WO2014204018A2 - 吸収性物品の個包装体 - Google Patents

吸収性物品の個包装体 Download PDFInfo

- Publication number

- WO2014204018A2 WO2014204018A2 PCT/JP2014/072019 JP2014072019W WO2014204018A2 WO 2014204018 A2 WO2014204018 A2 WO 2014204018A2 JP 2014072019 W JP2014072019 W JP 2014072019W WO 2014204018 A2 WO2014204018 A2 WO 2014204018A2

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- absorbent article

- underwear

- sheet

- region

- release sheet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/15577—Apparatus or processes for manufacturing

- A61F13/15707—Mechanical treatment, e.g. notching, twisting, compressing, shaping

- A61F13/15747—Folding; Pleating; Coiling; Stacking; Packaging

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/551—Packaging before or after use

- A61F13/5513—Packaging before or after use packaging of feminine sanitary napkins

- A61F13/55135—Packaging before or after use packaging of feminine sanitary napkins before use

- A61F13/5514—Packaging before or after use packaging of feminine sanitary napkins before use each item packaged single

Definitions

- the present invention relates to an individual package of an absorbent article that is used by being attached to a crotch part of an underwear such as a sanitary napkin.

- Absorbent articles used by attaching to the crotch of underwear such as sanitary napkins are provided with an underwear fixing adhesive part on the underwear contact surface for fixing to the underwear, and the underwear fixing adhesive part is a release sheet Covered with.

- the absorbent article is usually individually packaged with a packaging sheet so as to be convenient for carrying.

- the release sheet is extended to the take-out side from the adhesive fixing part for underwear, and the release sheet is made into a packaging sheet at the extended portion. Joining is performed (patent document 1).

- the pressure-sensitive adhesive portion for fixing the underwear of the absorbent article is applied to the underwear contact surface of the absorbent article after the pressure-sensitive adhesive has been applied to the surface of the release sheet that has been subjected to the peeling process.

- the transferred intermediate product is transported in a state where the release sheet is not fixed with an adhesive in the production process because the release sheet extends to the outlet side from the underwear fixing adhesive portion. Therefore, the problem of turning over during the conveyance occurs.

- This invention provides the individual package of the absorbent article which solved the problem of such turning.

- the absorbent article used by being attached to the crotch portion of the underwear is packaged by the packaging sheet,

- the absorbent article has an underwear-fixing adhesive portion on the underwear contact surface,

- the adhesive part for fixing underwear is covered with a release sheet,

- the release sheet is joined to the packaging sheet by the joint,

- the release sheet can be peeled from the absorbent article together with the packaging sheet by pinching the front end of the packaging sheet and the front end of the absorbent article and pulling in the opposite direction.

- the release sheet has a width direction center region, a right side region, and a left side region

- the joint is disposed in the central region in the width direction of the release sheet

- the underwear fixing adhesive portion is disposed in each region of the underwear contact surface of the absorbent article corresponding to each of the width direction central region, the right side region, and the left side region of the release sheet

- the front end of the underwear fixing adhesive portion arranged in the region of the underwear contact surface of the absorbent article corresponding to the widthwise central region is located behind the front end of the joint portion, Is at least a part of the front end of the underwear fixing adhesive portion disposed in each region of the underwear contact surface of the absorbent article corresponding to the right side region and the left side region positioned forward of the front end of the joint portion? Or it is in the position of the front-back direction substantially the same as the front end of a junction part.

- At least a part of the front end of the adhesive portion for fixing the undergarment disposed in each region of the underwear contact surface of the absorbent article corresponding to the right side region and the left side region is Since it is located in front of the front end of the joint part or is substantially in the same front-rear direction position as the front end of the joint part, it is possible to suppress the occurrence of a problem that the front side of the release sheet is turned in the middle of conveyance in the production process. .

- FIG. 1 is a perspective view of an individual package of absorbent articles.

- FIG. 2 is a cross-sectional view taken along the line II ′ of FIG.

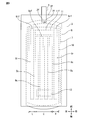

- FIG. 3 is a view of a developed individual package as viewed from the packaging sheet side.

- FIG. 4 shows one example of arrangement of the undergarment fixing adhesive portion.

- FIG. 5 is one example of the arrangement of the undergarment fixing adhesive portion.

