WO2014196670A1 - Article absorbant - Google Patents

Article absorbant Download PDFInfo

- Publication number

- WO2014196670A1 WO2014196670A1 PCT/JP2014/073686 JP2014073686W WO2014196670A1 WO 2014196670 A1 WO2014196670 A1 WO 2014196670A1 JP 2014073686 W JP2014073686 W JP 2014073686W WO 2014196670 A1 WO2014196670 A1 WO 2014196670A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- fiber density

- low

- top sheet

- sheet

- acid

- Prior art date

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/53—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium

- A61F13/534—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad

- A61F13/535—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad inhomogeneous in the plane of the pad, e.g. core absorbent layers being of different sizes

- A61F13/536—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad inhomogeneous in the plane of the pad, e.g. core absorbent layers being of different sizes having discontinuous areas of compression

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

- A61F13/51104—Topsheet, i.e. the permeable cover or layer facing the skin the top sheet having a three-dimensional cross-section, e.g. corrugations, embossments, recesses or projections

- A61F13/51108—Topsheet, i.e. the permeable cover or layer facing the skin the top sheet having a three-dimensional cross-section, e.g. corrugations, embossments, recesses or projections the top sheet having corrugations or embossments having one axis relatively longer than the other axis, e.g. forming channels or grooves in a longitudinal direction

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

- A61F13/513—Topsheet, i.e. the permeable cover or layer facing the skin characterised by its function or properties, e.g. stretchability, breathability, rewet, visual effect; having areas of different permeability

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

- A61F13/513—Topsheet, i.e. the permeable cover or layer facing the skin characterised by its function or properties, e.g. stretchability, breathability, rewet, visual effect; having areas of different permeability

- A61F13/51305—Topsheet, i.e. the permeable cover or layer facing the skin characterised by its function or properties, e.g. stretchability, breathability, rewet, visual effect; having areas of different permeability having areas of different permeability

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/53—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium

- A61F13/531—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having a homogeneous composition through the thickness of the pad

- A61F13/532—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having a homogeneous composition through the thickness of the pad inhomogeneous in the plane of the pad

- A61F13/533—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having a homogeneous composition through the thickness of the pad inhomogeneous in the plane of the pad having discontinuous areas of compression

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/53—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium

- A61F13/534—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad

- A61F13/537—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad characterised by a layer facilitating or inhibiting flow in one direction or plane, e.g. a wicking layer

- A61F13/53708—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad characterised by a layer facilitating or inhibiting flow in one direction or plane, e.g. a wicking layer the layer having a promotional function on liquid propagation in at least one direction

- A61F13/53713—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the absorbing medium having an inhomogeneous composition through the thickness of the pad characterised by a layer facilitating or inhibiting flow in one direction or plane, e.g. a wicking layer the layer having a promotional function on liquid propagation in at least one direction the layer having a promotional function on liquid propagation in the vertical direction

-

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61F—FILTERS IMPLANTABLE INTO BLOOD VESSELS; PROSTHESES; DEVICES PROVIDING PATENCY TO, OR PREVENTING COLLAPSING OF, TUBULAR STRUCTURES OF THE BODY, e.g. STENTS; ORTHOPAEDIC, NURSING OR CONTRACEPTIVE DEVICES; FOMENTATION; TREATMENT OR PROTECTION OF EYES OR EARS; BANDAGES, DRESSINGS OR ABSORBENT PADS; FIRST-AID KITS

- A61F13/00—Bandages or dressings; Absorbent pads

- A61F13/15—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators

- A61F13/51—Absorbent pads, e.g. sanitary towels, swabs or tampons for external or internal application to the body; Supporting or fastening means therefor; Tampon applicators characterised by the outer layers

- A61F13/511—Topsheet, i.e. the permeable cover or layer facing the skin

- A61F13/513—Topsheet, i.e. the permeable cover or layer facing the skin characterised by its function or properties, e.g. stretchability, breathability, rewet, visual effect; having areas of different permeability

- A61F2013/51355—Topsheet, i.e. the permeable cover or layer facing the skin characterised by its function or properties, e.g. stretchability, breathability, rewet, visual effect; having areas of different permeability for improving fluid flow

Definitions

- the present invention relates to an absorbent article.

- Patent Documents 1 and 2 formation of a ridge and a groove on the top sheet.

- the fiber density in the central region of the buttock is set to a substantially uniform fiber density lower than the average fiber density of the entire buttock, and the fiber density in the side edge region of the buttock is set to A substantially uniform fiber density that is higher than the overall average fiber density is used.

- region of a buttocks to an absorber improves.

- the contact area between the user's skin and the top sheet is reduced by the buttocks and the grooves, even if the menstrual blood once absorbed by the absorbent body returns to the top sheet, the reverted menstrual blood remains in the user's skin. It is hard to adhere to. Furthermore, even if force is applied to the buttocks, the center region is supported by the side edge region of the buttocks, so that the buttocks are not easily crushed.

- Patent Document 3 formation of a compressed recess in the absorber.

- the compression recessed part which consists of the high pressing recessed part which is scattered and the low pressing recessed part which connects the scattered high pressing recessed part is formed in an absorber.

- the rigidity of an absorber improves and generation

- a blood slipperiness imparting agent having a kinematic viscosity at 40 ° C. of 0.01 to 80 mm 2 / s, a water retention of 0.01 to 4.0% by mass and a weight average molecular weight of less than 1,000.

- Patent Document 4 the menstrual blood transfer property from a top sheet to an absorber is improved with a blood slipperiness

- An object of the present invention is to provide an absorbent article having improved liquid migration from a top sheet to an absorber.

- the present invention has a transverse direction, a longitudinal direction and a thickness direction orthogonal to each other, a liquid-permeable top sheet, a liquid-impermeable back sheet, the top sheet,

- An absorbent article comprising an absorbent body provided between back sheets, wherein the top sheet is a nonwoven fabric having a high fiber density region and a low fiber density region, and the absorbent body comprises absorbent fibers.

- An absorptive core containing, a topsheet side covering sheet for covering the topsheet side surface of the absorbent core, a backsheet side covering sheet for covering the backsheet side surface of the absorbent core, and the backsheet side covering

- a pressing recess formed by pressing the sheet toward the absorbent core, and the pressing recess is a low-pressure pressing formed in a mesh pattern And high pressing depressions formed so as to be scattered in the mesh pattern, and project the low fiber density region and the low pressing depression on a virtual plane perpendicular to the thickness direction. Then, the absorbent article is provided in which a projection region of the low fiber density region has an overlap with a projection region of the low-pressure depression.

- an absorbent article having improved liquid migration from the top sheet to the absorber is provided.

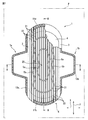

- FIG. 1 is a partially broken plan view of a sanitary napkin according to an embodiment of the absorbent article of the present invention.

- FIG. 2 is an enlarged sectional view taken along line AA in FIG.

- FIG. 3 is an enlarged sectional view taken along line BB in FIG.

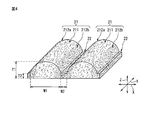

- FIG. 4 is an enlarged perspective view of a part of the top sheet included in the sanitary napkin shown in FIG. 1.

- FIG. 5 is a plan view of the back sheet side surface of the absorbent body included in the sanitary napkin shown in FIG. 1.

- FIG. 6 is an enlarged view of a portion indicated by C in FIG. FIG.

- FIG. 7 is a projection area of a groove portion generated when the groove portion of the top sheet and the low-pressure depression of the absorbent body are projected on a virtual plane perpendicular to the thickness direction of the sanitary napkin in the sanitary napkin shown in FIG. It is a one part enlarged view of a virtual plane which shows the overlap with the projection area

- the absorbent article of the present invention has a transverse direction, a longitudinal direction, and a thickness direction orthogonal to each other, and a liquid-permeable top sheet, a liquid-impermeable back sheet, and between the top sheet and the back sheet

- the top sheet is a non-woven fabric having a high fiber density region and a low fiber density region, and the absorber contains an absorptive fiber.

