WO2015093340A1 - 熱転写受像シート用表面基材、及び熱転写受像シート - Google Patents

熱転写受像シート用表面基材、及び熱転写受像シート Download PDFInfo

- Publication number

- WO2015093340A1 WO2015093340A1 PCT/JP2014/082487 JP2014082487W WO2015093340A1 WO 2015093340 A1 WO2015093340 A1 WO 2015093340A1 JP 2014082487 W JP2014082487 W JP 2014082487W WO 2015093340 A1 WO2015093340 A1 WO 2015093340A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- layer

- mass

- transfer image

- thermal transfer

- receiving sheet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M5/00—Duplicating or marking methods; Sheet materials for use therein

- B41M5/26—Thermography ; Marking by high energetic means, e.g. laser otherwise than by burning, and characterised by the material used

- B41M5/40—Thermography ; Marking by high energetic means, e.g. laser otherwise than by burning, and characterised by the material used characterised by the base backcoat, intermediate, or covering layers, e.g. for thermal transfer dye-donor or dye-receiver sheets; Heat, radiation filtering or absorbing means or layers; combined with other image registration layers or compositions; Special originals for reproduction by thermography

- B41M5/42—Intermediate, backcoat, or covering layers

- B41M5/44—Intermediate, backcoat, or covering layers characterised by the macromolecular compounds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/06—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material

- B32B27/08—Layered products comprising a layer of synthetic resin as the main or only constituent of a layer, which is next to another layer of the same or of a different material of synthetic resin

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/18—Layered products comprising a layer of synthetic resin characterised by the use of special additives

- B32B27/20—Layered products comprising a layer of synthetic resin characterised by the use of special additives using fillers, pigments, thixotroping agents

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B27/00—Layered products comprising a layer of synthetic resin

- B32B27/32—Layered products comprising a layer of synthetic resin comprising polyolefins

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M5/00—Duplicating or marking methods; Sheet materials for use therein

- B41M5/26—Thermography ; Marking by high energetic means, e.g. laser otherwise than by burning, and characterised by the material used

- B41M5/40—Thermography ; Marking by high energetic means, e.g. laser otherwise than by burning, and characterised by the material used characterised by the base backcoat, intermediate, or covering layers, e.g. for thermal transfer dye-donor or dye-receiver sheets; Heat, radiation filtering or absorbing means or layers; combined with other image registration layers or compositions; Special originals for reproduction by thermography

- B41M5/41—Base layers supports or substrates

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M5/00—Duplicating or marking methods; Sheet materials for use therein

- B41M5/26—Thermography ; Marking by high energetic means, e.g. laser otherwise than by burning, and characterised by the material used

- B41M5/40—Thermography ; Marking by high energetic means, e.g. laser otherwise than by burning, and characterised by the material used characterised by the base backcoat, intermediate, or covering layers, e.g. for thermal transfer dye-donor or dye-receiver sheets; Heat, radiation filtering or absorbing means or layers; combined with other image registration layers or compositions; Special originals for reproduction by thermography

- B41M5/42—Intermediate, backcoat, or covering layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/24—All layers being polymeric

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2250/00—Layers arrangement

- B32B2250/24—All layers being polymeric

- B32B2250/242—All polymers belonging to those covered by group B32B27/32

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2264/00—Composition or properties of particles which form a particulate layer or are present as additives

- B32B2264/10—Inorganic particles

- B32B2264/102—Oxide or hydroxide

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2264/00—Composition or properties of particles which form a particulate layer or are present as additives

- B32B2264/10—Inorganic particles

- B32B2264/104—Oxysalt, e.g. carbonate, sulfate, phosphate or nitrate particles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M2205/00—Printing methods or features related to printing methods; Location or type of the layers

- B41M2205/02—Dye diffusion thermal transfer printing (D2T2)

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M2205/00—Printing methods or features related to printing methods; Location or type of the layers

- B41M2205/32—Thermal receivers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M2205/00—Printing methods or features related to printing methods; Location or type of the layers

- B41M2205/36—Backcoats; Back layers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41M—PRINTING, DUPLICATING, MARKING, OR COPYING PROCESSES; COLOUR PRINTING

- B41M2205/00—Printing methods or features related to printing methods; Location or type of the layers

- B41M2205/38—Intermediate layers; Layers between substrate and imaging layer

Definitions

- the present invention relates to a surface substrate for a thermal transfer image receiving sheet and a thermal transfer image receiving sheet.

- a thermal transfer sheet provided with a color material layer containing a sublimation dye on a substrate and a thermal transfer image receiving sheet provided with a receiving layer on a support are superposed to form a full color image.

- a sublimation transfer recording system for forming a film uses sublimation dyes as a color material, so the density and gradation can be adjusted freely, and a full color image exactly as the original can be clearly displayed on the image-receiving sheet, so digital cameras, videos, computers, etc. It is applied to color image formation.

- the image is of a high quality comparable to a silver salt photograph.

- Patent Document 1 proposes a thermal transfer image receiving sheet in which a heat insulating layer containing a hollow polymer is provided between a support and a receiving layer.

- a heat insulating layer containing a hollow polymer is provided between a support and a receiving layer.

- layers called “microvoid layer”, “hollow particle layer”, “void film layer”, “void PP layer”, etc. have heat resistance and cushioning properties. It is known as a layer provided between the substrate and the receiving layer.

- a shrinkage stress is generated in the heat insulating layer due to a thermal history when the thermal transfer image receiving sheet is manufactured, and curling based on the contracting stress is likely to occur in the heat insulating layer. Also, due to the thermal history during image formation for forming a thermal transfer image on the receiving layer, shrinkage stress is generated in the heat insulating layer, and curling is likely to occur in the entire printed matter in which the thermal transfer image is formed on the receiving layer.

- This curl is usually curled inward with respect to the thermal transfer image forming surface side due to the relationship with the support of the thermal transfer image receiving sheet, and a printed matter in which the thermal transfer image is formed on the receiving layer of the thermal transfer image receiving sheet, For example, when a photograph or the like is displayed on a wall, the appearance of the printed matter is deteriorated. Further, even when curling does not occur immediately during thermal transfer image formation, curling occurs over time if shrinkage stress is inherent in the heat insulating layer. This is the same for various layers provided between the support and the receiving layer for the purpose of heat resistance and cushioning, in addition to a layer called a heat insulating layer.

- an effective measure is to reduce the shrinkage stress generated in the heat insulation layer.

- the thickness of the heat insulation layer is reduced.

- a method is mentioned.

- it becomes difficult to form an image having a sufficient density That is, it becomes difficult to form a high-quality image on the receiving layer.

- the support of the thermal transfer image receiving sheet often has foreign matters or defects, and when a heat insulating layer with a reduced thickness is provided on the support having such defects, the support The defects of the body cannot be concealed, and depending on the defects of the support, unevenness in density occurs in the thermal transfer image formed on the receiving layer, resulting in a decrease in print quality.

- Patent Document 2 discloses a polypropylene polymer composition containing specific amounts of calcium carbonate and titanium oxide as a support used for photographic paper for digital photo printers suitable for obtaining images with high printing quality.

- a biaxially stretched laminated polypropylene film in which a surface layer and a back surface layer are provided on both sides of a base material layer obtained from the above has been proposed.

- Patent Document 2 it is said that a high-quality image can be obtained by employing this biaxially stretched laminated polypropylene film as a support for a thermal transfer image receiving sheet.

- the biaxially stretched laminated polypropylene film proposed in this document cannot obtain a high-quality image when the thickness of the support is reduced in order to suppress the occurrence of curling. That is, it is impossible to achieve both curling of curling and obtaining a high-quality image.

- Patent Document 3 discloses a base material sheet, a porous layer having a thickness of less than 30 ⁇ m and including a polypropylene resin, and a receiving layer in this order on one surface of the base material sheet.

- a provided thermal transfer image receiving sheet has been proposed. According to the thermal transfer image-receiving sheet proposed in Patent Document 3, it is said that the amount of curling can be reduced and the quality after storage in each environment can be improved. There is room for improvement in this respect.

