WO2015136766A1 - 低熱膨張鋳造合金およびその製造方法 - Google Patents

低熱膨張鋳造合金およびその製造方法 Download PDFInfo

- Publication number

- WO2015136766A1 WO2015136766A1 PCT/JP2014/079097 JP2014079097W WO2015136766A1 WO 2015136766 A1 WO2015136766 A1 WO 2015136766A1 JP 2014079097 W JP2014079097 W JP 2014079097W WO 2015136766 A1 WO2015136766 A1 WO 2015136766A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- thermal expansion

- content

- less

- mass

- low thermal

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/10—Ferrous alloys, e.g. steel alloys containing cobalt

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/001—Heat treatment of ferrous alloys containing Ni

-

- C—CHEMISTRY; METALLURGY

- C21—METALLURGY OF IRON

- C21D—MODIFYING THE PHYSICAL STRUCTURE OF FERROUS METALS; GENERAL DEVICES FOR HEAT TREATMENT OF FERROUS OR NON-FERROUS METALS OR ALLOYS; MAKING METAL MALLEABLE, e.g. BY DECARBURISATION OR TEMPERING

- C21D6/00—Heat treatment of ferrous alloys

- C21D6/007—Heat treatment of ferrous alloys containing Co

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/02—Ferrous alloys, e.g. steel alloys containing silicon

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/04—Ferrous alloys, e.g. steel alloys containing manganese

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/08—Ferrous alloys, e.g. steel alloys containing nickel

-

- C—CHEMISTRY; METALLURGY

- C22—METALLURGY; FERROUS OR NON-FERROUS ALLOYS; TREATMENT OF ALLOYS OR NON-FERROUS METALS

- C22C—ALLOYS

- C22C38/00—Ferrous alloys, e.g. steel alloys

- C22C38/10—Ferrous alloys, e.g. steel alloys containing cobalt

- C22C38/105—Ferrous alloys, e.g. steel alloys containing cobalt containing Co and Ni

Definitions

- the present invention relates to a low thermal expansion cast alloy with extremely small thermal expansion suitable for, for example, ultra-precision equipment members such as semiconductor manufacturing equipment and a method for manufacturing the same.

- Non-Patent Document 1 the alloy of 32% Ni-5% Co-balance Fe (hereinafter referred to as Super Invar) has a heat around room temperature.

- the expansion coefficient is 1 ⁇ 10 ⁇ 6 / ° C. or less, and rolled materials and forged materials (hereinafter referred to as steel materials) are commercialized and commercially available (for example, Non-Patent Document 1).

- Patent Document 1 is made of an iron-based alloy containing, by weight, C: 0.1% or less, Ni: 30-34%, Co: 4-6%, and Mn: 0.1-1.0. % And S: 0.02 to 0.15%, and an alloy for free-cutting low thermal expansion casting with Mn / 54.94> S / 32.06 has been proposed.

- Patent Document 2 a super invar having a thermal expansion coefficient of 0.5 ⁇ 10 ⁇ 6 / ° C. is used for a resonator of a microwave waveguide and a wafer stage of a semiconductor immersion exposure apparatus, respectively. It is described.

- the above-described Super Invar steel material has been required to suppress C to an impurity level of 0.02% or less in order to reliably obtain a thermal expansion coefficient of 1 ⁇ 10 ⁇ 6 / ° C. or less.

- the inventor's knowledge when such a low C super invar is melted and cast in the atmosphere, gas defects frequently occur and industrial production is very difficult, so it is necessary to perform vacuum melting. is there. It is impractical to perform complex operations using expensive equipment for ordinary casters, and it is virtually impossible to produce a low-C super invar casting.

- Patent Document 1 the Ni content and the Co content are equivalent to those of Super Invar, and the C content is allowed to be within 0.1% or less to an air casting range.

- the coefficient of thermal expansion is 0.773 ⁇ 10 ⁇ 6 / ° C. or less at such a very low C content. It is only shown that. That is, Patent Document 1 also suggests that in order to obtain a thermal expansion coefficient of 1 ⁇ 10 ⁇ 6 / ° C. or less, C needs to be an extremely low value of about 0.01%.

