WO2017104512A1 - 積層不織布 - Google Patents

積層不織布 Download PDFInfo

- Publication number

- WO2017104512A1 WO2017104512A1 PCT/JP2016/086417 JP2016086417W WO2017104512A1 WO 2017104512 A1 WO2017104512 A1 WO 2017104512A1 JP 2016086417 W JP2016086417 W JP 2016086417W WO 2017104512 A1 WO2017104512 A1 WO 2017104512A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- group

- nonwoven fabric

- laminated nonwoven

- liquid film

- less

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 0 **CC1OC***1 Chemical compound **CC1OC***1 0.000 description 1

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers of the pads

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L15/00—Chemical aspects of, or use of materials for, bandages, dressings or absorbent pads

- A61L15/16—Bandages, dressings or absorbent pads for physiological fluids such as urine or blood, e.g. sanitary towels, tampons

- A61L15/20—Bandages, dressings or absorbent pads for physiological fluids such as urine or blood, e.g. sanitary towels, tampons containing organic materials

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L15/00—Chemical aspects of, or use of materials for, bandages, dressings or absorbent pads

- A61L15/16—Bandages, dressings or absorbent pads for physiological fluids such as urine or blood, e.g. sanitary towels, tampons

- A61L15/22—Bandages, dressings or absorbent pads for physiological fluids such as urine or blood, e.g. sanitary towels, tampons containing macromolecular materials

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61L—METHODS OR APPARATUS FOR STERILISING MATERIALS OR OBJECTS IN GENERAL; DISINFECTION, STERILISATION OR DEODORISATION OF AIR; CHEMICAL ASPECTS OF BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES; MATERIALS FOR BANDAGES, DRESSINGS, ABSORBENT PADS OR SURGICAL ARTICLES

- A61L15/00—Chemical aspects of, or use of materials for, bandages, dressings or absorbent pads

- A61L15/16—Bandages, dressings or absorbent pads for physiological fluids such as urine or blood, e.g. sanitary towels, tampons

- A61L15/42—Use of materials characterised by their function or physical properties

- A61L15/48—Surfactants

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/22—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed

- B32B5/24—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer

- B32B5/26—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by the presence of two or more layers which are next to each other and are fibrous, filamentary, formed of particles or foamed one layer being a fibrous or filamentary layer another layer next to it also being fibrous or filamentary

-

- D—TEXTILES; PAPER

- D04—BRAIDING; LACE-MAKING; KNITTING; TRIMMINGS; NON-WOVEN FABRICS

- D04H—MAKING TEXTILE FABRICS, e.g. FROM FIBRES OR FILAMENTARY MATERIAL; FABRICS MADE BY SUCH PROCESSES OR APPARATUS, e.g. FELTS, NON-WOVEN FABRICS; COTTON-WOOL; WADDING ; NON-WOVEN FABRICS FROM STAPLE FIBRES, FILAMENTS OR YARNS, BONDED WITH AT LEAST ONE WEB-LIKE MATERIAL DURING THEIR CONSOLIDATION

- D04H1/00—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres

- D04H1/40—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties

- D04H1/54—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties by welding together the fibres, e.g. by partially melting or dissolving

- D04H1/559—Non-woven fabrics formed wholly or mainly of staple fibres or like relatively short fibres from fleeces or layers composed of fibres without existing or potential cohesive properties by welding together the fibres, e.g. by partially melting or dissolving the fibres being within layered webs

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M13/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment

- D06M13/10—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment with compounds containing oxygen

- D06M13/165—Ethers

- D06M13/17—Polyoxyalkyleneglycol ethers

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M13/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment

- D06M13/10—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment with compounds containing oxygen

- D06M13/224—Esters of carboxylic acids; Esters of carbonic acid

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M13/00—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment

- D06M13/244—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment with compounds containing sulfur or phosphorus

- D06M13/282—Treating fibres, threads, yarns, fabrics or fibrous goods made from such materials, with non-macromolecular organic compounds; Such treatment combined with mechanical treatment with compounds containing sulfur or phosphorus with compounds containing phosphorus

- D06M13/292—Mono-, di- or triesters of phosphoric or phosphorous acids; Salts thereof

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/19—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with synthetic macromolecular compounds

- D06M15/37—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

- D06M15/53—Polyethers

-

- D—TEXTILES; PAPER

- D06—TREATMENT OF TEXTILES OR THE LIKE; LAUNDERING; FLEXIBLE MATERIALS NOT OTHERWISE PROVIDED FOR

- D06M—TREATMENT, NOT PROVIDED FOR ELSEWHERE IN CLASS D06, OF FIBRES, THREADS, YARNS, FABRICS, FEATHERS OR FIBROUS GOODS MADE FROM SUCH MATERIALS

- D06M15/00—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment

- D06M15/19—Treating fibres, threads, yarns, fabrics, or fibrous goods made from such materials, with macromolecular compounds; Such treatment combined with mechanical treatment with synthetic macromolecular compounds

- D06M15/37—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds

- D06M15/643—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds containing silicon in the main chain

- D06M15/647—Macromolecular compounds obtained otherwise than by reactions only involving carbon-to-carbon unsaturated bonds containing silicon in the main chain containing polyether sequences

Definitions

- the present invention relates to a laminated nonwoven fabric.

- Nonwoven fabrics used for surface sheets of absorbent articles there are some which try to improve dry feeling by increasing the pulling power of the liquid with a hydrophilicity gradient (for example, Patent Document 1 and Patent Document 2).

- Some of the topsheets contain a blood modifying agent to improve dry feeling. This blood modifying agent lowers the viscosity and surface tension of blood, stabilizes blood cells, makes it difficult to form a cash structure, and makes it easier for the absorber to absorb menstrual blood (for example, Patent Document 3).

- the present invention is a laminated nonwoven fabric having two adjacent fiber layers, wherein one of the two layers has a higher hydrophilicity than the other fiber layer, and at least one of the fiber layers.

- a laminated nonwoven fabric containing a liquid film cleaving agent is provided.

- the present invention relates to a laminated nonwoven fabric that realizes a higher level of dry feeling by reducing the liquid film formed between fibers. Moreover, this invention relates to the laminated nonwoven fabric suitable for the surface sheet of the absorbent article which makes dry feeling and soft touch compatible at a high level.

- the nonwoven fabric used for the surface sheet or the like there is a region where the distance between the fibers is narrow. Even if there is a space in the area that can pass excretory fluid (for example, urine and menstrual blood, also simply liquid), meniscus force between fibers, surface activity by plasma proteins, and blood surface viscosity are high. A stable liquid film is formed between the fibers, and the liquid tends to stay. Since this liquid film becomes a stable film between narrow fibers, once it occurs, it is difficult to eliminate even a blood modifying agent that stabilizes a hydrophilicity gradient or blood cells. For this reason, even a non-woven fabric using a conventional blood modifying agent or the like has not yet been sufficiently satisfactory in the dryness felt by the wearer.

- excretory fluid for example, urine and menstrual blood, also simply liquid

- the liquid to be absorbed is not limited to blood, and urine also has surface activity due to phospholipids, and a liquid film was formed in the same manner as described above, and the dryness was not yet satisfactory.

- the laminated nonwoven fabric of the present invention realizes a higher level of dry feeling by reducing the liquid film formed between the fibers. Moreover, if the laminated nonwoven fabric of this invention is used, the absorptive article which can make dry feeling and soft touch compatible at a high level can be provided.

- the laminated nonwoven fabric according to the present invention is a laminated nonwoven fabric having two adjacent layers, and one of the two layers is higher in hydrophilicity than the other fiber layer, and at least one of the fibers.

- the layer contains a liquid film cleaving agent.

- the laminated nonwoven fabric according to the present invention is a laminated nonwoven fabric having two adjacent fiber layers, and one of the two layers has a higher hydrophilicity than the other fiber layer, and at least Either one of the fiber layers contains a compound having a water solubility of 0 g or more and 0.025 g or less and an expansion coefficient of 16 mN / m or more for a liquid having a surface tension of 50 mN / m.

