WO2016139830A1 - 粉砕ローラ及び粉砕機 - Google Patents

粉砕ローラ及び粉砕機 Download PDFInfo

- Publication number

- WO2016139830A1 WO2016139830A1 PCT/JP2015/074635 JP2015074635W WO2016139830A1 WO 2016139830 A1 WO2016139830 A1 WO 2016139830A1 JP 2015074635 W JP2015074635 W JP 2015074635W WO 2016139830 A1 WO2016139830 A1 WO 2016139830A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- roller

- tab

- housing

- rotation direction

- base

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C15/00—Disintegrating by milling members in the form of rollers or balls co-operating with rings or discs

- B02C15/004—Shape or construction of rollers or balls

- B02C15/005—Rollers or balls of composite construction

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C15/00—Disintegrating by milling members in the form of rollers or balls co-operating with rings or discs

- B02C15/04—Mills with pressed pendularly-mounted rollers, e.g. spring pressed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B02—CRUSHING, PULVERISING, OR DISINTEGRATING; PREPARATORY TREATMENT OF GRAIN FOR MILLING

- B02C—CRUSHING, PULVERISING, OR DISINTEGRATING IN GENERAL; MILLING GRAIN

- B02C15/00—Disintegrating by milling members in the form of rollers or balls co-operating with rings or discs

- B02C2015/002—Disintegrating by milling members in the form of rollers or balls co-operating with rings or discs combined with a classifier

Definitions

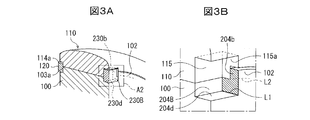

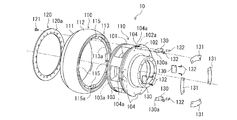

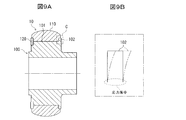

- a stopper portion 102 is formed on the outer periphery of one end side of the support portion 101 of the housing 100, and an annular groove portion fitted to the stopper portion 102 is formed on the inner periphery of the one end side of the roller 110. 113 is formed. Further, an annular groove portion 103 to which the holding plate 120 is attached is formed on the outer periphery of the other end side of the support portion 101 of the housing 100, and an annular groove portion to which the holding plate 120 is attached to the inner periphery of the other end side of the roller 110. 114 is formed.

- the solid material pulverized by the pulverizing roller 10 becomes a pulverized material, and is lifted while being dried by the primary air sent into the housing 11 from the inlet port 24 by driving the primary blower.

- the raised pulverized material is classified by the rotary separator 26, the coarse powder falls and is returned to the pulverization table 13 again to be pulverized again.

- the fine-grained powder passes through the rotary separator 26 and rides on the airflow. And discharged from the outlet port 27. Further, spillage such as gravel and metal pieces mixed in the solid matter is dropped outward from the outer peripheral portion by the centrifugal force of the crushing table 13, and is discharged by the foreign matter discharge pipe 28.

- a stopper portion 102 is formed on the outer periphery of one end side of the support portion 101 of the housing 100, and an annular groove portion fitted to the stopper portion 102 is formed on the inner periphery of the one end side of the roller 110. 113 is formed.

- An annular groove 103 to which the holding plate 120 is attached is formed on the outer periphery of the support portion 101 of the housing 100, and an annular groove that fits with the stopper portion 102 is formed on the inner periphery of the other end of the roller 110. 114 is formed.

- the holding plate 120 is a plate formed in an annular shape, and the annular groove 103 on the other end side of the housing 100 and the annular portion on the other end side of the roller 110 in a state where the roller 110 is fitted on the outer periphery of the support portion 101 of the housing 100. It is attached to the groove 114 and fastened to the housing 100 by a large number of bolts 121.

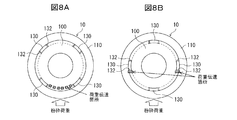

- the crushing roller 10 of this embodiment is characterized by the shape and size of the tab hole 204A of the housing 100 and the shape of the tab 230A, as shown in FIGS. 1A and 1B.