- a pressing recess formed by pressing in the direction of the sex core, and the pressing recess is a low pressing recess formed in a mesh pattern and the mesh High depressions formed so as to be scattered in the pattern, and when the low fiber density region and the low depressions are projected onto a virtual plane perpendicular to the thickness direction,

- the projection area of a fiber density area is related with the absorptive article which has an overlap with the projection area of the low-pressure pressing crevice.

- high fiber density and low fiber density mean the relative level of fiber density

- high pressure and low pressure mean the relative level of compression. means.

- the absorbent article of the present invention can exhibit the following effects.

- the top sheet is partitioned into a high fiber density region and a low fiber density region in plan view.

- the liquid is less liable to stay in the low fiber density region than in the high fiber density region, so that the liquid supplied to the top sheet easily moves to the absorbent body through the low fiber density region of the top sheet.

- the low fiber density region of the top sheet and the low pressing depression of the absorbent body overlap each other so that the projection region of the low fiber density region overlaps with the projection region of the low pressing depression (that is, in the thickness direction of the absorbent article).

- the liquid supplied to the top sheet moves to the absorbent body through the low fiber density region of the top sheet, the liquid tends to migrate to the low pressure depression of the absorbent body.

- the absorbent article of the present invention can exhibit improved liquid migration from the top sheet to the absorbent body.

- a preferable aspect (Aspect 1) of the absorbent article of the present invention 2% or more of the projected area of the low fiber density area overlaps with the projected area of the low-pressure depression. According to the aspect 1, the liquid transferability from the low fiber density region of the top sheet to the low pressure recessed portion of the absorber can be improved.

- the fiber density of the low-pressure depression is greater than the fiber density of the low fiber density region.

- the liquid transfer property from the low fiber density region of the top sheet to the low pressure recessed portion of the absorbent body is obtained by utilizing the property of the liquid that it is easy to transfer from the low fiber density part to the high fiber density part. Can be improved. Note that aspect 2 can be combined with aspect 1.

- the fiber density of the high-pressure recessed portion is larger than the fiber density of the high fiber density region.

- the liquid remaining in the low fiber density region and the high fiber density region of the top sheet is used to absorb the liquid remaining in the absorber using the characteristic of the liquid that easily shifts from the low fiber density portion to the high fiber density portion. It can be pulled into the high pressure depression.

- Aspect 3 can be combined with Aspect 1 and / or Aspect 2.

- the top sheet has a flange extending in the longitudinal direction and a groove extending in the longitudinal direction, and the flange Corresponds to the high fiber density region, and the groove corresponds to the low fiber density region.

- the liquid supplied to the top sheet is likely to spread in the longitudinal direction of the absorbent article along the ridges and the grooves, so that the liquid supplied to the top sheet is reduced in the short direction of the absorbent article. Spreading and leakage from the absorbent article due to this can be prevented.

- the aspect 4 can be combined with one of the aspects 1 to 3 or two or more aspects that can be arranged side by side.

- the low-pressure depression has an extending portion extending in the longitudinal direction, and the groove and the low-pressure depression are formed with the thickness.

- the projection area of the groove When projected onto a virtual plane perpendicular to the direction, the projection area of the groove has an overlap with the projection area of the extending portion.

- the extending direction of the groove portion (the liquid spreading direction in the top sheet) and the extending direction of the extending portion of the low-pressure squeezing concave portion (the liquid diffusion direction in the absorber) coincide with each other, and Since the extension part of a recessed part overlaps in the thickness direction of an absorbent article, the liquid transferability from the groove part of a top sheet to the extension part of a low pressing recessed part can be improved.

- Aspect 7 of the absorbent article according to Aspect 5 or Aspect 6, the overlap between the projection area of the groove and the projection area of the extending portion extends over the entire short direction of the projection area of the groove. Arise. According to the aspect 7, the liquid transferability from the groove portion of the top sheet to the extended portion of the low-pressure squeezed concave portion can be improved. Aspect 7 can be combined with Aspect 5 and / or Aspect 6.

- the collar portion has a central portion located in the center in the lateral direction, and the short side relative to the central portion. Both side portions located on both sides in the direction, the central portion has a fiber density lower than the average fiber density of the entire collar portion, and the both side portions have an average fiber density of the entire collar portion. Has higher fiber density.

- the aspect 8 since the fiber density of the both side parts of the collar part is higher than the fiber density of the center part of the collar part, the retention of the liquid in the center part of the collar part can be suppressed. The supplied liquid can be efficiently guided to the groove portion of the top sheet.

- the aspect 8 can be combined with one of the aspects 4 to 7 or two or more aspects that can be arranged side by side.

- the absorbent body has a central portion located at the center in the longitudinal direction, and both side portions located on both sides in the longitudinal direction with respect to the central portion.

- the pressing recess is formed in the both side portions, but is not formed in the central portion.

- the aspect 9 can be combined with one of the aspects 1 to 8 or two or more aspects that can be arranged side by side.

- the high-pressure depression is formed in an intersecting region of the mesh pattern.

- the high-pressure recessed portion is provided in the intersecting region of the mesh pattern in which force is easily applied when the absorbent article is used, the separation between the absorbent core and the backsheet-side covering sheet can be prevented. As a result, the mesh pattern of the low-pressure depressions can be maintained.

- the aspect 10 can be combined with one of the aspects 1 to 9 or two or more aspects that can be arranged side by side.

- the topsheet-side covering sheet is bonded to the topsheet-side surface of the absorbent core with an adhesive

- the backsheet-side covering sheet is The absorbent core is bonded to the back sheet side surface with an adhesive.

- the separation between the absorbent core and the top sheet side covering sheet and the back sheet side covering sheet and the deterioration of the liquid transferability due to the separation can be prevented.

- the aspect 11 can be combined with one of the aspects 1 to 10 or two or more aspects that can be arranged side by side.

- the top sheet has a kinematic viscosity at 40 ° C. of 0.01 to 80 mm 2 / s, a water retention of 0.01 to 4.0% by mass, A blood slipperiness imparting agent having a weight average molecular weight of less than 1,000 is applied.

- Aspect 12 is particularly useful when the liquid supplied to the top sheet is blood (for example, menstrual blood excreted from the wearer). That is, the blood supplied to the top sheet can slide down to the low fiber density region of the top sheet together with the blood slipperiness imparting agent applied to the top sheet, and can be transferred to the absorber. Therefore, according to the aspect 11, the blood remaining on the top sheet can be reduced, thereby preventing the stickiness of the top sheet and maintaining the smooth feeling.

- the aspect 12 can be combined with one of the aspects 1 to 11 or two or more aspects that can be arranged side by side.

- the IOB of the blood slipperiness imparting agent is preferably 0.00 to 0.60.

- the blood slipperiness imparting agent is preferably the following (i) to (iii): (I) hydrocarbons, (Ii) from (ii-1) a hydrocarbon moiety and (ii-2) a carbonyl group (—CO—) and an oxy group (—O—) inserted between the CC single bonds of the hydrocarbon moiety.

- the hydrocarbon moiety A compound having one or a plurality of the same or different groups selected from the group consisting of a carboxyl group (—COOH) and a hydroxyl group (—OH), which replaces a hydrogen atom; Selected from the group consisting of any combination thereof (in the compound (ii) or (iii), when two or more oxy groups are inserted, each oxy group is not adjacent) ).