- the laminated nonwoven fabric according to the present invention is a laminated nonwoven fabric having two adjacent fiber layers, and one of the two layers has a higher hydrophilicity than the other fiber layer, and at least In any one of the fiber layers, the water solubility is 0 g or more and 0.025 g or less, the expansion coefficient for a liquid having a surface tension of 50 mN / m is larger than 0 mN / m, and the interfacial tension for a liquid having a surface tension of 50 mN / m. Containing 20 mN / m or less of the compound.

- a liquid film cleaving agent is a liquid, for example, a highly viscous liquid such as menstrual blood or excreted liquid such as urine touches the laminated nonwoven fabric to cleave the liquid film formed between the fibers of the nonwoven fabric or on the fiber surface. It means an agent that inhibits the formation of a liquid film, and has an action of cleaving the formed liquid film and an action of inhibiting the formation of the liquid film.

- the cleaving of the liquid film is performed by the action of the liquid film cleaving agent to destabilize by pushing away a part of the liquid film layer. By the action of the liquid film cleaving agent, the liquid can easily pass through without staying in a narrow region between the fibers of the laminated nonwoven fabric.

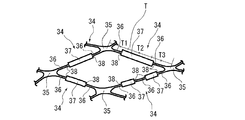

- Such a laminated nonwoven fabric can be used, for example, as a surface sheet for absorbent articles such as sanitary napkins, baby diapers, and adult diapers.

- the liquid film cleaving agent used in the present invention has the property of disappearing the liquid film, and due to this property, the liquid film cleaving agent is a test solution or artificial urine mainly composed of plasma components (composition: urea 1). 940 mass%, sodium chloride 0.795 mass%, magnesium sulfate 0.110 mass%, calcium chloride 0.062 mass%, potassium sulfate 0.197 mass%, red No. 2 (dye) 0.010 mass%, water (Approx. 96.88% by mass) and polyoxyethylene lauryl ether (approx.

- the liquid film disappearance effect here refers to the effect of inhibiting the liquid film formation of the structure and the formed structure of the structure in which air is held by the liquid film formed from the test liquid or artificial urine. It can be said that an agent that exhibits both of the effects of disappearing the body and that exhibits at least one of the effects has the property of exhibiting the effect of disappearing the liquid film.

- the test solution is a liquid component extracted from defibrinated horse blood (manufactured by Nippon Biotest Co., Ltd.).

- the defibrinated horse blood is separated into an upper layer and a lower layer. It is.

- the upper layer mainly contains plasma components

- the lower layer mainly contains blood cell components.

- a transfer pipette manufactured by Nippon Micro Corporation

- Whether or not a certain agent has the above-mentioned property of “disappearing the liquid film” depends on the occurrence of a structure in which air is trapped by the liquid film formed from the test solution or artificial urine to which the agent is applied. This is judged by the amount of the structure, that is, the liquid film when it is in an easy state. That is, the test solution or artificial urine is adjusted to a temperature of 25 ° C., and then 10 g is put into a screw tube (No. 5 body diameter 27 mm, total length 55 mm, manufactured by Maruemu Co., Ltd.) to obtain a standard sample.

- a screw tube No. 5 body diameter 27 mm, total length 55 mm, manufactured by Maruemu Co., Ltd.

- a measurement sample obtained by adding 0.01 g of an agent to be measured, which is adjusted in advance to 25 ° C., to the same sample as the standard sample is obtained.

- the standard sample and the measurement sample are vigorously shaken twice in the vertical direction of the screw tube, and then quickly placed on a horizontal plane. By shaking the sample, the structure of the liquid layer (lower layer) without the structure and a large number of structures formed on the liquid layer (the lower layer) is formed inside the screw tube after shaking. Upper layer). After the elapse of 10 seconds immediately after shaking, the height of the structure layers of both samples (the height from the liquid surface of the liquid layer to the upper surface of the structure layer) is measured.

- the agent to be measured has a liquid film cleavage effect.

- the liquid film cleaving agent used in the present invention satisfies the above properties by a single compound that applies to the above properties, a plurality of combinations of single compounds that apply to the above properties, or a combination of a plurality of compounds (liquid membranes).

- the compound applied to the fiber treatment agent in the nonwoven fabric contains a third component that does not meet the above definition, it is distinguished from the liquid film cleaving agent.

- the “single compound” is a concept including compounds having the same composition formula but having different molecular weights due to different numbers of repeating units.

- the liquid film cleaving agent is coated and contained on at least a part of the constituent fibers of the laminated nonwoven fabric.

- the at least part to be coated is preferably a part that receives the most liquid.

- the laminated nonwoven fabric of the present invention when used as a top sheet of an absorbent article such as a sanitary napkin, it is a region corresponding to the excretion part of the wearer that directly receives excretion fluid such as menstrual blood.

- it is preferably contained in at least the layer that receives the liquid (the layer that is close to the skin in the absorbent article).

- at least a liquid film cleaving agent is contained on the skin contact surface side that comes into contact with the wearer's skin.

- the phrase that the laminated nonwoven fabric contains or contains a liquid film cleaving agent mainly means that it is adhered to the surface of the fiber.

- the liquid film cleaving agent may be a liquid film cleaving agent that is encapsulated in the fiber or that is present inside the fiber by internal addition.

- various commonly used methods can be employed without any particular limitation. For example, application by spraying, application by slot coater, application by roll transfer, immersion and the like can be mentioned. These treatments may be performed on the fibers before being made into a web, or after the fibers are made into a web by various methods.

- the fiber having the liquid film cleaving agent attached to the surface is dried at a temperature sufficiently lower than the melting point of the fiber resin (for example, 120 ° C. or less) by, for example, a hot air blowing type dryer. Moreover, when attaching to a fiber using the said attachment method, it is performed using the solution containing the liquid film cleaving agent which melt

- the liquid film cleaving agent according to the present invention needs to exist as a liquid when the liquid film cleaving agent touches body fluid in order to have the liquid film cleaving effect described later in the nonwoven fabric.

- the melting point of the liquid film cleaving agent according to the present invention is preferably 40 ° C. or less, and more preferably 35 ° C. or less. Furthermore, the melting point of the liquid film cleaving agent according to the present invention is preferably ⁇ 220 ° C. or higher, more preferably ⁇ 180 ° C. or higher.

- the liquid film cleaving agent acts as a driving force for breaking and destabilizing a fine and stable liquid film generated between narrow fibers.

- the difference in hydrophilicity between adjacent fiber layers is changed from a fiber layer with low hydrophilicity to a fiber layer with high hydrophilicity before the liquid destabilized by rupturing is stabilized on the fiber surface again. Acts as a driving force for pulling out in one direction.

- the liquid film cleaving agent prevents stable liquid film formation and pulls it back toward the higher hydrophilicity.

- the driving force of both the hydrophilicity difference between the liquid film cleaving agent and the adjacent fiber layer cooperates to prevent the liquid from stabilizing between the fibers, and the liquid thickness in the laminated nonwoven fabric.

- the liquid permeability which can respond quickly also to a new liquid receiving is provided. This also makes it possible to form a soft laminated nonwoven fabric using fine fibers while maintaining a high level of dryness.

- the adjacent one of the fiber layers and the other fiber layer is not limited to the form in contact with the entire surface, but may have a form having a peeled portion.

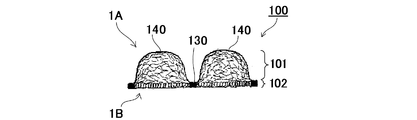

- the laminated nonwoven fabric 10 of 1st Embodiment has two layers of the 1st fiber layer 11 by the side of the 1st surface 1A, and the 2nd fiber layer 12 by the side of the 2nd surface 1B adjacent to this as shown in FIG. .

- the hydrophilicity of the second fiber layer 12 is higher than the hydrophilicity of the first fiber layer 11.

