WO2015001919A1 - インクジェット記録装置 - Google Patents

インクジェット記録装置 Download PDFInfo

- Publication number

- WO2015001919A1 WO2015001919A1 PCT/JP2014/065283 JP2014065283W WO2015001919A1 WO 2015001919 A1 WO2015001919 A1 WO 2015001919A1 JP 2014065283 W JP2014065283 W JP 2014065283W WO 2015001919 A1 WO2015001919 A1 WO 2015001919A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- printing

- nozzle

- print head

- abnormal

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/21—Ink jet for multi-colour printing

- B41J2/2132—Print quality control characterised by dot disposition, e.g. for reducing white stripes or banding

- B41J2/2139—Compensation for malfunctioning nozzles creating dot place or dot size errors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/015—Ink jet characterised by the jet generation process

- B41J2/02—Ink jet characterised by the jet generation process generating a continuous ink jet

- B41J2/03—Ink jet characterised by the jet generation process generating a continuous ink jet by pressure

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/07—Ink jet characterised by jet control

- B41J2/075—Ink jet characterised by jet control for many-valued deflection

- B41J2/08—Ink jet characterised by jet control for many-valued deflection charge-control type

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41J—TYPEWRITERS; SELECTIVE PRINTING MECHANISMS, i.e. MECHANISMS PRINTING OTHERWISE THAN FROM A FORME; CORRECTION OF TYPOGRAPHICAL ERRORS

- B41J2/00—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed

- B41J2/005—Typewriters or selective printing mechanisms characterised by the printing or marking process for which they are designed characterised by bringing liquid or particles selectively into contact with a printing material

- B41J2/01—Ink jet

- B41J2/07—Ink jet characterised by jet control

- B41J2/075—Ink jet characterised by jet control for many-valued deflection

- B41J2/095—Ink jet characterised by jet control for many-valued deflection electric field-control type

Definitions

- the present invention relates to an ink jet recording apparatus, and more particularly to an ink jet recording apparatus corresponding to a nozzle abnormality in an ink jet recording apparatus having two or more nozzles.

- Patent Document 1 JP 2010-137528 (Patent Document 1). This document describes control that “in an inkjet recording apparatus having two nozzles, provides a technique for making it possible to adjust the vertical spacing of characters printed by each nozzle”.

- FIG. 1 is an overall configuration and functional block diagram of a general inkjet recording apparatus. It is the structural example and printing example of a print head at the time of a twin nozzle. It is an example of the various printing parameters required for an inkjet recording device when printing with a twin nozzle. It is a figure which shows the printing parameter allocation at the time of nozzle vertical arrangement

- FIG. 5 is a diagram showing a nozzle printing range at normal time and abnormal time, and a table showing the number of ink particles flying from the nozzle when printing one vertical line in the printing range.

- the print head has two nozzles (hereinafter, this print head is referred to as a twin nozzle), and these are operated to print on one printed matter.

- this print head is referred to as a twin nozzle

- FIG. 1A is an overall view of a general ink jet recording apparatus.

- Reference numeral 1 denotes an ink jet recording apparatus

- 18 denotes a display

- 21 denotes a print head.

- FIG. 1B shows a functional block diagram of the inkjet recording apparatus 1.

- the ink jet recording apparatus 1 is roughly composed of a controller A and a printing apparatus B, and performs printing on a product 7 that is a printing object on the transport line 6.

- the ink jet recording apparatus 1 needs to analyze the information obtained from the input unit 2 in the control unit 3 having the control unit 8 and the storage unit 4 having the memory 9 and the program storage unit 10 so as to obtain an optimum printing result.

- the control signal is corrected and the output signal is transmitted from the output unit 5.

- the printing object detection device 12 that receives a signal from the printing material sensor 11 at the input unit 2 of the controller A

- the conveyance speed detection device 14 that receives a signal from the encoder 13

- an input device that receives an input signal from an operator.

- information on the printing apparatus B and the product is input, and calculation processing is performed by the control unit 3, and an output signal is transmitted from the output unit 5 to the printing apparatus B.

- the setting value input to the input device 15 of the controller A from the touch panel 16 as the input means of the printing device B is stored in the memory 9 of the storage unit 4.

- the information is stored and processed by the control device 8 of the control unit 3 and displayed on the display 18 via the display device 17.