- Patent Document 1 Although it is described in Patent Document 1 that an alloy suitable for the production of a thin-walled large casting can be provided, since it is actually necessary to reduce the C content, it is still necessary to melt and cast in the atmosphere. It is very difficult, and it is considered difficult for an ordinary caster to industrially use a cast alloy using the technique of Patent Document 1.

- Super Invar steel shown in Non-Patent Document 1 can be applied only to simple shapes such as plates and rods, and complicated shapes and large parts used for precision devices are manufactured by cutting or welding assembly. Although it is necessary, there is also a problem that a great number of man-hours and costs are required due to the low machinability and weldability of Super Invar.

- Patent Document 1 such a problem is solved by adding a predetermined amount of S and Mn and improving machinability by MnS in the matrix.

- the alloy of Patent Document 1 is used.

- an object of the present invention is to provide a low thermal expansion cast alloy having a very low thermal expansion coefficient equivalent to that of Super Invar, and a method for producing the same, while containing C at a level capable of normal atmospheric dissolution and casting. It is in.

- Another object of the present invention is to provide a machinability superior to that of Super Invar, having an extremely small thermal expansion coefficient equivalent to that of Super Invar, while containing C at a level that allows normal atmospheric dissolution.

- An object of the present invention is to provide a low thermal expansion cast alloy and a method for producing the same.

- the present invention provides the following (1) to (7).

- a low thermal expansion cast alloy having the composition as described in (1) or (2) above, and having an average thermal expansion coefficient of 20 to 25 ° C. of 1 ⁇ 10 ⁇ 6 / ° C. or less.

- a low thermal expansion cast alloy having the composition as described in (1) or (2) above, and having an average coefficient of thermal expansion of 20 to 25 ° C. of 0.5 ⁇ 10 ⁇ 6 / ° C. or less .

- a low thermal expansion cast alloy having an extremely small thermal expansion coefficient equivalent to that of Super Invar, and a method for producing the same, while containing C at a level capable of normal atmospheric dissolution and casting.

- the present inventors have made the C content in the alloy a level that enables atmospheric dissolution and atmospheric casting, i) adjusting the Co content according to the C content; ii) It was found that by defining the Ni content according to the Co content, an extremely small thermal expansion coefficient equivalent to that of Super Invar can be obtained.

- Patent Document 1 describes the reasons for limiting the ranges of C, Ni, and Co

- the composition of the example is a super invar composition (32% Ni-5% Co—Fe with a C of about 0.01%). ) it is only thereby 1 although ⁇ 10 -6 / ° C. or less of the thermal expansion coefficient is obtained, it is shown that the thermal expansion coefficient of 1 ⁇ 10 -6 / ° C. or less in the composition of claims is obtained It has not been.

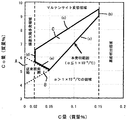

- the range of C content and Co content of Super Invar is the range indicated by region A in FIG. That is, conventionally, if C is suppressed to an impurity level, the coefficient of thermal expansion can be surely reduced to 1 ⁇ 10 ⁇ 6 / ° C. or less in the range of 4 to 6% Co. However, when C increases, the range becomes narrower, If C exceeds 0.05%, it has been considered impossible to obtain a thermal expansion coefficient of 1 ⁇ 10 ⁇ 6 / ° C. or less even if the amount of Co is adjusted.

- region A in FIG. 1 in which C capable of obtaining an air-dissolved cast product exceeds 0.02% to 0.05% or less (region B in FIG. 1), although a thermal expansion coefficient of 1 ⁇ 10 ⁇ 6 / ° C. or less can be obtained, when producing a cast product by melting in the atmosphere, in addition to C, Si and Mn that increase the thermal expansion coefficient are deoxidized and castability Since it is added for the purpose of improvement, a region where the thermal expansion coefficient actually exceeds 1 ⁇ 10 ⁇ 6 / ° C. is generated. Therefore, in order to obtain a thermal expansion coefficient of 1 ⁇ 10 ⁇ 6 / ° C. or lower, it is necessary to limit C lower as seen in Patent Document 1. As a result, in the casting material, the region B in FIG. 1 is translated to the low C side, the components must be adjusted to a limited range, and it is difficult to reliably produce an appropriate cast product. It was thought.

- a composition that can obtain a thermal expansion coefficient of 1 ⁇ 10 ⁇ 6 / ° C. or less is premised on the assumption that the C content exceeds 0.02%, which allows atmospheric melting and casting.