- the gradient of the hydrophilicity which increases from the first fiber layer 11 to the second fiber layer 12 is formed in the thickness direction of the laminated nonwoven fabric 10 and acts as the above-described liquid pulling driving force.

- the laminated nonwoven fabric 10 When the laminated nonwoven fabric 10 is applied as a top sheet of an absorbent article, it is preferable to use the second surface 1B side with higher hydrophilicity as the non-skin contact surface side.

- the laminated nonwoven fabric 10 may have another layer in addition to the two layers.

- the gradient of the hydrophilicity in the thickness direction of the laminated nonwoven fabric is opposite to the liquid receiving surface (for example, a skin contact surface in the case of a surface sheet such as a diaper) side (for example, the above-described surface). It means a state where the hydrophilicity on the non-skin contact surface) side of the topsheet is high.

- This “gradient” broadly includes various modes in which there is a difference in hydrophilicity between the liquid receiving surface side and the opposite surface side, and may be a gradually increasing mode or a stepwise increasing mode. But you can.

- At least one of the fiber layers has an expansion coefficient of 16 mN / m or more and a water solubility of 0 g or more and 0.025 g for a liquid having a surface tension of 50 mN / m.

- a liquid film cleaving agent which is the following compound.

- the liquid film cleaving agent may be in the first fiber layer 11 serving as a layer on the liquid receiving surface side, or in the second fiber layer 12 on the side of drawing the liquid from the first fiber layer 11.

- the liquid film cleaving agent may be present in both the first fiber layer 11 and the second fiber layer 12.

- At least the first fiber layer 11 has the liquid film cleaving agent because the liquid residue on the side close to the skin can be effectively prevented.

- the liquid film cleaving agent is at least in the first fiber layer 11, the liquid film cleaving agent is further transferred to the second fiber layer 12 together with the liquid even after the liquid film is cleaved, and the liquid at that position. This is preferable because it can act as a membrane cleavage.

- the “expansion coefficient with respect to a liquid having a surface tension of 50 mN / m” possessed by the liquid film cleaving agent refers to an expansion coefficient with respect to a liquid assuming the above-mentioned excretion liquid such as menstrual blood or urine.

- the “expansion coefficient” is a value obtained based on the following formula (1) from a measurement value obtained by a measurement method described later in an environmental region at a temperature of 25 ° C. and a relative humidity (RH) of 65%.

- the liquid film in Formula (1) means the liquid phase of "the liquid whose surface tension is 50 mN / m", the liquid of the state which stretched

- stretched Includes both, also simply called liquid.

- the surface tension of the formula (1) means the interfacial tension at the interface between the liquid film and the liquid film cleaving agent and the interfacial tension between the liquid phase and the liquid film cleaving agent. To do. This distinction applies to other descriptions in the present specification.

- the expansion coefficient (S) of the liquid film cleaving agent increases as the surface tension ( ⁇ o ) of the liquid film cleaving agent decreases, and the interfacial tension of the liquid film cleaving agent with the liquid film It increases as ( ⁇ wo ) decreases.

- the expansion coefficient is 16 mN / m or more

- the liquid film cleaving agent has high mobility on the surface of the liquid film generated in a narrow region between fibers, that is, high diffusibility.

- the expansion coefficient of the liquid film cleaving agent is more preferably 20 mN / m or more, further preferably 25 mN / m or more, and particularly preferably 30 mN / m or more.

- the upper limit is not particularly limited, but when a liquid having a surface tension of 50 mN / m is used from the formula (1), a liquid having an upper limit of 50 mN / m and a surface tension of 60 mN / m was used. In this case, when a liquid having an upper limit of 60 mN / m and a surface tension of 70 mN / m is used, the surface tension of the liquid forming the liquid film becomes an upper limit, such as 70 mN / m. Therefore, in the present invention, from the viewpoint of using a liquid having a surface tension of 50 mN / m, it is 50 mN / m or less.

- the “water solubility” of the liquid film cleaving agent is the dissolvable mass of the liquid film cleaving agent with respect to 100 g of deionized water. Based on the measurement method described below, the environment has a temperature of 25 ° C. and a relative humidity (RH) of 65%. A value measured in the region. When the water solubility is 0 g or more and 0.025 g or less, the liquid film cleaving agent is difficult to dissolve and forms an interface with the liquid film, thereby making the diffusibility more effective. From the same viewpoint, the water solubility of the liquid film cleaving agent is preferably 0.0025 g or less, more preferably 0.0017 g or less, and still more preferably less than 0.0001 g.

- the water solubility is preferably as small as possible, and is 0 g or more. From the viewpoint of diffusibility into the liquid film, it is practical to set the water solubility to 1.0 ⁇ 10 ⁇ 9 g or more. In addition, it is thought that said water solubility is applicable also to the menstrual blood, urine, etc. which have a water

- the surface tension ( ⁇ w ) of the liquid film (liquid having a surface tension of 50 mN / m), the surface tension ( ⁇ o ) of the liquid film cleaving agent, and the interfacial tension of the liquid film cleaving agent ( ⁇ wo )

- the water solubility of the liquid film cleaving agent is measured by the following method.

- the laminated nonwoven fabric to be measured is a member (for example, a surface sheet) incorporated in an absorbent article such as a sanitary product or a disposable diaper, the measurement is taken out as follows.

- the member to be measured is carefully peeled off and taken out.

- This extraction method is applied in the measurement related to the laminated nonwoven fabric of the present invention, such as measurement of the interfiber distance and the fineness described later.

- a washing liquid such as hexane, methanol, ethanol, and the solvent used for the washing (including the liquid film cleaving agent). The washing solvent is dried and removed.

- the mass of the substance taken out at this time is applied when calculating the content ratio (OPU) with respect to the fiber mass of the liquid film cleaving agent. If the amount of the extracted material is too small to measure the surface tension or interfacial tension, select an appropriate column and solvent according to the composition of the extracted material, and then fractionate each component by high performance liquid chromatography. Furthermore, the structure of each fraction is identified by performing MS measurement, NMR measurement, elemental analysis and the like for each fraction. When the liquid film cleaving agent contains a polymer compound, it becomes easier to identify the constituents by using a technique such as gel permeation chromatography (GPC) together.

- GPC gel permeation chromatography

- the substance is a commercial product, it is procured, and if it is not a commercial product, a sufficient amount is obtained by synthesis, and the surface tension and interfacial tension are measured.

- the liquid film cleaving agent obtained as described above is a solid, the liquid film cleaving agent is heated to the melting point of the liquid film cleaving agent + 5 ° C. to cause a phase transition to the liquid. Perform measurement under the same conditions.

- Measurement method of surface tension ( ⁇ w ) of liquid film (liquid) Measurement can be performed using a platinum plate by the plate method (Wilhelmy method) in an environmental region at a temperature of 25 ° C. and a relative humidity (RH) of 65%.

- a measuring device at that time an automatic surface tension meter “CBVP-Z” (trade name, manufactured by Kyowa Interface Science Co., Ltd.) can be used.

- a platinum plate having a purity of 99.9%, a size of 25 mm in width, and 10 mm in length is used.

- liquid having a surface tension of 50 mN / m is a polyoxyethylene sorbitan monolaur, which is a nonionic surfactant, in deionized water using the above measurement method.

- a solution adjusted to a surface tension of 50 ⁇ 1 mN / m by adding a rate (for example, trade name Leool Super TW-L120 manufactured by Kao Corporation) is used.

- the interfacial tension when the drop is formed (at 0 second) is read.

- the liquid film cleaving agent is heated to the melting point of the liquid film cleaving agent + 5 ° C. to cause a phase transition to the liquid, and the measurement is performed with the temperature condition.

- the measurement is performed with the temperature condition.

- the interfacial tension if the density difference between the liquid film cleaving agent and the liquid with a surface tension of 50 mN / m is very small, the viscosity is extremely high, or the interfacial tension value is below the pendant drop measurement limit, The interfacial tension measurement by the pendant drop method may be difficult.