- the position of the product 7 is specified by the printed material detection device 12 and the transport speed detection device 14.

- the ink supplied from the ink container 19 by the pump 20 is excited by the excitation voltage generator 23 at the nozzle 22 in the print head 21 to form ink particles 24, and the charging voltage is adjusted in accordance with the print data on the memory 9.

- the generator 25 applies a charging voltage to the charging electrode 26.

- the charged ink particles 24 are deflected when passing through the deflection electrode 28 to which the voltage of the deflection voltage generator 27 is applied, and a printing dot is formed on the product 7 to perform printing.

- the charging electrode 26 always applies the same direction of charge to the ink particles 24, and the deflection electrode 28 always applies the same voltage, so that the deflection direction of the print dots is always deflected upward.

- the ink particles 24 that are not charged are not used for printing but are collected by the gutter 59 and returned to the ink container 19. Further, the state of the print head 21 is constantly monitored by a control signal 29 which is an output of a detection unit including a sensor (not shown), and each element (nozzle 22, charging electrode 26, deflection electrode 28) of the print head 21 is abnormal. If there is, the ink jet recording apparatus 1 immediately performs an abnormality handling process.

- the state of the device power supply 30 is managed by the power supply device 31, and the state of the external connection terminal 32 is managed by the connection device 33.

- FIG. 2 shows a configuration example and a print example of the print head 21 at the time of twin nozzles.

- the print head 21 includes a nozzle 22a (hereinafter referred to as nozzle ⁇ ) and a nozzle 22b (hereinafter referred to as nozzle ⁇ ).

- the nozzle ⁇ includes a charging electrode 26a and a heel deflection. Printing is performed using the electrode 28a and the gutter 59a, and the nozzle ⁇ using the charging electrode 26b, the deflection electrode 28b and the gutter 59b.

- a nozzle, a charging electrode, a deflection electrode, and a gutter are collectively referred to as a sub print head.

- the ink jet recording apparatus controls the nozzle ⁇ and the nozzle ⁇ independently, and the print contents and print set values of the nozzle ⁇ and the nozzle ⁇ are different from each other.

- the arrangement of the nozzle ⁇ and the nozzle ⁇ may be a vertical arrangement method or a horizontal arrangement method.

- the deflection electrodes 28a and 28b are arranged in the vertical direction, characters in the vertical direction are displayed as shown in the printing example 7A. You can print at the same time.

- the deflection electrodes 28a and 28b are arranged in the horizontal direction, so that they are in the horizontal direction as shown in the printing example 7B. Characters can be printed simultaneously.

- FIG. 3 is a diagram showing an example of various printing parameters required by the ink jet recording apparatus when printing with twin nozzles.

- FIG. 6 is a diagram illustrating a relationship of necessary print parameters at that time.

- the nozzle abnormality means that the sub print head including the charging electrode, deflection electrode, and gutter including the nozzle is abnormal, and the ink particles emitted from the nozzle due to the abnormality are included in the target product. A state in which printing is not performed accurately.

- the abnormality of the sub print head will be described as nozzle abnormality.

- causes of the abnormality include clogging of the nozzle and a case where the charged charge amount at the charging electrode is different from a specified value.

- a control signal that is a sensor output. It is detected by constantly monitoring using 29.

- FIG. 3A is a diagram showing the print contents 34 and the print range when the nozzle ⁇ and the nozzle ⁇ are arranged in the vertical direction

- FIG. 3B is a diagram showing the nozzle ⁇ and the nozzle ⁇ in the horizontal direction

- FIG. 6 is a diagram showing the print contents 38 and the print range when they are arranged.

- FIG. 3C shows a configuration example of print parameters

- FIG. 3D shows a print parameter setting screen example.

- the print range (parameter L1) 35 printed by the nozzle ⁇ and the print range (parameter M1) 36 printed by the nozzle ⁇ are different in the vertical direction.

- the print range (parameter N1) 37 for printing the whole is a combination of the print range (parameter L1) 35 and the print range (parameter M1) 36. That is, when one nozzle becomes abnormal, when printing contents to be printed by the abnormal nozzles with the remaining normal nozzles, printing control is performed using the printing range (parameter N1) 37. Accordingly, the print content 34 is set so that printing can be performed using either a combination of the print range (parameter L1) 35 and the print range (parameter M1) 36 or a print range (parameter N1) 37.