- the blood slipperiness imparting agent is preferably the following (i ′) to (iii ′): (I ′) hydrocarbon, (Ii ′) (ii′-1) a hydrocarbon moiety and (ii′-2) a carbonyl bond (—CO—), an ester bond (—COO) inserted between the C—C single bonds of the hydrocarbon moiety.

- the blood slipperiness imparting agent is preferably the following (A) to (F): (A) (A1) a compound having a chain hydrocarbon moiety and 2 to 4 hydroxyl groups substituting hydrogen atoms in the chain hydrocarbon moiety, (A2) a chain hydrocarbon moiety, and the chain An ester with a compound having one carboxyl group for substituting a hydrogen atom in the hydrocarbon moiety, (B) (B1) a compound having a chain hydrocarbon moiety and 2 to 4 hydroxyl groups substituting for hydrogen atoms in the chain hydrocarbon moiety, (B2) a chain hydrocarbon moiety, and the chain An ether with a compound having one hydroxyl group replacing a hydrogen atom of the hydrocarbon moiety, (C) (C1) a carboxylic acid, a hydroxy acid, an alkoxy acid or an oxo acid containing a chain hydrocarbon moiety and 2 to 4 carboxyl groups replacing the hydrogen atom of the chain hydrocarbon moiety; C2) an ester of a chain

- the blood slipperiness imparting agent is preferably (a 1 ) an ester of a chain hydrocarbon tetraol and at least one fatty acid, or (a 2 ) a chain hydrocarbon triol and at least one fatty acid.

- the type and application of the absorbent article of the present invention are not particularly limited.

- the absorbent article include sanitary products and sanitary products such as sanitary napkins, disposable diapers, panty liners, incontinence pads, sweat removing sheets, etc., and these may be used for humans and other than humans such as pets. Animals may be targeted.

- the liquid which the absorbent article is to be absorbed is not particularly limited, and examples thereof include liquid excretion excreted from the wearer (for example, menstrual blood, urine, descending product, etc.).

- a sanitary napkin 1 includes a liquid-permeable top sheet 2, a liquid-impermeable back sheet 3, a top sheet 2 and a back sheet 3. And an absorber 4 provided between the two.

- the sanitary napkin 1 has a transverse direction X, a longitudinal direction Y, and a thickness direction Z that are orthogonal to each other.

- the top sheet 2, the absorber 4 and the back sheet 3 are sequentially laminated in the thickness direction Z, and the thickness direction Z coincides with the lamination direction of the top sheet 2, the absorber 4 and the back sheet 3.

- width means the dimension in the short direction X

- length means the dimension in the longitudinal direction Y

- Thickness means the dimension in the thickness direction Z. means.

- the sanitary napkin 1 has a skin-side surface located on the wearer's skin side and a clothing-side surface located on the wearer's clothing (underwear) side when worn.

- the skin side surface of the sanitary napkin 1 is constituted by one surface (the upper surface in FIGS. 2 and 3) of the top sheet 2, and the clothing side surface of the sanitary napkin 1 is one surface of the back sheet 3 ( 2 and 3, the lower surface).

- the sanitary napkin 1 is worn for the purpose of absorbing liquid excretion (particularly menstrual blood) excreted from the wearer.

- the top sheet 2 is worn on the skin side of the wearer, and the back sheet 3 is worn on the clothes (underwear) side of the wearer.

- the liquid excretion excreted from the wearer passes through the top sheet 2 to reach the absorber 4 and is absorbed and held by the absorber 4. Leakage of liquid excretion absorbed and held by the absorber 4 is prevented by the back sheet 3.

- the top sheet 2 and the back sheet 3 are joined at their longitudinal ends by seal portions 11 a and 11 b to form a main body portion 6, and end portions in the width direction are sealed portions 12 a. , 12b and substantially rectangular wings 7a, 7b extending in the width direction from the main body 6 are formed.

- the shape of the main body 6 can be appropriately changed within a range suitable for a female body, underwear, and the like, and may be, for example, a substantially rectangular shape, a substantially oval shape, a substantially saddle shape, or the like.

- the length of the main body 6 is usually 100 to 500 mm, preferably 150 to 350 mm, and the width of the main body 6 is usually 30 to 200 mm, preferably 40 to 180 mm.

- Examples of the bonding mode by the seal portions 11a, 11b, 12a, and 12b include bonding by heat embossing, bonding by ultrasonic embossing, and bonding by a hot melt adhesive. In order to increase the bonding strength, two or more bonding modes may be combined (for example, a combination of bonding with a hot-melt adhesive and embossing performed thereafter).

- adhesive portions 13 a and 13 b are provided on the clothing side of the backsheet 3 that forms the wing portions 7 a and 7 b, and on the clothing side of the backsheet 3 that forms the main body portion 6, An adhesive portion 13c is provided.

- the sanitary napkin 1 is obtained by attaching the adhesive part 13c to the crotch part of the underwear, bending the wing parts 7a and 7b to the outer surface side of the underwear, and attaching the adhesive parts 13a and 13b to the crotch part of the underwear. Stablely fixed to underwear.

- Examples of the adhesive contained in the adhesive portions 13a, 13b, and 13c include styrene-ethylene-butylene-styrene block copolymers, styrene-butylene polymers, styrene-butylene-styrene block copolymers, and styrene-isobutylene- Styrene polymers such as styrene copolymers; tackifiers such as C5 petroleum resins, C9 petroleum resins, dicyclopentadiene petroleum resins, rosin petroleum resins, polyterpene resins, terpene phenol resins; trifresyl phosphate, phthalic acid Examples include monomer plasticizers such as dibutyl and dioctyl phthalate; polymer plasticizers such as vinyl polymer and polyester.

- the top sheet 2 is a non-woven fabric through which liquid excretion excreted from the wearer can permeate.

- the kind of nonwoven fabric used as the top sheet 2, thickness, basic weight, etc. are not specifically limited as long as the liquid excretion excreted from the wearer can permeate.

- the fibers constituting the nonwoven fabric include natural fibers (for example, wool, cotton, etc.), regenerated fibers (for example, rayon, acetate, etc.), inorganic fibers (for example, glass fibers, carbon fibers, etc.), thermoplastic resin fibers (for example, polyolefins such as polyethylene, polypropylene, polybutylene, ethylene-vinyl acetate copolymer, ethylene-ethyl acrylate copolymer, ethylene-acrylic acid copolymer, ionomer resin; polyethylene terephthalate, polybutylene terephthalate, polytrimethylene And polyesters such as terephthalate and polylactic acid; polyamides such as nylon).

- natural fibers for example, wool, cotton, etc.

- regenerated fibers for example, rayon, acetate, etc.

- inorganic fibers for example, glass fibers, carbon fibers, etc.

- thermoplastic resin fibers for example, polyolefins such as poly

- the fibers constituting the nonwoven fabric are: core-sheath fibers, side-by-side fibers, island / sea fibers, etc .; hollow fibers; flat fibers, Y-shaped fibers, C-shaped fibers, etc .; latent crimps Alternatively, it may be a three-dimensional crimped fiber of actual crimp; a split fiber that is split by a physical load such as water flow, heat, embossing, or the like.

- Nonwoven fabric production methods include, for example, a method of forming a web (fleece) and physically and chemically bonding fibers.

- web formation methods include a spunbond method and a dry method (car Bonding methods, melt blown methods, airlaid methods, etc.), wet methods, and the like.

- bonding method include a thermal bond method, a chemical bond method, a needle punch method, a stitch bond method, and a spunlace method.