- the measurement can be performed by measuring by a spinning drop method in an environment region at a temperature of 25 ° C. and a relative humidity (RH) of 65%.

- a spinning drop interfacial tensiometer manufactured by KURUSS, trade name SITE100

- the interfacial tension when the drop shape is stabilized is read, and when the obtained liquid film cleaving agent is solid, it is heated to the melting point of the liquid film cleaving agent + 5 ° C. The phase is changed and the measurement is carried out with the temperature condition. Note that if the interfacial tension can be measured by both measuring devices, a smaller interfacial tension value is adopted as the measurement result.

- dissolution means both monodisperse dissolution and micelle dispersion dissolution, and the amount of dissolution when floating, precipitation, precipitation, or cloudiness is observed is the water solubility. It becomes.

- the liquid film cleaving agent of the present embodiment has the above expansion coefficient and water solubility, so that it spreads without dissolving on the surface of the liquid film and can displace the liquid film layer from the vicinity of the center of the liquid film. it can. As a result, the liquid film is destabilized and cleaved.

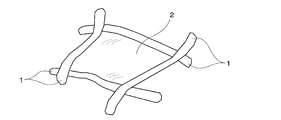

- action of the liquid film cleaving agent in the laminated nonwoven fabric of this embodiment is demonstrated concretely with reference to FIG.

- a highly viscous liquid such as menstrual blood or excreted liquid such as urine tends to stretch the liquid film 2.

- the liquid film cleaving agent destabilizes and breaks the liquid film in the following manner, inhibits formation, and promotes drainage from the nonwoven fabric.

- the liquid film cleaving agent 3 of the fiber 1 of the laminated nonwoven fabric moves on the surface of the liquid film 2 while maintaining the interface with the liquid film 2. .

- FIGS. 3A1 and 3B1 the liquid film cleaving agent 3 of the fiber 1 of the laminated nonwoven fabric moves on the surface of the liquid film 2 while maintaining the interface with the liquid film 2. .

- the liquid film cleaving agent 3 pushes away a part of the liquid film 2 and penetrates in the thickness direction, as shown in FIGS. 3 (A3) and (B3).

- the liquid film 2 is gradually changed to a non-uniform and thin film.

- the liquid film 2 is opened and cleaved so as to be repelled.

- the cleaved menstrual fluid or the like becomes droplets and easily passes between the fibers of the laminated nonwoven fabric, and the remaining liquid is reduced.

- action with respect to the liquid film of said liquid film cleaving agent is similarly demonstrated not only to the case with respect to the liquid film between fibers but with respect to the liquid film clinging to the fiber surface. That is, the liquid film cleaving agent can move over the liquid film clinging to the fiber surface and push away a part of the liquid film to cleave the liquid film. In addition, the liquid film cleaving agent can cleave the liquid film with respect to the liquid film clinging to the fiber surface without moving at the position attached to the fiber, and can inhibit the formation of the liquid film.

- the liquid film cleaving agent according to the present invention does not perform liquid modification such as lowering the surface tension of the liquid film, but cleaves and inhibits the liquid film itself generated between the fibers or on the fiber surface.

- liquid modification such as lowering the surface tension of the liquid film

- the liquid residue of a laminated nonwoven fabric can be reduced.

- the liquid stay between the fibers is suppressed, and a liquid permeation path to the absorber is secured. Thereby, the liquid permeability increases, the liquid flow on the sheet surface is suppressed, and the liquid absorption rate increases.

- the liquid film cleaving agent preferably further has an interface tension of 20 mN / m or less with respect to a liquid having a surface tension of 50 mN / m. That is, it is preferable that the “interfacial tension ( ⁇ wo ) of the liquid film cleaving agent with respect to the liquid film”, which is one variable for determining the value of the expansion coefficient (S) in the above-described formula (1), is 20 mN / m or less.

- the “interfacial tension with respect to a liquid having a surface tension of 50 mN / m” of the liquid film cleaving agent is more preferably 17 mN / m or less, further preferably 13 mN / m or less, still more preferably 10 mN / m or less, and 9 mN.

- the lower limit is not particularly limited, and may be larger than 0 mN / m from the viewpoint of insolubility in the liquid film.

- the expansion coefficient is 50.8 mN / m.

- the surface tension of the target liquid is 30 mN / m

- the surface tension of the liquid film cleaving agent is 21 mN / m

- the interfacial tension is 0.2 mN / m

- the expansion coefficient is 8.8 mN / m.

- the larger the expansion coefficient the greater the liquid film cleavage effect.

- the numerical value at the surface tension of 50 mN / m is defined.

- the surface tension of the liquid film cleaving agent is preferably 32 mN / m or less, more preferably 30 mN / m or less, further preferably 25 mN / m or less, and particularly preferably 22 mN / m or less. Moreover, the said surface tension is so good that it is small, and the minimum is not specifically limited. From the viewpoint of durability of the liquid film cleaving agent, 1 mN / m or more is practical. By setting the surface tension of the liquid film cleaving agent to be in the above range or less, even when the surface tension of the target liquid that stretches the liquid film is lowered, the liquid film cleaving action can be effectively exhibited.

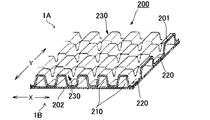

- the laminated nonwoven fabric 20 has two layers of the first fiber layer 11 and the second fiber layer 12 adjacent thereto, like the laminated nonwoven fabric 10 of the first embodiment.

- the hydrophilicity of the second fiber layer 12 is higher than the hydrophilicity of the first fiber layer 11.

- a gradient of hydrophilicity that increases from the first fiber layer 11 to the second fiber layer 12 is formed in the thickness direction of the laminated nonwoven fabric 20.

- the gradient of hydrophilicity here has the same meaning as in the first embodiment.

- the laminated nonwoven fabric 20 when the first fiber layer 11 is a layer on the liquid receiving surface side, the gradient of the hydrophilicity is from the first fiber layer 11 to the second fiber layer 12. It acts as a driving force for drawing the liquid and contributes to the improvement of the liquid permeability of the laminated nonwoven fabric 10.

- the laminated nonwoven fabric 10 may have another layer in addition to the two layers.

- the laminated nonwoven fabric 20 has an expansion coefficient greater than 0 mN / m for a liquid having a surface tension of 50 mN / m in at least one of the fiber layers, that is, a positive value.

- a liquid film cleaving agent which is a compound having a water solubility of 0 g or more and 0.025 g or less and an interfacial tension of 20 mN / m or less for a liquid having a surface tension of 50 mN / m.

- the “interfacial tension with respect to a liquid having a surface tension of 50 mN / m” is 20 mN / m or less, it means that the diffusibility of the liquid film cleaving agent on the liquid film is increased as described above.

- the expansion coefficient is relatively small such that the “expansion coefficient for a liquid having a surface tension of 50 mN / m” is less than 16 mN / m, a large amount of liquid film cleaving agent is removed from the fiber surface because of its high diffusibility.

- extension coefficient for a liquid having a surface tension of 50 mN / m is defined in the first embodiment.

- the measuring method is also the same.

- the “interface tension with respect to a liquid having a surface tension of 50 mN / m” is preferably 17 mN / m or less, and 13 mN / m or less. Is more preferably 10 mN / m or less, still more preferably 9 mN / m or less, and particularly preferably 1 mN / m or less.

- the lower limit is not particularly limited as in the first embodiment, and is practically larger than 0 mN / m from the viewpoint of not dissolving in a liquid film (a liquid having a surface tension of 50 mN / m). .

- the “expansion coefficient for a liquid having a surface tension of 50 mN / m” is preferably 9 mN / m or more, more preferably 10 mN / m or more, from the viewpoint of making the action of the liquid film cleaving agent more effective. More preferably, it is 16 mN / m or more.

- the upper limit is not particularly limited, but 50 mN / m or less is substantial from the viewpoint that the surface tension of the liquid forming the liquid film becomes the upper limit from the formula (1). Further, more preferable ranges of the surface tension and the water solubility of the liquid film cleaving agent are the same as those in the first embodiment.