- the printing range (parameter L2) 39 printed by the nozzle ⁇ and the printing range (parameter M2) 40 printed by the nozzle ⁇ are different in the horizontal direction.

- the print range (parameter N2) 41 for printing the whole is a combination of the print range (parameter L2) 39 and the print range (parameter M2) 40.

- the print range (parameter N2) 41 is used to perform print control. Accordingly, the print content 38 is set so that printing can be performed using either a combination of the print range (parameter L2) 39 and the print range (parameter M2) 40 or a print range (parameter N2) 41.

- the print parameters 42 shown in FIG. 3C include types such as a character size 43, a character height 44, and an ink particle usage rate 45. These parameters are input from the touch panel 16 and displayed on the display 18 as shown in the setting screen 46 shown in FIG. In FIG. 3D, when inputting from the touch panel 16, for example, items for each parameter and buttons for increasing / decreasing their set values may be set.

- the use range is distinguished for each print range.

- the print parameters 42 are distinguished by parameters L1, M1, and N1, respectively.

- the print parameters 42 are distinguished by parameters L2, M2, and N2.

- the print parameters are stored in the memory 9, and are read out and used as necessary. In the ink jet recording apparatus 1, these print parameters 42 are appropriately managed and used for printing.

- FIG. 4 shows the assignment of print parameters and the print results when the nozzles are vertically arranged with twin nozzles according to the present embodiment and both nozzles are normal and when either nozzle is abnormal.

- the nozzle ⁇ prints the print range 35 with the parameter L1, and the nozzle ⁇ prints the print range 36 with the parameter M1.

- the printing result at this time is normal printing 47 in FIG.

- the printing result is incorrect as in the abnormal printing 48.

- the nozzle ⁇ becomes abnormal the printing result is incorrect as in the abnormal printing 49.

- the normal nozzles are switched to the process of printing the print range 37 with the parameter N1. .

- the print result 50 shown in FIG. 4B is obtained, and even if an abnormality occurs, the print result is the same as that in the normal state.

- FIG. 5 shows the print parameter allocation and the print results when the nozzles are arranged in the horizontal direction in the twin nozzles according to the present embodiment, when both nozzles are normal and when either nozzle is abnormal.

- the nozzle ⁇ prints the print range 39 with the parameter L2, and the nozzle ⁇ prints the print range 40 with the parameter M2.

- the printing result at this time is normal printing 51 in FIG.

- the printing result is incorrect as in the abnormal printing 52.

- the nozzle ⁇ becomes abnormal the print result becomes incorrect as in the abnormal print 53.

- the normal nozzles are switched to the process of printing the print range 41 with the parameter N2. .

- the print result 54 shown in FIG. 5B is obtained, and the same print result as that in the normal state is obtained even if an abnormality occurs.

- the state is stored in the memory, and the state is notified to the outside of the ink jet recording apparatus, so that external correspondence associated with switching of printing control can be performed. Can be easily.

- the period during which printing cannot be completed until repair is completed is shortened. Therefore, there is an effect that generation of printing waste can be reduced and the influence on the customer's product development schedule can be suppressed.

- the present embodiment has been described assuming the case of twin nozzles.

- the case of having a plurality of nozzles can be expressed in a general form as follows.

- one parameter (parameter X) for printing one printing result with a plurality of nozzles and one parameter (parameter Y) for printing one printing result with a nozzle other than the nozzle that caused the abnormality (Nozzle number -1) are prepared.

- this can be realized by switching to a process in which other normal nozzles perform printing using the parameter Y.

- FIG. 6A shows an example of a screen 55 for making it possible to select whether or not to perform printing control using only normal nozzles when an abnormality occurs.

- FIG. 6B shows a nozzle control flowchart. Assuming that the process of performing printing control with only normal nozzles when an abnormality occurs is the relief control process when the nozzle is abnormal, the item 56 “Relief control when nozzle is abnormal” in the screen example 55 is an option of “do not / do” The relief control processing based on the present embodiment is performed only when “Yes” is held.

- a nozzle abnormal portion is determined at a branch 57.

- Nozzle abnormality is determined by monitoring the nozzle state using the control signal 29.