- the nonwoven fabric used as the top sheet 2 examples include an air-through nonwoven fabric, a spunbond nonwoven fabric, a point bond nonwoven fabric, a spunlace nonwoven fabric, a needle punched nonwoven fabric, a melt blown nonwoven fabric, and combinations thereof (for example, a spunbond / meltblown / spunbond ( SMS) non-woven fabric etc.), etc., among which air-through non-woven fabric is preferred. Since the air-through nonwoven fabric has a relatively low fiber density, the use of the air-through nonwoven fabric as the top sheet 2 can reduce liquid excrement remaining on the top sheet 2.

- the air-through nonwoven fabric can be produced, for example, by spraying hot air on a web containing thermoplastic resin fibers to thermally bond the thermoplastic resin fibers.

- the top sheet 2 has a surface region 20 that receives supply of liquid excretion excreted from the wearer.

- the surface region 20 is located substantially at the center of the absorber arrangement region, and the inner compressed groove 5a is intermittently formed at the periphery of the surface region 20.

- region is an area

- the position and size of the surface area 20 can be appropriately adjusted in consideration of the position and size of the excretory opening contact area where the wearer's excretion opening (eg, small labia, large labia, etc.) abuts.

- the surface area 20 is preferably set as an area larger than the excretion opening contact area including the excretion opening contact area and the surrounding area from the viewpoint of preventing leakage of liquid excretion to the outside.

- the length of the surface region 20 is usually 50 to 200 mm, preferably 70 to 150 mm, and the width of the surface region 20 is usually 10 to 80 mm, preferably 20 to 50 mm.

- the nonwoven fabric used as the top sheet 2 may contain an inorganic filler such as titanium oxide, barium sulfate, or calcium carbonate.

- an inorganic filler may be contained only in the core of the core-sheath-type conjugate fiber, or an inorganic filler may be contained only in the sheath of the core-sheath-type conjugate fiber.

- the top sheet 2 is a non-woven fabric having a plurality of ridges 21 extending in the longitudinal direction Y and a plurality of grooves 22 extending in the longitudinal direction Y.

- the top sheet 2 is partitioned into a high fiber density region and a low fiber density region in plan view (see FIG. 1), and the flange portion 21 corresponds to a high fiber density region having a fiber density higher than that of the groove portion 22.

- the liquid excrement supplied to the top sheet 2 tends to spread in the longitudinal direction Y along the collar part 21 and the groove part 22, the liquid excrement supplied to the top sheet 2 spreads in the short direction X and Leakage from the sanitary napkin 1 can be prevented.

- the ratio of the total area of the projection area of the groove 22 to the total area of the projection area of the flange 21 is usually 1: 1 to 1:20, preferably 1: 1 to 1:10, more preferably 1: 1 to 1: 8. It is.

- “High fiber density” and “low fiber density” mean relative high and low fiber density. Since the liquid tends to shift from a portion having a low fiber density to a portion having a high fiber density, the high or low fiber density is a liquid that is colored with respect to the nonwoven fabric used as the top sheet 2 (for example, a liquid containing a pigment). It can be evaluated by the shade of the color after dropping. That is, the dark part can be evaluated as a part with a large liquid migration amount, that is, a part with a relatively high fiber density, and the light color part has a small liquid migration amount, that is, a fiber density. It can be evaluated as a relatively small portion.

- the plurality of eaves portions 21 extending in the longitudinal direction Y are arranged in the short direction X at substantially equal intervals.

- the plurality of flange portions 21 extending in the longitudinal direction Y are also arranged in the short direction X at substantially equal intervals.

- the flange portions 21 and the groove portions 22 are alternately disposed in the lateral direction X, and one groove portion 22 is disposed between the two flange portions 21.

- Such an arrangement pattern of the flange portion 21 (high fiber density region) and the groove portion 22 (low fiber density region) is an example of an arrangement pattern of the high fiber density region and the low fiber density region.

- the arrangement pattern of the density region is not limited to this embodiment.

- the high fiber density region and the low fiber density region may extend in the lateral direction X and be aligned in the longitudinal direction Y.

- the high fiber density region and the low fiber density region may extend intermittently in the longitudinal direction Y.

- the high fiber density region and the low fiber density region may extend in the longitudinal direction Y while changing the extending direction (for example, wavy lines).

- two or more low fiber density regions extending in the longitudinal direction Y may be arranged between two high fiber density regions extending in the longitudinal direction Y.

- a plurality of high fiber density regions or low fiber density regions extending in the longitudinal direction Y may be arranged in the short direction X at different intervals.

- one of the high fiber density region and the low fiber density region may be scattered and surrounded by the other.

- two or more types of changes that can be juxtaposed may be combined.

- the surface of the flange 21 is a curved surface, and the cross-sectional shape of the flange 21 is a substantially inverted U shape toward the surface.

- a shape of the collar portion 21 is an example of a shape of the collar portion, and the shape of the collar portion is not limited to the present embodiment.

- the cross-sectional shape of the collar portion may be trapezoidal, triangular, ⁇ -shaped square, or the like.

- the cross-sectional shape of the collar portion is preferably a shape whose width decreases from the bottom portion toward the top portion.

- the flange portion 21 has a thickness T1

- the groove portion 22 has a thickness T2.

- the thickness T1 of the flange portion 21 is preferably 0.3 to 15 mm, more preferably 0.5 to 5 mm

- the thickness T2 of the groove portion 22 is usually 90% or less, preferably 50% of the thickness T1 of the flange portion 21.

- it is more preferably 20% or less.

- the thickness T2 of the groove portion 22 is usually 1% or more, preferably 5% or more of the thickness T1 of the flange portion 21.

- the thickness T1 of the flange portion 21 is measured as a distance from the lower surface of the topsheet 2 to the highest point of the flange portion 21 based on a cross-sectional photograph or a cross-sectional image of the topsheet 2 in a non-pressurized state. The same applies to the thickness T2 of the groove 22.

- the flange portion 21 has a width W1

- the groove portion 22 has a width W2.

- the width W1 of the flange portion 21 is preferably 0.5 to 30 mm, more preferably 1.0 to 10 mm

- the width W2 of the groove portion 22 is preferably 0.1 to 30 mm, more preferably 0.5 to 10 mm. It is.

- the interval between the flange portions 21 is usually equal to the width W2 of the groove portion, and the interval between the groove portions 22 is usually equal to the width of the flange portion 21.

- the width W1 of the flange portion 21 is measured as a distance between the boundary lines with the groove portion 22 located on both sides of the flange portion 21 based on a planar photograph or a plane image of the top sheet 2 in a non-pressurized state. .

- the width W2 of the groove 22 is the same.

- the thickness T1 and the width W1 of the flange 21 are substantially the same in any flange 21, but there may be flanges having different thicknesses and widths.

- the thickness T2 and the width W2 of the groove portion 22 are substantially the same in any groove portion 22, but there may be groove portions having different thicknesses and widths.

- the collar portion 21 includes a central portion 211 located in the center in the short direction X, and both side portions 212 a and 212 b located on both sides in the short direction X with respect to the central portion 211.

- the central portion 211 is thicker than the side portions 212a and 212b, and has a fiber density lower than the average fiber density of the entire collar portion 21.

- the fiber density of the center part 211 is substantially uniform.

- Both side portions 212a and 212b are thinner than the central portion 211, and have a fiber density higher than the average fiber density of the entire collar portion 21.

- the fiber density of both side parts 212a and 212b is substantially uniform.

- the fiber density of the central portion 211 and the side portions 212a and 212b are both higher than the fiber density of the groove portion 22. Therefore, the groove part 22 is a low fiber density area

- the fiber density of the central portion 211 of the collar portion 21 is preferably 0.005 to 0.20 g / cm 3 , more preferably 0.007 to 0.07 g / cm 3 .

- the fiber density of the central portion 211 is less than 0.005 g / cm 3 , when force (for example, body pressure of the wearer) is applied to the sanitary napkin 1, the central portion 211 is easily crushed and the absorbent body 4 The absorbed liquid excretion is likely to return backward through the central portion 211.