- the laminated nonwoven fabric of the first embodiment and the laminated nonwoven fabric of the second embodiment preferably further contain a phosphate ester type anionic surfactant in addition to the liquid film cleaving agent.

- a phosphate ester type anionic surfactant in addition to the liquid film cleaving agent.

- the content ratio of the liquid film cleaving agent to the phosphate ester type anionic surfactant is preferably 1: 1 to 19: 1, more preferably 2: 1 to 15: 1, and more preferably 3: 1 to 10 by mass ratio. : 1 is more preferable. In particular, the content ratio is preferably 5: 1 to 19: 1, more preferably 8: 1 to 16: 1, and even more preferably 11: 1 to 13: 1 in terms of mass ratio.

- the phosphate ester type anionic surfactant is not particularly limited.

- specific examples thereof include alkyl ether phosphates, dialkyl phosphates, and alkyl phosphates.

- alkyl phosphate ester is preferable from the viewpoint of enhancing the affinity with the liquid film and at the same time imparting the workability of the laminated nonwoven fabric.

- alkyl ether phosphates can be used without particular limitation.

- polyoxyalkylene stearyl ether phosphate examples include unsaturated carbon chains such as oxyalkylene oleyl ether phosphates and polyoxyalkylene palmitoleyl ether phosphates, and those having side chains in these carbon chains. More preferably, it is a completely neutralized or partially neutralized salt of a mono- or dipolyoxyalkylene alkyl ether phosphate ester having 16 to 18 carbon chains.

- Examples of the polyoxyalkylene include polyoxyethylene, polyoxypropylene, polyoxybutylene and those obtained by copolymerizing these constituent monomers.

- Examples of the salt of alkyl ether phosphate include alkali metals such as sodium and potassium, ammonia, and various amines. Alkyl ether phosphates can be used singly or in combination of two or more. Specific examples of the alkyl phosphate ester include those having a saturated carbon chain such as stearyl phosphate ester, myristyl phosphate ester, lauryl phosphate ester, palmityl phosphate ester, oleyl phosphate ester, palmitoleyl phosphate ester, etc.

- Examples include unsaturated carbon chains and those having side chains in these carbon chains. More preferably, it is a completely neutralized or partially neutralized salt of a mono- or dialkyl phosphate ester having 16 to 18 carbon chains.

- alkyl phosphate ester salt include alkali metals such as sodium and potassium, ammonia, and various amines.

- Alkyl phosphate ester can be used individually by 1 type or in mixture of 2 or more types.

- liquid film cleaving agent in the first embodiment and the second embodiment will be described. These are not soluble in water or have poor water-solubility because they are in the specific numerical range described above, and act to cleave the liquid film.

- surfactants used as conventional fiber treatment agents are practically water-soluble when used by dissolving in water, and are not the liquid film cleaving agent of the present invention. .

- the liquid film cleaving agent in the first embodiment and the second embodiment is preferably a compound having a mass average molecular weight of 500 or more.

- This mass average molecular weight greatly affects the viscosity of the liquid film cleaving agent.

- the liquid film cleaving agent keeps the viscosity high so that it is difficult for the liquid to flow down when the liquid passes between the fibers, and the liquid film cleaving effect in the nonwoven fabric can be maintained.

- the mass average molecular weight of the liquid film cleavage agent is more preferably 1000 or more, further preferably 1500 or more, and particularly preferably 2000 or more.

- the viscosity for maintaining diffusibility 50000 or less is preferable, 20000 or less is more preferable, and 10,000 or less is further preferable.

- the mass average molecular weight is measured using a gel permeation chromatograph (GPC) “CCPD” (trade name, manufactured by Tosoh Corporation). The measurement conditions are as follows. The calculated molecular weight is calculated with polystyrene. Separation column: GMHHR-H + GMHHR-H (cation) Eluent: L Farmin DM20 / CHCl3 Solvent flow rate: 1.0 ml / min Separation column temperature: 40 ° C

- the liquid film cleaving agent in the first embodiment is preferably a compound having at least one structure selected from the group consisting of the following structures X, XY, and YXY, as will be described later.

- Structure X is> C (A)- ⁇ C represents a carbon atom. ⁇ ,>, And-indicate a bond. The same applies hereinafter.

- a hydrogen atom or —C (A) 3 , —C (A) 2 B, —C (A) (B) 2, —C (A) 2 —C (R 1 ) 3 , -C (R 1 ) 2 A, -C (R 1 ) 3 , -OSi (R 1 ) 3 , -OSi (R 1 ) 2 (R 2 ), -Si (R 1 ) 3 , -Si (R 1 ) 2 It has at least one group selected from the group consisting of (R 2 ).

- R 1 and R 2 are each independently a hydrogen atom, an alkyl group (preferably having a carbon number of 1 to 20, preferably a methyl group, an ethyl group or a propyl group), an alkoxy group (having a carbon number of 1 to 20).

- Preferred examples include various substituents such as a methoxy group and an ethoxy group, an aryl group (preferably having 6 to 20 carbon atoms, eg a phenyl group), and a halogen atom (eg a fluorine atom is preferred). Show.

- a and B each independently represent a substituent containing an oxygen atom or a nitrogen atom, such as a hydroxyl group, a carboxylic acid group, an amino group, an amide group, an imino group, or a phenol group.

- R 1 , R 2 , A, and B in the structure X may be the same as or different from each other.

- a continuous bond between C (carbon atom) and Si is usually a single bond, but may include a double bond or a triple bond, and the bond between C and Si includes an ether group (- O-), amide group (—CONR A —: R A is a hydrogen atom or a monovalent group), ester group (—COO—), carbonyl group (—CO—), carbonate group (—OCOO—), etc. Groups may be included.

- the number of one C and Si bonded to the other C or Si is 1 to 4, and a long-chain silicone chain (siloxane chain) or mixed chain is branched or has a radial structure. There may be cases.

- Y represents a hydrophilic group having hydrophilicity including an atom selected from a hydrogen atom, a carbon atom, an oxygen atom, a nitrogen atom, a phosphorus atom, and a sulfur atom.

- a polyoxyethylene (POE) group a polyoxyalkylene group, Propylene (POP) group is preferred

- POP polyoxyethylene

- sulfonic acid group sulfuric acid group

- phosphoric acid group a polyoxyalkylene group

- sulfobetaine group a polyoxyalkylene group

- carbobetaine group a polyoxyalkylene group

- phosphobetaine group a hydrophilic group

- Y is plural, they may be the same or different. In structures XY and YXY, Y is attached to X or a terminal group of X.

- the terminal group of X is bonded to Y by removing, for example, the same number of hydrogen atoms as the number of bonds to Y.

- the hydrophilic groups Y, A, and B can be selected from the groups specifically described to satisfy the aforementioned expansion coefficient, water solubility, and interfacial tension.

- the target liquid film cleavage effect is expressed.

- the liquid film cleaving agent is preferably a compound in which the structure X is a siloxane structure. Furthermore, in the liquid film cleaving agent, as specific examples of the structures X, XY, and YXY, the structures represented by the following formulas (1) to (11) are arbitrarily combined from a siloxane chain. Is preferred. Furthermore, it is preferable from the viewpoint of the liquid film cleaving action that this compound has a mass average molecular weight in the above-mentioned range.

- M 1 , L 1 , R 21 , and R 22 represent the following monovalent or polyvalent (divalent or higher) groups.

- R 23 and R 24 represent the following monovalent or polyvalent (divalent or higher) group or a single bond.

- M 1 is a group having a polyoxyethylene group, a polyoxypropylene group, a polyoxybutylene group, or a polyoxyalkylene group obtained by combining them, an erythritol group, a xylitol group, a sorbitol group, a glycerin group or an ethylene glycol group.

