WO2015111345A1 - ブローバイガス用オイルセパレータ - Google Patents

ブローバイガス用オイルセパレータ Download PDFInfo

- Publication number

- WO2015111345A1 WO2015111345A1 PCT/JP2014/083946 JP2014083946W WO2015111345A1 WO 2015111345 A1 WO2015111345 A1 WO 2015111345A1 JP 2014083946 W JP2014083946 W JP 2014083946W WO 2015111345 A1 WO2015111345 A1 WO 2015111345A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- oil

- gas

- blow

- flow

- cyclones

- Prior art date

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01M—LUBRICATING OF MACHINES OR ENGINES IN GENERAL; LUBRICATING INTERNAL COMBUSTION ENGINES; CRANKCASE VENTILATING

- F01M13/00—Crankcase ventilating or breathing

- F01M13/04—Crankcase ventilating or breathing having means for purifying air before leaving crankcase, e.g. removing oil

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01M—LUBRICATING OF MACHINES OR ENGINES IN GENERAL; LUBRICATING INTERNAL COMBUSTION ENGINES; CRANKCASE VENTILATING

- F01M13/00—Crankcase ventilating or breathing

- F01M2013/0038—Layout of crankcase breathing systems

- F01M2013/005—Layout of crankcase breathing systems having one or more deoilers

- F01M2013/0061—Layout of crankcase breathing systems having one or more deoilers having a plurality of deoilers

- F01M2013/0066—Layout of crankcase breathing systems having one or more deoilers having a plurality of deoilers in parallel

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F01—MACHINES OR ENGINES IN GENERAL; ENGINE PLANTS IN GENERAL; STEAM ENGINES

- F01M—LUBRICATING OF MACHINES OR ENGINES IN GENERAL; LUBRICATING INTERNAL COMBUSTION ENGINES; CRANKCASE VENTILATING

- F01M13/00—Crankcase ventilating or breathing

- F01M13/04—Crankcase ventilating or breathing having means for purifying air before leaving crankcase, e.g. removing oil

- F01M2013/0422—Separating oil and gas with a centrifuge device

- F01M2013/0427—Separating oil and gas with a centrifuge device the centrifuge device having no rotating part, e.g. cyclone

Definitions

- the present invention relates to a blowby gas oil separator provided with a plurality of cyclones capable of separating oil mist contained in the blowby gas.

- blowby gas that has leaked from the combustion chamber into the crankcase is returned to the intake passage and reburned in the combustion chamber. Since the blowby gas contains an oil mist in which engine oil or the like is dispersed in fine particles, it is necessary to separate the oil mist from the blowby gas before burning in the combustion chamber.

- the above-mentioned oil separator for blowby gas is used for such a use.

- the conventional oil separator for blow-by gas described in Patent Document 1 is provided with an oil discharge port at the lower part which is supplied with the blow-by gas of the internal combustion engine and separates and discharges the oil mist contained in the blow-by gas.

- a plurality of cyclones provided at the top with a blowby gas outlet for letting out gas, an oil receiving portion facing oil outlets of the plurality of cyclones, and a blowby gas outlet of the plurality of cyclones communicate with an intake passage of the internal combustion engine And an oil receiving chamber formed by a plurality of cyclones and the oil receiving portion.

- the blowby gas is sucked by the negative pressure generated in the intake passage of the internal combustion engine and supplied to each cyclone, and the blowby gas after oil separation is sucked into the blowby gas circulation unit through each blowby gas outlet.

- the oil separated by each cyclone is discharged to the oil receiving portion by its own weight through the oil discharge port.

- the oil outlet provided at the lower part of the cyclone and the blowby gas outlet provided at the upper part of the cyclone are in communication with each other inside the cyclone. Therefore, the negative pressure generated in the intake passage is also introduced to the oil outlet.

- the strength of the negative pressure introduced into the oil outlet becomes stronger as the blowby gas outlet communicating with the oil outlet opens at a position closer to the flow valve.

- oil for example, in the form of droplets discharged into the oil receiving chamber is drawn back from the oil discharge port acting on a strong negative pressure close to the flow valve and flows back into the inside of the cyclone There is a fear.