- 1A and 1B are cross-sectional views of the housing 100 and the tab holes 204A and 115 of the roller 110 that are broken at the center in the circumferential direction (center in the rotation direction) and showing half of the tab holes 204A and 115. The half is formed in a symmetrical shape.

- 1A shows a state in which the tab 230A and the shim 132 are mounted

- FIG. 1B shows a state in which the tab 230A and the shim 132 are removed.

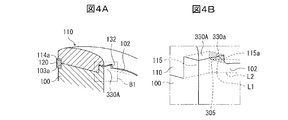

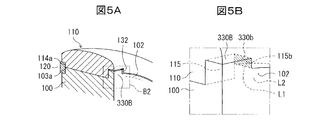

- the tab 230A is also formed to be large in the radial direction in accordance with the shape of the tab hole 204A, and faces the rotation direction surface 230a of the tab 230A that faces the rotation direction surface 204a of the tab hole 204A and the bottom surface 204c of the tab hole 204A.

- the bottom surface 230c of the tab 230A is also formed in accordance with the shape of the tab hole 204A.

- the tab hole 115 of the roller 110 is not particularly changed.

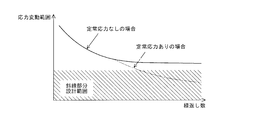

- rotation direction surface 204a of the tab hole 204A and the rotation direction surface 230a of the tab 230A are expanded as compared with the case where the base portion of the rotation direction surface 204a of the tab hole 204A is aligned with the base portion of the stopper portion 102 in the radial direction.

- the rotational force transmitted to the rotational direction surfaces 204a and 230a is dispersed by the expansion of the contact area, and from this point, stress concentration is alleviated.

- the line L2 where the fastening stress due to the presser plate 120 at the base of the stopper 102 is concentrated and the line L1 where the stress due to the grinding load received by the roller body 110 at the base of the tab hole 204A of the roller housing 100 is concentrated are shifted. Therefore, stress concentration is reduced.

- the rotational direction surface 204a of the tab hole 204A is expanded, the rotational direction force transmitted by the rotational direction surfaces 204a and 230a is dispersed, and the stress concentration is alleviated. Furthermore, since the boundary portion between the rotation direction surface 204a of the tab hole 204A and the bottom surface 204c of the tab hole 204A is connected to the smooth curved surface 205, stress concentration is reduced.

Landscapes

- Engineering & Computer Science (AREA)

- Food Science & Technology (AREA)

- Crushing And Grinding (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US15/554,561 US11224881B2 (en) | 2015-03-05 | 2015-08-31 | Grinding roller and mill |

| CN201580077141.6A CN107249748B (zh) | 2015-03-05 | 2015-08-31 | 粉碎辊以及粉碎机 |

| EP15883996.9A EP3248686A4 (en) | 2015-03-05 | 2015-08-31 | Crushing roller and crusher |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2015-043497 | 2015-03-05 | ||

| JP2015043497A JP6578110B2 (ja) | 2015-03-05 | 2015-03-05 | 粉砕ローラ及び粉砕機 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2016139830A1 true WO2016139830A1 (ja) | 2016-09-09 |

Family

ID=56843821

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2015/074635 Ceased WO2016139830A1 (ja) | 2015-03-05 | 2015-08-31 | 粉砕ローラ及び粉砕機 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US11224881B2 (enExample) |

| EP (1) | EP3248686A4 (enExample) |

| JP (1) | JP6578110B2 (enExample) |

| CN (1) | CN107249748B (enExample) |

| TW (1) | TW201632263A (enExample) |

| WO (1) | WO2016139830A1 (enExample) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6469343B2 (ja) * | 2013-12-13 | 2019-02-13 | 三菱日立パワーシステムズ株式会社 | 固体燃料粉砕装置および固体燃料粉砕装置の製造方法 |

| JP2023088544A (ja) * | 2021-12-15 | 2023-06-27 | 三菱重工業株式会社 | 粉砕ローラ及び固体燃料粉砕装置並びに粉砕ローラの製造方法 |

| JP2023091410A (ja) * | 2021-12-20 | 2023-06-30 | 三菱重工業株式会社 | 粉砕ローラ及び固体燃料粉砕装置並びに粉砕ローラの製造方法 |