- FIG. 6 is one example of the arrangement of the undergarment fixing adhesive portion.

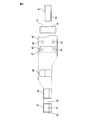

- FIG. 7 is a diagram illustrating a process up to a packaging process among manufacturing processes of an individual package.

- FIG. 8 is a diagram illustrating a packaging process in the manufacturing process of the individual package.

- FIG. 1 is a perspective view of an individual package of absorbent articles.

- the individual package 1 is obtained by packaging an absorbent article 2 with a packaging sheet 3. Both sides of the individual package 1 are sealed to form side seal portions 4, and the opening of the individual package 1 is fastened with a lead tape 5.

- the absorbent article according to the present invention is an absorbent article used by being attached to a crotch portion of underwear such as a sanitary napkin, a panty liner, an incontinence pad.

- FIG. 2 is a cross-sectional view (schematic diagram) taken along the line II ′ of FIG.

- the absorbent article 2 includes a top sheet 6, an absorber 7 and a back sheet 8.

- the absorber 7 is disposed between the top sheet 6 and the back sheet 8.

- An underwear-fixing adhesive portion 9 is provided on the underwear contact surface S of the absorbent article 2, that is, the back sheet 8 surface, and the release sheet 10 covers it.

- the absorbent article 2 comprising the top sheet 6, the absorbent body 7, the back sheet 8, the underwear fixing adhesive portion 9 and the release sheet 10 is folded and wrapped by the packaging sheet 3, and the open end of the packaging sheet 3 is the lead tape. It is fixed at 5.

- FIG. 1 In the embodiment of FIG.

- the absorbent article 2 is tri-folded, but may be folded into four or more folds such as four folds and five folds.

- the release sheet 10 is joined to the packaging sheet 3 by a joining portion 11 formed of an adhesive or the like.

- the second joint 12 is provided in addition to the joint 11, but the second joint 12 is not essential.

- the absorbent article 2 used by being attached to the crotch portion of the underwear is packaged by the packaging sheet 3, and the absorbent article 2 is fixed to the underwear contact surface S with the underwear.

- the adhesive part 9 for fixing underwear is covered with a release sheet 10, and the release sheet 10 is joined to the packaging sheet 3 by the joining part 11.

- the front end of the packaging sheet The release sheet 10 can be peeled from the absorbent article 2 together with the packaging sheet 3 by pinching the part 3f and the front end 2f of the absorbent article and pulling them in the opposite direction.

- front is defined as “front” when the packaging sheet is peeled off from the absorbent article, regardless of whether the absorbent article is attached or not, and is peeled off afterwards. Is defined as “after”. That is, when the absorbent article is taken out from the individual package, the release sheet is peeled off from the absorbent article together with the packaging sheet by pinching one end of the packaging sheet and one end of the absorbent article and pulling them in the opposite direction. In this case, one end of the packaging sheet and one end of the absorbent article, which are pinched by hand, are the front end of the packaging sheet and the front end of the absorbent article, respectively.

- FIG. 3 is a view of a developed individual package as viewed from the packaging sheet side.

- the release sheet 10 has a center region C in the width direction, a right side region R, and a left side region L.

- the joining part 11 is arrange

- the underwear fixing adhesive portion 9 is disposed in each region of the underwear contact surface of the absorbent article corresponding to each of the width direction central region C, the right side region R, and the left side region L of the release sheet.

- the front end 9cf of the underwear fixing adhesive portion 9c arranged in the region of the underwear contact surface of the absorbent article corresponding to the width direction central region C is located behind the front end 11f of the joint portion 11.

- the front ends 9rf and 9lf of the underwear fixing adhesive portions 9r and 9l arranged in the respective regions of the underwear contact surface of the absorbent article corresponding to the right side region R and the left side region L are more than the front end 11f of the joint portion 11. Located in front. In the embodiment of FIG. 3, the second joint 12 is provided, but this is not essential.

- the center region C in the width direction of the release sheet is a straight line parallel to the length direction of the absorbent article passing through the right end of the joint portion 11 and parallel to the length direction of the absorbent article passing through the left end of the joint portion 11.

- the right side region R of the release sheet refers to a release sheet region sandwiched between a straight line parallel to the length direction of the absorbent article that passes through the right end of the joint portion 11 and the right side of the release sheet.