- the oil flows back into the inside of the cyclone, the oil is drawn into the blowby gas distribution unit through the blowby gas outlet and easily flows into the intake passage through the distribution valve.

- the present invention has been made in view of the above-described circumstances, and an object of the present invention is to provide a blowby gas oil separator capable of preventing backflow of oil discharged into an oil receiving chamber into the inside of a cyclone.

- the oil separator for blow-by gas is characterized in that the blow-by gas of an internal combustion engine is provided, and an oil outlet is provided at the lower part for separating and discharging the oil mist contained in the blow-by gas.

- a plurality of cyclones provided at the top with a blowby gas outlet for letting out the gas, an oil receiving portion facing the oil outlet of the plurality of cyclones, and the blowby gas outlet of the plurality of cyclones are communicated

- a blow-by gas distribution unit connected to an intake passage of an internal combustion engine via a distribution valve, an oil receiving chamber formed by the plurality of cyclones and the oil receiving unit, and partitioning the adjacent oil discharge ports And a partition wall.

- a partition that divides adjacent oil discharge ports is provided in the oil receiving chamber. Therefore, it is possible to prevent, for example, oil in the form of droplets discharged from the oil discharge port to the oil receiving portion from flowing backward from another oil discharge port into the inside of the cyclone.

- Another feature of the present invention is that the partition is integrally provided on the side of the cyclone, and a gap is formed between the lower end of the partition and the oil receiving portion.

- the discharged oil can easily flow toward the drain hole or the like opened in the oil receiving portion, for example, through the gap between the lower end of the partition wall and the oil receiving portion.

- blowby gas circulation unit includes an inner bottom portion which becomes lower as it goes away from the circulation valve.

- blowby gas circulation unit has an inner bottom portion opened by each of the blowby gas flow outlets, and the blowby gas flow outlet is away from the flow valve while avoiding the blowby gas flow outlet at the inner bottom portion.

- the blowby gas circulation unit when the blowby gas circulation unit has an inner bottom opened by each of the blowby gas flow outlets, oil in the middle of flowing through the oil flow passage flows from the blowby gas flow outlet into the inside of the cyclone; Oil separation capacity may be reduced.

- the oil separator for blowby gas of this configuration has an oil flow path in which the oil sucked into the blowby gas flow portion can flow while avoiding the blowby gas flow outlet, and the oil receiving chamber at the end of the oil flow path.

- a communication passage which can communicate is provided. Therefore, the oil in the middle of flowing through the oil flow path can be made to flow from the communication path into the oil receiving chamber without flowing into the inside of the cyclone, and a drop in the oil separation capability due to the cyclone can be prevented.

- the inner bottom portion is provided with a projecting portion which divides one end side in the width direction of the oil flow path from the blowby gas outlet side.

- the spread in the flow passage width direction of the oil flowing in the oil flow passage can be restricted by the ridges, and the oil in the middle of flowing in the oil flow passage toward the communication passage is inside the cyclone Inflow can be reliably prevented.

- Another feature of the present invention is that a recess deeper than the flow passage on the upstream side is formed on the end side of the oil flow passage, and the communication passage is opened at the bottom of the recess.

- the oil flowing in the oil flow passage can be made to flow into the recess at the end side thereof, and be allowed to flow into the oil receiving chamber from the communication passage opened at the bottom of the recess. Since the recess is deeper than the flow path portion on the upstream side, there is little possibility that the oil accumulated in the recess is drawn to the flow valve side. In particular, even when the posture with respect to the level is likely to change, such as an oil separator for automobiles, the oil can be reliably prevented from flowing into the inside of the cyclone.

- FIG. 3 is a cross-sectional view taken along line III-III in FIG.

- FIG. 4 is a cross-sectional view taken along line IV-IV in FIG.

- FIG. 5 is a sectional view taken along line VV in FIG. 3;

- FIG. 6 is a cross-sectional view taken along the line VI-VI in FIG. It is a longitudinal cross-sectional view which shows the oil separator of 2nd Embodiment.

- FIG. 8 is a cross-sectional view taken along line VIII-VIII in FIG. 7; It is a longitudinal cross-sectional view which shows the oil separator of 3rd Embodiment.

- FIG. 12 is a cross-sectional view taken along line XII-XII in FIG.