- the present invention has been made in such a situation, and even when the thickness is reduced in order to suppress the occurrence of curling, high-quality image formation can be performed on the receiving layer. It is a main subject to provide a surface substrate for a thermal transfer image receiving sheet and a thermal transfer image receiving sheet provided with the surface substrate for a thermal transfer image receiving sheet.

- the present invention for solving the above problems is a surface substrate for a thermal transfer image receiving sheet provided between a support of a thermal transfer image receiving sheet and a receiving layer, wherein the surface substrate for the thermal transfer image receiving sheet is a substrate layer A surface layer is provided on one surface of the substrate layer, and a back surface layer is provided on the other surface of the base material layer.

- the base material layer includes (A) a propylene-based polymer, and (B). It contains calcium carbonate, (C) titanium oxide, and the mass of (A) is 70% by mass or more when the total mass of (A), (B) and (C) is 100% by mass.

- the mass of (B) is 5% by mass or more and 28% by mass or less

- the mass of (C) is 0.5% by mass or more and less than 3% by mass

- the surface layer is modified.

- a propylene-based polymer, and the back layer contains a propylene-based polymer. And said that you are.

- the surface layer contains (D) a propylene homopolymer, or (D) a propylene homopolymer, and (E) a propylene / ⁇ -olefin random copolymer

- the (D) is the modified propylene polymer

- the surface layer contains the (E). Is the mass of (E) is 50% by mass or less when the total mass of (D) and (E) is 100% by mass, and any of (D) and (E) Either or both are preferably the modified propylene-based polymer.

- the back layer contains (F) a propylene homopolymer, (G) a propylene / ⁇ -olefin random copolymer, and a total of (F) and (G). It is preferable that the mass of (F) when the mass is 100 mass% is 40 mass% or more and 90 mass% or less.

- the modified propylene polymer is preferably a propylene polymer graft-modified with an unsaturated carboxylic acid or a derivative thereof.

- the thickness of the surface layer is preferably 0.5 ⁇ m or more and 10 ⁇ m or less. Moreover, it is preferable that an adhesive layer is further provided on the surface layer.

- the present invention for solving the above problems is a thermal transfer image-receiving sheet in which a receiving layer is provided on one side of a support, and between the support and the receiving layer, from the support

- the surface substrate for a thermal transfer image receiving sheet having the above characteristics is provided so that the back layer, the substrate layer, and the surface layer are in this order.

- the thickness of the support is preferably 150 ⁇ m or more and 300 ⁇ m or less.

- the thickness is reduced in order to suppress the occurrence of curling in the thermal transfer image receiving sheet using the surface base material for the thermal transfer image receiving sheet.

- a high quality image can be formed.

- a high-quality image can be formed even when the thickness of the surface substrate for the thermal transfer image receiving sheet is reduced in order to suppress the occurrence of curling. .

- the curl generation suppressing effect can be further enhanced.

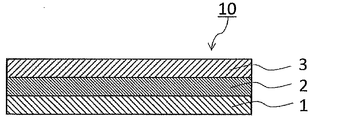

- FIG. 1 is a schematic cross-sectional view of the surface substrate 10 of the present invention.

- the surface base material 10 of this invention takes the structure by which the back layer 1, the base material layer 2, and the surface layer 3 were laminated

- each layer of the surface base material 10 of the present invention will be specifically described.

- a base material layer 2 is provided between the back surface layer 1 and the front surface layer 3.

- the base material layer 2 is an essential layer in the surface base material 10 of the present invention, and is a layer that mainly plays a role of heat insulating properties, cushioning properties, and concealing properties.

- the base material layer 2 is composed of a polymer composition (2) containing at least (A) a propylene-based polymer, (B) calcium carbonate, and (C) titanium oxide. That is, the base material layer 2 contains at least the (A) propylene polymer, (B) calcium carbonate, and (C) titanium oxide.

- the polymer composition (2) constituting the base material layer 2 contains a propylene-based polymer as an essential component.

- the propylene-based polymer according to the present invention is a polyolefin resin generally produced and sold under the name of polypropylene, and usually has a density of 0.890 to 0.930 g / cm 3 and a melt flow rate (MFR) (ASTM D1238).

- MFR melt flow rate

- ⁇ -olefin such as ethylene, 1-butene, 1-hexene, 4-methyl / 1-pentene, 1-octene and the like.

- These propylene polymers are one or more compositions, for example, a composition of a homopolymer of propylene having the same or different molecular weight (MFR) and a propylene / ⁇ -olefin random copolymer. Also good.

- the polymer composition (2) constituting the base material layer 2 contains, as a propylene-based polymer, a propylene homopolymer or a polymer having a high isotacticity with a random copolymer of 1 mol% or less. However, it preferably contains a homopolymer of propylene and a propylene / ⁇ -olefin random copolymer having a melting point of 100 to 150 ° C., preferably 110 to 145 ° C.

- the propylene / ⁇ -olefin random copolymer having a melting point in the above range usually contains 5 mol% or less of ⁇ -olefin such as ethylene.

- the polymer composition (2) which comprises the base material layer 2 contains calcium carbonate as an essential component. According to the surface base material provided with the base material layer 2 composed of the polymer composition (2) containing calcium carbonate, the whiteness of the surface base material can be increased.

- the particle size of calcium carbonate is not particularly limited, but the average particle size of calcium carbonate contained in the polymer composition (2) is preferably 1 ⁇ m or more and 5 ⁇ m or less, and more preferably 1.5 ⁇ m or more and 4 ⁇ m or less. preferable. According to the surface base material provided with the base material layer 2 composed of the polymer composition (2) containing calcium carbonate having an average particle diameter in this range, the whiteness of the surface base material can be further increased.

- the particle size of calcium carbonate is the particle size when measured by a light transmission measurement method by centrifugal sedimentation using an ultracentrifugal automatic particle size distribution analyzer (model CAPA-700, manufactured by HORIBA, Ltd.).

- the polymer composition (2) constituting the base material layer 2 preferably contains calcium carbonate having a maximum particle size of 10 ⁇ m or less, preferably 9 ⁇ m or less.

- the polymer composition (2) constituting the base material layer 2 has a particle size distribution in which the proportion of calcium carbonate having a particle diameter of 5 ⁇ m or less with respect to the whole calcium carbonate is 80% by mass or more, preferably 85% by mass or more. As such, it is preferable that calcium carbonate having an average particle diameter of 1 ⁇ m to 5 ⁇ m is included. The condition that the average particle size is 1 ⁇ m or more and 5 ⁇ m or less is satisfied, and the size of voids due to the calcium carbonate particles becomes uniform by including calcium carbonate having the above particle size distribution in the polymer composition (2). Therefore, it can be set as a surface base material with no unevenness and particularly excellent whiteness.

- the surface of the calcium carbonate contained in the polymer composition (2) constituting the substrate layer 2 is preferably surface-treated with a higher fatty acid, preferably a higher fatty acid having 10 to 28 carbon atoms. .

- a higher fatty acid preferably a higher fatty acid having 10 to 28 carbon atoms.

- higher fatty acid examples include decanoic acid, undecanoic acid, lauric acid, tridecylic acid, myristic acid, pentadecylic acid, palmitic acid, heptadecylic acid, stearic acid, nonadecanoic acid, arachidic acid, behenic acid, lignoceric acid, and cellotine.

- the water content of calcium carbonate contained in the polymer composition (2) constituting the base material layer 2 is preferably 0.5% by mass or less.

- a surface base material having a uniform and excellent whiteness can be obtained.

- the whiteness of calcium carbonate is more preferably 90% or more.

- the amount of water of calcium carbonate here means the amount of water measured by the Karl Fischer method (under 200 ° C.).

- the polymer composition (2) constituting the base material layer 2 contains titanium oxide as an essential component together with the (A) propylene polymer and (B) calcium carbonate.

- Titanium oxide is also called titanium white and has a rutile type and an anatase type, but the rutile type is preferable because of its high hiding power. Moreover, it is preferable that the surface of the titanium oxide contained in the polymer composition (2) constituting the base material layer 2 is treated with alumina. Furthermore, the thing whose whiteness is 95% or more is preferable. The appearance of the surface base material can be further improved by using a titanium oxide surface treated.