- the process moves to normal abnormality processing in processing 58.

- normal abnormality processing printing of the nozzle that has become abnormal is interrupted, and a message is displayed on the display 18 that the nozzle is in an abnormal state.

- the setting of the item 56 “rescue control when the nozzle is abnormal” is checked in processing 59.

- the setting is “NO”

- the process proceeds to a normal abnormality process in process 58.

- the relief control process f2 is executed.

- the relief control process since it is possible to input a setting as to whether or not the relief control process is performed when the nozzle is abnormal, it is possible to automatically stop the conveyance line or automatically when setting in the test mode.

- the relief control process can be set to OFF.

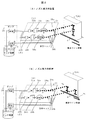

- FIG. 7 is an example of ink particle flight in normal printing and abnormal printing in this embodiment when the nozzles are arranged in the vertical direction with twin nozzles.

- FIG. 7A shows an ink particle flight example 62 for normal printing 47 when both nozzle ⁇ and nozzle ⁇ operate normally

- FIG. 7B shows printing 50 when nozzle ⁇ is abnormal

- Ink particle flight example 63- ⁇ is shown for - ⁇

- FIG. 7C shows ink particle flight example 63- ⁇ for print 50- ⁇ when nozzle ⁇ is abnormal.

- the ink particle flight example shows the vertical direction of the character.

- the ink particle flight example 62 normally flies in accordance with the printing contents. Further, when the nozzle ⁇ is abnormal, as shown in FIG. 7B, printing is performed only with the nozzle ⁇ , so the range in which the nozzle ⁇ prints compared to the normal printing 47 as in the ink particle flight example 63- ⁇ . Although spread in the vertical direction of the character, the landing position of the ink particles 24 is the same place as the ink particle flight example 62 of the normal print 47.

- FIG. 8 is an example of ink particle flight in normal printing and abnormal printing in this embodiment when the nozzles are arranged in a horizontal direction with twin nozzles.

- FIG. 8A shows an ink particle flight example 64 for normal printing 51 when both nozzle ⁇ and nozzle ⁇ operate normally

- FIG. 8B shows printing 54 when nozzle ⁇ is abnormal.

- the ink particle flight example 65- ⁇ is shown for - ⁇

- FIG. 8C shows the ink particle flight example 65- ⁇ for the print 54- ⁇ when the nozzle ⁇ is abnormal.

- the ink particle flight example shows the direction of the transport line.

- the ink particle flight example 64 normally flies in accordance with the printing content. Further, when the nozzle ⁇ is abnormal, as shown in FIG. 8B, printing is performed only with the nozzle ⁇ , so the range in which the nozzle ⁇ prints compared to the normal printing 51 as in the ink particle flying example 65- ⁇ . Although spreading in the transport line direction, the landing position of the ink particles is the same place as the ink particle flight example 64 of the normal print 51.

- the ink particle landing position is the same location as the ink particle flight example 64 of the normal print 51.

- the printing position may move depending on the position of the normal nozzles, and it is necessary to change the printing control.

- the relief control process f2 for solving this will be described below.

- FIG. 9 shows the relief executed when the item 56 “Relief Control at Nozzle Abnormality” shown in FIG. 6A is “Yes” when the nozzle control flowchart shown in FIG. It is a flowchart f2 of a control process.

- FIG. 9 first, at branch 66, it is checked whether the abnormal nozzle is nozzle ⁇ or nozzle ⁇ .

- the nozzle ⁇ When the nozzle ⁇ is abnormal, it is set in the “relief control mode” in which the inkjet recording apparatus performs the relief control in the process r1, and the outside is notified in the process r2 that it is in the relief control mode.

- the notification means is a screen display on the display 18 or a communication / signal on the connection device 33.

- printing is performed using the print parameter N in a process 68, and printing is continued in a process 69.

- the printing of the nozzle ⁇ is interrupted in a process 70, and a message is displayed on the display 18 that the nozzle ⁇ is in an abnormal state in a process 71.

- guidance for prompting the change of the print head position is displayed.

- This guidance is a display for allowing the customer to select whether or not to change the print head position. As described with reference to FIG. 7, this is a countermeasure for a case where the print position moves.

- a relief is performed in which print control is performed using only normal nozzles when an abnormality occurs. Control becomes possible.