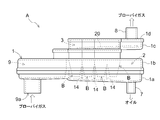

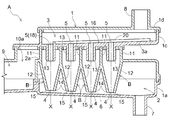

- FIGS. 1 to 6 show a cyclone type blow-by gas oil separator A according to the present invention installed inside, for example, a cylinder head cover (not shown) of an internal combustion engine such as an automobile engine.

- the oil separator A sucks the blowby gas of the internal combustion engine flowing from the crankcase (not shown) into the inside of the cylinder head cover by the negative pressure generated in the intake passage (not shown) along with the intake operation of the internal combustion engine.

- B. Supply to B and centrifuge to remove oil mist contained in blowby gas. After removing the oil mist, the blowby gas is returned to the intake passage of the internal combustion engine through a flow valve (not shown) such as a PCV valve (positive crankcase ventilation valve) to be reburned in the combustion chamber.

- the oil separator A receives a plurality of (four in the present embodiment) cyclones B supplied with blow-by gas inside the resin housing 1 and an oil that receives the oil separated by each cyclone B.

- a receiving chamber 2 and a blow-by gas distribution chamber (blow-by gas distribution unit) 3 connected to an intake passage of an internal combustion engine via a distribution valve are provided.

- Each cyclone B is provided with an oil outlet 4 at the lower part for separating oil mist contained in the blowby gas and discharging it by its own weight, and a blowby gas outlet 5 for discharging the blowby gas after oil separation at the upper part.

- the oil receiving chamber 2 is formed between the four cyclones B and the oil receiving portion 6 opposed to the oil discharge port 4 thereof, and the oil discharged from each oil discharge port 4 is collected to form the engine from the drain pipe 7 It is configured to be able to return to the inside.

- Each blow-by gas outlet 5 is in communication with the blow-by gas distribution chamber 3, and the blow-by gas after oil separation flowing in from each blow-by gas outlet 5 is collected, and the intake of the internal combustion engine from the gas discharge pipe 8 through the distribution valve. It is configured to return to the aisle.

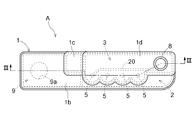

- the housing 1 is assembled by fitting the lower case 1a, the intermediate case 1b, the upper case 1c, and the lid case 1d from each other in the vertical direction.

- a space formed between the lower case 1 a and the intermediate case 1 b is divided into a gas introduction chamber 9 into which blowby gas inside the cylinder head cover is introduced from a gas introduction port 9 a and an oil receiving chamber 2.

- a flow straightening chamber 10 for straightening the flow of blowby gas before flowing into each cyclone B, and a blowby gas from the gas introduction chamber 9 to the flow straightening chamber 10

- a blow-by gas inflow path 10a for introducing the

- the oil receiving portion 6 is formed by the bottom plate portion of the lower case 1 a and is inclined so that the oil flows toward the drain pipe 7 by its own weight.

- an oil receiving chamber upper wall 2a partitioning the flow straightening chamber 10 and the oil receiving chamber 2 up and down, and an oil receiving chamber upper wall 2a vertically penetrating the oil receiving chamber upper wall 2a.

- Two cyclones B are integrally formed.

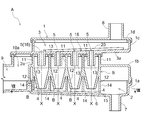

- each of the cyclones B is a cylindrical wall having a constant inner diameter and extending upward from the upper edges of the conical cylindrical wall portion 12 whose inner diameter decreases toward the lower side and the conical cylindrical wall portion 12.

- the portion 11 is integrally provided around the cylinder axis X along the vertical direction.

- the four cyclones B are arranged side by side in a state in which the cylindrical wall portions 11 are integrally connected with each other by linearly arranging the positions of the cylinder axis X at regular intervals in plan view.

- the cylindrical wall portion 11 is provided so as to protrude from the oil receiving chamber upper wall 2a to the inside of the straightening chamber 10, and allows the blowby gas of the straightening chamber 10 to flow into the cylindrical wall portion 11 from the tangential direction.

- the conical cylindrical wall portion 12 is provided to project from the oil receiving chamber upper wall 2 a into the oil receiving chamber 2, and the lower end opening of the conical cylindrical wall portion 12 functions as the oil discharge port 4.