- the polymer composition (2) constituting the substrate layer 2 is composed of the propylene-based polymer (A), the calcium carbonate (B), and the oxidation (C). While containing titanium, the mass of (A) is 70 mass% or more and 94.5 mass% or less, and the mass of (B) when the total mass of the (A), (B) and (C) is 100 mass%. 5 mass% or more and 28 mass% or less, and the mass of (C) is 0.5 mass% or more and less than 3 mass%.

- the base material layer 2 that includes the components (A), (B), and (C) and whose content is composed of the polymer composition (2) that is defined within the above range, The cushioning property, concealing property and appearance of the surface base material can be improved.

- the average particle size of titanium oxide contained in the polymer composition (2) constituting the base material layer 2 is not particularly limited, but from the viewpoint of further improving the appearance of the surface base material, the average particle size of titanium oxide is It is preferably within a range of 0.1 ⁇ m or more and 0.5 ⁇ m or less, and more preferably 0.2 ⁇ m or more and 0.3 ⁇ m or less.

- the particle diameter of titanium oxide is a particle diameter measured by a light scattering method.

- the polymer composition (2) constituting the substrate layer 2 includes, as an optional component, a heat resistance stabilizer, a weather resistance stabilizer, an ultraviolet absorber, a lubricant, a slip agent, a nucleating agent, Various additives usually used for polyolefins such as antiblocking agents, antistatic agents, antifogging agents, pigments, dyes, inorganic compounds other than the above calcium carbonate and titanium oxide may be included within a range not impairing the object of the present invention. .

- heat stabilizer for example, 3,5-di-t-butyl-4-hydroxytoluene, tetrakis [methylene (3,5-di-t-butyl-4-hydroxy) hydrocinnamate] methane, n- Phenolic antioxidants such as octadecyl-3- (4′-hydroxy-3,5-di-t-butylphenyl) propionate, 2,2′-methylenebis (4-methyl-6-t-butylphenol), 2-hydroxy-4 Benzophenone antioxidants such as 2-methoxybenzophenone, 2-hydroxy-4-octoxybenzophenone and 2,4-dihydroxybenzophenone, benzotriazoles such as 2 (2'-hydroxy-5-methylphenyl) benzotriazole and substituted benzotriazole -Based antioxidant, 2-ethylhexyl-2-cyano- , 3-diphenylacrylate, ethyl-2-cyano-3,3-diphenyl

- Antistatic agents include, for example, alkylamines and derivatives thereof, higher alcohols, glycerol esters of higher fatty acids, pyridine derivatives, sulfated oils, soaps, sulfates of olefins, alkyl sulfates, fatty acid ethyl sulfonates , Alkyl sulfonate, alkyl naphthalene sulfonate, alkyl benzene sulfonate, naphthalene sulfonate, oxalate sulfonate, phosphate ester, partial fatty acid ester of polyhydric alcohol, ethylene oxide adduct of fatty alcohol , Fatty acid ethylene oxide adduct, fatty amino or fatty acid amide ethylene oxide adduct, alkylphenol ethylene oxide adduct, alkyl naphthol ethylene oxide adduct, polyvalent alcohol Partial fatty acid esters of ethylene oxide

- lubricant examples include stearic acid, stearic acid amide, oleic acid amide, higher alcohol, liquid paraffin, and the like.

- Examples of the ultraviolet absorber include ethylene-2-cyano-3,3′-diphenyl acrylate, 2- (2′-hydroxy-5′-methylphenyl) benzotriazole, and 2- (2′-hydroxy-3′-). t-butyl-5′-methylphenyl) 5-chlorobenzotriazole, 2-hydroxy-4-methoxybenzophenone, 2,2′-dihydroxy-4-methoxybenzophenone, 2-hydroxy-4 octoxybenzophenone and the like.

- the thickness of the base material layer 2 is not particularly limited, but is preferably 10 ⁇ m or more and 49 ⁇ m or less, and particularly preferably 15 ⁇ m or more and 39 ⁇ m or less.

- a surface layer 3 is provided on one surface of the base material layer 2 (in the case shown in FIG. 1, the upper surface of the base material layer 2).

- the surface layer 3 is composed of a polymer composition (3) containing at least a modified propylene polymer. That is, the surface layer 3 contains at least a modified propylene polymer.

- the modified propylene polymer may be referred to as a modified propylene polymer.

- the polymer composition (3) constituting the surface layer 3 contains a modified propylene polymer.

- the polymer composition (3) may contain only a modified propylene polymer, and may contain an unmodified propylene polymer together with the modified propylene polymer.

- the propylene-based polymer for the modified propylene-based polymer usually has a melt flow rate (MFR) (ASTM D1238 load 2160 g, temperature 230 ° C.) of 0.5 to 60 g / 10 min, preferably 0.8. It is in the range of 5 to 10 g / 10 minutes, more preferably 1 to 5 g / 10 minutes.

- MFR melt flow rate

- the polymer composition (3) constituting the surface layer 3 comprises (D) a propylene homopolymer alone or (D) both a propylene homopolymer and (E) a propylene / ⁇ -olefin random copolymer. It is preferable to include.

- the polymer composition (3) is “modified” obtained by modifying a propylene homopolymer as the above (D).

- the propylene homopolymer is preferably included. According to the surface layer 3 composed of the polymer composition (3) having this configuration, the surface layer 3 can be provided with good adhesiveness.

- the polymer composition (3) contains both (D) a propylene homopolymer and (E) a propylene / ⁇ -olefin random copolymer, either (D) or (E) One or both are preferably modified.

- the polymer composition (3) includes a “modified propylene homopolymer” obtained by modifying a propylene homopolymer, an unmodified propylene / ⁇ -olefin random copolymer, or an unmodified Propylene homopolymers and modified propylene / ⁇ -olefin random copolymers, or “modified propylene / ⁇ -olefin random copolymers” or “modified propylene homopolymers” and “modified”

- the propylene / ⁇ -olefin random copolymer ” is preferably included.

- the surface layer 3 made of the polymer composition (3) having this configuration can also impart good adhesion to the surface layer 3.

- the polymer composition (3) constituting the surface layer 3 contains both (D) a propylene homopolymer and (E) a propylene / ⁇ -olefin random copolymer, (D)

- the mass of (E) with respect to the total mass of (E) is preferably 50% by mass or less.

- Propylene / ⁇ -olefin random copolymer to make “modified propylene / ⁇ -olefin random copolymer” is propylene and other small amount, for example, 5 mol% or less ⁇ -olefin, for example, Random copolymers with ethylene, 1-butene, 1-hexene, 4-methyl / 1-pentene, 1-octene and the like.

- the random copolymer may be a ternary random copolymer composed of propylene and two or more ⁇ -olefins.

- the propylene / ⁇ -olefin random copolymer usually has a melting point of 100 to 150 ° C., preferably 120 to 145 ° C.

- modified propylene homopolymer and “modified propylene / ⁇ -olefin random copolymer” include propylene homopolymer, propylene and ethylene, 1-butene, 1-hexene, 4- A copolymer mainly composed of propylene with an ⁇ -olefin such as methyl 1-pentene and 1-octene is modified by adding a polar group.

- a propylene homopolymer or a propylene / ⁇ -olefin random copolymer graft-modified with an unsaturated carboxylic acid or a derivative thereof is included in the polymer composition (3) constituting the surface layer 3.

- an arbitrary adhesive layer described later is provided on the surface layer 3, it is preferable in that the adhesion between the surface layer 3 and the adhesive layer can be improved.

- unsaturated carboxylic acids or derivatives thereof include acrylic acid, maleic acid, fumaric acid, tetrahydrophthalic acid, itaconic acid, citraconic acid, crotonic acid, isocrotonic acid, nadic acid (endocis-bicyclo [2.2.1] hept Unsaturated carboxylic acids such as -5-ene-2,3-dicarboxylic acid); or derivatives thereof such as acid halides, amides, imides, anhydrides, esters and the like.

- Specific examples of such derivatives include maleyl chloride, maleimide, maleic anhydride, citraconic anhydride, monomethyl maleate, dimethyl maleate, glycidyl maleate and the like.