- the left side area L of the release sheet refers to an area of the release sheet sandwiched between a straight line parallel to the length direction of the absorbent article passing through the left end of the joint portion 11 and the left side of the release sheet.

- the front end 9cf of the underwear fixing adhesive portion 9c disposed in the region of the underwear contact surface of the absorbent article corresponding to the width direction central region C is located rearward of the front end 11f of the joint portion 11,

- the front end portion 13 of the packaging sheet and the front end portion 14 of the absorbent article are pinched and pulled in the opposite direction, so that the release sheet 10 together with the packaging sheet 3 is used as the absorbent article. 2 can be easily peeled off.

- the joint portion 11 and the underwear fixing adhesive portion 9 c disposed in the region of the underwear contact surface of the absorbent article corresponding to the widthwise central region C have no overlapping portions, but the width As long as the requirement that the front end 9cf of the underwear fixing adhesive portion 9c arranged in the region of the underwear contact surface of the absorbent article corresponding to the direction center region C is located behind the front end 11f of the joint portion 11 is satisfied.

- a part of the bonding part 11 and a part of the adhesive part 9c for fixing the undergarment disposed in the region of the underwear contact surface of the absorbent article corresponding to the central region C in the width direction may overlap (see FIG. 5). .

- the front ends 9rf and 9lf of the underwear fixing adhesive portions 9r and 9l arranged in the respective regions of the underwear contact surface of the absorbent article corresponding to the right side region R and the left side region L are joined. Although it is located in front of the front end 11 f of the part 11, it is not necessarily located in front of the front end 11 f of the joint part 11, and even if it is in substantially the same front-rear direction position as the front end 11 f of the joint part 11. Good (see FIG. 4).

- all of the front ends 9rf and 9lf of the underwear fixing adhesive portions 9r and 9l arranged in the regions of the underwear contact surface of the absorbent article corresponding to the right side region R and the left side region L It is not necessary to be located in front of the front end 11f or in the front-rear direction position substantially the same as the front end of the joint, and each region of the underwear contact surface of the absorbent article corresponding to the right side region R and the left side region L

- At least a part of the front ends 9rf, 9lf of the undergarment fixing adhesive portions 9r, 9l arranged at the front is located in front of the front end 11f of the joint portion 11 or at substantially the same longitudinal position as the front end of the joint portion.

- the part is located in front of the front end 11f of the joint part 11, or is substantially at the same longitudinal position as the front end of the joint part.

- At least a part of the front ends 9rf, 9lf of the underwear fixing adhesive portions 9r, 9l arranged in the respective regions of the underwear contact surface of the absorbent article corresponding to the right side region R and the left side region L is the front end of the joint portion 11. Since a part of the adhesive portion for fixing the undergarment exists up to the vicinity of the front end of the release sheet by being located in front of 11f or substantially in the same longitudinal direction as the front end of the joint, Occurrence of the problem that the front side turns during the conveyance can be suppressed.

- the joining portion 11 is provided at the center in the width direction, and a part of the adhesive for fixing the underwear is wider than the joining portion 11 Since it has arrange

- the individual packaging body of the present invention removes the packaging sheet and the release sheet, a force is applied to the joint portion 11, and the force propagates in the width direction so that the adhesive portions on the left and right outer sides of the joint portion 11 are peeled off. By applying a force in the front-rear direction, the adhesive portion behind the joint portion 11 is exposed.

- the absorbent article on the outer side in the width direction is more likely to be twisted due to external pressure, but is difficult to twist because the adhesive portions on both outer sides are formed long.

- the absorbent article is peeled from the underwear after use, since the peeling starting points are dispersed in the longitudinal direction, damage to the back sheet can be reduced and the back sheet is not easily torn.

- the underwear fixing adhesive portions 9r and 9l are disposed as close to the front end of the release sheet as possible, but the underwear fixing adhesive completely to the front end of the release sheet. If it is going to arrange

- an adhesive is attached to the cutter when cutting, and the cutting performance of the cutter is lowered.

- the part is generally located 5 to 10 mm behind the front end of the release sheet 10.

- the front end of the junction part 11 is the front end of the peeling sheet 10. It is generally located 5 to 10 mm behind.

- the size of the joint portion 11 is not particularly limited, but the longitudinal dimension of the joint portion 11 is preferably 5 to 40 mm, more preferably 10 to 30 mm, and still more preferably 15 to 25 mm.