- force for example, body pressure of the wearer

- liquid excreta tends to stay in the central portion 211.

- the fiber density of both side portions 212a and 212b of the flange portion 21 is preferably 0.007 to 0.40 g / cm 3 , more preferably 0.01 to 0.20 g / cm 3 .

- both side portions 212a and 212b are easily stretched by line tension.

- the fiber density of both side portions 212a and 212b is larger than 0.40 g / cm 3 , liquid excrement tends to stay in both side portions 212a and 212b.

- the average fiber density of the entire collar portion 21 is preferably 0.005 to 0.2 g / cm 3 , more preferably 0.007 to 0.07 g / cm 3 .

- Fiber density of the groove 22 is preferably 0.002 ⁇ 0.18g / cm 3, more preferably 0.005 ⁇ 0.05g / cm 3.

- the fiber density of the groove part 22 is smaller than 0.002 g / cm 3 , the groove part 22 of the top sheet 2 is easily damaged when the sanitary napkin 1 is used.

- the fiber density of the groove part 22 is larger than 0.18 g / cm ⁇ 3 >, liquid excretion will stay in the groove part 22 easily.

- the average basis weight of the whole nonwoven fabric used as the top sheet 2 is preferably 10 to 200 g / m 2 , more preferably 20 to 100 g / m 2 . If the average basis weight is less than 10 g / m 2 , the top sheet 2 may be damaged when the sanitary napkin 1 is used. On the other hand, the average basis weight of greater than 200 g / m 2, the liquid excrement tends to stay in the top sheet 2.

- the basis weight of the groove portion 22 is adjusted to be smaller than the basis weight of the flange portion 21 and smaller than the average basis weight of the entire nonwoven fabric.

- the basis weight of the groove 22 is preferably 3 to 150 g / m 2 , more preferably 5 to 80 g / m 2 . If the basis weight of the groove 22 is less than 3 g / m 2 , the top sheet 2 may be damaged when the sanitary napkin 1 is used. On the other hand, when the basis weight of the groove part 22 is larger than 150 g / m 2 , liquid excrement tends to stay in the groove part 22.

- the collar portion 21 is adjusted so that the average basis weight is higher than that of the groove portion 22.

- the basis weight of the central portion 211 of the collar portion 21 is usually 15 to 250 g / m 2 , preferably 20 to 120 g / m 2 .

- the central portion 211 is liable to be crushed and the liquid excretion absorbed by the absorbent body 4 is easily returned under pressure.

- the basis weight of the central portion 211 is larger than 250 g / m 2 , liquid excreta tends to stay in the central portion 211.

- the basis weight of both side portions 212a and 212b of the flange portion 21 is preferably 20 to 280 g / m 2 , more preferably 25 to 150 g / m 2 . If the basis weight of both side portions 212a and 212b is smaller than 20 g / m 2 , both side portions 212a and 212b are easily stretched by line tension. On the other hand, if the basis weights of both side portions 212a and 212b are larger than 280 g / m 2 , the transferability of liquid excreta is lowered and the liquid excrement tends to stay in both side portions 212a and 212b.

- the average basis weight of the groove portion 22 is adjusted to be lower than the average basis weight of the entire flange portion 21.

- the average basis weight of the groove portion 22 is usually 90% or less, preferably 3 to 90%, more preferably 3 to 70% of the average basis weight of the entire flange portion 21. If the average basis weight of the groove part 22 is larger than 90% of the average basis weight of the entire collar part 21, liquid excrement tends to stay in the groove part 22, and liquid excrement may overflow from the groove part 22. On the other hand, if the average basis weight of the entire groove portion 22 is smaller than 3% of the average basis weight of the entire collar portion 21, the top sheet 2 may be damaged when the sanitary napkin 1 is used.

- the nonwoven fabric used as the top sheet 2 preferably contains thermoplastic resin fibers.

- a nonwoven fabric contains a thermoplastic resin fiber

- the morphology of the collar part 21 and the groove part 22 can be maintained by heat-seal

- the thermoplastic resin constituting the thermoplastic resin fiber include polyolefin, polyester, polyamide, and the like.

- polystyrene resin examples include, for example, linear low density polyethylene (LLDPE), low density polyethylene (LDPE), medium density polyethylene (MDPE), high density polyethylene (HDPE), polypropylene, polybutylene, and copolymers based on these (for example, Ethylene-vinyl acetate copolymer (EVA), ethylene-ethyl acrylate copolymer (EEA), ethylene-acrylic acid copolymer (EAA), ionomer resin) and the like.

- LLDPE linear low density polyethylene

- LDPE low density polyethylene

- MDPE medium density polyethylene

- HDPE high density polyethylene

- EVA Ethylene-vinyl acetate copolymer

- EAA ethylene-ethyl acrylate copolymer

- EAA ethylene-acrylic acid copolymer

- polyesters examples include linear or branched carbon atoms of up to 20 including polyethylene terephthalate (PET), polytrimethyl terephthalate (PTT), polybutylene terephthalate (PBT), polylactic acid, and polyglycolic acid. And polyesters such as polyhydroxyalkanoic acid, copolymers based on these, and copolymerized polyesters obtained by copolymerizing alkylene terephthalate as a main component with a small amount of other components.

- polyamide examples include 6-nylon and 6,6-nylon.

- the fineness of the thermoplastic resin fiber is usually 1.1 to 8.8 dtex, preferably 2.2 to 5.6 dtex, and the fiber length is usually 20 to 100 mm, preferably 35 to 65 mm.

- the thermoplastic resin fiber may be hydrophilized.

- the hydrophilic treatment of thermoplastic resin fibers include, for example, treatment using a surfactant, a hydrophilic agent, etc. (for example, kneading of a surfactant inside the fiber, application of a surfactant to the fiber surface, etc.), etc. Is mentioned.

- a nonwoven fabric is formed by placing a fiber web on a breathable support member (for example, a net-like support member) and continuously blowing gas onto the upper surface of the fiber web while moving the breathable support member in a predetermined direction.

- the flange portion 21 and the groove portion 22 are formed in the bottom.

- the groove part 22 extended in the moving direction of a breathable support member is formed in the area

- the fiber density of both side portions 212a and 212b of the flange portion 21 is increased.

- the fiber density of the flange portion 21 and the groove portion 22 can be adjusted to a desired range by adjusting conditions such as the amount of gas blown and the tension of the fiber web.

- the thickness and density of the nonwoven fabric can be measured as follows.

- the thickness of the nonwoven fabric having a size of 100 mm ⁇ 100 mm is measured under no load, and the average value of the measured values for the ten nonwoven fabrics is defined as the thickness t 0 (cm) of the nonwoven fabric.

- a mass w 0 (g / cm 2 ) per unit area is obtained from the mass of 10 nonwoven fabrics having a size of 100 mm ⁇ 100 mm, and the value of w 0 / t 0 is defined as a density under no load.

- the sanitary napkin 1 may include a liquid permeable sheet other than the top sheet 2.

- the liquid permeable sheet other than the top sheet 2 include a second sheet disposed between the top sheet 2 and the absorber 4.

- the liquid permeable sheet used as the second sheet include a nonwoven fabric, a woven fabric, and a synthetic resin film in which liquid permeable holes are formed. Among these, a nonwoven fabric is preferable.

- the specific example of the fiber which comprises a nonwoven fabric, and the specific example of the manufacturing method of a nonwoven fabric are the same as the specific example described regarding the top sheet 2. FIG.

- the back sheet 3 is a liquid impervious sheet through which liquid excretion excreted from the wearer cannot permeate.