- unsaturated dicarboxylic acids or acid anhydrides thereof are suitable, and maleic acid, nadic acid or acid anhydrides thereof are particularly preferably used.

- the modified propylene polymer graft-modified with an unsaturated carboxylic acid or a derivative thereof is preferably 0.05 to 15% by mass, more preferably 0.1 to 10% by mass, based on the propylene polymer before modification. It is desirable to be graft-modified with an unsaturated carboxylic acid or a derivative thereof.

- the modified propylene polymer preferably has a melt flow rate (MFR) (ASTM D1238 load 2160 g, temperature 230 ° C.) of 0.1 to 50 g / 10 minutes, more preferably 0.3 to 30 g / 10 minutes. It is in.

- the polymer composition (3) constituting the surface layer 3 includes, as an optional component, together with the modified propylene polymer, the heat resistance stabilizer, weather resistance stabilizer, ultraviolet absorber described in the base material layer 2, Various additives usually used for polyolefins such as lubricants, slip agents, nucleating agents, antistatic agents, antifogging agents, pigments, dyes and the like may be included as long as the object of the present invention is not impaired.

- the thickness of the surface layer 3 is not particularly limited, but is preferably 0.5 ⁇ m or more and 10 ⁇ m or less, and particularly preferably 0.5 ⁇ m or more and 5 ⁇ m or less.

- the back surface layer 1 is provided on the other surface of the base material layer 2 (in the case shown in FIG. 1, the bottom surface of the base material layer 2).

- the back layer 1 is composed of a polymer composition (1) containing at least a propylene polymer. That is, the back layer 1 contains at least a propylene polymer.

- the propylene polymer contained in the polymer composition (1) constituting the back layer 1 can be used as it is, and description thereof is omitted here.

- the polymer composition (1) constituting the back layer 1 preferably contains (F) a propylene homopolymer and (G) a propylene / ⁇ -olefin random copolymer.

- the back surface layer 1 which consists of a polymer composition (1) of this structure, adhesiveness with the layer which contact

- the total mass of the above (F) and (G) is 100.

- the mass of (F) based on mass% is preferably 40% by mass or more and 90% by mass or less, and particularly preferably 50% by mass or more and 80% by mass or less.

- the polymer composition (1) which comprises the back surface layer 1 is the same as the polymer composition (2) which comprises the said base material layer 2, and the polymer composition (3) which comprises the surface layer 3.

- various additives usually used for polyolefins such as heat stabilizers, weather stabilizers, UV absorbers, lubricants, slip agents, nucleating agents, antiblocking agents, antistatic agents, antifogging agents, pigments, dyes, etc. May be included as long as the object of the present invention is not impaired.

- the thickness of the back surface layer 1 it is preferable that they are 0.5 micrometer or more and 10 micrometers or less, and it is especially preferable that they are 0.5 micrometer or more and 5 micrometers or less.

- Adhesive layer An adhesive layer (not shown) is preferably provided on the surface layer 3.

- the adhesive layer contains a resin having adhesiveness. Although there is no limitation in particular about resin which has adhesiveness, a polyurethane-type resin is preferable.

- polyurethane resins include dry polyurethane, water-based dry laminate, solventless laminate, polyester polyurethane, polyether polyurethane, which are generally used as adhesives for films, water-based dry laminates, solventless laminates, and electron beam curable laminate adhesives.

- polyurethane polyurea resin examples include polyurethane polyurea resin.

- the polyurethane-based resin may be either a water-dispersed type or a solvent-type, but a water-dispersed polyurethane-based resin is preferable from the viewpoint of the work environment at the production site because the degree of crosslinking of the polyurethane-based resin coating layer can be easily adjusted.

- the glass transition temperature (Tg) of the polyurethane-based resin is preferably 35 ° C. or higher, and particularly preferably 50 ° C. or higher.

- Tg glass transition temperature

- the polyurethane resin having a preferable glass transition temperature (Tg) can be obtained by various known methods. For example, it can be obtained by variously selecting polyether glycol, polyester glycol, or an isocyanate compound.

- a commercially available polyurethane resin can be used as it is.

- water-dispersed polyurethane resins include self-emulsifying polyurethane systems in which hydrophilic groups such as carboxylates (such as —COONa) and sulfonates (such as —SO 3 Na) are introduced into the main chain or side chain of the polyurethane resin. Resins are preferred.

- an isocyanate resin is used as a crosslinking agent to form a polyurethane having a three-dimensional structure

- the water dispersion type is often a linear polyurethane or polyurethane polyurea resin

- a crosslinking agent such as a melamine resin, an epoxy resin, or an imine resin may be added to the polyurethane resin at about 3 to 10% by mass, or an acid catalyst is added at about 0.5 to 1% by mass for curing. The reaction can be further promoted.

- Such a crosslinking agent not only improves the water resistance and solvent resistance of the easy-adhesive film, but also contributes to an improvement in adhesion.

- the adhesive layer may contain inorganic fine particles, organic fine particles, and the like as necessary for the purpose of preventing blocking together with the above adhesive resin, for example, polyurethane resin.

- the thickness of the adhesive layer is not particularly limited, but is preferably 0.1 ⁇ m or more and 1 ⁇ m or less, and particularly preferably 0.1 ⁇ m or more and 0.5 ⁇ m or less.

- the thickness of the surface substrate is not particularly limited, but the thickness of each layer constituting the surface substrate is within the preferable thickness range described above, and the thickness of the entire surface substrate is 15 ⁇ m or more and 50 ⁇ m. Or less, and particularly preferably 18 ⁇ m or more and 40 ⁇ m or less.

- the surface substrate for the thermal transfer image-receiving sheet of the present invention can be prepared by various known methods, for example, the propylene polymer composition (2) that becomes the substrate layer 2 of the surface substrate for the thermal transfer image-receiving sheet, and the surface layer 3 described above.

- a multilayer sheet obtained by coextrusion molding of the propylene polymer composition (3) and the propylene polymer composition (1) to be the back layer 1 is obtained by using a known simultaneous biaxial stretching method or sequential biaxial method. It can be obtained by a biaxially stretched film manufacturing method such as a stretching method.

- the biaxial stretching conditions include known biaxially stretched polypropylene production conditions, for example, in the sequential biaxial stretching method, the longitudinal stretching temperature is 100 ° C. to 145 ° C., the stretching ratio is in the range of 4 to 7 times, and the transverse stretching temperature is 150.

- the stretching ratio may be in the range of ⁇ 190 ° C. and the draw ratio in the range of 8 to 11.

- an adhesive layer for example, an aqueous solution or dispersion of the polyurethane resin to be the adhesive layer is applied on the surface layer 3, for example, an air knife coater, a direct gravure coater, a gravure offset coater, an arc.

- the method of laminating the adhesive layer on the surface layer 3 after stretching the multilayer sheet by the method described above, the method of subsequently coating the surface layer 3 with a polyurethane resin or the like (in-line coating method) ), Or once a surface substrate for a thermal transfer image-receiving sheet is produced by the method described above, and then various other known methods such as a method of separately coating the surface layer 3 with a polyurethane resin or the like (offline coating method).

- the manufacturing method can be adopted.

- an adhesive layer made of polyurethane resin or the like on the surface layer 3 before laminating an adhesive layer made of polyurethane resin or the like on the surface layer 3, various known methods such as corona treatment, flame treatment, or aromatic can be used to improve the adhesion with the polyurethane resin.

- the surface layer 3 may be coated (primer-treated) using an ester, organic titanate, or polyethyleneimine as an anchor layer.

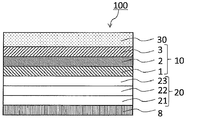

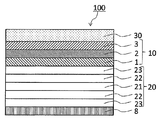

- FIG. 2 is a schematic sectional view of the thermal transfer image receiving sheet of the present invention.

- the thermal transfer image receiving sheet 100 of the present invention is provided with a receiving layer 30 on one side of a support 20, and a back layer from the support side between the support 20 and the receiving layer 30.

- the surface base material 10 of the present invention described above is provided so that 1, the base material layer 2 and the surface layer 3 are in this order.