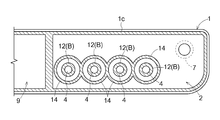

- the upper case 1c as shown in FIGS. 3 and 4, includes a flow chamber lower wall 3a that divides the blowby gas flow chamber 3 and the flow straightening chamber 10 up and down, and each blowby gas outlet 5 is divided into the flow chamber lower wall 3a. It is made to open. Accordingly, the blowby gas flow chamber 3 has an inner bottom portion 16 in which each of the blowby gas outlets 5 is opened. The upper end portion of each cylindrical wall portion 11 is fitted and fixed to the lower surface side of the flow chamber lower wall 3a.

- a cylindrical portion 13 forming the blow-by gas outlet 5 is integrally formed on the lower surface side of the flow chamber lower wall 3a.

- the respective cylindrical portions 13 are provided so as to be concentrically inserted at the inner side of the cylindrical wall portion 11 of the corresponding cyclone B at radial intervals.

- the lid case 1d is provided with a gas discharge pipe 8 connected to the intake passage of the internal combustion engine via a flow valve. As shown in FIG. 4, the gas discharge pipe 8 is provided so as to communicate with the inside of the blowby gas distribution chamber 3 at one end side in the arrangement direction of the blowby gas outlets 5 (side away from the blowby gas inflow path 10a). .

- the blowby gas inside the cylinder head cover is drawn from the gas introduction port 9 a by the negative pressure generated in the intake passage along with the intake operation of the internal combustion engine and introduced into the gas introduction chamber 9.

- the blowby gas introduced into the gas introduction chamber 9 flows into the straightening chamber 10 through the blowby gas inflow path 10a, and flows into the inside of the cylindrical wall portion 11 from each blowby gas supply port 11a.

- the oil mist contained in the blowby gas that has flowed into the cylindrical wall portion 11 is aggregated and separated into oil in the form of liquid droplets by the centrifugal force accompanying the turning around the cylinder axial core (cylindrical portion 13) X.

- the oil separated into droplets in each cyclone B drops from the oil outlet 4 into the oil receiving chamber 2 and is collected in the oil receiving portion 6 and returned to the inside of the engine through the drain pipe 7.

- the blowby gas after the oil mist is separated is drawn into the blowby gas distribution chamber 3 from the blowby gas outlet 5 through the cylindrical portion 13 and is returned from the gas discharge pipe 8 to the combustion chamber through the intake passage.

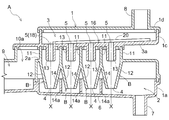

- the oil outlet 4 provided in each cyclone B is in internal communication with the blowby gas outlet 5. For this reason, the negative pressure generated in the intake passage also acts on the oil discharge port 4 and the oil in the form of droplets discharged to the oil receiving chamber 2 is sucked from the oil discharge port 4 and blow-by gas passes through the inside of the cyclone B. There is a risk of backflow into the distribution room 3.

- the magnitude of the negative pressure acting on the oil outlet 4 is arranged such that the blowby gas outlet 5 communicating with the oil outlet 4 is near the inlet of the gas outlet pipe 8 (downstream of the blowby gas into the intake passage) Cyclone B becomes bigger. For this reason, from the oil discharge port 4 different from the oil discharge port 4 of the droplet-like oil discharged from the oil discharge port 4 to the oil receiving chamber 2, specifically, cyclone B provided with the oil discharge port 4 Also, it is necessary to prevent suction from the oil outlet 4 provided in the cyclone B disposed downstream in the flow direction of the blowby gas into the gas outlet pipe 8.

- a strip plate that prevents suction of oil droplets from the oil discharge port 4 that is likely to exert a strong negative pressure by partitioning between adjacent oil discharge ports 4 The bulkhead 14 is provided.

- the dividing wall 14 has a straight line crossing the inside of the oil receiving chamber 2 in a direction perpendicular to the direction in which the cyclones B are arranged between adjacent conical cylindrical wall portions 12 so that the cyclone B side, that is, the middle It is integrally provided in the case 1b. Between the lower end of the partition wall 14 and the oil receiving portion 6, a slit-like space 15 is formed along the oil receiving surface of the oil receiving portion 6.