- the backsheet 3 preferably has moisture permeability in addition to liquid impermeability in order to reduce stuffiness when worn.

- the type, thickness, basis weight, etc. of the liquid impermeable sheet used as the back sheet 3 are not particularly limited as long as the liquid excretion excreted from the wearer cannot permeate.

- the liquid-impermeable sheet used as the back sheet 3 include a waterproof nonwoven fabric, a synthetic resin (for example, polyethylene, polypropylene, polyethylene terephthalate, etc.) film, a composite sheet of a nonwoven fabric and a synthetic resin film (for example, a span).

- an SMS nonwoven fabric in which a melt-blown nonwoven fabric having high water resistance is sandwiched between strong spunbond nonwoven fabrics, and the like.

- the absorbent body 4 includes an absorbent core 41, a topsheet-side covering sheet 42 that covers the surface of the absorbent core 41 on the topsheet 2 side, and a backsheet side of the absorbent core 41. It has the back sheet side coating sheet 43 which coat

- the top sheet side covering sheet 42 is bonded to the top sheet side surface of the absorbent core 41 with an adhesive (for example, hot melt adhesive), and the back sheet side covering sheet 43 is the back sheet side of the absorbent core 41. It is preferable to be bonded to the surface by an adhesive (for example, a hot melt adhesive).

- an adhesive for example, a hot melt adhesive.

- seat side coating sheet 43 and the fall of the transferability of the liquid excretion resulting therefrom can be prevented.

- the adhesive is not applied to the entire interface between the top sheet side covering sheet 42 and the absorbent core 41 and the entire interface between the back sheet side covering sheet 43 and the absorbent core 41.

- the coating is performed in a pattern such as a dot, a spiral, or a stripe.

- the adhesive for example, styrene-ethylene-butadiene-styrene (SEBS), styrene-butadiene-styrene (SBS), styrene-isoprene-styrene (SIS) or the like mainly composed of rubber or linear low density Pressure-sensitive adhesive or heat-sensitive adhesive mainly composed of olefin such as polyethylene; water-soluble polymer (for example, polyvinyl alcohol, carboxymethyl cellulose, gelatin, etc.) or water-swellable polymer (for example, polyvinyl acetate, polyacrylic acid) And water-sensitive adhesives such as sodium).

- SEBS styrene-ethylene-butadiene-styrene

- SBS styrene-butadiene-styrene

- SIS styrene-isoprene

- the coating amount (basis weight) of the adhesive is usually 0.1 to 200 g / m 2 , preferably 1 to 100 g / m 2 .

- the length and width of the covering sheets 42 and 43 are larger than the length and width of the absorbent core 41, and the portion of the covering sheets 42 and 43 that extends from the absorbent core 41 is the covering sheet 42. , 43 are bonded by an adhesive applied to at least one of them (for example, a hot melt adhesive). Therefore, in the present embodiment, the entire absorbent core 41 is covered with the covering sheets 42 and 43.

- such a covering form by the covering sheets 42 and 43 is an example of a covering form of the absorbent core by the top sheet side covering sheet and the back sheet side covering sheet, and by the top sheet side covering sheet and the back sheet side covering sheet.

- the covering form of the absorbent core is not limited to this embodiment.

- the length and width of the topsheet-side covering sheet may be substantially the same as or less than the length and width of the topsheet-side surface of the absorbent core.

- the length and width of the backsheet-side cover sheet may be substantially the same as or less than the length and width of the backsheet-side surface of the absorbent core.

- the absorbent core 41 contains absorbent fibers capable of absorbing and holding liquid excretion excreted from the wearer.

- the kind of the absorbent fiber contained in the absorbent core 41 is not particularly limited as long as the liquid excretion excreted from the wearer can be absorbed and retained.

- the absorbent core 41 may contain a superabsorbent material (for example, a superabsorbent resin, a superabsorbent fiber, etc.) in addition to the absorbent fiber.

- the absorbent core 41 is made of an antioxidant, a light stabilizer, an ultraviolet absorber, a neutralizer, a nucleating agent, an epoxy stabilizer, a lubricant, an antibacterial agent, a flame retardant, an antistatic agent, a pigment, a plasticizer, and the like. You may contain an additive as needed.

- the absorptive fibers include cellulosic fibers

- examples of the cellulosic fibers include wood pulp obtained from softwood or hardwood as a raw material (for example, groundwood pulp, refiner ground pulp, thermomechanical pulp, chemithermomechanical).

- Machine pulp such as pulp; chemical pulp such as kraft pulp, sulfide pulp and alkali pulp; semi-chemical pulp etc.); mercerized pulp or crosslinked pulp obtained by subjecting wood pulp to chemical treatment; bagasse, kenaf, bamboo, hemp, Non-wood pulp such as cotton (for example, cotton linter); regenerated cellulose such as rayon and fibril rayon; semi-synthetic cellulose such as acetate and triacetate.

- the superabsorbent material examples include starch, cellulose, and synthetic polymer superabsorbent materials.

- examples of the starch-based or cellulose-based superabsorbent material include starch-acrylic acid (salt) graft copolymers, saponified starch-acrylonitrile copolymers, and crosslinked products of sodium carboxymethyl cellulose.

- high-absorbency materials include polyacrylates, polysulfonates, maleic anhydrides, polyacrylamides, polyvinyl alcohols, polyethylene oxides, polyaspartates, polyglutamates , Polyalginate-based, starch-based, cellulose-based superabsorbent resins (Superabsorbent® Polymer: SAP), etc., among which polyacrylate-based (especially sodium polyacrylate-based) superabsorbent Resins are preferred.

- the shape of the superabsorbent material include a particulate shape, a fibrous shape, and a scaly shape. In the case of the particulate shape, the particle size is preferably 50 to 1000 ⁇ m, more preferably 100 to 600 ⁇ m. .

- the absorbent core 41 contains a superabsorbent material (for example, a superabsorbent resin, a superabsorbent fiber, etc.), the content of the superabsorbent material is usually 5 to 80% by mass of the absorbent core 41, preferably Is 10 to 60% by mass, more preferably 20 to 40% by mass.

- a superabsorbent material for example, a superabsorbent resin, a superabsorbent fiber, etc.

- the thickness, basis weight, and the like of the absorbent core 41 can be appropriately adjusted according to characteristics (for example, absorbency, strength, lightness, etc.) that the sanitary napkin 1 should have.

- the thickness of the absorbent core 41 is usually 0.1 to 20 mm, preferably 1 to 15 mm, and the basis weight is usually 30 to 1500 g / m 2 , preferably 50 to 1000 g / m 2 .

- the top sheet side covering sheet 42 and the back sheet side covering sheet 43 are liquid permeable sheets through which liquid excretion excreted from the wearer can permeate.

- the kind, thickness, basis weight, etc. of the liquid permeable sheet used as the top sheet side covering sheet 42 and the back sheet side covering sheet 43 are not particularly limited as long as the liquid excretion excreted from the wearer can permeate.

- Examples of the liquid permeable sheet used as the top sheet side covering sheet 42 and the back sheet side covering sheet 43 include a nonwoven fabric, a woven fabric, and a synthetic resin film in which liquid permeable holes are formed. Nonwoven fabric is preferred.

- the specific example of the fiber which comprises a nonwoven fabric, and the specific example of the manufacturing method of a nonwoven fabric are the same as the specific example described regarding the top sheet 2.

- nonwoven fabric used as the top sheet side coating sheet 42 and the back sheet side coating sheet 43 for example, an air-through nonwoven fabric, a spunbond nonwoven fabric, a point bond nonwoven fabric, a spunlace nonwoven fabric, a needle punch nonwoven fabric, a melt blown nonwoven fabric, and a combination thereof (for example, spunbond, meltblown, spunbond (SMS) non-woven fabric, etc.) are mentioned.