- Hydrophilic groups having a plurality of hydroxyl groups hydrophilic groups formed by removing one hydrogen atom from the above compound having a plurality of hydroxyl groups such as erythritol), hydroxyl groups, carboxylic acid groups, mercapto groups, alkoxy groups (preferably having 1 to 20 carbon atoms) For example, a methoxy group is preferred), amino group, amide group, imino group, phenol group, sulfonic acid group, quaternary ammonium group, sulfobetaine group, hydroxysulfobetaine group, phosphobetaine group, imidazolium betaine group, carbobetaine.

- M 1 is a polyvalent group

- M 1 represents a group obtained by removing one or more hydrogen atoms from each of the above groups or functional groups.

- L 1 is an ether group, an amino group (an amino group that can be taken as L 1 is represented by> NR C (R C is a hydrogen atom or a monovalent group)), an amide group, an ester group, a carbonyl group, The bonding group of a carbonate group is shown.

- R 21 , R 22 , R 23 , and R 24 are each independently an alkyl group (preferably having 1 to 20 carbon atoms.

- methyl group, ethyl group, propyl group, isopropyl group, butyl group, pentyl group, hexyl group) Group, heptyl group, 2-ethylhexyl group, nonyl group and decyl group are preferred

- alkoxy group preferably having 1 to 20 carbon atoms, for example, preferably methoxy group and ethoxy group

- aryl group having 6 to 6 carbon atoms.

- R 20 is preferable, for example, a phenyl group is preferable), a fluoroalkyl group, an aralkyl group, a hydrocarbon group obtained by combining them, or a halogen atom (for example, a fluorine atom is preferable).

- R ⁇ 22 > and R ⁇ 23 > are polyvalent groups

- examples of the group that can be taken as R 22 or R 23 include an imino group that can be taken as R 32 in addition to the above groups, the hydrocarbon group, or the halogen atom. It is done.

- the liquid film cleaving agent has a structure represented by any one of formulas (1), (2), (5) and (10) as X, and the end of X or the end of X and Y

- a compound having a structure represented by any one of the above formulas other than these formulas is preferable.

- X or a group consisting of X terminal and Y has a structure represented by any of the above formulas (2), (4), (5), (6), (8) and (9).

- a compound composed of a siloxane chain having at least one is preferable.

- organic surfactants that are silicone surfactants.

- examples of the organic modified silicone modified with a reactive organic group include amino modified, epoxy modified, carboxy modified, diol modified, carbinol modified, (meth) acryl modified, mercapto modified, and phenol modified.

- Organic modified silicones modified with non-reactive organic groups include polyether modified (including polyoxyalkylene modified), methylstyryl modified, long chain alkyl modified, higher fatty acid ester modified, higher alkoxy modified, higher fatty acid. Examples include modified and fluorine-modified ones.

- the expansion coefficient exhibiting the above-mentioned liquid film cleavage action can be obtained.

- the “long chain” refers to those having 12 or more carbon atoms, preferably 12 to 20 carbon atoms.

- the term “higher” means that having 6 or more carbon atoms, preferably 6 to 20 carbon atoms.

- a modified silicone having a structure in which a liquid film cleaving agent that is a modified silicone has at least one oxygen atom in a modified group such as polyoxyalkylene-modified silicone, epoxy-modified silicone, carbinol-modified silicone, and diol-modified silicone is preferable.

- polyoxyalkylene-modified silicone is preferred. Since the polyoxyalkylene-modified silicone has a polysiloxane chain, it hardly penetrates into the inside of the fiber and tends to remain on the surface.

- the addition of a hydrophilic polyoxyalkylene chain is preferable because the affinity with water is increased and the interfacial tension is low, so that the movement on the surface of the liquid film is likely to occur.

- the movement on the surface of the liquid film described above easily occurs.

- the polyoxyalkylene-modified silicone is subjected to hot melt processing such as embossing, it tends to remain on the fiber surface at that portion, and the liquid film cleavage action is difficult to reduce.

- the liquid film cleaving action is sufficiently exhibited at the embossed portion where the liquid tends to accumulate, which is preferable.

- polyoxyalkylene-modified silicone examples include those represented by the following formulas [I] to [IV]. Furthermore, the polyoxyalkylene-modified silicone preferably has a mass average molecular weight within the above-mentioned range from the viewpoint of the liquid film cleavage action.

- R 31 is an alkyl group (preferably having 1 to 20 carbon atoms. For example, methyl group, ethyl group, propyl group, isopropyl group, butyl group, pentyl group, hexyl group, heptyl group, 2-ethyl-hexyl group, Nonyl group and decyl group are preferred).

- R 32 represents a single bond or an alkylene group (preferably having a carbon number of 1 to 20, for example, a methylene group, an ethylene group, a propylene group or a butylene group is preferred), and preferably represents the alkylene group.

- the plurality of R 31 and the plurality of R 32 may be the same as or different from each other.

- M 11 represents a group having a polyoxyalkylene group, and a polyoxyalkylene group is preferable.

- the polyoxyalkylene group include a polyoxyethylene group, a polyoxypropylene group, a polyoxybutylene group, or a copolymer of these constituent monomers.

- m and n are each independently an integer of 1 or more. The symbols of these repeating units are determined separately in each of the formulas (I) to (IV), and do not necessarily indicate the same integer and may be different.

- the polyoxyalkylene-modified silicone may have one or both modified groups of polyoxyethylene-modified and polyoxypropylene-modified.

- a methyl group in the alkyl group R 31 of the silicone chain is not particularly limited, and examples thereof include those described in paragraphs [0006] and [0012] of JP-A No. 2002-161474. More specifically, polyoxyethylene (POE) polyoxypropylene (POP) modified silicone, polyoxyethylene (POE) modified silicone, polyoxypropylene (POP) modified silicone and the like can be mentioned.

- Examples of the POE-modified silicone include POE (3) -modified dimethyl silicone added with 3 moles of POE.

- Examples of the POP-modified silicone include POP (10) -modified dimethyl silicone, POP (12) -modified dimethyl silicone, POP (24) -modified dimethyl silicone to which POP is added at 10 mol, 12 mol, or 24 mol.

- the expansion coefficient and water solubility of the first embodiment described above are, for example, the number of added moles of a polyoxyalkylene group (an oxyalkylene group that forms a polyoxyalkylene group with respect to 1 mole of the polyoxyalkylene-modified silicone). ), The following modification rate, and the like.

- the surface tension and the interfacial tension can also be set within predetermined ranges in the same manner. From the above viewpoint, those having an addition mole number of the polyoxyalkylene group of 1 or more are preferable.

- the number of added moles is more preferably 3 or more, and further preferably 5 or more.

- the number of added moles is preferably 30 or less, more preferably 20 or less, and still more preferably 10 or less. If the modification rate of the modified silicone is too low, the hydrophilicity is impaired, so that it is preferably 5% or more, more preferably 10% or more, and even more preferably 20% or more.

- the modification rate of the modified silicone is the ratio of the number of repeating units of the modified siloxane bonding portion to the total number of repeating units of the siloxane bonding portion in one molecule of the modified silicone. For example, (n / m + n) ⁇ 100% in the above formulas [I] and [IV], (2 / m) ⁇ 100% in the formula [II], and (1 / m) in the formula [III]. ⁇ 100%.

- the modified groups are water-soluble polyoxyethylene groups, water-insoluble polyoxypropylene groups, and polyoxybutylene groups, respectively.

- the molecular weight of the water-insoluble silicone chain By changing the molecular weight of the water-insoluble silicone chain, introducing an amino group, an epoxy group, a carboxy group, a hydroxyl group, a carbinol group, etc. in addition to the polyoxyalkylene modification as the modifying group, etc. Can be set within the range.

- the polyalkylene-modified silicone used as the liquid film cleaving agent is preferably contained in an amount of 0.02% by mass or more and 5.0% by mass or less as a content ratio to the fiber mass (Oil Per Unit).

- the content (OPU) of the polyalkylene-modified silicone is more preferably 1.0% by mass or less, and further preferably 0.40% by mass or less. By doing so, the laminated nonwoven fabric is not sticky and the tactile sensation is preferable.

