WO2014007073A1 - ペット用吸収性シートおよびペット用吸収性シートの製造方法 - Google Patents

ペット用吸収性シートおよびペット用吸収性シートの製造方法 Download PDFInfo

- Publication number

- WO2014007073A1 WO2014007073A1 PCT/JP2013/067011 JP2013067011W WO2014007073A1 WO 2014007073 A1 WO2014007073 A1 WO 2014007073A1 JP 2013067011 W JP2013067011 W JP 2013067011W WO 2014007073 A1 WO2014007073 A1 WO 2014007073A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- sheet

- absorbent

- pets

- layer

- absorber

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01K—ANIMAL HUSBANDRY; AVICULTURE; APICULTURE; PISCICULTURE; FISHING; REARING OR BREEDING ANIMALS, NOT OTHERWISE PROVIDED FOR; NEW BREEDS OF ANIMALS

- A01K1/00—Housing animals; Equipment therefor

- A01K1/01—Removal of dung or urine ; Removal of manure from stables

- A01K1/0107—Cat trays; Dog urinals; Toilets for pets

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01K—ANIMAL HUSBANDRY; AVICULTURE; APICULTURE; PISCICULTURE; FISHING; REARING OR BREEDING ANIMALS, NOT OTHERWISE PROVIDED FOR; NEW BREEDS OF ANIMALS

- A01K1/00—Housing animals; Equipment therefor

- A01K1/015—Floor coverings, e.g. bedding-down sheets ; Stable floors

- A01K1/0152—Litter

-

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01K—ANIMAL HUSBANDRY; AVICULTURE; APICULTURE; PISCICULTURE; FISHING; REARING OR BREEDING ANIMALS, NOT OTHERWISE PROVIDED FOR; NEW BREEDS OF ANIMALS

- A01K1/00—Housing animals; Equipment therefor

- A01K1/015—Floor coverings, e.g. bedding-down sheets ; Stable floors

- A01K1/0157—Mats; Sheets

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/10—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the pressing technique, e.g. using action of vacuum or fluid pressure

- B32B37/1027—Pressing using at least one press band

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/14—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers

- B32B37/16—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers with all layers existing as coherent layers before laminating

- B32B37/18—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the properties of the layers with all layers existing as coherent layers before laminating involving the assembly of discrete sheets or panels only

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/726—Permeability to liquids, absorption

Definitions

- the present invention relates to a construction technique for a pet absorbent sheet and a method for producing a pet absorbent sheet.

- Japanese Patent Application Laid-Open No. 2011-205979 discloses a pet absorbent sheet having a liquid-permeable top sheet, a liquid-impervious back sheet, and an absorbent body disposed between both sheets. ing.

- the top sheet, the absorbent body, and the second sheet interposed between the top sheet and the absorbent body are joined and integrated by embossing.

- the embossing is a technique in which a sheet-like material is supplied and pressed to a concavo-convex roll or plate to press-mold a predetermined convex relief pattern or concave dent pattern on the absorbent sheet.

- a method is used in which the sheet is integrally formed by forming a convex or concave pattern by such embossing in a predetermined region.

- the absorbent sheet for pets is integrally formed by embossing

- the absorbent body (and the surface sheet) is relatively embossed by the embossing, compared to the portion not embossed. A region having a high basis weight is formed.

- the excrement from a pet contains a lot of moisture, the excrement diffuses widely in the surface direction of the absorbent sheet along the high weight area where the embossing is performed.

- the aim is to avoid the concentration of excrement locally in the absorbent sheet by promoting diffusion of the excrement in the surface direction of the absorption sheet in this way.

- an object of the present invention is to provide a technique capable of effectively absorbing excrement in an absorbent sheet for pets.

- the solution according to the present invention includes a liquid-permeable top sheet that receives pet excrement, a liquid-impermeable back sheet, and the top sheet and the back sheet that are transmitted through the top sheet.