- the blowby gas flow chamber 3 is configured such that the upper surface of the flow chamber lower wall 3a forming the inner bottom portion 16 of the blowby gas flow chamber 3 can be discharged to the oil receiving chamber 2 so as to discharge the oil accumulated therein. It is provided in a posture inclined with respect to the horizontal so as to be lower as it goes away from the flow valve, that is, as it gets away from the inlet of the gas discharge pipe 8.

- the oil flow in the inner bottom portion 16 allows the oil to flow by its own weight so as to be away from the flow valve while avoiding the blowby gas outlet 5, that is, away from the inlet of the gas discharge pipe 8.

- a passage 17 is provided.

- a communication passage 18 capable of communicating the oil passage 17 with the oil receiving chamber 2 is opened at the end of the oil passage 17.

- the communication passage 18 is formed by the cylindrical portion 13.

- the oil passage 17 is provided with a side wall portion 19 surrounding the blowby gas flow chamber 3 of the upper case 1c, and a protrusion provided on the inner bottom portion 16 along the direction in which the blowby gas outlets 5 are separated. It is formed as a flow path sandwiched between the protruding ridges 20.

- the ridge portion 20 is provided in series from near the inlet lower part of the gas discharge pipe 8 to the blowby gas outlet 5 at a position farthest from the inlet of the gas discharge pipe 8, and one end side of the oil passage 17 in the width direction And the blow-by gas outlet 5 side.

- the communication passage 18 is formed of a cylindrical portion 13 in communication with the blow-by gas outlet 5 at a position farthest from the flow valve among the plurality of cyclones B, that is, a position farthest from the inlet of the gas discharge pipe 8. Therefore, the oil flowing into the communication passage 18 from the oil passage 17 is discharged from the oil discharge port 4 to the oil receiving chamber 2 through the inside of the cyclone B.

- Second Embodiment 7 and 8 show another embodiment of the present invention.

- the present embodiment in the first embodiment, in order to prevent suction from the oil discharge port 4 other than the oil discharge port 4 of the droplet oil discharged from the oil discharge port 4 into the oil receiving chamber 2.

- a cylindrical partition 14 extending in a cylindrical shape surrounding the conical cylindrical wall portion 12 is provided on the lower end side of the cylindrical wall portion 11 constituting the cyclone B, and adjacent oil discharges There is a division between the four outlets.

- the lower end of the cylindrical partition 14 is separated from the oil receiving portion 6 to form a gap 15 between the lower end of the cylindrical partition 14 and the oil receiving portion 6.

- the other configuration is the same as that of the first embodiment.

- FIG. 9 shows another embodiment of the present invention.

- the second embodiment in order to prevent suction from the oil discharge port 4 other than the oil discharge port 4 of the droplet oil discharged from the oil discharge port 4 into the oil receiving chamber 2.

- an annular partition wall 14 is provided in which the lower end of the conical cylindrical wall portion 12 constituting the cyclone B is extended toward the oil receiving portion 6, and between the adjacent oil discharge ports 4 It is divided.

- the other configuration is the same as that of the second embodiment.

- FIG. 10 shows another embodiment of the present invention.

- the present embodiment in the first embodiment, in order to prevent suction from the oil discharge port 4 other than the oil discharge port 4 of the droplet oil discharged from the oil discharge port 4 into the oil receiving chamber 2.

- a strip-like partition 14 integrally provided in the lower case 1a forming the oil receiving chamber 2 is provided, and the adjacent oil discharge ports 4 are provided. There is a division between the two.

- the partition wall 14 is provided along a straight line crossing the inside of the oil receiving chamber 2 in the direction orthogonal to the direction in which the cyclones B are arranged, between adjacent conical cylindrical wall portions 12.

- an arc-shaped through hole 14a is formed so as not to prevent the flow of oil to the drain pipe 7.

- the other configuration is the same as that of the first embodiment.

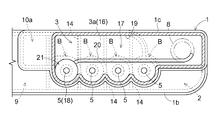

- Fifth Embodiment 11 and 12 show another embodiment of the present invention.

- a circular recess 21 deeper than the flow path portion on the upstream side is formed.

- the recess 21 is formed concentrically with the cylindrical portion 13 communicating with the blow-by gas outlet 5 at a position farthest from the flow valve among the plurality of cyclones B, that is, a position farthest from the inlet of the gas discharge pipe 8

- the blowby gas outlet 5 forming the communication passage 18 is opened at the bottom of the recess 21.

- the other configuration is the same as that of the first embodiment.

- Embodiments 1 The oil separator according to the present invention may be mounted on the outside of the cylinder head cover. 2.

- the oil separator according to the present invention can be installed in various internal combustion engines other than those for automobiles.

- Oil Receiving Room 3 Blow-by Gas Distribution Unit (Blow-by Gas Distribution Room) Reference Signs List 4 oil outlet 5 blow-by gas outlet 6 oil receiver 14 partition 15 air gap 16 inner bottom 17 oil passage 18 communicating passage 20 protrusion 21 recess B cyclone

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Lubrication Details And Ventilation Of Internal Combustion Engines (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US15/112,919 US20160376950A1 (en) | 2014-01-24 | 2014-12-22 | Blow-by gas oil separator |

| CN201490001330.6U CN206175024U (zh) | 2014-01-24 | 2014-12-22 | 窜漏气体用油分离器 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2014011387A JP2015137631A (ja) | 2014-01-24 | 2014-01-24 | ブローバイガス用オイルセパレータ |

| JP2014-011387 | 2014-01-24 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2015111345A1 true WO2015111345A1 (ja) | 2015-07-30 |

Family

ID=53681162

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2014/083946 WO2015111345A1 (ja) | 2014-01-24 | 2014-12-22 | ブローバイガス用オイルセパレータ |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US20160376950A1 (de) |

| JP (1) | JP2015137631A (de) |

| CN (1) | CN206175024U (de) |

| WO (1) | WO2015111345A1 (de) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112774378A (zh) * | 2020-12-22 | 2021-05-11 | 中国船舶重工集团公司第七0三研究所 | 一种带有旋风分离的燃气轮机油气分离器 |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US10151225B2 (en) * | 2016-10-26 | 2018-12-11 | GM Global Technology Operations LLC | Integrated oil separator assembly for crankcase ventilation |

| JP6908374B2 (ja) * | 2016-12-09 | 2021-07-28 | 株式会社Roki | オイルセパレータ |

| JP6881019B2 (ja) * | 2017-05-19 | 2021-06-02 | スズキ株式会社 | 内燃機関のブローバイガス処理装置 |

| KR20190130476A (ko) * | 2018-05-14 | 2019-11-22 | 가부시끼 가이샤 구보다 | 블로바이 가스 환류장치 부착 엔진 |

| US10823019B2 (en) * | 2018-07-31 | 2020-11-03 | Ford Global Technologies, Llc | Ducted positive crankcase ventilation plenum |

| CN110693391A (zh) * | 2019-11-27 | 2020-01-17 | 珠海格力电器股份有限公司 | 吸尘器、旋风分离机构及安装支架 |

| CN114622996A (zh) * | 2020-12-10 | 2022-06-14 | 通用电气阿维奥有限责任公司 | 空气/油分离器装置及方法 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007298001A (ja) * | 2006-05-01 | 2007-11-15 | Toyota Motor Corp | エンジンの気液分離装置 |

| JP2012057496A (ja) * | 2010-09-06 | 2012-03-22 | Nifco Inc | オイルセパレータ |

| JP2014013013A (ja) * | 2012-07-04 | 2014-01-23 | Aisin Seiki Co Ltd | オイルセパレータ |

| JP2014013033A (ja) * | 2012-11-22 | 2014-01-23 | Aisin Seiki Co Ltd | オイルセパレータ |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE19912271A1 (de) * | 1999-03-18 | 2000-09-28 | Hengst Walter Gmbh & Co Kg | Ölabscheider zur Entölung von Kurbelgehäuse-Entlüftungsgasen einer Brennkraftmaschine |

| DE29908116U1 (de) * | 1999-05-06 | 2000-09-28 | Hengst Walter Gmbh & Co Kg | Ölabscheider zur Entölung von Kurbelgehäuse-Entlüftungsgasen einer Brennkraftmaschine |

| JP2001246216A (ja) * | 1999-12-28 | 2001-09-11 | Denso Corp | 気液分離装置 |

| DE10251947A1 (de) * | 2002-11-08 | 2004-05-19 | Robert Bosch Gmbh | Vorrichtung zur Abscheidung von Flüssigkeit aus einem Gasstrom |

| DE10325055A1 (de) * | 2003-06-02 | 2004-12-23 | Mann + Hummel Gmbh | Einrichtung zum Schalten von Zyklonen |

| DE102006038700B4 (de) * | 2006-08-18 | 2021-11-11 | Polytec Plastics Germany Gmbh & Co. Kg | Vorrichtung zur Abscheidung von Flüssigkeiten aus Gasen |

| DE202007003292U1 (de) * | 2007-03-02 | 2008-07-10 | Hengst Gmbh & Co.Kg | Ölabscheider mit mindestens einem Zyklon |

| KR101028552B1 (ko) * | 2008-11-18 | 2011-04-11 | 기아자동차주식회사 | 블로우바이 가스 오일 분리장치 |

-

2014

- 2014-01-24 JP JP2014011387A patent/JP2015137631A/ja active Pending

- 2014-12-22 US US15/112,919 patent/US20160376950A1/en not_active Abandoned

- 2014-12-22 CN CN201490001330.6U patent/CN206175024U/zh not_active Expired - Fee Related

- 2014-12-22 WO PCT/JP2014/083946 patent/WO2015111345A1/ja active Application Filing

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2007298001A (ja) * | 2006-05-01 | 2007-11-15 | Toyota Motor Corp | エンジンの気液分離装置 |

| JP2012057496A (ja) * | 2010-09-06 | 2012-03-22 | Nifco Inc | オイルセパレータ |

| JP2014013013A (ja) * | 2012-07-04 | 2014-01-23 | Aisin Seiki Co Ltd | オイルセパレータ |

| JP2014013033A (ja) * | 2012-11-22 | 2014-01-23 | Aisin Seiki Co Ltd | オイルセパレータ |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112774378A (zh) * | 2020-12-22 | 2021-05-11 | 中国船舶重工集团公司第七0三研究所 | 一种带有旋风分离的燃气轮机油气分离器 |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2015137631A (ja) | 2015-07-30 |

| US20160376950A1 (en) | 2016-12-29 |

| CN206175024U (zh) | 2017-05-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2015111345A1 (ja) | ブローバイガス用オイルセパレータ | |

| JP5847445B2 (ja) | 内燃機関のオイルセパレータ | |

| US7776139B2 (en) | Separator with transfer tube drainage | |

| US20160177791A1 (en) | Oil mist separator | |

| WO2012157309A1 (ja) | 内燃機関のオイルセパレータ | |

| US9630128B2 (en) | Oil separator | |

| JP2015137631A5 (de) | ||

| JP2018531340A6 (ja) | オイル分離装置 | |

| JP2018531340A (ja) | オイル分離装置 | |

| JP2010203299A (ja) | オイルセパレータ | |

| KR20160057114A (ko) | 오일 세퍼레이터 | |

| JP6248804B2 (ja) | オイルセパレータ | |

| JP4352228B2 (ja) | ブリーザ装置 | |

| JP2014074343A (ja) | オイルセパレータ | |

| JP6284904B2 (ja) | オイル分離装置 | |

| EP3126030B1 (de) | Schmutzablauffiltersystem und -kartusche | |

| JP2015217367A5 (de) | ||

| JP4423243B2 (ja) | 内燃機関 | |

| JP2014101866A (ja) | ブローバイガス還流装置 | |

| US20190178122A1 (en) | Oil Separators | |

| JP2008196469A (ja) | オイル分離装置 | |

| JP5997513B2 (ja) | オイルセパレータ | |

| WO2018194060A1 (ja) | フィルタ装置 | |

| US9394856B2 (en) | Oil separator for separating oil from blow-by gas of internal combustion engine | |

| CN104005813A (zh) | 具有由盖垫片遮蔽的曲轴箱强制通风分离器入口的发动机 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 14879940 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 15112919 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 14879940 Country of ref document: EP Kind code of ref document: A1 |