- the thermal transfer image-receiving sheet 100 of the present invention having the above-described configuration, the occurrence of curling is suppressed because the surface base material 10 of the present invention described above is provided between the support 20 and the receiving layer 30. Therefore, even when the thickness is reduced, a high-quality thermal transfer image can be formed on the receiving layer 30 due to the heat resistance and cushioning properties of the surface substrate 10.

- the surface base material 10 of the present invention having concealability is provided between the support 20 and the receiving layer 30, even if the support 20 has foreign matter, defects, etc. These defects and the like can be concealed by the surface substrate 10 of the invention, and the texture of the thermal transfer image receiving sheet can be improved.

- the support 20 is not particularly limited as long as it can support the surface base material 10 of the present invention and the back layer 8 having an arbitrary configuration.

- the support 20 may have a laminated structure in which a core material 21, a polyolefin-based resin layer 22, and an adhesive layer 23 are laminated in this order, as shown in FIG.

- the adhesive layer 23, the polyolefin resin layer 22, the core material 21, the polyolefin resin layer 22, and the adhesive layer 23 may be stacked in this order. Further, it may have a single layer structure.

- Examples of the support 20 having a single layer structure include a support 20 made of a core material 21 and a support 20 made of a polyolefin resin layer 22.

- Core As the core material 21, high-quality paper, coated paper, resin-coated paper, art paper, cast-coated paper, paperboard, synthetic paper (polyolefin-based, polystyrene-based), synthetic resin or emulsion-impregnated paper, synthetic rubber latex-impregnated paper, synthetic resin Examples thereof include internal paper and cellulose fiber paper.

- the thickness of the core material 21 is not particularly limited, and is usually about 10 to 300 ⁇ m. Particularly preferred is a thickness of 100 to 250 ⁇ m.

- a commercially available core material can also be used, for example, RC paper paper (manufactured by Mitsubishi Paper Industries Co., Ltd., trade name: STF-150), coated paper (manufactured by Nippon Paper Industries Co., Ltd., trade name) : Aurora coat) and the like can be suitably used.

- Polyolefin resin layer As a component of the polyolefin-based resin layer 22, polyolefins such as polyester, polypropylene, polybutene, polyisobutene, polyisobutylene, polybutadiene, polyisoprene, ethylene-vinyl acetate copolymer having high heat resistance such as polyethylene, polyethylene terephthalate, and polyethylene naphthalate are used. Based resins.

- the polyolefin resin layer 22 may be stretched or unstretched.

- the polyolefin resin layer may contain a white pigment or a filler. Moreover, you may have a micro void inside.

- the thickness of the polyolefin resin layer 22 is usually about 10 to 40 ⁇ m in a dry state.

- a support body 20 in which a polyolefin resin layer 22 is provided on both sides of a core material 21.

- a polyolefin-based resin layer 22 By providing the polyolefin-based resin layer 22 on both sides of the core material 21, it is possible to improve the curl generation suppressing effect that may occur in the thermal transfer image receiving sheet 100 due to the synergistic effect with the surface base material of the present invention.

- the polyolefin resin layer 22 is provided only on one surface side of the core material 21, stress due to shrinkage of the polyolefin resin layer 22 occurs only on the surface side where the polyolefin resin layer 22 is provided.

- the thermal transfer image receiving sheet 100 tends to be curled.

- the support 20 preferably has a laminated structure in which the adhesive layer 23 is located on the surface that directly contacts the surface base material 10.

- the adhesive layer 23 includes an adhesive and has an adhesive function.

- the adhesive component include urethane resins, ⁇ -olefin-maleic anhydride resin and other polyolefin resins, polyester resins, acrylic resins, epoxy resins, urea resins, melamine resins, phenol resins, Examples thereof include vinyl acetate resins and cyanoacrylate resins. Among them, a reactive type of acrylic resin, a modified type, etc.

- an isocyanate compound is generally used, but aliphatic amines, cycloaliphatic amines, aromatic amines, acid anhydrides and the like can be used.

- the thickness of the adhesive layer 23 is usually about 2 ⁇ m to 10 ⁇ m in a dry state.

- generally used coating means can be used, for example, by means of gravure printing, screen printing, reverse roll coating using a gravure plate, etc., It can be obtained by drying. Further, EC sand lamination using polyethylene or the like may be performed.

- the thickness of a support body is 150 micrometers or more.

- the surface base material 10 that exerts an effect of suppressing the occurrence of curling is provided between the support 20 and the receiving layer 30, depending on the thermal history at the time of image formation, There may be a case where the surface substrate slightly shrinks.

- the support body 20 functions as a resistance force against shrinkage stress (shrinkage) that can occur in the surface base material 10, and the resistance force increases as the thickness of the support body 20 is increased.

- shrinkage stress that can occur can be reduced.

- the thickness of the support 20 is set to the above preferable thickness, the thickness of the support 20 and the surface base 10 of the present invention have a relatively thick thickness due to a synergistic effect. Even so, curling can be eliminated or extremely small.

- the preferable upper limit of the thickness of the support body 20 there is no limitation in particular about the preferable upper limit of the thickness of the support body 20, and it can set suitably in consideration of the thickness of the thermal transfer image receiving sheet 100 whole.

- An example of a preferred upper limit is about 300 ⁇ m.

- a receiving layer 30 is provided on the surface substrate 10 of the present invention.

- the receiving layer 30 is an essential component in the thermal transfer image receiving sheet 100 used in the present invention.

- the receiving layer 30 contains a binder resin as an essential component.

- a conventionally known resin material that can easily receive the dye of the dye layer of the thermal transfer sheet can be used.

- polyolefin resin such as polypropylene, halogenated resin such as polyvinyl chloride or polyvinylidene chloride, polyvinyl acetate, vinyl chloride-vinyl acetate copolymer, ethylene-vinyl acetate copolymer or polyacrylate Vinyl resins, polyester resins such as polyethylene terephthalate or polybutylene terephthalate, polystyrene resins, polyamide resins, copolymers of olefins such as ethylene or propylene and other vinyl polymers, cellulose resins such as ionomers or cellulose diastases And solvent-based resins such as polycarbonate and acrylic resins.

- a water-based resin such as a water-soluble resin, a water-soluble polymer, or a water-based resin can also be used as the binder resin.

- the receiving layer 30 containing a water-based resin an image having a higher printing density can be formed as compared with a solvent-based receiving layer, and light resistance and glossiness after image formation are improved. Can do.

- water-soluble resin and water-soluble polymer examples include polyvinyl pyrrolidone resin, polyvinyl alcohol resin, and gelatin.

- water-based resin include emulsions such as a vinyl chloride resin, an acrylic resin, and a urethane resin, or a resin in which a part of a solvent such as a dispersion is composed of water.

- the aqueous resin can be formed, for example, by dispersing and adjusting a solution containing a solvent-based resin by a method such as a homogenizer.

- the receiving layer 30 may contain a release agent for improving the release property from the thermal transfer sheet.

- the release agent include solid waxes such as polyethylene wax, amide wax, and Teflon (registered trademark) powder, fluorine or phosphate surfactant, silicone oil, reactive silicone oil, and curable silicone oil. And various modified silicone oils, and various silicone resins.

- the various binder resins described above are preferably contained in an amount of 50% by mass or more based on the total solid content of the receiving layer 30.

- high gloss can be imparted to the formed image. The same applies to the case of using other binder resins.

- the method for forming the receiving layer 30 is not particularly limited, and the binder resin described above and various additives added as necessary are dissolved or dispersed in an appropriate solvent such as water or a solvent to form a receiving layer.

- a coating solution can be prepared, and this can be formed by coating and drying on the surface substrate 10 by means such as a gravure printing method, a screen printing method, or a reverse coating method using a gravure plate.

- the thickness of the receiving layer 30 is not particularly limited, but a preferable range is about 1 g / m 2 to 10 g / m 2 .

- a receiving layer 30 is provided on one surface of a support 20, and the surface substrate 10 of the present invention is provided between the support 20 and the receiving layer 30.

- any layer other than these layers can be provided.