- An absorber that absorbs the liquid, and the top sheet is configured to receive pet excrement in a state where the back sheet is placed on the place of placement.

- It is configured as a non-embossed region having a front surface side covering sheet facing the front surface sheet, a back surface side covering sheet facing the back surface sheet, and an absorbent layer disposed between the front surface side covering sheet and the back surface side covering sheet,

- a main absorption part of excrement is provided in the central region of the absorber, and the basis weight of the absorber at least in the main absorption region is 40 g / m 2 to 220 g / m 2 .

- it is configured as an absorbent sheet for pets that is set to be substantially uniform at a predetermined value within a range of 50 g / m 2 to 150 g / m 2 .

- the absorbent layer is bonded to at least one of the front surface side coating sheet and the rear surface side coating sheet through an adhesive throughout.

- the absorption layer includes an absorption first layer having hydrophilic fibers and an absorption second layer having a hydrophilic resin.

- the second absorption layer is disposed between the surface-side coating sheet and the first layer, and at least the surface-side coating sheet and the absorption second layer. The layers are joined together through the adhesive.

- an average basis weight of the absorption first layer is a predetermined value within a range of 30 g / m 2 to 150 g / m 2 , more preferably 40 g / m 2 to 100 g / m 2.

- the average weight of the second absorption layer is 10 g / m 2 to 70 g / m 2 , more preferably 10 g / m 2 to 50 g. / M 2 is set to a predetermined value within the range.

- the first absorption layer is made of a pulp material.

- the second absorption layer is made of a highly water-absorbing polymer.

- the topsheet is configured to receive pet excrement in a state where the backsheet is placed on a placement location, and the absorber is the topsheet

- the absorber is the topsheet

- the manufacturing method of the absorptive sheet for pets formed by the surface side covering sheet facing the back surface, the back surface side covering sheet facing the back surface sheet, and the absorbent layer disposed between the surface side covering sheet and the back surface side covering sheet

- pet method of manufacturing an absorbent sheet which comprises forming an absorber having a non-embossed region is formed.

- the pressure part is constituted by a pressure roller having a curved pressure surface that does not have an uneven part on the surface.

- the thickness of the laminate after being fed to the pressurizing unit and being pressurized is before the laminate is fed to the pressurizing unit. It is configured to be fixed at a predetermined value smaller than the thickness.

- a main absorption part of excrement is provided in the central region of the absorber, and the basis weight of at least the main absorption region of the absorber is from 40 g / m 2. It is set to be substantially uniform at a predetermined value within a range of 220 g / m 2 , more preferably 50 g / m 2 to 150 g / m 2 .

- the absorbent sheet for pets is formed by joining the top sheet and the back sheet to the absorbent body. To do.

- a technique capable of effectively absorbing excrement in the pet absorbent sheet is provided.

- the whole structure of the pet absorbent sheet 100 according to the first embodiment of the present invention is schematically shown.

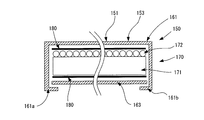

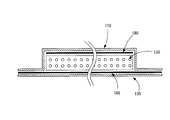

- 1 schematically shows a cross-sectional structure taken along the line II in FIG. 1 schematically shows an absorbent cross-sectional structure according to a first embodiment of the present invention.

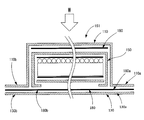

- the detail of the cross-section of the absorbent sheet 100 for pets concerning 1st Embodiment of this invention is shown.

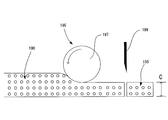

- the manufacturing process of the absorbent sheet 100 for pets concerning 1st Embodiment of this invention is shown roughly.

- the manufacturing process of the absorbent sheet 100 for pets concerning 1st Embodiment of this invention is shown roughly.

- the cross-section of the absorptive sheet for pets concerning a 2nd embodiment of the present invention is shown roughly.