- the range of C content and Co content satisfies the range of region C in FIG. 1, and by defining the Ni content according to the Co content, thermal expansion of 1 ⁇ 10 ⁇ 6 / ° C. or less It was newly found that the coefficient can be obtained.

- Tool lubrication can be promoted by appropriately distributing sulfides, and a cast alloy having a low machinability of 1 ⁇ 10 ⁇ 6 / ° C. or less and good machinability without causing solidification cracks can be obtained. I found out.

- the first embodiment is to obtain a cast alloy having a low thermal expansion coefficient equivalent to that of Super Invar while containing C at a level that allows normal atmospheric dissolution and atmospheric casting.

- % display in the component is mass%

- thermal expansion coefficient is an average thermal expansion coefficient of 20 to 25 ° C.

- [Chemical composition] C more than 0.02% and not more than 0.15% C is an element that remarkably increases the thermal expansion coefficient.

- C is 0 If the content exceeds 0.02%, it has been difficult to obtain a low thermal expansion coefficient of 1 ⁇ 10 ⁇ 6 / ° C. or less.

- C has an effect of improving the castability and soundness of a low thermal expansion alloy cast product having a super invar composition, and in the present invention, an appropriate casting design is performed so that a sound cast product can be obtained even in air melting.

- the C content is more than 0.02%. Specifically, as shown in FIG.

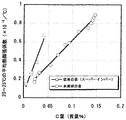

- FIG. 2 shows the relationship between the C content and the coefficient of thermal expansion in the conventional alloy (Super Invar) and the alloy of the present invention. As shown in this figure, it can be seen that in the present invention, low thermal expansion is obtained even if the C content is large.

- Si is an element added for the purpose of deoxidation and improvement of hot water flow. However, if its content exceeds 0.3%, an increase in the coefficient of thermal expansion cannot be ignored like C. Therefore, the Si content is set to 0.3% or less.

- Mn is an element effective for deoxidation. However, if the content is less than 0.25%, the effect is small, and if it exceeds 0.6%, the thermal expansion coefficient increases greatly. Therefore, the Mn content is in the range of 0.25 to 0.6%.

- Co is an important element that determines the thermal expansion coefficient together with Ni, which will be described later, and is an indispensable element for obtaining a smaller thermal expansion coefficient than when Ni alone is added. If it is less than 5%, the coefficient of thermal expansion exceeds 1 ⁇ 10 ⁇ 6 / ° C., and if it exceeds 9.5%, the coefficient of thermal expansion is still 1 ⁇ 10 ⁇ 6 / ° C. even if the amount of Co is adjusted with respect to the amount of C described later. Over. Therefore, the Co content is in the range of 5 to 9.5%.

- Ni 29-32.5%

- Ni is an important element that determines the thermal expansion coefficient together with Co, and the thermal expansion coefficient can be reduced to 1 ⁇ 10 ⁇ 6 / ° C. or less by adjusting it to the range described later according to the amount of Co.

- Ni is less than 29% or more than 32.5%, the thermal expansion coefficient exceeds 1 ⁇ 10 ⁇ 6 / ° C. even by the above adjustment. Therefore, Ni is made 29 to 32.5% of range.

- Co and C are (a) [Co] ⁇ 40 ⁇ [C] +3, (B) [C] ⁇ 0.15, (C) [Co] ⁇ (70/3) ⁇ [C] +6, (D) [C]> 0.02.

- E) [Co] ⁇ ⁇ 20 ⁇ [C] +6 [Ni] + 0.8 ⁇ [Co] is in a range of 35.5 to 36.5%

- the low thermal expansibility of the Fe—Ni—Co alloy is remarkably obtained when the Ni equivalent represented by [Ni] + 0.8 ⁇ [Co] is in the range of 35.5 to 36.5%. Even if it is less than 5% or more than 36.6%, it is difficult to obtain a desired low thermal expansion property. Therefore, the Ni equivalent is set in the range of 35.5 to 36.5%.

- the balance is Fe and inevitable impurities.

- S is contained as an impurity.

- the cast alloy of the present embodiment as described above can obtain a low coefficient of thermal expansion of 1 ⁇ 10 ⁇ 6 / ° C. or less, and is 0.5 ⁇ 10 ⁇ 6 / ° C. or less by optimizing the composition. An extremely low coefficient of thermal expansion can be obtained.