- a primer layer (not shown) for preventing the surface substrate 10 from being destroyed by the solvent of the receptor layer 30 can be provided between the surface substrate 10 and the receptor layer 30.

- an additional layer for example, an intermediate layer for improving interlayer adhesion can be provided between the support 20 and the surface base material 10.

- the back layer 8 can be provided on the surface of the support 20 that is not in contact with the surface base material 10.

- the back layer 8 has an arbitrary configuration in the thermal transfer image receiving sheet of the present invention.

- the material for the back layer 8 is not particularly limited, and examples thereof include resins such as acrylic resins, cellulose resins, polycarbonate resins, polyvinyl acetal resins, polyvinyl alcohol resins, polyamide resins, polystyrene resins, polyester resins, and halogenated polymers. Can be mentioned.

- the above resin is cured by a curing agent.

- a curing agent generally known ones can be used, and among them, an isocyanate compound is preferable.

- the above resin reacts with an isocyanate compound and the like to form a urethane bond to be cured / three-dimensionalized, whereby the heat resistant storage stability and solvent resistance of the back layer 8 can be improved. Adhesion can be improved.

- the amount of the curing agent added is preferably 1 to 2 with respect to the resin 1 reactive group equivalent exemplified above. If it is less than 1, it may take a long time to complete the curing, and the heat resistance and solvent resistance may deteriorate. On the other hand, when the ratio is larger than 2, there may be a problem that a change with time occurs after the film formation or that the life of the coating solution for the back layer is short.

- the back layer 8 may contain an organic filler or an inorganic filler as an additive together with the resin.

- an organic filler include acrylic filler, polyamide filler, fluorine filler, and polyethylene wax. Of these, polyamide filler is particularly preferred.

- the inorganic filler include silicon dioxide and metal oxides.

- the polyamide filler preferably has a molecular weight of 100,000 to 900,000, is spherical, and has an average particle diameter of 0.01 to 30 ⁇ m.

- nylon 12 filler is more preferable because it is excellent in water resistance and has no characteristic change due to water absorption.

- the method for forming an image on the receiving layer surface using the thermal transfer image receiving sheet of the present invention is not particularly limited, and can be performed by a known thermal transfer method.

- thermal transfer sheet used in the image formation for example, a heat transferable color material layer is provided on one surface of a substrate such as a polyester film, and a back layer is provided on the other surface of the substrate.

- a thermal transfer sheet can be used.

- the thermal transfer sheet will be described.

- the base material of the thermal transfer sheet may be any conventionally known material having a certain degree of heat resistance and strength.

- the base material of the thermal transfer sheet may be any conventionally known material having a certain degree of heat resistance and strength.

- the thickness of the base material of the thermal transfer sheet is not particularly limited, but is usually 0.5 ⁇ m to 50 ⁇ m, preferably about 1.5 to 10 ⁇ m.

- the base material of the thermal transfer sheet may be subjected to a surface treatment in order to improve adhesion with an adjacent layer.

- a surface treatment known resin surface modification techniques such as corona discharge treatment, flame treatment, ozone treatment, ultraviolet treatment, radiation treatment, surface roughening treatment, chemical treatment, plasma treatment, grafting treatment, etc. can be applied. it can. Only one type of surface treatment may be performed, or two or more types may be performed. Moreover, the undercoat layer (primer layer) may be provided in the one surface or both surfaces as needed.

- the thermal transfer colorant layer is a layer containing a sublimation dye when the thermal transfer sheet is a sublimation type thermal transfer sheet, and a layer containing a thermal melt composition containing a colorant in the case of a thermal melt type thermal transfer sheet. It becomes. Also, thermal transfer in which a layer region containing a sublimable dye and a layer region containing a heat-meltable ink comprising a heat-melting composition containing a colorant are provided on a single continuous substrate in a surface sequential manner. A sheet can also be used.

- sublimation dyes include diarylmethane dyes; triarylmethane dyes; thiazole dyes; merocyanine dyes; pyrazolone dyes; methine dyes; indoaniline dyes; Azomethine dyes such as azomethine and pyridone azomethine; xanthene dyes; oxazine dyes; cyanostyrene dyes such as dicyanostyrene and tricyanostyrene; thiazine dyes; azine dyes; acridine dyes; benzeneazo dyes; Azo dyes such as azo, isothiazole azo, pyrrole azo, pyrazole azo, imidazole azo, thiadiazole azo, triazole azo, disazo; spiropyran dyes; indolinospiropyran Fee; fluoran dyes; rhodamine lactam dyes; naphthoquino

- the content of the sublimable dye is in the range of 5% to 90% by weight, preferably 10% to 70% by weight, based on the total solid content of the heat transferable color material layer. Is preferred.

- the content of the sublimation dye is less than the above range, the print density may be lowered, and when it exceeds the above range, the storage stability may be lowered.

- binder resin for supporting the dye examples include cellulose resins such as ethyl cellulose resin, hydroxyethyl cellulose resin, ethyl hydroxy cellulose resin, methyl cellulose resin, nitrocellulose resin, and cellulose acetate resin, polyvinyl alcohol resin, and polyvinyl acetate resin.

- cellulose resins such as ethyl cellulose resin, hydroxyethyl cellulose resin, ethyl hydroxy cellulose resin, methyl cellulose resin, nitrocellulose resin, and cellulose acetate resin

- polyvinyl alcohol resin and polyvinyl acetate resin

- acrylic resins such as poly (meth) acrylate and poly

- the heat transferable color material layer may contain a release agent, inorganic fine particles, organic fine particles and the like.

- the mold release agent include silicone oil, polyethylene wax, and phosphate ester.

- the silicone oil include straight silicone oil, modified silicone oil, and cured products thereof.

- the silicone oil may be reactive or non-reactive.

- Inorganic fine particles include carbon black, aluminum, molybdenum disulfide and the like.

- the modified silicone oil can be classified into a reactive silicone oil and a non-reactive silicone oil.

- the reactive silicone oil includes amino modification, epoxy modification, carboxyl modification, hydroxy modification, methacryl modification, mercapto modification, phenol modification, one-terminal reactivity and heterofunctional modification.

- Non-reactive silicone oils include polyether modification, methylstyryl modification, alkyl modification, higher fatty acid ester modification, hydrophilic special modification, higher alkoxy modification, fluorine modification and the like.

- the amount of silicone oil added is preferably 0.1 to 15% by mass, more preferably 0.3 to 10% by mass, based on the mass of the binder.

- Examples of the organic fine particles include polyethylene wax.

- the heat transferable color material layer is, for example, a coating solution for a heat transferable color material layer in which a sublimable dye, a binder resin, and various components optionally added as necessary are dispersed or dissolved in an appropriate solvent. It can be formed on a substrate by coating and drying using a conventionally known coating method. Conventionally known coating methods include a ravia printing method, a reverse roll coating method using a gravure plate, a roll coater, a bar coater and the like. Examples of the solvent include toluene, methyl ethyl ketone, ethanol, isopropyl alcohol, cyclohexanone, dimethylformamide [DMF] and the like.

- the thickness of the heat transferable color material layer is not particularly limited, and is usually about 0.2 ⁇ m to 5 ⁇ m.

- a back layer for improving heat resistance, running performance of the thermal head during printing, and the like may be provided on the other surface of the substrate.

- the back layer of the thermal transfer sheet can be formed by appropriately selecting a conventionally known thermoplastic resin or the like.

- a thermoplastic resin for example, polyester resins, polyacrylate resins, polyvinyl acetate resins, styrene acrylate resins, polyurethane resins, polyethylene resins, polypropylene resins, and other polyolefin resins, Polystyrene resin, polyvinyl chloride resin, polyether resin, polyamide resin, polyimide resin, polyamideimide resin, polycarbonate resin, polyacrylamide resin, polyvinyl chloride resin, polyvinyl butyral resin, polyvinyl acetoacetal resin, etc.

- thermoplastic resins such as polyvinyl acetal resin, and silicone modified products thereof.

- a polyamideimide resin or a modified silicone product thereof can be preferably used.

