12-22 | 2016-02-18 | トヨタ紡織株式会社 | 熱可塑性樹脂組成物及びその製造方法 |

| JP2014025060A (ja) * | 2012-06-22 | 2014-02-06 | Toyota Central R&D Labs Inc | 樹脂組成物 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP3438180A4 * |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11643532B2 (en) * | 2017-04-19 | 2023-05-09 | Toyota Boshoku Kabushiki Kaisha | Thermoplastic resin composition, molded object, and production methods therefor |

Also Published As

| Publication number | Publication date |

|---|---|

| EP3438180A4 (en) | 2019-11-06 |

| US11014516B2 (en) | 2021-05-25 |

| BR112018068375A2 (pt) | 2019-01-15 |

| SG11201806523UA (en) | 2018-08-30 |

| CN108884279A (zh) | 2018-11-23 |

| CN108884279B (zh) | 2021-02-26 |

| JP6384507B2 (ja) | 2018-09-05 |

| KR102116918B1 (ko) | 2020-05-29 |

| RU2018136244A (ru) | 2020-04-30 |

| RU2018136244A3 (enExample) | 2020-04-30 |

| EP3438180B1 (en) | 2025-05-07 |

| JP2017179237A (ja) | 2017-10-05 |

| RU2744290C2 (ru) | 2021-03-04 |

| US20200180535A1 (en) | 2020-06-11 |

| EP3438180A1 (en) | 2019-02-06 |

| KR20180126541A (ko) | 2018-11-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6384507B2 (ja) | エネルギー吸収体 | |

| JP5836923B2 (ja) | 植物由来ポリアミド樹脂を用いた熱可塑性樹脂組成物及び成形体 | |

| JP5798595B2 (ja) | 樹脂組成物 | |

| JP5859952B2 (ja) | 熱可塑性樹脂組成物 | |

| JP5879253B2 (ja) | 熱可塑性樹脂組成物及びその製造方法 | |

| KR102073259B1 (ko) | 열가소성 수지 조성물, 그 제조방법 및 성형체 | |

| JP5914318B2 (ja) | 熱可塑性樹脂組成物の製造方法 | |

| JP6311852B2 (ja) | 発泡樹脂成形体及びその製造方法 | |

| WO2013094763A1 (ja) | 熱可塑性樹脂組成物及びその製造方法並びに成形体 | |

| JP6916459B2 (ja) | 樹脂組成物 | |

| JP6288142B2 (ja) | 分散径の調整方法及び熱可塑性樹脂組成物 | |

| EP3613795A1 (en) | Molded article and method for producing same | |

| EP3613804B1 (en) | Thermoplastic resin composition, molded object, and production methods therefor | |

| JP7250254B2 (ja) | 熱可塑性樹脂組成物 | |

| JP6332569B2 (ja) | 熱可塑性樹脂組成物及び成形体 | |

| JP7677996B2 (ja) | 熱可塑性樹脂組成物およびその製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 11201806523U Country of ref document: SG |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| REG | Reference to national code |

Ref country code: BR Ref legal event code: B01A Ref document number: 112018068375 Country of ref document: BR |

|

| ENP | Entry into the national phase |

Ref document number: 20187030603 Country of ref document: KR Kind code of ref document: A |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2017774120 Country of ref document: EP |

|

| ENP | Entry into the national phase |

Ref document number: 2017774120 Country of ref document: EP Effective date: 20181031 |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 17774120 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 112018068375 Country of ref document: BR Kind code of ref document: A2 Effective date: 20180911 |

|

| WWG | Wipo information: grant in national office |

Ref document number: 2017774120 Country of ref document: EP |