- the first embodiment since it has a low thermal expansion coefficient equivalent to that of Super Invar and contains C at a level that allows normal atmospheric dissolution and atmospheric casting, a low thermal expansion cast alloy can be obtained. For this reason, it can obtain without welding the complicated shape goods and large sized parts of low thermal expansion.

- the second embodiment can obtain a thermal expansion coefficient equivalent to that of Super Invar while containing C at a level that allows normal atmospheric dissolution and atmospheric casting, and has excellent machinability.

- Mn is an element effective for deoxidation, and also plays an important role in improving machinability by forming sulfides with S as described later. If the content is less than 0.25%, the effect is small, and if it exceeds 0.6%, the thermal expansion coefficient increases greatly. Therefore, the Mn content is in the range of 0.25 to 0.6%.

- S forms sulfides with Mn and contributes to improvement of machinability, it is positively added in this embodiment. However, if it is contained in a large amount in the alloy, low melting point FeS is formed at the grain boundary and becomes brittle, causing ductility and cracking. If it exceeds 0.035%, it becomes a complicated shape or a large casting. Prone to solidification cracking. On the other hand, if the content is less than 0.015%, the machinability improving effect is small. Therefore, the S content is in the range of 0.015 to 0.035%.

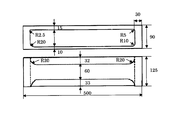

- [Mn] / [S] ⁇ 46-1335 / t + 1430 / t 2 (However, [Mn] and [S] are their contents, and t is the maximum thickness (mm) of the cast product) [Mn] / [S] influences the amount and composition of sulfides and is an important parameter for determining the tendency of solidification cracking.

- the tendency of solidification cracking is influenced not only by the ratio of Mn and S but also by t.

- FIG. 4 shows the maximum thickness t (mm) corresponding to the size of R.

- solidification cracking can be effectively prevented by setting Mn / S to about 34 for a casting having a maximum thickness of 100 mm.

- the balance of C, Si, Mn, S, Co, and Ni is Fe and inevitable impurities.

- the alloy of the first embodiment further contains S.

- the S content is within the range of the present embodiment, thermal expansion is not affected. That is, the cast alloy of the present embodiment can obtain a low coefficient of thermal expansion of 1 ⁇ 10 ⁇ 6 / ° C. or less, as well as the cast alloy of the first embodiment. A very low coefficient of thermal expansion of ⁇ 10 ⁇ 6 / ° C. or less can be obtained.

- the second embodiment while having a low thermal expansion coefficient equivalent to that of Super Invar, it contains C at a level that allows normal atmospheric dissolution and casting, and improves machinability without causing solidification cracking. Thus, a free-cutting low thermal expansion cast alloy can be obtained. For this reason, it is possible to manufacture a complex shape product or a large component with low thermal expansion without welding and with good machinability.

- the first example corresponds to the first embodiment.

- an alloy having each chemical composition shown in Table 1 was melted in the atmosphere in a high frequency induction furnace, and a specimen according to JIS G0307, FIG. 1 b) was cast. In either case, a CO 2 silica sand mold was used as a mold.

- the second example corresponds to the second embodiment.

- an alloy having each chemical composition shown in Table 2 is melted in the atmosphere in a high frequency induction furnace, and a test material and a 60 mm ⁇ 250 mm ⁇ 25 mm machinability test piece according to JIS G0307 FIG. No. 2 21-No. 24 and no.

- a solidified cracking test piece shown in FIG. 3 was cast. In either case, a CO 2 silica sand mold was used as a mold.

- a ⁇ 6 ⁇ 12 mm thermal expansion test piece was taken from the test material, and the average thermal expansion coefficient between 20 and 25 ° C. was measured with a laser interference thermal dilatometer.

- the crack test pieces were confirmed by the dye penetrant inspection method for the presence or absence of cracks in the four types of R in FIG.

- the alloy of the present invention is No. Nos. 21 to 28 all have an average coefficient of thermal expansion between 20 to 25 ° C. of 1 ⁇ 10 ⁇ 6 / ° C. or less.

- 21 and no. 27 and no. 28 is 0.5 ⁇ 10 ⁇ 6 / ° C. or less.