- the lateral dimension of the joint portion 11 is preferably 20 to 80% of the lateral dimension of the release sheet, more preferably 30 to 70% of the lateral dimension of the release sheet, and still more preferably the lateral dimension of the release sheet. 40-60% of the dimensions.

- the dimension in the left-right direction of the release sheet is 60 mm

- the dimension in the left-right direction of the joint portion 11 is preferably 12 to 48 mm, more preferably 18 to 42 mm, and still more preferably 24 to 36 mm.

- the shape of the junction part 11 is not specifically limited, Preferably it is a rectangle.

- the joints 11 are not necessarily arranged symmetrically, but are preferably arranged symmetrically.

- the adhesiveness of the adhesive parts 9r, 9l for fixing the underwear disposed in the respective areas of the underwear contact surface of the absorbent article corresponding to the right side region R and the left side region L is the center region in the width direction.

- the adhesiveness of the underwear fixing adhesive portion 9c disposed in the region of the underwear contact surface of the absorbent article corresponding to C it may be weak, strong, or the same,

- the former tackiness is preferably weaker than the latter tackiness.

- the present invention is characterized by the arrangement of the undergarment fixing adhesive portion 9, but in addition to the embodiment shown in FIG. 3, other embodiments of the arrangement of the undergarment fixing adhesive portion 9 are shown in FIGS. 4 to 6 are views in which the individual package is unfolded as seen from the release sheet side, as in FIG. 3, but in order to make the drawings easier to understand, in FIGS. It is omitted.

- the underwear fixing adhesive portion 9 c arranged in the region of the underwear contact surface of the absorbent article corresponding to the center region C in the width direction is composed of one adhesive portion, and the right side region R and the left side region L

- the front end 9rf, 9lf of the underwear fixing adhesive portions 9r, 9l arranged in each region of the underwear contact surface of the corresponding absorbent article is in the same front-rear direction position as the front end 11f of the joint portion 11.

- the undergarment fixing adhesive portion 9 c arranged in the region of the underwear contact surface of the absorbent article corresponding to the center region C in the width direction is divided into a plurality of parts. Need not be divided as shown in FIG. In the embodiment of FIG.

- the adhesiveness of the underwear-fixing adhesive portions 9 r and 9 l arranged in the respective regions of the underwear contact surface of the absorbent article corresponding to the right side region R and the left side region L is determined in the width direction central region. It may be weaker than the adhesiveness of the underwear fixing adhesive portion 9c disposed in the region of the underwear contact surface of the absorbent article corresponding to C.

- FIG. 5 shows an underwear for an absorbent article corresponding to an underwear fixing adhesive portion 9c, a right side region R, and a left side region L arranged in the region of the underwear contact surface of the absorbent product corresponding to the center region C in the width direction.

- the underwear-fixing adhesive portions 9r and 9l arranged in each region of the contact surface are continuous, and a region of the underwear contact surface of the absorbent article corresponding to a part of the joint portion 11 and the central region C in the width direction.

- a mode in which a part of the disposed underwear fixing adhesive portion 9c overlaps is shown.

- the undergarment-fixing adhesive portion 9 has an undergarment-fixing adhesive portion 9c, a right-side region R, and a left-side region L arranged in the region of the underwear contact surface of the absorbent article corresponding to the center region C in the width direction.

- the front end 9cf of the underwear fixing adhesive portion disposed in the region of the underwear contact surface of the absorbent article corresponding to the central region in the width direction only needs to be positioned behind the front end 11f of the joint portion.

- a part of the joint part 11 and a part of the underwear fixing adhesive part 9c arranged in the region of the underwear contact surface of the absorbent article corresponding to the center region C in the width direction may overlap. .

- FIG. 6 shows that the underwear fixing adhesive portions 9r and 9l arranged in the respective regions of the underwear contact surface of the absorbent article corresponding to the right side region R and the left side region L are divided in the front-rear direction and near the center in the left-right direction. Shows an embodiment in which there is no undergarment fixing adhesive part.

- the undergarment fixing adhesive portion 9 may be divided into a plurality of parts in the front-rear direction. Moreover, the underwear-fixing adhesive portion 9 may be disposed not only near the center in the left-right direction but exclusively near the left-right side portion.