- process 74 the print head position is physically moved, the guidance is deleted in process 75, and the process shifts to a printable state in process 76. Thereafter, after the processes r1 and r2 described above are performed, only the nozzle ⁇ is controlled in process 77, printing using the print parameter N is performed in process 68, and printing is continued in process 69.

- the relief control for performing the print control with only normal nozzles when an abnormality occurs cannot be performed. Therefore, the guidance display is minimized in process 78 and the process is terminated. At this time, the “relief control mode” is not executed in spite of the nozzle abnormality, and the normal printing control is performed. If it is desired to set the “relief control mode” in this state, it is possible to change to the “relief control mode” by maximizing the guidance display again and then changing the print head position in step 73.

- FIG. 10 is a processing flowchart when the nozzle abnormality is canceled by the relief control in which the printing control is performed only with the normal nozzle when the abnormality occurs. It is determined whether or not the abnormality has been canceled at branch 79, and if it is canceled, it is checked at branch 80 whether printing has been performed in the repair control mode. If it is in the relief control mode, the nozzle that has been abnormally released is checked at branch 81.

- the notification means is a screen display on the display 18 or a communication / signal on the connection device 33.

- the print parameters L (L1, L2) and M (M1, M2) which are the print ranges of the nozzles ⁇ and ⁇ , respectively.

- step 84 printing is continued.

- a guidance for prompting a change of the print head position is displayed in processing 85.

- This guidance is a display for allowing the customer to select whether or not to change the print head position.

- the print head position is changed at the branch 86, the normal print control can be returned. At this time, the print head position is changed in process 87, and the guidance is erased in process 88. Thereafter, the process proceeds to the processes n1 and n2.

- the guidance display is minimized in process 89 and the process is terminated. In this case, even if the nozzle abnormality is canceled, the operation is performed in the “relief control mode” instead of the normal print control. If normal print control is desired in this state, the guidance display can be maximized again and then the print head position can be changed at branch 86 to change to normal print control.

- FIG. 11A shows the printing range of the nozzle ⁇ in the normal printing 47 when the nozzles ⁇ and ⁇ are both normal and the abnormal printing 50 when the nozzle ⁇ is abnormal in the present embodiment.

- FIG. 11B is a table showing the number of ink particles flying from the nozzle ⁇ necessary for printing one vertical line 90 in the printing range of FIG.

- the number of ink flights when printing one vertical line 90 varies depending on the value of the ink particle usage rate 45 in the printing parameters.

- the ink particle usage rate 45 is a parameter for designating a ratio of thinning out ink particles actually used for printing out of the ink particles output from the nozzle, and the number of ink particles used for printing is output from the nozzle.

- 1 / N is designated and used.

- the ink particle usage rate 45 varies depending on the print quality and the conveyance line speed. In general, increasing the thinning ratio can suppress the influence between inks, so that it is possible to improve the printing quality, but it is difficult to cope with an increase in the conveyance line speed. .

- the number of ink particles used for printing in the normal printing 47 and the abnormal printing 50 when the ink particle usage rate 45 is the same will be described.

- the ink particle usage rate 45 is 1/1

- the number 92 of ink particles used for printing in the normal time printing 47 is 8

- the number 93 of ink particles used for printing in the abnormal time printing 50 is 16.

- the ink particle usage rate 45 is 1/2

- the number 94 of ink particles used for printing in the normal printing 47 is 16

- the number 95 of ink particles used for printing in the abnormal printing 50 is 32. . Since the ink particles are output from the nozzles at a constant speed, the number of ink particles used for printing is equal to the time required for printing one vertical line 90.

- correction processing methods There are two types of correction processing methods. One is a method in which the conveyance line speed is also slowed at the time of abnormal printing 50. This correction process has an advantage that printing can be performed without changing the printing parameters internally. In this case, it is necessary to notify the outside whether or not it is in the relief control mode, and this can be realized by the process r2 in the flowchart f2 in FIG. 9 or the process n2 in the flowchart in FIG.