- Embodiments of the present invention relate to an absorbent sheet for pets and a method for producing the same.

- the “pet” in the present embodiment widely includes vertebrates (mammals, reptiles, birds, amphibians) and invertebrates, but typically, pets such as cats, dogs, rabbits, hamsters, and the like. It corresponds to.

- This pet absorbent sheet is provided between a top sheet and a back sheet, and absorbs excretion that has passed through the top sheet, provided between the top sheet and the back sheet. Having a body.

- the top sheet and the back sheet are also referred to as a top sheet and a bottom sheet, respectively.

- This pet absorbent sheet is a flat sheet having a predetermined thickness, spread in a flat state, and in a state where the back sheet is placed at the placement location, the pet receiving excrement, Has a pet use mode.

- the pet absorbent sheet according to the present embodiment is preferably configured as a rectangular (rectangular or square) sheet, but may be configured as a circle, an ellipse, or a polygon.

- the term “pet excrement” here includes not only pet manure but also body fluids such as saliva and menstrual blood.

- the top sheet is a flat excrement receiving surface (hereinafter also referred to as a main absorption area) that receives pet excrement in a non-contact state with the pet, and allows the pet to walk.

- the pet absorbent sheet is laid directly on the floor or the like, or the pet absorbent sheet is attached to the holding holder and the holding holder is installed on the floor or the like. And the like are included.

- the top sheet and the back sheet are formed so as to be slightly larger than the absorbent body, and the peripheral edges of the top sheet and the back sheet are joined to each other while the absorbent body is disposed therebetween. Thereby, it is possible to reliably cover the absorber with the top sheet and the back sheet.

- the surface sheet can be composed of, for example, a nonwoven fabric made of thermoplastic fibers, and is composed of, for example, a spunbond nonwoven fabric composed of thermoplastic long fibers, an air-through nonwoven fabric composed of thermoplastic short fibers, a point bond nonwoven fabric, or an apertured film. It is preferable.

- the back sheet is particularly preferably composed of a resin film sheet.

- This back sheet can be configured using, for example, a film of polyethylene, polypropylene, polyethylene terephthalate, or the like.

- coated the water repellent to the nonwoven fabric can also be used.

- the absorber is formed by a surface side covering sheet facing the surface sheet, a back surface covering sheet facing the back sheet, and an absorbent layer disposed between the surface side covering sheet and the back surface covering sheet.

- the covering sheet is also called a carrier tissue or the like, and can be formed of a tissue made of softwood pulp, for example.

- the covering sheet can also be configured as a nonwoven fabric sheet made of thermoplastic fibers, particularly a sheet containing a melt blown nonwoven fabric. Specifically, it is possible to use a three-layer structure in which a spunbond nonwoven fabric is superposed on both sides of the melt blown nonwoven fabric sheet. This three-layer nonwoven fabric sheet is also referred to as “SMS nonwoven fabric sheet”.

- the covering sheet in the present embodiment can be composed of a material or property having absorbability itself, and is itself composed of a material or property having liquid permeability, as well as absorption and retention. It is good also as a structure which takes over to an absorption layer.

- the “absorbing layer” is intended to be a laminated structure of a plurality of absorptive members having different materials, properties, or absorptive properties, or may be a single-layered structure of a single absorptive member.

- the material of the absorbent layer typically corresponds to an absorbent resin material or a fiber assembly.

- the absorber according to the present invention has a front surface side covering sheet facing the front surface sheet, a back surface side covering sheet facing the back surface sheet, and a non-absorbing layer disposed between the front surface side covering sheet and the back surface side covering sheet. Configured as an embossing area.

- the “non-embossing region” corresponds to a region where the embossing process is not performed.

- “Embossing” as used herein refers to a technique for pressing and molding a predetermined convex embossed pattern or concave indented pattern on an absorbent sheet by supplying and pressing a sheet-like material to an uneven roll or plate. is there.