- a release agent such as wax, higher fatty acid amide, phosphate ester compound, metal soap, silicone oil, surfactant, etc. is used for the back layer of the thermal transfer sheet. It is preferable that various additives such as organic powders such as fluororesin, inorganic particles such as silica, clay, talc, and calcium carbonate are contained, and that at least one of phosphate ester or metal soap is contained. Is particularly preferred.

- the back layer of the thermal transfer sheet may be, for example, a gravure printing method or screen printing on a substrate with a coating solution in which the above thermoplastic resin or various additives added as necessary are dispersed or dissolved in an appropriate solvent. It can be formed by coating and drying by a known means such as a reverse roll coating printing method using a gravure plate.

- the thickness of the back layer is preferably 2 ⁇ m or less, more preferably about 0.1 ⁇ m to 1 ⁇ m.

- Calcium carbonate (b1) As calcium carbonate (b1), powdered calcium carbonate (average particle size: 1.2 ⁇ m) coated with stearic acid was prepared.

- Titanium oxide (c1) As the titanium oxide (c1), alumina-treated rutile type titanium oxide (average particle size 0.2 ⁇ m) was prepared.

- ADMER maleic anhydride graft-modified propylene homopolymer

- Surface layer (1) As the surface layer (1), a surface layer containing 50% by mass of (PP-3) and 50% by mass of (PP-2) by dry blending the above (PP-3) and (PP-2). Got ready.

- Surface layer (2) As the surface layer (2), a surface layer containing 70% by mass of (PP-3) and 30% by mass of (PP-2) by dry blending the above (PP-3) and (PP-2). Got ready.

- Back side layer As the back side layer, a back side layer containing 30% by mass of (PP-1) and 70% by mass of (PP-2) by dry blending the above (PP-1) and (PP-2). Got ready.

- the mass of (c1) with respect to the total mass of mass%, (a1), (b1), and (c1) is 1.1 mass%, and the thickness is 24.2 ⁇ m on one surface of the base material layer (1).

- a surface base material (1) provided with the surface layer (1) having a thickness of 0.5 ⁇ m and the back surface layer having a thickness of 0.5 ⁇ m provided on the other surface of the base material layer (1) is prepared. did.

- ⁇ Preparation of surface substrate (2)> Including (a1), (b1), (c1) prepared above, the mass of (b1) with respect to the total mass of (a1), (b1), (c1) is 12.6% by mass, (a1), ( The surface layer having a thickness of 1.8 ⁇ m on one surface of the base material layer (2) having a mass of (c1) of 1.3 mass% and a thickness of 18 ⁇ m with respect to the total mass of b1) and (c1) (1) was provided and the surface base material (2) in which the said back surface layer with a thickness of 0.5 micrometer was provided in the other surface of the base material layer (2) was prepared.

- ⁇ Preparation of surface substrate (3)> Including (a1), (b1), (c1) prepared above, the mass of (b1) is 12% by mass with respect to the total mass of (a1), (b1), (c1), (a1), (b1)

- ⁇ Preparation of surface substrate (4)> Including (a1), (b1) and (c1) prepared above, the mass of (b1) with respect to the total mass of (a1), (b1) and (c1) is 13.2% by mass, (a1), ( b1) The mass of (c1) with respect to the total mass of (c1) is 2.2% by mass, and the thickness of the above is 4.3 ⁇ m on one surface of the substrate layer (4) having a thickness of 18.2 ⁇ m.

- ⁇ Preparation of surface substrate (5)> Including (a1), (b1) and (c1) prepared above, the mass of (b1) with respect to the total mass of (a1), (b1) and (c1) is 6.0% by mass, (a1), ( b1) The mass of (c1) with respect to the total mass of (c1) is 1.2% by mass, and the thickness is 0.5 ⁇ m on one surface of the base material layer (5) having a thickness of 36.5 ⁇ m.

- a surface base material (5) was prepared in which a surface layer (1) was provided and the other surface of the base material layer (5) was provided with the back surface layer having a thickness of 0.5 ⁇ m.

- ⁇ Preparation of surface substrate (A)> Including (a1), (b1), (c1) prepared above, the mass of (b1) with respect to the total mass of (a1), (b1), (c1) is 3.3% by mass, (a1), ( b1) The mass of (c1) with respect to the total mass of (c1) is 1.1% by mass, and the thickness is 0.5 ⁇ m on one surface of the substrate layer (A) having a thickness of 19.6 ⁇ m.

- a surface base material (A) was prepared in which the surface layer (1) was provided and the other surface of the base material layer (5) was provided with the back surface layer having a thickness of 0.5 ⁇ m.

- Example 1 As the base sheet, RC paper (thickness 190 ⁇ m, manufactured by Mitsubishi Paper Industries Co., Ltd.) is prepared, and the coating amount of the adhesive layer having the following composition is dried on the base sheet, and the coating amount becomes 5 g / m 2 .

- an adhesive layer was formed by coating with a gravure coater, and was bonded to the surface base material (1) prepared above by a dry lamination method.

- an intermediate layer coating solution having the following composition was dried and coated with a gravure coater so that the coating amount became 2 g / m 2, and dried at 110 ° C. for 1 minute to be intermediate.

- a layer is formed, and on the intermediate layer, a dye-receiving layer coating solution having the following composition is dried and coated with a gravure coater so that the coating amount becomes 4 g / m 2, and dried at 110 ° C. for 1 minute.

- a thermal transfer image-receiving sheet of Example 1 was prepared by laminating a substrate sheet / adhesive layer / surface substrate (1) / intermediate layer / dye-receiving layer in this order.

- ⁇ Dye-receiving layer coating solution > ⁇ 60 parts of vinyl chloride-vinyl acetate copolymer (Solvine C Nissin Chemical Industry Co., Ltd.) ⁇ Epoxy-modified silicone 1.2 parts (X-22-3000T Shin-Etsu Chemical Co., Ltd.) ⁇ Methylstil modified silicone 0.6 parts (24-510 Shin-Etsu Chemical Co., Ltd.) ⁇ Methyl ethyl ketone / toluene (mass ratio 1/1) 5 parts

- Example 2 A thermal transfer image-receiving sheet of Example 2 was formed in the same manner as Example 1 except that the surface substrate (1) was changed to the surface substrate (2) prepared above.

- Example 3 A thermal transfer image-receiving sheet of Example 3 was formed in the same manner as Example 1 except that the surface substrate (1) was changed to the surface substrate (3) prepared above.

- Example 4 A thermal transfer image-receiving sheet of Example 4 was formed in the same manner as Example 1 except that the surface substrate (1) was changed to the surface substrate (4) prepared above.

- Example 5 A thermal transfer image-receiving sheet of Example 5 was formed in the same manner as Example 1 except that the surface substrate (1) was changed to the surface substrate (5) prepared above.

- Comparative Example 1 A thermal transfer image-receiving sheet of Comparative Example 1 was formed in the same manner as Example 1 except that the surface substrate (1) was changed to the surface substrate (A) prepared above.

- Comparative Example 2 A thermal transfer image-receiving sheet of Comparative Example 2 was formed in the same manner as in Example 1 except that the surface substrate (1) was changed to the surface substrate (B) prepared above.

- ⁇ Print density evaluation >> Combine the thermal transfer sheet (for Megapixel III, Altech AD S Co., Ltd. genuine product) with the thermal transfer image-receiving sheet of each example and comparative example, and print the gradation pattern under the following printing conditions to obtain the density characteristics. Examined. The density was evaluated at the highest density when the maximum energy was applied, and the print density was evaluated based on the following evaluation criteria. The reflection density was measured with a spectrophotometer (Spectrolino, manufactured by Gretag Macbeth Co.). The evaluation results are shown in Table 1.