- the other is a method in which the ink particle usage rate 45 that can be set is limited in advance, and when printing 50 is performed in an abnormal state, the ink particle usage rate 45 is corrected to perform printing. Specifically, when the ink particle usage rate 45 of the nozzles ⁇ and ⁇ is set to 1 / N, N is set in advance as an equal value with an even value. When normal printing 47 is performed in this state, the nozzles ⁇ and ⁇ print with the ink particle usage rate 45 set. In addition, when the abnormal printing 50 is performed in the relief control mode, the number of ink particles used for printing by a normal nozzle is doubled. Therefore, a value twice the set ink particle usage rate 45 (that is, N is halved).

- N is set in advance as an even value is that it is easier to handle a divisible value because it must be halved in the relief control mode, and the reason for setting the same value is that each nozzle print control is easy. It is to make it.

- the ink particle usage rate of the nozzles ⁇ and ⁇ is 1/1. First, it is set as 1/2, and the number of ink particles 96 at this time is 16. After that, when the abnormal printing 50 is obtained in the relief control mode, the ink particle usage rate is doubled, so the ink particle usage rate is doubled to a value set to 1/1. Correction is made, and the number of ink particles 97 at this time is also 16. This correction process has the advantage that it is not necessary to change the transport line speed.

- the print quality in normal printing and abnormal printing is made the same by correcting a predetermined ink particle usage rate. There is an effect that can be done.

- the print range of the normal nozzle can be minimized.

- the present invention is not limited to the above-described embodiments, and includes various modifications.

- the above-described embodiment has been described in detail for easy understanding of the present invention.

- the arrangement of the twin nozzles has been described for the vertical and horizontal cases.

- the diagonal direction is considered to be a combination of the vertical and horizontal arrangements, by using the vertical and horizontal controls simultaneously or in combination in the above-described embodiment, the same applies. Can solve the problem.

- Inkjet recording apparatus 21 Print head 22a: Nozzle ⁇ with twin nozzles 22b: Nozzle ⁇ with twin nozzle 37: Print range (parameter N1) 41: Print range (parameter N2) 42: Print parameter 56: Item “Relief control when nozzle is abnormal” f2: Relief control flowchart

Landscapes

- Engineering & Computer Science (AREA)

- Quality & Reliability (AREA)

- Ink Jet (AREA)

- Particle Formation And Scattering Control In Inkjet Printers (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201480034834.2A CN105339174B (zh) | 2013-07-03 | 2014-06-10 | 喷墨记录装置 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013-139817 | 2013-07-03 | ||

| JP2013139817A JP6114125B2 (ja) | 2013-07-03 | 2013-07-03 | インクジェット記録装置 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2015001919A1 true WO2015001919A1 (ja) | 2015-01-08 |

Family

ID=52143503

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2014/065283 WO2015001919A1 (ja) | 2013-07-03 | 2014-06-10 | インクジェット記録装置 |

Country Status (3)

| Country | Link |

|---|---|

| JP (1) | JP6114125B2 (ko) |

| CN (1) | CN105339174B (ko) |

| WO (1) | WO2015001919A1 (ko) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105584218A (zh) * | 2016-02-01 | 2016-05-18 | 厦门英杰华机电科技有限公司 | 平行双嘴cij喷码系统 |

Families Citing this family (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6338861B2 (ja) | 2014-01-08 | 2018-06-06 | 株式会社日立産機システム | インクジェット記録装置 |

| EP3501831B1 (en) * | 2016-08-22 | 2022-08-17 | Hitachi Industrial Equipment Systems Co., Ltd. | Inkjet recording device and inkjet recording device control method |

| US11027540B2 (en) | 2017-04-05 | 2021-06-08 | Hitachi Industrial Equipment Systems Co., Ltd. | Inkjet recording device |

| JP7112257B2 (ja) * | 2018-06-11 | 2022-08-03 | 株式会社日立産機システム | インクジェット記録装置管理システムおよびインクジェット記録装置 |

| JP7124524B2 (ja) | 2018-07-31 | 2022-08-24 | 住友ゴム工業株式会社 | ゴルフボール |

| CN111000357B (zh) * | 2018-10-04 | 2023-01-03 | 卡西欧计算机株式会社 | 美甲打印装置、美甲打印方法及记录介质 |

| WO2024201551A1 (ja) * | 2023-03-24 | 2024-10-03 | 株式会社日立産機システム | インクジェットプリンタシステム及びインクジェットプリンタ異常予兆検知方法 |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH08238760A (ja) * | 1995-03-03 | 1996-09-17 | Hitachi Ltd | インクジェット記録装置 |

| JP2009018453A (ja) * | 2007-07-10 | 2009-01-29 | Seiko Epson Corp | 液体吐出装置、液体吐出装置の制御方法および液体吐出装置の制御プログラム |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4629465B2 (ja) * | 2005-03-11 | 2011-02-09 | 株式会社日立産機システム | インクジェット記録装置 |

| JP5364360B2 (ja) * | 2008-12-15 | 2013-12-11 | 株式会社日立産機システム | インクジェット記録装置 |

| US8807714B2 (en) * | 2009-06-24 | 2014-08-19 | Hitachi Industrial Equipment Systems Co., Ltd. | Ink-jet recording apparatus |

| JP5475578B2 (ja) * | 2010-07-12 | 2014-04-16 | 株式会社日立産機システム | インクジェット記録装置およびその制御方法 |

| JP5759830B2 (ja) * | 2011-08-19 | 2015-08-05 | 株式会社日立産機システム | インクジェット記録装置 |

-

2013

- 2013-07-03 JP JP2013139817A patent/JP6114125B2/ja active Active

-

2014

- 2014-06-10 CN CN201480034834.2A patent/CN105339174B/zh active Active

- 2014-06-10 WO PCT/JP2014/065283 patent/WO2015001919A1/ja active Application Filing

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH08238760A (ja) * | 1995-03-03 | 1996-09-17 | Hitachi Ltd | インクジェット記録装置 |

| JP2009018453A (ja) * | 2007-07-10 | 2009-01-29 | Seiko Epson Corp | 液体吐出装置、液体吐出装置の制御方法および液体吐出装置の制御プログラム |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105584218A (zh) * | 2016-02-01 | 2016-05-18 | 厦门英杰华机电科技有限公司 | 平行双嘴cij喷码系统 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN105339174B (zh) | 2017-11-24 |

| JP6114125B2 (ja) | 2017-04-12 |

| CN105339174A (zh) | 2016-02-17 |

| JP2015013385A (ja) | 2015-01-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6114125B2 (ja) | インクジェット記録装置 | |

| EP2789468B1 (en) | Image recording apparatus, control method thereof, and program | |

| US20140313255A1 (en) | Image recording apparatus, control method thereof, and recording medium | |

| JP2017177423A (ja) | 液滴吐出装置、液滴吐出装置の管理システム、液滴吐出装置のメンテナンス方法 | |

| US9969168B2 (en) | Recording apparatus, recording system, and maintenance method for recording apparatus | |

| JP2015013385A5 (ko) | ||

| JP5743802B2 (ja) | インクジェット記録装置 | |

| JP6053244B2 (ja) | プリントヘッドの検査方法、プリント方法、プリントヘッドの検査装置及びプリンタ | |

| JP2011255594A (ja) | 液体噴射装置、及び、液体噴射方法 | |

| US9636911B2 (en) | Inkjet recording device | |

| JP2015157426A (ja) | プリンター、プリンターの印刷制御方法および印刷制御装置 | |

| WO2013027475A1 (ja) | インクジェット記録装置 | |

| EP3045316B1 (en) | Recording apparatus and recording method | |

| JP2014200971A (ja) | インクジェット印刷方法およびインクジェットプリンター | |

| JP2013173314A (ja) | インクジェット記録装置及び方法並びに衛生用品の製造方法 | |

| US9517634B2 (en) | Printing control apparatus and printing control method | |

| WO2015186499A1 (ja) | 画像形成装置及び画像形成方法 | |

| JP2016002650A (ja) | 画像形成装置、方法およびプログラム | |

| JP2021084392A (ja) | 液体吐出装置、および液体吐出装置における吐出制御方法 | |

| WO2022097491A1 (ja) | 印刷装置および印刷方法 | |

| JP4200582B2 (ja) | インクジェットプリンタ | |

| JP2015033821A (ja) | インクジェット記録装置 | |

| JP2014188784A (ja) | プリンターの印刷方法およびプリンター | |

| JP5736757B2 (ja) | 印刷装置、及び、印刷方法 | |

| US20210197564A1 (en) | Printing method and printing apparatus |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 201480034834.2 Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 14820391 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 14820391 Country of ref document: EP Kind code of ref document: A1 |