- a main absorption part of excrement is provided in the central region of the absorber, and the basis weight of at least the main absorption region of the absorber is 40 g / m 2 to 220 g / m 2 , Preferably, it is set to be substantially uniform at a predetermined value in the range of 50 g / m 2 to 150 g / m 2 .

- the constituent layers of the absorbent sheet for pets are bonded by pressure bonding, but in the present embodiment, as described above, the absorbent layer is bonded to the surface side covering sheet and Because it is configured to be integrated by bonding via an adhesive throughout at least one of the back surface side coating sheet, by further constructing the absorber as a non-embossed region, securing the bonding strength, It is possible to effectively secure both of excessive diffusion suppression of excrement.

- the non-embossing region in the present invention is a configuration for avoiding a local increase in the basis weight of the absorber due to the embossing, if such avoidance is possible, Even if some uneven regions are formed, they are still included in the non-embossed region of the present invention.

- the absorption layer includes an absorption first layer having hydrophilic fibers, and an absorption layer disposed between the surface-side covering sheet and the first layer while having a water absorbent resin.

- the absorption basis weight of the first absorption layer is set to a predetermined value within a range of 30 g / m 2 to 150 g / m 2 , more preferably 40 g / m 2 to 100 g / m 2 . Is preferred.

- the absorbent layer has an absorbent first layer having hydrophilic fibers and a water absorbent resin and is disposed between the surface-side covering sheet and the first layer.

- an average basis weight of the second absorption layer is set to a predetermined value within a range of 10 g / m 2 to 70 g / m 2 , more preferably 10 g / m 2 to 50 g / m 2. It is preferable.

- the absorbent layer is bonded to at least one of the front surface side coating sheet and the back surface side coating sheet through an adhesive throughout. “At least one” of the front surface side covering sheet and the back surface side covering sheet is sufficient if the absorbent layer is fixed to any one of the covering sheets. Of course, you may join to the coating sheet of both the surface side and a back surface side. “Overall” bonding means that it is sufficient that the absorption layer is bonded to at least one of the front-side coating sheet and the back-side coating sheet, and the entire surface of the absorption layer (ie, 100%).

- both the form in which the adhesive is applied over the surface and the form in which the absorbent layer is entirely joined to the covering sheet while partially applying the adhesive to the surface of the absorbent layer are suitably included.

- the adhesive is spirally, latticed, or striped in order to ensure a liquid-permeable passage from the surface sheet to the absorbent layer.

- it is preferable to apply in a discontinuous pattern such as a shape or a dotted shape, such a form shall satisfy “overall” in the present invention.

- the heat-fusible adhesive is also referred to as HMA (Hot Melting Adhesive), and refers to an adhesive that melts by heating and exhibits adhesive ability.

- HMA Hot Melting Adhesive

- the absorbent layer in the absorbent body is bonded to at least one of the front surface side covering sheet and the back surface side covering sheet through the adhesive throughout, thereby absorbing layer. Can be firmly bonded to the cover sheet side.

- the absorbent layer may be inadvertently moved or lifted up to hinder the usability. It is possible to prevent it.

- the absorption layer has an absorption first layer having hydrophilic fibers and an absorption second layer having a hydrophilic resin.

- the absorbent sheet for pets according to the present invention is a technique related to the absorption structure of the liquid in excrement such as pet urine and stool, the absorption target is not necessarily limited to “water” in a narrow sense.

- the hydrophilicity of the pet's excrement falls under this category. It is preferable to adopt an embodiment using a fiber or a resin.

- the said absorption 1st layer is comprised with the pulp material, and it is preferable that the said pulp material has an average fabric weight of 60 g / m ⁇ 2 >.

- the said absorption 2nd layer is comprised with the highly water-absorbing polymer excellent in the water absorption characteristic regarding hydrophilic resin especially.