- the content ratio (OPU) is more preferably 0.04% by mass or more, and further preferably 0.10% by mass or more.

- the liquid film cleaving agent in the second embodiment is preferably a compound having at least one structure selected from the group consisting of the following structures Z, ZY, and YZY.

- the structure Z includes:> C (A)- ⁇ C: carbon atom>, -C (A) 2- , -C (A) (B)-,> C (A) -C (R 3 ) ⁇ ,> C Any basic structure of (R 3 ) —, —C (R 3 ) (R 4 ) —, —C (R 3 ) 2 —,> C ⁇ is repeated, or two or more are combined Represents a hydrocarbon chain of structure.

- R 3 and R 4 are each independently a hydrogen atom or an alkyl group (preferably having 1 to 20 carbon atoms.

- methyl group, ethyl group, propyl group, isopropyl group, butyl group, pentyl group, hexyl group, heptyl Group, 2-ethyl-hexyl group, nonyl group and decyl group are preferable

- alkoxy group preferably having 1 to 20 carbon atoms, for example, methoxy group and ethoxy group are preferable

- aryl group having 6 to 20 carbon atoms.

- Preferred examples thereof include a phenyl group.

- a and B each independently represent a substituent containing an oxygen atom or a nitrogen atom, such as a hydroxyl group, a carboxylic acid group, an amino group, an amide group, an imino group, or a phenol group.

- R 3 , R 4 , A and B in the structure X they may be the same as or different from each other.

- the bond between successive C (carbon atoms) is usually a single bond, but may include a double bond or a triple bond, and the bond between C includes an ether group, an amide group, an ester group.

- a linking group such as a carbonyl group or a carbonate group may be contained.

- Y represents a hydrophilic group having hydrophilicity including an atom selected from a hydrogen atom, a carbon atom, an oxygen atom, a nitrogen atom, a phosphorus atom, and a sulfur atom.

- a hydroxyl group, a carboxylic acid group, an amino group, an amide group, an imino group, a phenol group; or a polyoxyalkylene group (the oxyalkylene group preferably has 1 to 4 carbon atoms.

- a hydrophilic group such as a sulfonic acid group, a sulfuric acid group, a phosphoric acid group, a sulfobetaine group, a carbobetaine group, a phosphobetaine group, a quaternary ammonium group, an imidazolium betaine group, an epoxy group, a carbinol group, or a methacryl group;

- Y When Y is plural, they may be the same or different.

- Y is bonded to Z or a terminal group of Z.

- the terminal group of Z is bonded to Y by removing, for example, the same number of hydrogen atoms as the number of bonds to Y.

- the hydrophilic groups Y, A, and B can be selected from the groups specifically described to satisfy the aforementioned expansion coefficient, water solubility, and interfacial tension. Thus, the target liquid film cleavage effect is expressed.

- the liquid film cleaving agent is preferably a compound in which the structures represented by the following formulas (12) to (25) are arbitrarily combined as specific examples of the structures Z, ZY, and YZY. . Furthermore, it is preferable from the viewpoint of the liquid film cleaving action that this compound has a mass average molecular weight in the above-mentioned range.

- M 2 , L 2 , R 41 , R 42 , and R 43 represent the following monovalent or polyvalent groups (divalent or higher).

- M 2 is a group having a polyoxyethylene group, a polyoxypropylene group, a polyoxybutylene group, or a polyoxyalkylene group in combination thereof, an erythritol group, a xylitol group, a sorbitol group, a glycerin group or an ethylene glycol group.

- Hydrophilic groups having a plurality of hydroxyl groups, hydroxyl groups, carboxylic acid groups, mercapto groups, alkoxy groups (preferably having 1 to 20 carbon atoms, preferably methoxy groups), amino groups, amide groups, imino groups, phenol groups, sulfonic acids Group, quaternary ammonium group, sulfobetaine group, hydroxysulfobetaine group, phosphobetaine group, imidazolium betaine group, carbobetaine group, epoxy group, carbinol group, (meth) acryl group, or a functional group combining them. Show.

- L 2 is an ether group, an amino group, an amide group, an ester group, a carbonyl group, a carbonate group, or a polyoxyethylene group, a polyoxypropylene group, a polyoxybutylene group, or a polyoxyalkylene group obtained by combining them.

- the bonding group of is shown.

- R 41 , R 42 , and R 43 are each independently a hydrogen atom or an alkyl group (preferably having 1 to 20 carbon atoms.

- a methyl group, an ethyl group, a propyl group, an isopropyl group, a butyl group, a pentyl group, a hexyl group) , A heptyl group, a 2-ethylhexyl group, a nonyl group and a decyl group are preferable, an alkoxy group (preferably having 1 to 20 carbon atoms, for example, a methoxy group and an ethoxy group are preferable), an aryl group (having 6 to 20 carbon atoms).

- a phenyl group is preferable), a fluoroalkyl group, an aralkyl group, a hydrocarbon group obtained by combining them, or various substituents composed of a halogen atom (for example, a fluorine atom is preferable).

- R 42 is a polyvalent group

- R 42 is the above-described substituent, further showing a group obtained by removing one or more hydrogen atoms.

- another structure may be arbitrarily connected to the tip of the bond described in each structure, or a hydrogen atom may be introduced.

- polyether compounds and nonionic surfactants can be mentioned.

- a polyoxyalkylene glycol represented by the formula (VI) having a mass average molecular weight of 1000 or more steareth, behenez

- PPG Examples include myristyl ether, PPG stearyl ether, and PPG behenyl ether.

- the polyoxyalkylene alkyl ether is preferably lauryl ether to which POP is added in an amount of 3 mol to 24 mol, preferably 5 mol.

- polypropylene glycol having a weight average molecular weight of 1000 to 10,000, preferably 3000, to which polypropylene glycol (PPG) is added in an amount of 17 to 180 mol, preferably about 50 mol, is preferable.

- PPG polypropylene glycol

- the measurement of said mass mean molecular weight can be performed with the measuring method mentioned above.

- the polyether compound and the nonionic surfactant are preferably contained in an amount of 0.10% by mass to 5.0% by mass with respect to the fiber mass (Oil Per Unit).

- the content ratio (OPU) of the polyether compound or nonionic surfactant is more preferably 1.0% by mass or less, and further preferably 0.40% by mass or less. By doing so, the non-woven fabric is not sticky and the tactile sensation is preferable. Further, from the viewpoint of sufficiently exerting the liquid film cleavage effect by the polyether compound or the nonionic surfactant, the content ratio (OPU) is more preferably 0.15% by mass or more, and further 0.20% by mass or more. preferable.

- L 21 represents an ether group, an amino group, an amide group, an ester group, a carbonyl group, a carbonate group, a polyoxyethylene group, a polyoxypropylene group, a polyoxybutylene group, or a polyoxyalkylene group obtained by combining them

- a linking group such as R 51 is a hydrogen atom, methyl group, ethyl group, propyl group, isopropyl group, butyl group, pentyl group, hexyl group, heptyl group, 2-ethylhexyl group, nonyl group, decyl group, methoxy group, ethoxy group, phenyl group , A fluoroalkyl group, an aralkyl group, a hydrocarbon group obtained by combining them, or various substituents composed of a fluorine atom.

- A, b, m and n are each independently an integer of 1 or more.

- the number of carbon atoms and the number of hydrogen atoms are determined independently in each of the formulas (V) and (VI), and do not necessarily indicate the same integer, and may be different.

- “m” in — (C a H b O) m — is an integer of 1 or more.

- the value of this repeating unit is determined independently in each of the formulas (V) and (VI), and does not necessarily indicate the same integer, and may be different.

- the expansion coefficient, surface tension, and water solubility of the second embodiment described above can be set within a predetermined range, for example, depending on the number of moles of the polyoxyalkylene group in the polyether compound or nonionic surfactant.

- the number of moles of the polyoxyalkylene group is preferably 1 or more and 70 or less. If it is less than 1, the interfacial tension is high, and the liquid film cleavage action is weakened. In this respect, the number of moles is more preferably 5 or more, and even more preferably 7 or more.