| CN115069371B (zh) * | 2022-08-05 | 2025-09-26 | 西安科技大学 | 一种实验室用磨筛一体的磨煤机 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS62126255U (enExample) * | 1986-01-31 | 1987-08-11 | ||

| JPH03115044U (enExample) * | 1990-03-09 | 1991-11-27 | ||

| JPH0753710Y2 (ja) * | 1989-09-14 | 1995-12-13 | 川崎重工業株式会社 | 竪形ミルのローラ構造 |

Family Cites Families (24)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1478478A (en) * | 1921-05-25 | 1923-12-25 | Otto A Kreutzberg | Pulverizing apparatus |

| US4717082A (en) | 1978-12-28 | 1988-01-05 | Foster Wheeler Energy Corporation | Fixed roller pulverizing mill |

| US4232834A (en) | 1979-08-13 | 1980-11-11 | Minneapolis Electric Steel Castings Company | Roll crusher |

| DE3412033A1 (de) * | 1984-03-31 | 1985-10-03 | Abraham, Paul, 4350 Recklinghausen | Quetschrolle fuer quetschrollenmuehlen |

| JPS62126255A (ja) | 1985-11-26 | 1987-06-08 | Yamaha Motor Co Ltd | 気化器の始動回路 |

| JPS6325149A (ja) | 1986-07-18 | 1988-02-02 | Omron Tateisi Electronics Co | ヘツドライト制御装置 |

| JPS6325149U (enExample) * | 1986-07-31 | 1988-02-19 | ||

| DE3921419A1 (de) | 1989-06-29 | 1991-01-10 | Loesche Gmbh | Mahlflaeche von waelzmuehlen |

| JPH03115044A (ja) | 1989-09-29 | 1991-05-16 | Mitsubishi Heavy Ind Ltd | 巻取紙自動仕立装置 |

| JPH0753710A (ja) | 1993-08-19 | 1995-02-28 | Teijin Ltd | ポリカーボネート樹脂の製造方法 |

| DE4400090C1 (de) * | 1994-01-04 | 1995-04-20 | Loesche Gmbh | Mahlwalze |

| US6549935B1 (en) * | 1999-05-25 | 2003-04-15 | Silverbrook Research Pty Ltd | Method of distributing documents having common components to a plurality of destinations |

| US7267293B2 (en) * | 2005-05-13 | 2007-09-11 | Alstom Technology Ltd | High efficiency bowl mill |

| US7395981B2 (en) * | 2005-06-07 | 2008-07-08 | Robert L. Parham And Patricia L. Parham, Trustees, Or Their Successors In Trust, Under The Parham Family Trust Dated August 29, 2000, And Any Amendments Or Restatements Thereof | Plunger can assembly |

| US8357114B2 (en) * | 2006-01-06 | 2013-01-22 | Acelrx Pharmaceuticals, Inc. | Drug dispensing device with flexible push rod |

| CN106727271B (zh) * | 2006-01-06 | 2020-02-14 | 阿塞尔Rx制药有限公司 | 小体积口腔经粘膜剂型 |

| JP4801552B2 (ja) * | 2006-09-28 | 2011-10-26 | 三菱重工業株式会社 | バイオマス粉砕装置及びその制御方法 |

| EP2517794A1 (en) * | 2009-12-25 | 2012-10-31 | Ing Shoji Co., Ltd. | Vertical roller mill |

| JP2011245357A (ja) * | 2010-05-21 | 2011-12-08 | Mitsubishi Heavy Ind Ltd | バイオマス粉砕装置及びバイオマス・石炭混焼システム |

| DE102010056044A1 (de) | 2010-12-23 | 2012-06-28 | Keller Hcw Gmbh | Läufermantel und Felge für einen Kollerläufer, Kollerläufer sowie Verfahren zum Herstellen des Kollerläufers |

| JP2013066859A (ja) * | 2011-09-22 | 2013-04-18 | Mitsubishi Heavy Ind Ltd | 竪型ミル |