- the adhesiveness of the underwear fixing adhesive portions 9 r and 9 l arranged on the left and right outer sides of the joint portion 11 is compared with the adhesiveness of the underwear fixing adhesive portion 9 disposed behind the joint portion 11. It may be weakened.

- the absorbent article 2 includes a top sheet 6, a back sheet 8, and an absorbent body 7 disposed between the top sheet and the back sheet, but underwearing of the absorbent article corresponding to the right side area and the left side area. It is preferable that the front ends 9rf and 9lf of the undergarment fixing adhesive portions 9r and 9l arranged in the respective areas of the contact surface are located behind the front end 7f of the absorbent body 7.

- the place where the absorber is arranged is higher in bending rigidity (compared to the front end and rear end portion of the front sheet and the back sheet only) in the main body of the absorbent article, so that the adhesive part is peeled off from the absorbent article.

- Cheap In other words, if the bending rigidity of the absorbent article main body is soft, when the packaging sheet and the release sheet are pulled to peel off, the absorbent article main body is also pulled at the same time (following) and is difficult to peel off.

- the top sheet constituting the absorbent article has a function of allowing liquid excretion from the body, such as menstrual blood, urine, etc., to pass through the absorber provided in the lower layer, and between the liquid-impermeable back sheet. This is for holding the absorber by sandwiching the absorber.

- All or part of the surface sheet is liquid-permeable, and the liquid-permeable region has a liquid-permeable nonwoven fabric or woven fabric, a resin film having a large number of liquid-permeable holes, and a net-like sheet having a large number of meshes. Etc. are formed.

- the resin film and the net-like sheet those formed of polypropylene (PP), polyethylene (PE), polyethylene terephthalate (PET) or the like can be used.

- PP polypropylene

- PE polyethylene

- PET polyethylene terephthalate

- the spunlace nonwoven fabric formed from cellulose fibers, such as rayon, a synthetic resin fiber, etc., the air through nonwoven fabric formed from the said synthetic resin fiber, etc. can be used.

- natural products capable of biodegradability such as polylactic acid, chitosan, polyalginic acid and the like can be used.

- a large number of liquid-permeable holes may be formed, and a silicone-based or fluorine-based water-repellent oil agent may be applied to make it difficult for body fluids to adhere to the outer surface.

- the back sheet constituting the absorbent article has a function of preventing liquids such as menstrual blood and urine absorbed by the absorber from leaking out, and such liquid leaks out.

- Materials that can be prevented are used.

- a material that does not allow liquid to pass through but is breathable it is possible to reduce stuffiness during wearing and to reduce discomfort during wearing.

- Examples of such a material include a liquid-impermeable film mainly composed of polyethylene (PE), polypropylene (PP), etc., a breathable film, and a composite in which a liquid-impermeable film is laminated on one side of a nonwoven fabric such as spunbond. A sheet etc. are mentioned.

- a hydrophobic nonwoven fabric a water-impermeable plastic film, a laminate sheet of a nonwoven fabric and a water-impermeable plastic film, or the like can be used.

- an SMS nonwoven fabric in which a melt-blown nonwoven fabric having high water resistance is sandwiched between strong spunbond nonwoven fabrics may be used.

- the absorbent body constituting the absorbent article has a function of absorbing and retaining liquids such as menstrual blood and urine, and is preferably bulky, hardly deformed, and has little chemical irritation.

- the absorber which consists of fluffy pulp or an airlaid nonwoven fabric and a superabsorbent polymer can be illustrated.

- artificial cellulose fibers such as chemical pulp, cellulose fiber, rayon, and acetate can be exemplified.

- Pulp is 500 g / m 2

- polymer is 20 g / m 2 (polymer is dispersed throughout), and a mixture of pulp and polymer uniformly distributed is wrapped in tissue with a weight of 15 g / m 2 Can be mentioned.

- a superabsorbent polymer has a three-dimensional network structure in which water-soluble polymers are appropriately cross-linked. It absorbs water several tens to thousand times but is essentially insoluble in water. The water that does not release even when a certain pressure is applied can be exemplified by starch-based, acrylic acid-based, and amino acid-based particulate or fibrous polymers.

- shape and structure of the absorbent body can be changed as necessary, the total amount of absorbent body absorbed needs to correspond to the design insertion amount as the absorbent article and the desired application. Further, the size and absorption capacity of the absorber are varied according to the application.