- the non-woven fabric used as the topsheet-side covering sheet 42 is preferably an air-through non-woven fabric

- the nonwoven fabric used as 43 is preferably an SMS nonwoven fabric or an airlaid nonwoven fabric.

- the air-through nonwoven fabric has a relatively large interfiber distance

- the use of the air-through nonwoven fabric as the top sheet-side covering sheet 42 can suppress the retention of liquid excrement in the top sheet-side covering sheet 42, thereby The transferability of liquid excretion from the sheet-side covering sheet 42 to the absorbent core 41 can be improved.

- the SMS nonwoven fabric has high rigidity, by using the SMS nonwoven fabric as the backsheet-side covering sheet 43, deformation that may occur during use of the sanitary napkin 1 can be suppressed.

- the backsheet-side covering sheet 43 by using an airlaid nonwoven fabric as the backsheet-side covering sheet 43, the liquid excrement transferred from the absorbent core 41 to the backsheet-side covering sheet 43 can diffuse in the surface direction of the backsheet-side covering sheet 43. Thereby, the absorptivity and the retainability of the liquid excrement of the absorber 4 can be improved.

- the backsheet-side covering sheet 43 is an airlaid nonwoven fabric containing hydrophilic fibers, such an effect becomes more remarkable.

- the air-through nonwoven fabric can be produced, for example, by spraying hot air on a web containing thermoplastic resin fibers to heat-seal the thermoplastic resin fibers, and the air-laid nonwoven fabric can be produced, for example, from a web containing hydrophilic fibers. After forming by the airlaid method, it can be produced by bonding the fibers constituting the web with a binder.

- Specific examples of the hydrophilic fiber are the same as the specific examples of the absorbent fiber described for the

- the nonwoven fabric used as the top sheet side covering sheet 42 and the back sheet side covering sheet 43 is a nonwoven fabric containing thermoplastic resin fibers. Thereby, the intensity

- the thermoplastic resin fiber may be hydrophilized. Specific examples of the thermoplastic resin fibers and specific examples of the hydrophilic treatment of the thermoplastic resin fibers are the same as the specific examples described for the top sheet 2.

- the pressing recess 45 formed by pressing the backsheet-side covering sheet 43 in the direction of the absorbent core 41 has a concave surface toward the topsheet 2.

- a space is formed between the compressed recess 45 and the backsheet 3.

- the absorber 4 has a central portion 40a located in the center in the longitudinal direction Y, and both side portions 40b and 40c located on both sides in the longitudinal direction Y with respect to the central portion 40a.

- the pressing recess 45 is formed in the both side portions 40b and 40c, but is not formed in the central portion 40a.

- liquid excrement having a relatively high flow rate immediately after being supplied to the top sheet 2 can be absorbed.

- the liquid excrement having a relatively low flow velocity flowing through the surface of the top sheet 2 is absorbed by the absorbent body 4. Can be pulled into.

- the pressing recess 45 includes a high-pressure pressing recess 451 and a low-pressure pressing recess 452.

- “High-pressure expression” and “low-pressure expression” mean the relative height of the expression, and as shown in FIG. 3, the thickness of the high-pressure depression 451 formed by high-pressure expression is compared with the thickness of the low-pressure depression 452. Thus, the thickness of the low-pressure depression 452 formed by low-pressure squeezing is relatively larger than the thickness of the high-pressure depression 451.

- the thickness of the high-pressure depression 451 is preferably 0.05 to 0.3 mm, more preferably 0.05 to 0.2 mm, and the thickness of the low-pressure depression 452 is preferably 0.3 to 0.8 mm, Preferably, it is 0.3 to 0.7 mm.

- the fiber density of the high-pressure squeezed recess 451 formed by high-pressure squeezing is relatively large compared to the fiber density of the low-pressure squeezed concave 452, and the fiber density of the low-pressure squeezed concave 452 formed by low-pressure squeezing is The fiber density is relatively large.

- the fiber density of the high-pressure depression 451 is preferably 0.15 to 0.30 g / cm 3 , more preferably 0.15 to 0.25 g / cm 3

- the fiber density of the low-pressure depression 452 is preferably 0. 0.06 to 0.2 g / cm 3 , more preferably 0.08 to 0.15 g / cm 3 .

- the fiber density of the low pressing recessed part 452 is smaller than the thickness of the area

- the stiffness of 452 is higher than the stiffness of region 46.

- the fiber density of the low pressure recessed part 452 is larger than the fiber density of the groove part 22. Therefore, the transferability of the liquid excretion from the groove part 22 to the low pressing recessed part 452 can be improved using the characteristic of the liquid that it is easy to transfer to a part with a high fiber density from a part with a low fiber density.

- the fiber density of the high pressure recessed part 451 is larger than the fiber density of the collar part 21. Therefore, the liquid excretion remaining in the flange portion 21 and the groove portion 22 of the top sheet 2 is drawn into the high-pressure squeezed recess portion 451 by utilizing the characteristic of the liquid that it is easy to shift from the low fiber density portion to the high fiber density portion. be able to.

- the low pressing recesses 452 are formed in a mesh pattern, and the high pressing recesses 451 are mesh-like. It is formed so as to be scattered in the pattern.

- the high-pressure recessed portion 451 is formed in the intersecting region of the mesh pattern.

- the high pressing recesses 451 are scattered in the short direction X and the long direction Y

- the low pressing recesses 452 are formed so as to connect the high pressing recesses 451 in the short direction X and the long direction Y.

- the mesh pattern of the low pressure depression 452 can be maintained.

- each mesh in the mesh pattern of the low-pressure depression 452 is a regular hexagon, and the high-pressure depression 451 is arranged at the apex of the regular hexagon,

- the low pressure recessed part 452 is arrange

- one high pressing recessed part 451 is comprised by four component 451a, 451b, 451c, 451d which adjoins mutually, and component 451a, 451b, 451c, 451d are each formed in a rectangular shape in plan view.

- the low pressing recessed part 452 is arrange

- the low pressure depression 452 (the low pressure depression 452 extending from the high pressure depression 451 downward, upper left and right upward, respectively, a first low pressure depression 452p, a second low pressure depression 452q, and a third low pressure depression 452r, respectively.

- the angle ⁇ 1 formed by the first low pressure depression 452p and the second low pressure depression 452q, the angle ⁇ 2 formed by the first low pressure depression 452p and the third low pressure depression 452r, and the second The angle ⁇ 3 formed by the low-pressure depression 452q and the third low-pressure depression 452r is 120 degrees. That is, in this embodiment, in the three low-pressure depressions 452 extending from one high-pressure depression 451, the first direction in which one arbitrarily selected low-pressure depression 452 extends and the remaining low-pressure depressions 452 are arbitrarily selected.

- the plurality of low-pressure squeezing recesses 452 are arranged so that the second direction in which the single low-squeezing recess 452 extends is not 180 degrees (so as not to be linear).

- Such an arrangement pattern of the high pressing depression 451 and the low pressing depression 452 is an example of an arrangement pattern of the high pressing depression and the low pressing depression, and the arrangement pattern of the high pressing depression and the low pressing depression is limited to the present embodiment. It is not something.

- the pressing recess 45 is formed by heat embossing the absorbent body 4 from the cover sheet 43 side.

- a predetermined portion of the surface of the backsheet-side covering sheet 43 is compressed in the direction of the absorbent core 41 until reaching the topsheet-side covering sheet 42 and heated, whereby the backsheet-side covering sheet 43 is heated.

- a high-pressure recessed portion 451 for integrating the absorbent core 41 and the top sheet-side covering sheet 42 is formed.