- the superabsorbent polymer may be configured as a blend polymer in which a plurality of superabsorbent polymers (also referred to as “SAP” Super Absorbent Polymer) are blended.

- the superabsorbent polymer constituting the second absorption layer preferably has an average basis weight of 39 g / m 2 .

- the water absorption rate based on the vortex method is set to 10 seconds or less.

- the second absorption layer it is disposed between the surface-side coating sheet and the first absorption layer, and at least the surface-side coating sheet and the second absorption layer, It is preferable that the entire structure is joined through the adhesive. Moreover, it is preferable to set it as the structure by which the said back surface side coating sheet and the said absorption 1st layer are joined via the said adhesive agent over the whole. With these configurations, it is possible to reliably and firmly join the constituent members of the absorber.

- a liquid-permeable top sheet, a liquid-impermeable back sheet, and a liquid that is transmitted through the top sheet are provided between the top sheet and the back sheet.

- An absorbent body, and the top sheet is configured to receive pet excrement in a state where the back sheet is placed on a placement place, and the absorbent body is a surface facing the top sheet.

- the “non-embossing region” corresponds to a region where the embossing process is not performed.

- Embossing refers to a technique for pressing and molding a predetermined convex embossed pattern or concave indented pattern on an absorbent sheet by supplying and pressing a sheet-like material to an uneven roll or plate. is there.

- the non-embossing region in the present invention is a configuration for avoiding a local increase in the basis weight of the absorber due to the embossing, if such avoidance is possible, Even if some uneven regions are formed, they are still included in the non-embossed region of the present invention.

- the pressure portion is constituted by a pressure roller having a curved pressure surface that does not have an uneven portion on the surface.

- the thickness of the laminate after being fed to the pressurizing unit and being pressurized is fixed at a predetermined value smaller than the thickness of the laminate before being fed to the pressurizing unit. It is configured as follows.

- the absorbent sheet for pets is provided with a main absorption part of excrement in the central region of the absorber, and the basis weight of the absorber is at least 40 g / in the main absorption region. It is preferably set so as to be substantially uniform at a predetermined value within a range of m 2 to 220 g / m 2 , more preferably 50 g / m 2 to 150 g / m 2 .

- the basis weight of the absorber is at least 40 g / in the main absorption region. It is preferably set so as to be substantially uniform at a predetermined value within a range of m 2 to 220 g / m 2 , more preferably 50 g / m 2 to 150 g / m 2 .

- the overall configuration of the pet absorbent sheet 100 according to the first embodiment of the present invention is shown as a perspective view in FIG. 1, and the cross-sectional structure of the pet absorbent sheet 100 taken along the line II in FIG. This is schematically shown in FIG.

- the pet absorbent sheet 100 is mainly composed of a top sheet 110, a back sheet 130 placed on the placement surface F, and an absorbent body 150 provided between the top sheet 110 and the back sheet 130.

- the top sheet 110 is an example of a configuration corresponding to the “top sheet” in the present invention.

- the back sheet 130 is an example of a configuration corresponding to the “back sheet” in the present invention.

- the absorber 150 is an example of a configuration corresponding to the “absorber” in the present invention.

- the top sheet 110 can be composed of, for example, a nonwoven fabric made of thermoplastic fibers, and is composed of, for example, a spunbond nonwoven fabric composed of thermoplastic long fibers, an air-through nonwoven fabric composed of thermoplastic short fibers, a point bond nonwoven fabric, or an apertured film.

- the back sheet 130 is constituted by a resin film sheet.

- the detailed structure of the absorbent body 150 in the pet absorbent sheet 100 is shown in a sectional view in FIG.

- the absorbent body 150 has a front-side tissue layer 161 and a back-side tissue layer 163 that form the outer structure of the absorbent body 150, and constitutes an absorbent first layer while being covered with both tissue layers 161 and 163.