- No. 28 is 0.2 ⁇ 10 ⁇ 6 / ° C., which is equivalent to the conventional super invar, and it has been confirmed that it has characteristics that can meet recent severe demands.

- no gas defects were produced during casting, and no cracks could be confirmed in any R part of the solidification cracking test piece, indicating good solidification cracking resistance.

- machinability was also good.

- the third embodiment relates to manufacturing conditions.

- No. 1 in Table 1 is used.

- a plurality of specimens having a composition of 5 and heat-treated under the respective heat treatment conditions 1 to 13 shown in Table 3 were prepared, and the thermal expansion coefficient was obtained.

- the results are shown in Table 4.

- Table 4 after heating in the temperature range of 700 to 950 ° C., 5 ° C./sec. If conditions 5, 6, 8, 9, and 11 satisfying the conditions for cooling to 450 ° C. or lower at the above cooling rate, the thermal expansion coefficient is 1 ⁇ 10 ⁇ 6 / ° C. or lower and cracks are not generated. It was done.

- the thermal expansion coefficient exceeds 1 ⁇ 10 ⁇ 6 / ° C.

- the thermal expansion coefficient is 1 ⁇ 10 ⁇ 6 / ° C.

- the thermal expansion coefficient exceeds 1 ⁇ 10 ⁇ 6 / ° C.

- the thermal expansion coefficient is 1 ⁇ 10 ⁇ 6 / ° C.

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Crystallography & Structural Chemistry (AREA)

- Heat Treatment Of Steel (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Treatment Of Steel In Its Molten State (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| KR1020167007739A KR102077297B1 (ko) | 2014-03-10 | 2014-10-31 | 저열팽창 주조 합금 및 그 제조 방법 |

| CN201480059372.XA CN106103767B (zh) | 2014-03-10 | 2014-10-31 | 低热膨胀铸造合金及其制造方法 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014-045971 | 2014-03-10 | ||

| JP2014045971A JP5893659B2 (ja) | 2014-03-10 | 2014-03-10 | 低熱膨張鋳造合金およびその製造方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2015136766A1 true WO2015136766A1 (ja) | 2015-09-17 |

Family

ID=54071232

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2014/079097 Ceased WO2015136766A1 (ja) | 2014-03-10 | 2014-10-31 | 低熱膨張鋳造合金およびその製造方法 |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JP5893659B2 (enExample) |

| KR (1) | KR102077297B1 (enExample) |

| TW (1) | TWI568861B (enExample) |

| WO (1) | WO2015136766A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4144880A4 (en) * | 2020-04-27 | 2024-01-24 | Shinhokoku Material Corp. | CASTING WITH LOW THERMAL EXPANSION AND PRODUCTION PROCESS THEREOF |

| EP4183501A4 (en) * | 2020-07-17 | 2024-08-07 | Shinhokoku Material Corp. | Low thermal expansion casting and method for producing same |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6350446A (ja) * | 1986-08-19 | 1988-03-03 | Hitachi Metarupureshijiyon:Kk | 低熱膨張合金 |

| JP2001011580A (ja) * | 1999-07-02 | 2001-01-16 | Shin-Hokoku Steel Corp | 低温安定型Ni−Co−Fe系低熱膨張合金 |

| JP2001192776A (ja) * | 1999-10-29 | 2001-07-17 | Dainippon Printing Co Ltd | 展張型シャドウマスク |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH11279707A (ja) * | 1998-03-31 | 1999-10-12 | Nippon Chuzo Kk | 快削性低熱膨張合金およびその製造方法 |

| JP4253100B2 (ja) * | 2000-03-17 | 2009-04-08 | 日本鋳造株式会社 | 被削性に優れた低熱膨張合金およびその製造方法 |

| JP2002206142A (ja) | 2000-12-28 | 2002-07-26 | Kobe Steel Ltd | 快削性低熱膨張鋳物用合金 |

| JP4615210B2 (ja) | 2003-12-16 | 2011-01-19 | 財団法人国際科学振興財団 | 液浸型露光装置 |

| JP2010206615A (ja) | 2009-03-04 | 2010-09-16 | Mitsubishi Electric Corp | 光マイクロ波発振器 |