- a so-called pressure-sensitive adhesive can be used as the pressure-sensitive adhesive that constitutes the undergarment fixing pressure-sensitive adhesive part.

- a pressure-sensitive adhesive can be adhered to other surfaces with extremely weak pressure such as light finger pressure without the need for water, solvent or heat, and can be easily peeled off. It is an adhesive that can be attached.

- Specific examples of the pressure-sensitive adhesive include those made of tackifier, oil, and base polymer. Examples of tackifiers include rosin-based, terpene-based, terpene-phenol-based, phenol-based, chromanindene-based resins, and petroleum resins. Examples of the oil include paraffin oil and naphthen oil.

- the base polymer examples include styrene-ethylene / butylene-styrene block copolymer (SEBS), styrene-butadiene-styrene block copolymer (SBS), and styrene-isoprene-styrene block copolymer (SIS).

- SEBS styrene-ethylene / butylene-styrene block copolymer

- SBS styrene-butadiene-styrene block copolymer

- SIS styrene-isoprene-styrene block copolymer

- Tackiness can be controlled by the mixing ratio of tackifier, oil and base polymer. Specifically, by increasing the compounding ratio of tackifier, the hardness can be increased and the tackiness can be suppressed.

- the adhesiveness of the adhesive part for fixing underwear can be changed by the basis weight of the adhesive. In general, increasing the

- the adhesive constituting the joint is not particularly limited as long as it can adhere more firmly than the underwear-fixing adhesive part.

- a thermoplastic resin adhesive, a thermosetting resin adhesive, and a synthetic rubber A system adhesive or the like can be used.

- the adhesive that forms the joint has a stronger adhesive force than the adhesive that makes up the underwear-fixing adhesive part, but unlike the adhesive that makes up the underwear-fixing adhesive part, once peeled off, it is difficult to re-apply Is used.

- the release sheet is a sheet used to cover and protect the underwear fixing adhesive portion, and at least one surface of the release sheet has a property that it can be easily peeled off even after being attached to the underwear fixing adhesive portion.

- Specific examples of the release sheet include those obtained by applying a solvent type, solventless type, or emulsion type silicone resin to a base sheet such as paper or a plastic sheet.

- the packaging sheet is not particularly limited as long as the absorbent article can be packaged, and examples thereof include a nonwoven fabric, a woven fabric, paper, and a plastic film. Among these, a nonwoven fabric is preferably used.

- the absorbent article according to the present invention is not particularly limited as long as it is used by being attached to the crotch portion of the undergarment, and examples thereof include sanitary napkins, panty liners, and incontinence pads.

- the absorbent article shown in drawing is a thing without a wing

- the absorbent article which concerns on this invention may have a wing and may have a hip flap.

- the absorbent article which concerns on this invention may have a side sheet

- Drawing 7 is a figure showing a process until the packaging process among the manufacturing processes of the individual packing object of the present invention.

- the tissue is unwound from the tissue roll 21, and the pulp pulverized on the tissue by the pattern drum 22 and the superabsorbent polymer are laminated, and wrapped by the tissue in the sailor 23 to form an absorbent body.

- the absorber is formed to a predetermined thickness by the absorber embossing roll 24 and is cut into a predetermined size and shape by the absorber cutter 25.

- the surface sheet is unwound from the surface sheet roll 26, the surface sheet is coated with the hot melt adhesive by the coater 27, and the surface sheet coated with the hot melt adhesive is joined to the main line and absorbed. Bonded with the body.

- a compression groove having a predetermined shape is formed on the top sheet side by the hinge seal 28.

- the back sheet is unwound from the back sheet roll 29, the hot sheet adhesive is applied to the back sheet by the coater 30, and the back sheet coated with the hot melt adhesive is joined to the main line and absorbed. Affixed to the back side of the body.

- the laminate of the top sheet, the absorbent body, and the back sheet is embossed so as to reinforce the outer edge of the absorbent article with the end seal 31.

- the release sheet is unwound from the release sheet raw roll 32, and the adhesive for forming the adhesive part for fixing the underwear is applied in a predetermined pattern on the surface of the release sheet that has been peeled off by the coater 33.

- the release sheet coated with the pressure-sensitive adhesive is cut into a predetermined length by the cutter 34, and then joined to the main line and bonded to the back sheet side of the laminate. At this time, the adhesive is transferred to the back sheet surface.

- the laminate on which the release sheet is bonded is cut into an absorbent article shape by the end cutter 35 to form an absorbent article.

- the formed absorbent article is carried to the packaging process.

- FIG. 8 is a diagram showing a packaging process in the manufacturing process of the individual package according to the present invention.

- the formed absorbent article 41 is rotated 90 degrees.

- the bonding sheet forming adhesive 44 and the second bonding section forming adhesive 45 are coated on the packaging sheet 43, and the absorbent article 42 rotated 90 degrees is joined and overlapped thereon, and the packaging is performed.

- the sheet 43 and the release sheet 46 are bonded via the adhesives 44 and 45, thereby forming the bonding portion 47 and the second bonding portion 48.

- the absorbent article 42 is folded together with the packaging sheet 43 from the rear end side of the absorbent article to the surface side of the absorbent article (49 in FIG. 8).

- the individual package of the absorbent article of the present invention can be suitably used as an individual package for sanitary napkins, panty liners, incontinence pads and the like.

Landscapes

- Health & Medical Sciences (AREA)

- Engineering & Computer Science (AREA)

- Epidemiology (AREA)

- Heart & Thoracic Surgery (AREA)

- Biomedical Technology (AREA)

- Vascular Medicine (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Absorbent Articles And Supports Therefor (AREA)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201480022588.9A CN105142584B (zh) | 2013-09-03 | 2014-08-22 | 吸收性物品的单个包装体 |

| KR1020167008731A KR102283401B1 (ko) | 2013-09-03 | 2014-08-22 | 흡수성 물품의 개별 포장체 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013-182335 | 2013-09-03 | ||

| JP2013182335A JP5762487B2 (ja) | 2013-09-03 | 2013-09-03 | 吸収性物品の個包装体 |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| WO2014204018A2 true WO2014204018A2 (ja) | 2014-12-24 |

| WO2014204018A3 WO2014204018A3 (ja) | 2015-03-12 |

| WO2014204018A4 WO2014204018A4 (ja) | 2015-04-30 |

Family

ID=52105438

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2014/072019 Ceased WO2014204018A2 (ja) | 2013-09-03 | 2014-08-22 | 吸収性物品の個包装体 |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JP5762487B2 (enExample) |

| KR (1) | KR102283401B1 (enExample) |

| CN (1) | CN105142584B (enExample) |

| WO (1) | WO2014204018A2 (enExample) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2015043593A (ja) * | 2009-10-14 | 2015-03-05 | クゥアルコム・インコーポレイテッドQualcomm Incorporated | チャネル利用率制御のための方法および装置 |

| US11793684B2 (en) | 2017-06-30 | 2023-10-24 | Johnson & Johnson Consumer Inc. | Folded individual article in a circular package |

| US11896467B2 (en) | 2017-06-30 | 2024-02-13 | Johnson & Johnson Consumer Inc. | Folded individual article in a circular package |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6336432B2 (ja) * | 2015-12-28 | 2018-06-06 | ユニ・チャーム株式会社 | 吸収性物品の包装体 |

| JP6346259B1 (ja) * | 2016-12-26 | 2018-06-20 | 花王株式会社 | 吸収性物品の個装体 |

| WO2020075851A1 (ja) * | 2018-10-12 | 2020-04-16 | ユニ・チャーム株式会社 | 吸収性物品包装体 |

| JP7335846B2 (ja) * | 2020-03-27 | 2023-08-30 | 大王製紙株式会社 | 個装吸収性物品 |

| JP7766056B2 (ja) * | 2023-02-16 | 2025-11-07 | ユニ・チャーム株式会社 | 吸収性物品の包装体 |

Family Cites Families (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2900284B2 (ja) | 1990-09-12 | 1999-06-02 | カシオ計算機株式会社 | 薄膜形成方法 |

| JP3190565B2 (ja) * | 1996-03-26 | 2001-07-23 | 花王株式会社 | 吸収性物品の包装構造 |

| US8211074B2 (en) | 2002-02-22 | 2012-07-03 | The Procter And Gamble Company | Absorbent article including undergarment fastener adhesive having improved adhesive pattern |