- the added mole number is preferably 70 or less, more preferably 60 or less, and still more preferably 50 or less.

- the entanglement of the molecular chain becomes moderately weak, and the diffusibility in the liquid film is excellent, which is preferable.

- the expansion coefficient, surface tension, interfacial tension and water solubility described above are the same for water-soluble polyoxyethylene groups, water-insoluble polyoxypropylene groups and polyoxybutylene groups in polyether compounds and nonionic surfactants, respectively.

- Use in combination change the chain length of the hydrocarbon chain, use a hydrocarbon chain having a branched chain, use a hydrocarbon chain having a double bond, benzene ring or naphthalene in the hydrocarbon chain It can be set within a predetermined range by using one having a ring or by appropriately combining the above.

- hydrocarbon compounds having 5 or more carbon atoms can be mentioned.

- the number of carbon atoms is preferably 100 or less, more preferably 50 or less, from the viewpoint that the liquid is more easily expanded to the liquid film surface.

- This hydrocarbon compound excludes polyorganosiloxane, and is not limited to a straight chain, but may be a branched chain, and the chain is not particularly limited to saturated or unsaturated.

- This hydrocarbon compound is preferably contained in an amount of 0.10% by mass to 5.0% by mass with respect to the fiber mass (Oil Per Unit).

- the content ratio (OPU) of the hydrocarbon compound is preferably 1.0% by mass or less, more preferably 0.99% by mass or less, and further preferably 0.40% by mass or less. By doing so, the surface material is not sticky and the tactile sensation is preferable. Further, from the viewpoint of sufficiently exhibiting the liquid film cleavage effect by the hydrocarbon compound, the content ratio (OPU) is more preferably 0.15% by mass or more, and further preferably 0.20% by mass or more.

- Hydrocarbon compounds include oils or fats, such as natural oils or natural fats. Specific examples include coconut oil, camellia oil, castor oil, coconut oil, corn oil, olive oil, sunflower oil, tall oil, and mixtures thereof. Moreover, the fatty acids as represented by Formula (VII), such as caprylic acid, capric acid, oleic acid, lauric acid, palmitic acid, stearic acid, myristic acid, behenic acid, and mixtures thereof, can be mentioned.

- oils or fats such as natural oils or natural fats. Specific examples include coconut oil, camellia oil, castor oil, coconut oil, corn oil, olive oil, sunflower oil, tall oil, and mixtures thereof.

- the fatty acids as represented by Formula (VII) such as caprylic acid, capric acid, oleic acid, lauric acid, palmitic acid, stearic acid, myristic acid, behenic acid, and mixtures thereof, can be mentioned.

- n and n are each independently an integer of 1 or more.

- C m H n is a hydrocarbon group of each of the above fatty acids.

- linear or branched, saturated or unsaturated, substituted or unsubstituted polyhydric alcohol fatty acid esters or mixtures of polyhydric alcohol fatty acid esters as represented by formula (VIII-I) or (VIII-II)

- examples thereof include glycerin fatty acid esters and pentaerythritol fatty acid esters, and specific examples include glyceryl tricaprylate, glyceryl tripalmitate, and mixtures thereof. Note that a mixture of glycerin fatty acid ester and pentaerythritol fatty acid ester typically contains some mono-, di-, and triesters.

- glycerin fatty acid ester examples include glyceryl tricaprylate, a mixture of glyceryl tricapryate, and the like. Also, from the viewpoint of reducing the interfacial tension and obtaining a higher expansion coefficient, a polyhydric alcohol fatty acid ester having a polyoxyalkylene group introduced to such an extent that water insolubility can be maintained may be used.

- m, m ′, m ′′, n, n ′, and n ′′ are each independently an integer of 1 or more.

- the plurality of m and the plurality of n may be the same as or different from each other.

- C m H n, C m 'H n' and C m '' H n '' are each a hydrocarbon group of each of the fatty acid.

- fatty acids or fatty acid mixtures in which linear or branched, saturated or unsaturated fatty acids form esters with polyols having a large number of hydroxyl groups, and some of the hydroxyl groups remain unesterified are represented by the formula ( IX), a glycerin fatty acid ester, a sorbitan fatty acid ester, and a partially esterified product of pentaerythritol fatty acid ester represented by any one of formula (X) or formula (XI).

- a mixture of partially esterified products such as glycerin fatty acid ester, sorbitan fatty acid ester, pentaerythritol fatty acid ester and the like typically contains some fully esterified compound.

- m and n are each independently an integer of 1 or more.

- the plurality of m and the plurality of n may be the same as or different from each other.

- C m H n is a hydrocarbon group of each of the above fatty acids.

- R 52 represents a linear or branched, saturated or unsaturated hydrocarbon group (an alkyl group, an alkenyl group, an alkynyl group, or the like) having 2 to 22 carbon atoms. Specific examples include 2-ethylhexyl group, lauryl group, myristyl group, palmityl group, stearyl group, behenyl group, oleyl group, linole group and the like.

- m and n are each independently an integer of 1 or more.

- the plurality of m and the plurality of n may be the same as or different from each other.

- C m H n is a hydrocarbon group of each of the above fatty acids.

- sterols can be mentioned.

- Specific examples include cholesterol, sitosterol, stigmasterol, ergosterol, and mixtures thereof having a sterol structure of the formula (XII).

- alcohols include lauryl alcohol, myristyl alcohol, cetyl alcohol, stearyl alcohol, cetostearyl alcohol, behenyl alcohol, and mixtures thereof as represented by formula (XIII).

- n and n are each independently an integer of 1 or more.

- C m H n is a hydrocarbon group of each of the above alcohol.

- fatty acid ester examples include isopropyl myristate, isopropyl palmitate, cetylethylhexanoate, triethylhexanoin, octyldodecyl myristate, ethylhexyl palmitate, ethylhexyl stearate, butyl stearate represented by the formula (XIV). Rate, myristyl myristate, stearyl stearate, cholesteryl isostearate and mixtures thereof.

- m and n are each independently an integer of 1 or more.

- two C m H n may be the same or different.

- C m H n -COO- of C m H n is a hydrocarbon group of each of the above fatty acids.

- C m H n in —COOC m H n represents an alcohol-derived hydrocarbon group that forms an ester.

- wax examples include ceresin, paraffin, petrolatum, mineral oil, liquid isoparaffin, and the like represented by the formula (XV).

- n and n are each independently an integer of 1 or more.

- the expansion coefficient, surface tension, water solubility, and interfacial tension of the second embodiment described above can maintain, for example, hydrophilic polyoxyethylene groups in water-insoluble in the above-described hydrocarbon compound having 5 or more carbon atoms.

- liquid film cleaving agent in addition to the above-described liquid film cleaving agent, other components may be included as necessary. Moreover, you may use the liquid film cleaving agent of 1st Embodiment, and the liquid film cleaving agent of 2nd Embodiment combining both agents other than the form used separately. This also applies to the first compound and the second compound in the liquid film cleaving agent of the second embodiment.

- the hydrophilicity of the first fiber layer 11 and the hydrophilicity of the second fiber layer 12 are both the hydrophilicity of the fibers constituting each fiber layer, and can be determined using the contact angle of deionized water to the constituent fibers as an index. it can.

- the contact angle is an angle between the fibrous water droplet and the fiber surface, and a decrease in hydrophilicity is synonymous with an increase in contact angle. This contact angle can be obtained by the following measuring method.

- the difference (W) between the contact angle of the first fiber layer 11 and the contact angle of the second fiber layer 12 is preferably 5 ° or more, more preferably 10 ° or more, and 15 ° from the viewpoint of the above-described liquid drawing-in property. The above is more preferable. Further, the larger the difference between the contact angle of the first fiber layer 11 and the contact angle of the second fiber layer 12, the better, but from the viewpoint of adjusting the hydrophilicity by adjusting the fiber treatment agent and the amount of adhesion. It is realistic to set it below the degree.