-

2014

- 2014-03-10 JP JP2014045971A patent/JP5893659B2/ja active Active

- 2014-10-31 KR KR1020167007739A patent/KR102077297B1/ko active Active

- 2014-10-31 WO PCT/JP2014/079097 patent/WO2015136766A1/ja not_active Ceased

- 2014-11-11 TW TW103139053A patent/TWI568861B/zh active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS6350446A (ja) * | 1986-08-19 | 1988-03-03 | Hitachi Metarupureshijiyon:Kk | 低熱膨張合金 |

| JP2001011580A (ja) * | 1999-07-02 | 2001-01-16 | Shin-Hokoku Steel Corp | 低温安定型Ni−Co−Fe系低熱膨張合金 |

| JP2001192776A (ja) * | 1999-10-29 | 2001-07-17 | Dainippon Printing Co Ltd | 展張型シャドウマスク |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP4144880A4 (en) * | 2020-04-27 | 2024-01-24 | Shinhokoku Material Corp. | CASTING WITH LOW THERMAL EXPANSION AND PRODUCTION PROCESS THEREOF |

| US12421565B2 (en) | 2020-04-27 | 2025-09-23 | Shinhokoku Material Corp. | Low thermal expansion cast steel and method of production of same |

| EP4183501A4 (en) * | 2020-07-17 | 2024-08-07 | Shinhokoku Material Corp. | Low thermal expansion casting and method for producing same |

| US12421584B2 (en) | 2020-07-17 | 2025-09-23 | Shinhokoku Material Corp. | Low thermal expansion cast steel and method of producing same |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2015168865A (ja) | 2015-09-28 |

| KR102077297B1 (ko) | 2020-02-13 |

| TW201534740A (zh) | 2015-09-16 |

| JP5893659B2 (ja) | 2016-03-23 |

| CN106103767A (zh) | 2016-11-09 |

| KR20160131997A (ko) | 2016-11-16 |

| TWI568861B (zh) | 2017-02-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6046591B2 (ja) | オーステナイト系耐熱鋳鋼 | |

| KR20160004194A (ko) | 저열팽창 주강품 및 그의 제조 방법 | |

| JP6188643B2 (ja) | 極低熱膨張合金及びその製造方法 | |

| JP2019065344A (ja) | 低熱膨張合金 | |

| JP7310978B2 (ja) | 析出硬化型Ni合金の製造方法 | |

| JP2017145456A (ja) | 低熱膨張鋳鋼品及びその製造方法 | |

| JP5893659B2 (ja) | 低熱膨張鋳造合金およびその製造方法 | |

| JP2018188690A (ja) | 低熱膨張合金 | |

| JP6504807B2 (ja) | 塑性加工用または鋳造用高ヤング率低熱膨張合金およびその製造方法 | |

| JP3654899B2 (ja) | 高強度低膨脹鋳鉄の製造方法 | |

| JP2001262277A (ja) | 被削性に優れた低熱膨張合金およびその製造方法 | |

| JP2018145491A (ja) | 低熱膨張合金 | |

| JP2010095747A (ja) | 低熱膨張鋳鉄材の製造方法 | |

| JP6793583B2 (ja) | 低熱膨張合金 | |

| WO2024014484A1 (ja) | 低熱膨張合金 | |

| CN106103767B (zh) | 低热膨胀铸造合金及其制造方法 | |

| WO2017006659A1 (ja) | 高温用高強度低熱膨張鋳造合金およびその製造方法、ならびにタービン用鋳造品 | |

| JP7541705B2 (ja) | 低熱膨張鋳物 | |

| JP6949352B2 (ja) | 低熱膨張合金 | |

| TWI663263B (zh) | 高抗潛變等軸晶鎳基超合金 | |

| JP6872786B2 (ja) | 異方性が小さく経年変化の少ない低熱膨張鋳鋼及び鍛鋼品 | |

| JP6205854B2 (ja) | 真空浸炭処理方法 | |

| JP5518244B1 (ja) | 低熱膨張鋳物 | |

| JP6270559B2 (ja) | 低熱膨張鋳物 | |

| TW202503082A (zh) | 低熱膨脹合金 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 14885692 Country of ref document: EP Kind code of ref document: A1 |

|

| ENP | Entry into the national phase |

Ref document number: 20167007739 Country of ref document: KR Kind code of ref document: A |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 14885692 Country of ref document: EP Kind code of ref document: A1 |