- the predetermined portion of the surface of the backsheet side covering sheet 43 is compressed in the direction of the absorbent core 41 until reaching the absorbent core 41 and heated, whereby the backsheet side covering sheet 43 and the absorption are obtained.

- a low-pressure squeezed recess 452 that integrates the sex core 41 is formed.

- the heat embossing treatment is performed, for example, between an embossing roll having convex portions provided on the outer peripheral surface and a flat roll having a smooth outer peripheral surface, the back sheet side covering sheet 43, the absorbent core 41, and the top sheet side covering sheet. It is carried out by passing the laminated body in which 42 is sequentially laminated and embossing from the back sheet side covering sheet 43 side. Under the present circumstances, the heating at the time of compression is possible by heating of an embossing roll and / or a flat roll.

- the convex part of the embossing roll is provided so as to correspond to the shape, arrangement pattern, and the like of the high-pressure recessed part 451 and the low-pressure recessed part 452.

- a method for forming the pressing recess 45 including the high-pressure pressing recess 451 and the low-pressure pressing recess 452 is described in detail in Japanese Patent Application Laid-Open No. 2013-78366.

- the high pressing recessed portion 451 appears on the top sheet side surface of the top sheet side covering sheet 42 because the back sheet side covering sheet 43, the absorbent core 41 and the top sheet side covering sheet 42 are integrated.

- the low-pressure recessed portion 452 does not appear on the top sheet side surface of the top sheet side covering sheet 42 because the back sheet side covering sheet 43 and the absorbent core 41 are integrated.

- the high-pressure recessed portion 451 integrates the backsheet-side covering sheet 43, the absorbent core 41 and the topsheet-side covering sheet 42, but the backsheet-side covering sheet 43 and the absorbent core 41 are integrated. It may be converted.

- the backsheet side covering sheet 43 and / or the absorbent core 41 is effectively integrated by integrating the backsheet side covering sheet 43 and the absorbent core 41 by thermal fusion of thermoplastic resin fibers. It is preferable to contain a thermoplastic resin fiber. In the heat embossing treatment, the back sheet side covering sheet 43, the absorbent core 41, and the top sheet side covering sheet 42 are effectively integrated by thermal fusion of thermoplastic resin fibers. It is preferable that one or two or more of the absorbent core 41 and the topsheet-side covering sheet 42 contain thermoplastic resin fibers.

- the thermoplastic resin fiber may be hydrophilized. Specific examples of the thermoplastic resin fibers and specific examples of the hydrophilic treatment of the thermoplastic resin fibers are the same as the specific examples described for the top sheet 2.

- the sanitary napkin 1 has an inner pressing groove 5a and an outer pressing groove 5b formed by pressing the top sheet 2 in the direction of the absorbent body 4.

- the inner side pressing groove 5a is intermittently formed in the periphery of the surface area

- the outer side pressing groove 5b is formed in the outer side of the inner side pressing groove 5b.

- a pressing groove is not essential for the sanitary napkin 1, and the presence / absence of the inner pressing groove and the outer pressing groove, the formation pattern, and the like can be changed as appropriate.

- the inner pressing groove 5a and the outer pressing groove 5b are recesses formed by heat embossing.

- a predetermined part of the skin side surface of the top sheet 2 is compressed and heated in the direction of the absorbent body 4 until it reaches the absorbent core 41.

- the inner side pressing groove 5a and the outer side pressing groove 5b which integrate the top sheet 2, the top sheet side coating sheet 42, and the absorptive core 41 are formed as a recessed part.

- the top sheet 2 and the absorbent body 4 are passed between an embossing roll having convex portions provided on the outer peripheral surface and a flat roll having a smooth outer peripheral surface, and from the top sheet 2 side.

- embossing Implemented by embossing.

- the heating at the time of compression is possible by heating of an embossing roll and / or a flat roll.

- the convex part of the embossing roll is provided so as to correspond to the shape, arrangement pattern, and the like of the inner pressing groove 5a and the outer pressing groove 5b.

- the heating temperature is usually 80 to 180 ° C., preferably 120 to 160 ° C.

- the pressure is 10 to 3000 N / mm, preferably 50 to 500 N / mm

- the treatment time is usually 0.0001 to 5 seconds, preferably 0. 0.005 to 2 seconds.

- the top sheet 2, the top sheet side covering sheet 42, and the absorbent core 41 are effectively integrated by thermal fusion of thermoplastic resin fibers. And it is preferable that 1 or 2 or more of the absorptive core 41 contains a thermoplastic resin fiber.

- FIG. 7 shows a projection region of the groove portion 22 that is generated when the groove portion 22 of the top sheet 2 and the low-pressure depression 452 of the absorber 4 are projected onto a virtual plane P (see FIGS. 1 to 3) perpendicular to the thickness direction Z. It is a partial enlarged view of the virtual plane P which shows the overlap with the projection area

- the projection region R1 of the groove 22 is shown on the back side of the drawing, and the projection region R2 of the low-pressure depression 452 is shown on the front side of the drawing.

- the projection area R1 of the groove 22 has an overlap L with the projection area R2 of the low-pressure depression 452. That is, the groove part 22 and the low pressure recessed part 452 are arrange

- the ratio of the portion overlapping the projection region R2 of the low-pressure depression 452 in the projection region R1 of the groove 22 is preferably 2% or more, more preferably 5% or more, and even more preferably 7% or more. Thereby, the transferability of the liquid excretion from the groove part 22 of the top sheet 2 to the low pressing recessed part 452 of the absorber 4 can be improved.

- the ratio of the portion overlapping the projection region R2 of the low-pressure depression 452 in the projection region R1 of the groove 22 is usually 50% or less, preferably 30% or less.

- region of the high pressing recessed part 451 is included in the projection area

- the low-pressure recessed portion 452 has an extending portion (for example, the first low-pressure recessed portion 452 p) extending in the longitudinal direction Y, and the projection region R ⁇ b> 1 of the groove portion 22. However, it has the overlap L with the projection area

- the proportion of the portion of the extended portion of the low-pressure depression 452 that overlaps with the projection region R21 is preferably 5% or more, more preferably 7% or more, and even more preferably 10% or more. .

- region R1 of the groove part 22 is 50% or less normally, Preferably it is 30% or less.

- the overlap L between the projection region R1 of the groove 22 and the projection region R21 of the extended portion of the low-pressure depression 452 extends over the entire short direction X of the projection region R1 of the groove 22. Arise. Thereby, the transferability of the liquid excretion from the groove part 22 of the top sheet 2 to the extension part of the low pressing recessed part 452 can be improved.

- the width of the groove portion 22 is equal to or less than the width of the low-pressure recessed portion 452.

- the overlap L between the projection region R1 of the groove 22 and the projection region R2 of the low-pressure squeezed recess 452 is the projection of the extended portion of the projection region R1 of the groove 22 and the low-squeeze dent 452. This coincides with the overlap L with the region R21.

- the projection area of the groove portion has an overlap with the projection area of the portion other than the extension portion of the low-pressure depression in addition to the overlap with the projection area of the extension portion of the low-pressure depression. May be changed. Such a change can be realized by changing the number of grooves and / or the interval. For example, in FIG.

- the groove projection area overlaps with the projection area of the extension portion of the low-pressure depression, It will have an overlap with the projection area

- the projection region of the groove portion is the same as the projection region of the extension portion of the low-pressure depression.

- the projection region of the portion other than the extended portion of the low-pressure recessed portion there will be an overlap with the projection region of the portion other than the extended portion of the low-pressure recessed portion. Two or more kinds of these changes may be combined.

- the top sheet 2 is a non-woven fabric having a ridge portion 21 corresponding to a high fiber density region and a groove portion 22 corresponding to a low fiber density region

- the absorbent body 4 includes an absorbent core 41 containing absorbent fibers and an absorbent.