- SYMBOLS 10 Surface base material 1 ... Back surface layer 2 ... Base material layer 3 ... Surface layer 100 ... Thermal transfer image receiving sheet 20 ... Support body 22 ... Polyolefin-type resin layer 23 ... Adhesive layer 30 ... Receiving layer

Landscapes

- Physics & Mathematics (AREA)

- Optics & Photonics (AREA)

- Laminated Bodies (AREA)

- Thermal Transfer Or Thermal Recording In General (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP14871854.7A EP3085548B1 (en) | 2013-12-18 | 2014-12-09 | Surface substrate for heat transfer image reception sheet, and heat transfer image reception sheet |

| US15/105,672 US9776446B2 (en) | 2013-12-18 | 2014-12-09 | Front face side substrate for thermal transfer image-receiving sheet, and thermal transfer sheet |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013-261223 | 2013-12-18 | ||

| JP2013261223A JP6205262B2 (ja) | 2013-12-18 | 2013-12-18 | 熱転写受像シート用表面基材、及び熱転写受像シート |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2015093340A1 true WO2015093340A1 (ja) | 2015-06-25 |

Family

ID=53402689

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2014/082487 Ceased WO2015093340A1 (ja) | 2013-12-18 | 2014-12-09 | 熱転写受像シート用表面基材、及び熱転写受像シート |

Country Status (4)

| Country | Link |

|---|---|

| US (1) | US9776446B2 (enExample) |

| EP (1) | EP3085548B1 (enExample) |

| JP (1) | JP6205262B2 (enExample) |

| WO (1) | WO2015093340A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110497664A (zh) * | 2018-05-18 | 2019-11-26 | 上海恩捷新材料科技股份有限公司 | 一种铝塑复合包装膜及其制备方法 |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6709521B2 (ja) * | 2015-09-24 | 2020-06-17 | 大日本印刷株式会社 | 転写シート |

| KR101832737B1 (ko) * | 2016-02-19 | 2018-04-13 | 율촌화학 주식회사 | 폴리올레핀계 적층필름 및 이의 제조 방법 |

| EP3603955A4 (en) * | 2017-03-31 | 2021-01-06 | Dai Nippon Printing Co., Ltd. | GAS BARRIER LAMINATE, AS WELL AS GAS BARRIER PACKAGING MATERIAL AND PILLOW PACKAGING BAG EACH FORMED LAMINATED |

| JP2020151864A (ja) * | 2019-03-18 | 2020-09-24 | 凸版印刷株式会社 | 樹脂シート |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0749062A (ja) | 1991-05-15 | 1995-02-21 | Mitsui Eng & Shipbuild Co Ltd | 内燃機関のnox 低減システム |

| JPH07125453A (ja) * | 1993-06-28 | 1995-05-16 | Oji Yuka Synthetic Paper Co Ltd | 熱転写画像受容シート |

| WO2000018829A1 (en) * | 1998-09-25 | 2000-04-06 | Yupo Corporation | Thermoplastic resin film and label sheet comprising the same |

| WO2006121217A1 (ja) * | 2005-05-13 | 2006-11-16 | Oji Paper Co., Ltd. | 二軸延伸積層ポリプロピレンフィルム及びその用途 |

| JP2007022065A (ja) * | 2005-06-16 | 2007-02-01 | Chisso Corp | 昇華型熱転写受像体 |

| JP2007229988A (ja) | 2006-02-28 | 2007-09-13 | Fujifilm Corp | 感熱転写受像シートおよびその製造方法 |

| JP2012158121A (ja) | 2011-02-01 | 2012-08-23 | Dainippon Printing Co Ltd | 熱転写受像シート |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP0515969B1 (de) * | 1991-05-28 | 1996-09-04 | Hoechst Aktiengesellschaft | Siegelbare, opake, biaxial orientierte Polypropylen-Mehrschichtfolie, Verfahren zu ihrer Herstellung und ihre Verwendung |

| TWI350246B (en) * | 2003-07-04 | 2011-10-11 | Mitsui Chemicals Tohcello Inc | Biaxially oriented multi-layer polypropylene film and the use thereof |

-

2013

- 2013-12-18 JP JP2013261223A patent/JP6205262B2/ja active Active

-

2014

- 2014-12-09 US US15/105,672 patent/US9776446B2/en active Active

- 2014-12-09 WO PCT/JP2014/082487 patent/WO2015093340A1/ja not_active Ceased

- 2014-12-09 EP EP14871854.7A patent/EP3085548B1/en active Active

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH0749062A (ja) | 1991-05-15 | 1995-02-21 | Mitsui Eng & Shipbuild Co Ltd | 内燃機関のnox 低減システム |

| JPH07125453A (ja) * | 1993-06-28 | 1995-05-16 | Oji Yuka Synthetic Paper Co Ltd | 熱転写画像受容シート |

| WO2000018829A1 (en) * | 1998-09-25 | 2000-04-06 | Yupo Corporation | Thermoplastic resin film and label sheet comprising the same |

| WO2006121217A1 (ja) * | 2005-05-13 | 2006-11-16 | Oji Paper Co., Ltd. | 二軸延伸積層ポリプロピレンフィルム及びその用途 |

| JP4941941B2 (ja) | 2005-05-13 | 2012-05-30 | 三井化学東セロ株式会社 | 二軸延伸積層ポリプロピレンフィルム及びその用途 |

| JP2007022065A (ja) * | 2005-06-16 | 2007-02-01 | Chisso Corp | 昇華型熱転写受像体 |

| JP2007229988A (ja) | 2006-02-28 | 2007-09-13 | Fujifilm Corp | 感熱転写受像シートおよびその製造方法 |

| JP2012158121A (ja) | 2011-02-01 | 2012-08-23 | Dainippon Printing Co Ltd | 熱転写受像シート |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110497664A (zh) * | 2018-05-18 | 2019-11-26 | 上海恩捷新材料科技股份有限公司 | 一种铝塑复合包装膜及其制备方法 |

Also Published As

| Publication number | Publication date |

|---|---|

| US9776446B2 (en) | 2017-10-03 |

| EP3085548A1 (en) | 2016-10-26 |

| US20170043604A1 (en) | 2017-02-16 |

| JP2015116730A (ja) | 2015-06-25 |

| EP3085548B1 (en) | 2020-09-30 |

| JP6205262B2 (ja) | 2017-09-27 |

| EP3085548A4 (en) | 2017-11-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5447557B2 (ja) | 熱転写シート | |

| JP5641405B2 (ja) | 熱転写シート | |

| EP2762325A1 (en) | Image forming method, and combination of thermal transfer sheet and thermal transfer image receiving sheet | |

| JP6205262B2 (ja) | 熱転写受像シート用表面基材、及び熱転写受像シート | |

| JP6536121B2 (ja) | 熱転写受像シート用支持体および熱転写受像シートならびにそれらの製造方法 | |

| JP4941941B2 (ja) | 二軸延伸積層ポリプロピレンフィルム及びその用途 | |

| JP2012006342A (ja) | 熱転写シート | |

| JP5874188B2 (ja) | 画像形成方法 | |

| JP6627237B2 (ja) | 熱転写受像シート用支持体の製造方法および熱転写受像シートの製造方法 | |

| JP2012158121A (ja) | 熱転写受像シート | |

| JP2014198418A (ja) | 熱転写受像シートの製造方法 | |

| JP2009061733A (ja) | 熱転写受像シート | |

| JP4073852B2 (ja) | 熱転写受像シートおよびその製造方法 | |

| US9290007B2 (en) | Thermal transfer image receiving sheet and image forming method | |

| JP2012152968A (ja) | 耐熱滑性層形成用組成物、およびそれを用いた熱転写シートの製造方法 | |

| JP2009083297A (ja) | 熱転写受像シートの製造方法 | |

| JP2008162155A (ja) | 熱転写受像シートの製造方法 | |

| JP2018118389A (ja) | 熱転写受像シート | |

| JP2006264091A (ja) | 熱転写受像シート | |

| JP4073866B2 (ja) | 熱転写受像シートおよびその製造方法 | |

| JP2009090521A (ja) | 熱転写受像シートの製造方法 | |

| JP2014198427A (ja) | 熱転写インクシートと熱転写受像シートのセットおよびそれを用いた画像形成方法 | |

| JP4073853B2 (ja) | 熱転写受像シートおよびその製造方法 | |

| JP2019166687A (ja) | 熱転写受像シート | |

| JP2014069460A (ja) | 熱転写受像シート |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 14871854 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 15105672 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| REEP | Request for entry into the european phase |

Ref document number: 2014871854 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2014871854 Country of ref document: EP |