| IN2014CN03273A (enExample) * | 2011-11-11 | 2015-07-03 | Kawasaki Heavy Ind Ltd | |

| JP5906782B2 (ja) * | 2012-02-13 | 2016-04-20 | 宇部興産機械株式会社 | 竪型粉砕機 |

| JP5854902B2 (ja) * | 2012-03-21 | 2016-02-09 | 三菱日立パワーシステムズ株式会社 | 竪型粉砕機 |

-

2015

- 2015-03-05 JP JP2015043497A patent/JP6578110B2/ja active Active

- 2015-08-31 US US15/554,561 patent/US11224881B2/en active Active

- 2015-08-31 EP EP15883996.9A patent/EP3248686A4/en not_active Withdrawn

- 2015-08-31 WO PCT/JP2015/074635 patent/WO2016139830A1/ja not_active Ceased

- 2015-08-31 CN CN201580077141.6A patent/CN107249748B/zh active Active

- 2015-09-10 TW TW104129941A patent/TW201632263A/zh unknown

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS62126255U (enExample) * | 1986-01-31 | 1987-08-11 | ||

| JPH0753710Y2 (ja) * | 1989-09-14 | 1995-12-13 | 川崎重工業株式会社 | 竪形ミルのローラ構造 |

| JPH03115044U (enExample) * | 1990-03-09 | 1991-11-27 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP3248686A4 * |

Also Published As

| Publication number | Publication date |

|---|---|

| TWI561309B (enExample) | 2016-12-11 |

| EP3248686A1 (en) | 2017-11-29 |

| US20180071745A1 (en) | 2018-03-15 |

| JP2016159285A (ja) | 2016-09-05 |

| TW201632263A (zh) | 2016-09-16 |

| JP6578110B2 (ja) | 2019-09-18 |

| CN107249748B (zh) | 2019-12-13 |

| US11224881B2 (en) | 2022-01-18 |

| EP3248686A4 (en) | 2018-01-24 |

| CN107249748A (zh) | 2017-10-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6578110B2 (ja) | 粉砕ローラ及び粉砕機 | |

| EP2745939B1 (en) | Grinding mill | |

| EP3471887B1 (en) | System, method and apparatus for upgrading a pulverizer | |

| AU2014286527B2 (en) | Gyratory crusher topshell assembly | |

| CA2742607C (en) | Roller mill for grinding particulate material | |

| JP2012189211A (ja) | エアシールアッセンブリ | |

| JP7311440B2 (ja) | ローラミル装置及びローラミル装置の改造方法 | |

| JP2016150300A (ja) | 竪型粉砕機 | |

| TWI586433B (zh) | 碾碎輥子及碾碎裝置 | |

| US20130056569A1 (en) | Vertical mill | |

| CN108025311B (zh) | 用于粉碎设备的转子 | |

| US20100181403A1 (en) | Drum liner assembly for a mill drum having replaceable drum liner segments | |

| MX2014006968A (es) | Montaje base amortiguador de vibracion para un molino triturador. | |

| JP6413025B2 (ja) | 粉砕ローラ | |

| TW202302220A (zh) | 選粒器、及包含選粒器之粉碎機、及操作粉碎機之方法、及選粒器之用途 | |

| CN207745940U (zh) | 隔振型煤粉研磨机 | |

| JP2690753B2 (ja) | 竪型ローラミル | |

| KR102392240B1 (ko) | 분리형 분쇄 롤러 조립체 | |

| US20130146695A1 (en) | Journal brush seal assemblies | |

| JP5625401B2 (ja) | 竪型ミル及びテーブルセグメントの取付け方法 | |

| US20170348696A1 (en) | Secondary shredder | |

| JP2006513024A (ja) | 摩砕エレメント | |

| CN207839113U (zh) | 一种锤片粉碎机转子 | |

| BR112020020752A2 (pt) | Rolo de moagem e prensa de rolos | |

| KR20000025088A (ko) | 내마모성 미분기 분쇄장치 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 15883996 Country of ref document: EP Kind code of ref document: A1 |

|

| REEP | Request for entry into the european phase |

Ref document number: 2015883996 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 15554561 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |