WO2015199217A1 - 長尺状の偏光子の製造方法 - Google Patents

長尺状の偏光子の製造方法 Download PDFInfo

- Publication number

- WO2015199217A1 WO2015199217A1 PCT/JP2015/068504 JP2015068504W WO2015199217A1 WO 2015199217 A1 WO2015199217 A1 WO 2015199217A1 JP 2015068504 W JP2015068504 W JP 2015068504W WO 2015199217 A1 WO2015199217 A1 WO 2015199217A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- polarizer

- protective film

- manufacturing

- polarizing

- long

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D11/00—Producing optical elements, e.g. lenses or prisms

- B29D11/00634—Production of filters

- B29D11/00644—Production of filters polarizing

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C55/00—Shaping by stretching, e.g. drawing through a die; Apparatus therefor

- B29C55/02—Shaping by stretching, e.g. drawing through a die; Apparatus therefor of plates or sheets

- B29C55/023—Shaping by stretching, e.g. drawing through a die; Apparatus therefor of plates or sheets using multilayered plates or sheets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29C—SHAPING OR JOINING OF PLASTICS; SHAPING OF MATERIAL IN A PLASTIC STATE, NOT OTHERWISE PROVIDED FOR; AFTER-TREATMENT OF THE SHAPED PRODUCTS, e.g. REPAIRING

- B29C55/00—Shaping by stretching, e.g. drawing through a die; Apparatus therefor

- B29C55/02—Shaping by stretching, e.g. drawing through a die; Apparatus therefor of plates or sheets

- B29C55/04—Shaping by stretching, e.g. drawing through a die; Apparatus therefor of plates or sheets uniaxial, e.g. oblique

- B29C55/06—Shaping by stretching, e.g. drawing through a die; Apparatus therefor of plates or sheets uniaxial, e.g. oblique parallel with the direction of feed

- B29C55/065—Shaping by stretching, e.g. drawing through a die; Apparatus therefor of plates or sheets uniaxial, e.g. oblique parallel with the direction of feed in several stretching steps

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/08—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/30—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers

- B32B27/306—Layered products comprising a layer of synthetic resin comprising vinyl (co)polymers; comprising acrylic (co)polymers comprising vinyl acetate or vinyl alcohol (co)polymers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/36—Layered products comprising a layer of synthetic resin comprising polyesters

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B3/00—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form

- B32B3/26—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer

- B32B3/266—Layered products comprising a layer with external or internal discontinuities or unevennesses, or a layer of non-planar shape; Layered products comprising a layer having particular features of form characterised by a particular shape of the outline of the cross-section of a continuous layer; characterised by a layer with cavities or internal voids ; characterised by an apertured layer characterised by an apertured layer, the apertures going through the whole thickness of the layer, e.g. expanded metal, perforated layer, slit layer regular cells B32B3/12

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/14—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers

- B32B37/16—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers with all layers existing as coherent layers before laminating

- B32B37/20—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers with all layers existing as coherent layers before laminating involving the assembly of continuous webs only

- B32B37/203—One or more of the layers being plastic

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B1/00—Optical elements characterised by the material of which they are made; Optical coatings for optical elements

- G02B1/10—Optical coatings produced by application to, or surface treatment of, optical elements

- G02B1/14—Protective coatings, e.g. hard coatings

-

- G—PHYSICS

- G02—OPTICS

- G02B—OPTICAL ELEMENTS, SYSTEMS OR APPARATUS

- G02B5/00—Optical elements other than lenses

- G02B5/30—Polarising elements

- G02B5/3025—Polarisers, i.e. arrangements capable of producing a definite output polarisation state from an unpolarised input state

- G02B5/3033—Polarisers, i.e. arrangements capable of producing a definite output polarisation state from an unpolarised input state in the form of a thin sheet or foil, e.g. Polaroid

- G02B5/3041—Polarisers, i.e. arrangements capable of producing a definite output polarisation state from an unpolarised input state in the form of a thin sheet or foil, e.g. Polaroid comprising multiple thin layers, e.g. multilayer stacks

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2629/00—Use of polyvinylalcohols, polyvinylethers, polyvinylaldehydes, polyvinylketones or polyvinylketals or derivatives thereof, for preformed parts, e.g. for inserts

- B29K2629/04—PVOH, i.e. polyvinyl alcohol

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29K—INDEXING SCHEME ASSOCIATED WITH SUBCLASSES B29B, B29C OR B29D, RELATING TO MOULDING MATERIALS OR TO MATERIALS FOR MOULDS, REINFORCEMENTS, FILLERS OR PREFORMED PARTS, e.g. INSERTS

- B29K2667/00—Use of polyesters or derivatives thereof for preformed parts, e.g. for inserts

- B29K2667/003—PET, i.e. poylethylene terephthalate

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B38/00—Ancillary operations in connection with laminating processes

- B32B38/0012—Mechanical treatment, e.g. roughening, deforming, stretching

- B32B2038/0028—Stretching, elongating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B38/00—Ancillary operations in connection with laminating processes

- B32B38/04—Punching, slitting or perforating

- B32B2038/047—Perforating

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/02—2 layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/24—All layers being polymeric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/40—Properties of the layers or laminate having particular optical properties

- B32B2307/42—Polarizing, birefringent, filtering

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2309/00—Parameters for the laminating or treatment process; Apparatus details

- B32B2309/08—Dimensions, e.g. volume

- B32B2309/10—Dimensions, e.g. volume linear, e.g. length, distance, width

- B32B2309/105—Thickness

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2329/00—Polyvinylalcohols, polyvinylethers, polyvinylaldehydes, polyvinylketones or polyvinylketals

- B32B2329/04—Polyvinylalcohol

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2367/00—Polyesters, e.g. PET, i.e. polyethylene terephthalate

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2457/00—Electrical equipment

- B32B2457/20—Displays, e.g. liquid crystal displays, plasma displays

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/02—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by a sequence of laminating steps, e.g. by adding new layers at consecutive laminating stations

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/14—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers

- B32B37/144—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers using layers with different mechanical or chemical conditions or properties, e.g. layers with different thermal shrinkage, layers under tension during bonding

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B38/00—Ancillary operations in connection with laminating processes

- B32B38/10—Removing layers, or parts of layers, mechanically or chemically

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B38/00—Ancillary operations in connection with laminating processes

- B32B38/18—Handling of layers or the laminate

- B32B38/1825—Handling of layers or the laminate characterised by the control or constructional features of devices for tensioning, stretching or registration

Definitions

- the present invention relates to a method for producing a long polarizer. More specifically, the present invention relates to a method for manufacturing a long polarizer having non-polarizing portions arranged in a predetermined pattern.

- the present invention has been made to solve the above-described conventional problems, and its main purpose is to realize multi-functionality and high-functionality of electronic devices such as image display apparatuses, and there is variation in quality.

- Another object of the present invention is to provide a method for producing a long polarizer that can produce a polarizer as a final product without cost and with high productivity.

- a method for producing a long polarizer having a non-polarizing portion is provided.

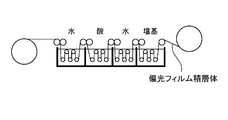

- a long surface protective film having through holes arranged at predetermined intervals in the long direction and / or the width direction is laminated on one surface of a long polarizer, Forming a linear polarizing film laminate; partially decolorizing the polarizer through a through-hole of the surface protective film to form a non-polarizing portion; and removing the surface protective film ;including.

- the through holes are arranged at predetermined intervals in the longitudinal direction. In one embodiment, the through holes are arranged at substantially equal intervals in at least the longitudinal direction.

- the decolorization is performed by immersing the polarizer in a basic solution.

- the said manufacturing method forms a recessed part in the said surface protection film side of the said polarizer by the said decoloring.

- the said non-polarizing part formed by the said decoloring is a low concentration part in which content of a dichroic substance is lower than another site

- the reduction of the dichroic substance is performed such that the content of the dichroic substance in the low concentration portion is 0.2% by weight or less.

- the manufacturing method reduces the alkali metal and / or alkaline earth metal contained in the polarizer at the contact portion where the basic solution of the polarizer is contacted after the decolorization. Further comprising.

- a long surface protective film having through holes arranged at predetermined intervals in the long direction and / or the width direction is provided on one surface of a long polarizer.

- the “elongate shape” means an elongated shape having a sufficiently long length with respect to the width, for example, an elongated shape having a length of 10 times or more, preferably 20 times or more with respect to the width. Including.

- the polarizer before forming a non-polarization part is an intermediate body of the polarizer which has a non-polarization part obtained by the manufacturing method of this invention strictly, it is only called a polarizer in this specification.

- polarizer means an intermediate or a polarizer having a non-polarization part obtained by the production method of the present invention. be able to.

- A-1-1 Preparation of laminate of resin substrate / PVA resin layer

- a PVA resin layer is formed on a resin substrate by applying a coating liquid containing a PVA resin and drying it.

- a laminate of PVA resin layers is prepared.

- the water absorption rate of the resin base material can be adjusted, for example, by introducing a modifying group into the forming material.

- the water absorption is a value determined according to JIS K 7209.

- the thickness of the resin base material before stretching is preferably 20 ⁇ m to 300 ⁇ m, more preferably 50 ⁇ m to 200 ⁇ m. If it is less than 20 ⁇ m, it may be difficult to form a PVA-based resin layer. If it exceeds 300 ⁇ m, for example, in stretching in water, it takes a long time for the resin base material to absorb water, and an excessive load may be required for stretching.

- the average degree of polymerization of the PVA resin can be appropriately selected according to the purpose.

- the average degree of polymerization is usually 1000 to 10,000, preferably 1200 to 4500, and more preferably 1500 to 4300.

- the average degree of polymerization can be determined according to JIS K 6726-1994.

- the laminate When employing an underwater stretching method, it is preferable to stretch the laminate by immersing it in an aqueous boric acid solution (stretching in boric acid in water).

- an aqueous boric acid solution as the stretching bath, the PVA resin layer can be provided with rigidity that can withstand the tension applied during stretching and water resistance that does not dissolve in water.

- boric acid can form a tetrahydroxyborate anion in an aqueous solution and crosslink with a PVA resin by hydrogen bonding.

- rigidity and water resistance can be imparted to the PVA-based resin layer, the film can be stretched well, and a polarizer having excellent optical characteristics can be produced.

- the laminate may be appropriately subjected to treatment for using the PVA resin layer as a polarizer.

- the treatment for obtaining a polarizer include insolubilization treatment, crosslinking treatment, washing treatment, and drying treatment.

- count, order, etc. of these processes are not specifically limited.

- a protective film is bonded to the polarizer surface of the resin base material / polarizer laminate, the resin base material is then peeled off, and further separated from the release surface of the resin base material as necessary.

- the protective film can be bonded. Bonding of the protective film can be typically performed by roll-to-roll.

- the manufacturing method of the present invention can also be a manufacturing method of a long polarizing plate including a polarizer having a non-polarizing portion.

- roll to roll means aligning and sticking together each other's elongate direction, conveying a roll-shaped film.

- FIG. 3 is a schematic cross-sectional view of the polarizing film laminate obtained as described above.

- the exposed portion 51 where the polarizer 10 is exposed is defined by the through hole 61 of the first surface protective film 50.

- borate As a metal salt which can produce

- the borate can be generated by neutralizing boric acid contained in the resin film with a basic solution (a solution of an alkali metal hydroxide and / or an alkaline earth metal hydroxide).

- the borate (metaborate) can be hydrolyzed to generate hydroxide ions as shown in the following formula, for example, when a polarizer is placed in a humidified environment. (Wherein X represents an alkali metal or alkaline earth metal)

- a method of bringing the treatment liquid into contact with the basic solution is preferably used. According to such a method, the content of the alkali metal and / or alkaline earth metal can be reduced by transferring the alkali metal and / or alkaline earth metal from the resin film to the treatment liquid.

- Examples of acidic compounds that can satisfy the above pKa include hydrochloric acid (pKa: -3.7), sulfuric acid (pK 2 : 1.96), nitric acid (pKa: -1.8), hydrogen fluoride (pKa: 3 .17), inorganic acids such as boric acid (pKa: 9.2), formic acid (pKa: 3.54), oxalic acid (pK 1 : 1.04, pK 2 : 3.82), citric acid (pK 1 : 3.09, pK 2 : 4.75, pK 3 : 6.41), acetic acid (pKa: 4.8), benzoic acid (pKa: 4.0), and other organic acids.

- hydrochloric acid pKa: -3.7

- sulfuric acid pK 2 : 1.96

- nitric acid pKa: -1.8

- hydrogen fluoride pKa: 3 .17

- inorganic acids such as boric acid (pK

- the above polarizer piece means a polarizer obtained by cutting a long polarizer.

- the polarizer piece may be simply referred to as a polarizer in the context.

- the non-polarizing portion is a low concentration portion where the content of the dichroic material is relatively low.

- the low-concentration part has a lower dichroic substance content than other parts.

- the non-polarizing portion is formed mechanically (for example, by a method of mechanically cutting off using a sculpture blade punching, a plotter, a water jet, etc.), a crack, Quality problems such as delamination (delamination) and paste sticking are avoided.

- the content of the dichroic substance itself is low in the low-concentration part, the transparency of the non-polarizing part is higher than when the non-polarizing part is formed by decomposing the dichroic substance with laser light or the like. Maintained well.

- the polarizer can be provided as a polarizing plate practically.

- the polarizing plate has a polarizer and a protective film disposed on at least one side of the polarizer (not shown).

- the polarizing plate has an adhesive layer as the outermost layer.

- the pressure-sensitive adhesive layer is typically the outermost layer on the image display device side.

- a separator is temporarily attached to the pressure-sensitive adhesive layer so as to be peeled off, and the pressure-sensitive adhesive layer is protected until actual use, and roll formation is possible.

- the polarizer is subjected to cutting to the predetermined size in the state of a polarizing plate.

- the polarizing plate is cut to a predetermined size and used to produce a plurality of polarizing plate pieces each having a polarizer having a non-polarizing portion and a protective film disposed on at least one side of the polarizer. It is done.

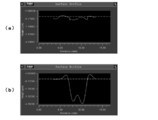

- the pressure-sensitive adhesive ester resin film with through-holes formed thereon is bonded to the polarizer surface of the obtained polarizing plate by roll-to-roll, and this is immersed in a 1 mol / L (1N) sodium hydroxide aqueous solution for 180 seconds. Then, it was immersed in 1 mol / L (1N) hydrochloric acid for 60 seconds. Then, it dried at 60 degreeC and formed the transparent part in the polarizer.

Landscapes

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Manufacturing & Machinery (AREA)

- Health & Medical Sciences (AREA)

- Ophthalmology & Optometry (AREA)

- Polarising Elements (AREA)

- Nonlinear Science (AREA)

- Mathematical Physics (AREA)

- Chemical & Material Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US15/321,974 US20170129197A1 (en) | 2014-06-27 | 2015-06-26 | Method for manufacturing long polarizer |

| KR1020157036688A KR101848987B1 (ko) | 2014-06-27 | 2015-06-26 | 장척상 편광자의 제조 방법 |

| CN201580035100.0A CN106471404B (zh) | 2014-06-27 | 2015-06-26 | 长条状的偏光件的制造方法 |

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014-132608 | 2014-06-27 | ||

| JP2014132608 | 2014-06-27 | ||

| JP2015-127644 | 2015-06-25 | ||

| JP2015127644A JP6215262B2 (ja) | 2014-06-27 | 2015-06-25 | 長尺状の偏光子の製造方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2015199217A1 true WO2015199217A1 (ja) | 2015-12-30 |

Family

ID=54938294

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2015/068504 Ceased WO2015199217A1 (ja) | 2014-06-27 | 2015-06-26 | 長尺状の偏光子の製造方法 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US20170129197A1 (enExample) |

| JP (1) | JP6215262B2 (enExample) |

| KR (1) | KR101848987B1 (enExample) |

| CN (1) | CN106471404B (enExample) |

| TW (1) | TWI669542B (enExample) |

| WO (1) | WO2015199217A1 (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20170083789A (ko) * | 2016-01-11 | 2017-07-19 | 주식회사 엘지화학 | 편광자, 이의 제조 방법 및 이를 포함하는 표시 장치 |

| JP2017142293A (ja) * | 2016-02-08 | 2017-08-17 | 日東電工株式会社 | 光学フィルム及び光学表示パネル |

| CN109478383A (zh) * | 2016-07-22 | 2019-03-15 | 日东电工株式会社 | 光学显示面板的制造方法和光学显示面板的制造系统 |

Families Citing this family (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6214594B2 (ja) | 2014-04-25 | 2017-10-18 | 日東電工株式会社 | 偏光子、偏光板および画像表示装置 |

| JP6215864B2 (ja) | 2014-04-25 | 2017-10-18 | 日東電工株式会社 | 偏光子、偏光板および画像表示装置 |

| JP6713189B2 (ja) * | 2014-06-27 | 2020-06-24 | 日東電工株式会社 | 長尺状の偏光フィルム積層体 |

| JP6215261B2 (ja) | 2014-06-27 | 2017-10-18 | 日東電工株式会社 | 長尺状の偏光子、長尺状の偏光板および画像表示装置 |

| CN105393147B (zh) * | 2014-06-30 | 2018-12-18 | Lg化学株式会社 | 具有局部去偏光区域的偏光板的制备方法,通过使用该方法制造的偏光板 |

| JP7163000B2 (ja) | 2015-06-25 | 2022-10-31 | 日東電工株式会社 | 非偏光部を有する偏光子 |

| JP6422415B2 (ja) | 2015-09-28 | 2018-11-14 | 日東電工株式会社 | 偏光子、偏光板および画像表示装置 |

| JP6619619B2 (ja) | 2015-11-04 | 2019-12-11 | 日東電工株式会社 | 偏光子、偏光板および偏光子の製造方法 |

| JP2018028563A (ja) * | 2016-08-15 | 2018-02-22 | 日東電工株式会社 | 偏光板およびその製造方法、ならびに該偏光板を用いた画像表示装置 |

| JP2018031954A (ja) * | 2016-08-26 | 2018-03-01 | 日東電工株式会社 | 偏光板およびその製造方法、ならびに該偏光板を用いた画像表示装置 |

| JP6945286B2 (ja) * | 2016-09-13 | 2021-10-06 | 日東電工株式会社 | 偏光子の製造方法 |

| CN106772755B (zh) * | 2017-02-27 | 2019-03-29 | 合肥京东方光电科技有限公司 | 一种偏光片和液晶显示设备 |

| JP7068456B2 (ja) | 2018-07-11 | 2022-05-16 | 日産自動車株式会社 | 走行環境情報の生成方法、運転制御方法、走行環境情報生成装置 |

| JP6956268B2 (ja) | 2018-07-11 | 2021-11-02 | 日産自動車株式会社 | 走行環境情報の生成方法、運転制御方法、走行環境情報生成装置 |

| JP7191578B2 (ja) * | 2018-08-01 | 2022-12-19 | 日東電工株式会社 | 偏光子、偏光板、および、画像表示装置 |

| JP2020020973A (ja) * | 2018-08-01 | 2020-02-06 | 日東電工株式会社 | 偏光子、偏光板、および、画像表示装置 |

| JP2020024240A (ja) * | 2018-08-06 | 2020-02-13 | 日東電工株式会社 | 偏光子の製造方法 |

| TWI755623B (zh) | 2018-08-22 | 2022-02-21 | 南韓商Lg化學股份有限公司 | 遮罩膜、影像顯示裝置、偏光片及其製備方法 |

| KR102239441B1 (ko) | 2018-08-22 | 2021-04-12 | 주식회사 엘지화학 | 마스크 필름을 이용한 편광판의 제조방법 및 그 편광판 |

| JP7294908B2 (ja) * | 2018-10-15 | 2023-06-20 | 日東電工株式会社 | 位相差層付偏光板およびそれを用いた画像表示装置 |

| JP7294909B2 (ja) * | 2018-10-15 | 2023-06-20 | 日東電工株式会社 | 位相差層付偏光板およびそれを用いた画像表示装置 |

| JP6655205B1 (ja) | 2018-12-13 | 2020-02-26 | 住友化学株式会社 | 打抜き用具、及び、打抜き方法 |

| KR102783428B1 (ko) | 2019-09-30 | 2025-03-18 | 삼성디스플레이 주식회사 | 표시 장치 |

| WO2021157228A1 (ja) * | 2020-02-03 | 2021-08-12 | 富士フイルム株式会社 | 偏光板、円偏光板、および、偏光板の製造方法 |

| KR102841168B1 (ko) | 2020-03-05 | 2025-07-31 | 삼성디스플레이 주식회사 | 표시 패널 및 이를 구비하는 표시 장치 |

| CN113703086B (zh) * | 2021-09-09 | 2022-07-26 | 武汉华星光电半导体显示技术有限公司 | 偏光片及其制作方法、显示装置 |

| CN113777689B (zh) * | 2021-09-24 | 2023-07-18 | 业成科技(成都)有限公司 | 去偏光方法、偏光板及显示装置 |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS58168019A (ja) * | 1982-03-29 | 1983-10-04 | Nitto Electric Ind Co Ltd | 部分カラ−偏光フイルムの製法 |

| US5327285A (en) * | 1990-06-11 | 1994-07-05 | Faris Sadeg M | Methods for manufacturing micropolarizers |

| WO2009128122A1 (ja) * | 2008-04-15 | 2009-10-22 | 日東電工株式会社 | 光学フィルムの積層体ロール並びにその製造方法及び装置 |

| JP2012137738A (ja) * | 2010-10-29 | 2012-07-19 | Apple Inc | 偏光窓及び不透明マスク層を有する電子デバイスのディスプレイ |

| JP2014081482A (ja) * | 2012-10-16 | 2014-05-08 | Nitto Denko Corp | 偏光子および画像表示装置 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4396646A (en) * | 1981-07-20 | 1983-08-02 | Polaroid Corporation | Method of making patterned polarizers |

| JPH10183390A (ja) * | 1996-12-25 | 1998-07-14 | Nikko Kinzoku Kk | 長尺金属条体のパターンめっき方法 |

| JP2003207608A (ja) * | 2001-11-12 | 2003-07-25 | Sony Corp | Ndフィルターとその製造方法及び撮像装置 |

| KR20150111878A (ko) * | 2014-03-26 | 2015-10-06 | 주식회사 엘지화학 | 국지적 탈색 영역을 포함하는 편광 부재의 제조 방법, 편광 부재 롤의 제조 방법 및 매엽형 편광 부재의 제조 방법 |

-

2015

- 2015-06-25 JP JP2015127644A patent/JP6215262B2/ja active Active

- 2015-06-26 WO PCT/JP2015/068504 patent/WO2015199217A1/ja not_active Ceased

- 2015-06-26 KR KR1020157036688A patent/KR101848987B1/ko active Active

- 2015-06-26 US US15/321,974 patent/US20170129197A1/en not_active Abandoned

- 2015-06-26 TW TW104120914A patent/TWI669542B/zh active

- 2015-06-26 CN CN201580035100.0A patent/CN106471404B/zh active Active

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS58168019A (ja) * | 1982-03-29 | 1983-10-04 | Nitto Electric Ind Co Ltd | 部分カラ−偏光フイルムの製法 |

| US5327285A (en) * | 1990-06-11 | 1994-07-05 | Faris Sadeg M | Methods for manufacturing micropolarizers |

| WO2009128122A1 (ja) * | 2008-04-15 | 2009-10-22 | 日東電工株式会社 | 光学フィルムの積層体ロール並びにその製造方法及び装置 |

| JP2012137738A (ja) * | 2010-10-29 | 2012-07-19 | Apple Inc | 偏光窓及び不透明マスク層を有する電子デバイスのディスプレイ |

| JP2014081482A (ja) * | 2012-10-16 | 2014-05-08 | Nitto Denko Corp | 偏光子および画像表示装置 |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20170083789A (ko) * | 2016-01-11 | 2017-07-19 | 주식회사 엘지화학 | 편광자, 이의 제조 방법 및 이를 포함하는 표시 장치 |

| KR102097816B1 (ko) * | 2016-01-11 | 2020-04-07 | 주식회사 엘지화학 | 편광자, 이의 제조 방법 및 이를 포함하는 표시 장치 |

| JP2017142293A (ja) * | 2016-02-08 | 2017-08-17 | 日東電工株式会社 | 光学フィルム及び光学表示パネル |

| JP2023061955A (ja) * | 2016-02-08 | 2023-05-02 | 日東電工株式会社 | 光学フィルム及び光学表示パネル |

| JP7334024B2 (ja) | 2016-02-08 | 2023-08-28 | 日東電工株式会社 | 光学フィルム及び光学表示パネル |

| JP7755607B2 (ja) | 2016-02-08 | 2025-10-16 | 日東電工株式会社 | 光学フィルム及び光学表示パネル |

| CN109478383A (zh) * | 2016-07-22 | 2019-03-15 | 日东电工株式会社 | 光学显示面板的制造方法和光学显示面板的制造系统 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP6215262B2 (ja) | 2017-10-18 |

| US20170129197A1 (en) | 2017-05-11 |

| CN106471404B (zh) | 2019-11-19 |

| TW201606361A (zh) | 2016-02-16 |

| CN106471404A (zh) | 2017-03-01 |

| KR20160016904A (ko) | 2016-02-15 |

| JP2016027394A (ja) | 2016-02-18 |

| KR101848987B1 (ko) | 2018-04-13 |

| TWI669542B (zh) | 2019-08-21 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6215262B2 (ja) | 長尺状の偏光子の製造方法 | |

| JP6215261B2 (ja) | 長尺状の偏光子、長尺状の偏光板および画像表示装置 | |

| JP6872309B2 (ja) | 偏光子 | |

| JP6713189B2 (ja) | 長尺状の偏光フィルム積層体 | |

| CN112051636A (zh) | 偏振片的制造方法 | |

| JP7369237B2 (ja) | 偏光板の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| ENP | Entry into the national phase |

Ref document number: 20157036688 Country of ref document: KR Kind code of ref document: A |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 15811537 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 15321974 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 15811537 Country of ref document: EP Kind code of ref document: A1 |