- An absorbent layer 170 including a pulp layer 171 and a superabsorbent polymer layer 172 constituting the second absorbent layer is disposed.

- the present invention is an improved technique relating to the absorption structure of liquid components in pet excrement, and the absorption target includes manure, saliva, menstrual blood, and the like, and is not necessarily limited to “water”.

- the surface-side tissue layer 161 is an example of a configuration corresponding to the “surface-side covering sheet” in the present invention.

- the back side tissue layer 163 is an example of a configuration corresponding to the “back side covering sheet” in the present invention.

- the absorption layer 170 is an example of a configuration corresponding to the “absorption layer” in the present invention.

- the pulp layer 171 is an example of a configuration corresponding to “pulp material” or “absorption first layer” in the present invention.

- the superabsorbent polymer layer 172 is an example of a configuration corresponding to the “absorbing second layer” in the present invention.

- the superabsorbent polymer layer 172 in this embodiment is provided so as to be located between the surface side tissue layer 161 and the pulp layer 171.

- the front surface tissue layer 161 has bent portions 161 a and 161 b that are set to be folded back so as to overlap the upper portion of the end region of the back surface tissue layer 163 in the end region. Thereby, it is comprised so that the absorption layer 170 may be reliably coat

- the front side tissue layer 161 and the back side tissue layer 163 are each formed of tissue.

- the pulp layer 171 constituting the absorption first layer is configured by accumulating pulp materials so as to have an average basis weight of approximately 60 g / m 2 .

- the superabsorbent polymer 172 constituting the absorbent second layer is a resin layer having a plurality of superabsorbent polymer materials (also referred to as “SAP” Super Absorbent Polymer) blended and having an average basis weight of approximately 39 g / m 2. It is configured as.

- the superabsorbent polymer 172 has a water absorption rate based on the vortex method set to 10 seconds or less, and the water absorption rate in the absorber 150 (absorbing layer 170) is optimized.

- the superabsorbent polymer layer 172 in this example is bonded to the surface tissue layer 161 over the entire surface of the superabsorbent polymer layer 172 by a hot melt adhesive 180.

- the lower surface portion of the pulp layer 171 is bonded to the back surface tissue layer 163 over the entire lower surface portion of the pulp layer 171 by the hot melt adhesive 180.

- the hot melt adhesive 180 is also referred to as HMA (Hot Melting Adhesive).

- HMA Hot Melting Adhesive

- the hot melt adhesive 180 is applied to both the tissue layers 161 and 163 in a spiral pattern. Water permeability is ensured in the absorbent layer 170 and the tissue layers 161 and 163.

- the hot melt adhesive 180 in this example is a rubber-based hot containing SIS (styrene-isopropylene-styrene copolymer) or SBS (styrene-butadiene-styrene copolymer) from the standpoint of flexibility and pressure bonding. It is composed of a melt-type adhesive and has a basis weight set to a predetermined value within a range of approximately 0.3 g / m 2 to 2.0 g / m 2 .

- the hot melt adhesive 180 is an example of a configuration corresponding to the “adhesive” or “heat-welding adhesive” in the present invention.

- the absorbent body 150 is disposed between the top sheet 110 and the back sheet 130 and bonded to the sheets 110 and 130 through the hot melt adhesive 180 over substantially the entire surface.

- the top sheet 110 and the back sheet 130 are formed to have a longer dimension than the absorber 150 in a sectional view.

- region 110a, 110b of the surface sheet 110 interposes the absorber 150 by edge part extension area

- the pet absorbent sheet 100 is configured as shown in FIG. In this state, the substantially central region of the pet absorbent sheet 100 is defined as a main absorbent region 151, and the pet absorbent sheet 100 in a state of being placed on the placement surface F (also FIG. 2). Reference), and is configured to receive excrement W.

- the main absorption region 151 is an example of a configuration corresponding to the “main absorption region” in the present invention.