| JP4732497B2 (ja) * | 2008-09-30 | 2011-07-27 | 大王製紙株式会社 | 吸収性物品 |

| JP5503925B2 (ja) * | 2009-08-28 | 2014-05-28 | 大王製紙株式会社 | 個装吸収性物品 |

| JP5590880B2 (ja) | 2009-12-28 | 2014-09-17 | 大王製紙株式会社 | 包装吸収性物品 |

| JP5576194B2 (ja) * | 2010-06-29 | 2014-08-20 | ユニ・チャーム株式会社 | 包装構造 |

-

2013

- 2013-09-03 JP JP2013182335A patent/JP5762487B2/ja active Active

-

2014

- 2014-08-22 KR KR1020167008731A patent/KR102283401B1/ko active Active

- 2014-08-22 CN CN201480022588.9A patent/CN105142584B/zh active Active

- 2014-08-22 WO PCT/JP2014/072019 patent/WO2014204018A2/ja not_active Ceased

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2015043593A (ja) * | 2009-10-14 | 2015-03-05 | クゥアルコム・インコーポレイテッドQualcomm Incorporated | チャネル利用率制御のための方法および装置 |

| US11793684B2 (en) | 2017-06-30 | 2023-10-24 | Johnson & Johnson Consumer Inc. | Folded individual article in a circular package |

| US11896467B2 (en) | 2017-06-30 | 2024-02-13 | Johnson & Johnson Consumer Inc. | Folded individual article in a circular package |

Also Published As

| Publication number | Publication date |

|---|---|

| JP2015047408A (ja) | 2015-03-16 |

| WO2014204018A4 (ja) | 2015-04-30 |

| KR20160052654A (ko) | 2016-05-12 |

| WO2014204018A3 (ja) | 2015-03-12 |

| JP5762487B2 (ja) | 2015-08-12 |

| KR102283401B1 (ko) | 2021-07-29 |

| CN105142584A (zh) | 2015-12-09 |

| CN105142584B (zh) | 2019-09-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5762487B2 (ja) | 吸収性物品の個包装体 | |

| KR100821819B1 (ko) | 위생용 제품 | |

| CN102523734B (zh) | 吸收性物品和卫生巾 | |

| JP5410897B2 (ja) | 着用物品の製造方法 | |

| WO2012091016A1 (ja) | 吸収性物品の包装体及び吸収性物品の包装体の折り畳み方法 | |

| WO2013172176A1 (ja) | 吸収性物品 | |

| JP5702105B2 (ja) | 吸収性物品の個装体 | |

| JP5114078B2 (ja) | 吸収性物品、及び、吸収体 | |

| TW201818896A (zh) | 獨立包裝吸收性物品、吸收性物品以及折疊吸收性物品的方法 | |

| JP6596706B2 (ja) | 吸収性物品 | |

| JP2012157396A (ja) | 吸収性物品の包装体及び吸収性物品の包装体の製造方法 | |

| WO2010035648A1 (ja) | 個装吸収性物品 | |

| JP5030548B2 (ja) | 生理用ナプキン及びその製造方法 | |

| JP5475353B2 (ja) | 被包装吸収性物品 | |

| JP2016013200A (ja) | 吸収性物品 | |

| JP5750146B2 (ja) | 吸収性物品の包装体 | |

| JP5841734B2 (ja) | 吸収性物品 | |

| JP6220805B2 (ja) | 吸収性物品及び吸収性物品の製造方法 | |

| JP5186331B2 (ja) | 吸収性物品 | |

| JP6062198B2 (ja) | 廃棄手段を備えた吸収性物品 | |

| JP5993235B2 (ja) | 吸収性物品及び吸収性物品の製造方法 | |

| JP5963409B2 (ja) | 吸収性物品および包装品 | |

| TWM481712U (zh) | 拋棄式尿布 | |

| JP2011229663A (ja) | 吸収性物品積層体 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| WWE | Wipo information: entry into national phase |

Ref document number: 201480022588.9 Country of ref document: CN |

|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 14814104 Country of ref document: EP Kind code of ref document: A2 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: IDP00201507370 Country of ref document: ID |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| ENP | Entry into the national phase |

Ref document number: 20167008731 Country of ref document: KR Kind code of ref document: A |

|

| 122 | Ep: pct application non-entry in european phase |

Ref document number: 14814104 Country of ref document: EP Kind code of ref document: A2 |