- Absorber 150 has a basis weight of approximately 40 g / m 2 to 220 g / m 2 , more preferably 50 g / m 2 to 150 g / m 2 in a region corresponding to main absorbent portion 151. It is set to be uniform. Thereby, it is effectively prevented that the excrement or the liquid component of the excrement is excessively diffused along the region having a relatively high basis weight.

- FIG. 5 shows a method for manufacturing the absorbent body 150 of the above-described pet absorbent sheet 100.

- a pulp layer 171, a superabsorbent polymer layer 172, a front-side tissue layer 161, and a back-side tissue layer 163 are preliminarily stacked to form the absorbent body 150 shown in FIG.

- a laminate 190 is prepared in a state where the agent 180 is disposed between the superabsorbent polymer layer 172 and the front-side tissue layer 161 and between the pulp layer 171 and the back-side tissue layer 163.

- the laminate 190 is fed to the pressurizing unit 195.

- the pressure unit 195 is configured mainly with a pressure roller 197. As shown in FIG.

- the pressure roller 197 has a predetermined pressure clearance C, and is set to compress and mold the fed laminate 190 according to the pressure clearance C. ing.

- the pressure clearance C is set to 1.6 millimeters, and the thickness of the stacked body 190 after being pressed is the stack before the pressure unit 195 is fed. It is configured to be fixed at a predetermined value smaller than the thickness of the body 195.

- the cylindrical pressure surface of the pressure roller has a flat surface configuration with no irregularities and substantially no undulations. For this reason, the laminated body 190 is only compressed (or heated) in the pressurizing step, and an embossing process is avoided as in a conventional pet absorbent sheet.

- the pressure roller 197 in this embodiment is heated to 100 ° C., and the hot melt adhesive in the laminate 190 is melted during the pressurization.

- the melted hot melt adhesive is solidified according to the temperature drop after pressurization, and joins the constituent layers of the absorber 150.

- the laminated body 190 subjected to the pressure compression treatment as described above is then cut into a predetermined size by the cutter 199 to obtain the absorbent body 150.

- the top sheet 110 and the back sheet 130 are disposed on the upper surface side and the lower surface side of the absorbent body 150 with the hot melt adhesive 180 interposed therebetween, and the absorbent body is bonded by thermal welding. 150. Thereby, the pet absorbent sheet 100 shown in FIG. 4 is manufactured.

- the cylindrical roller of the pressure roller 197 is related to the configuration of the pressure unit 195 for manufacturing the absorbent body 150 by compressing the laminate 190.

- the pressing surface has a flat surface configuration with no irregularities and substantially no undulations.

- the laminate 190 is only compressed (or heated) in the pressurizing step, and is not embossed as in the prior art. That is, the absorbent body 150 manufactured through the above manufacturing method is formed as a non-embossed region as a whole including the main absorption region 151 shown in FIG. 4, and the absorbent layer 170 and the top sheet 110 or back sheet.

- the joining with 130 employ

- the absorbent body 150 is defined as a non-embossed area.

- the performance evaluation of the pet absorbent sheet 100 based on the first embodiment and a pet absorbent sheet having a conventional embossed region was performed. Specifically, an absorbent body in which 9 g of a superabsorbent polymer layer of 3.4 seconds was uniformly dispersed and arranged by a vortex method on the upper layer side of a 60 gsm pulp layer was prepared, and this was heat-welded according to the above embodiment. A sample fixed with an adhesive and a comparative sample obtained by embossing the absorber are prepared.

- the embossing treatment in the comparative sample is performed by performing a grid-like embossing treatment with a width of 1.5 mm on the upper layer side of the absorbent body, a rectangular uncompressed region having a length of 10 mm, and a width of 1 mm.

- region in which many compression areas of 5 millimeters were alternately and continuously formed is formed.

- liquid diffusibility of the pet absorbent sheet is determined using the liquid diffusion area calculated by the following method.

- a polyvinyl chloride pipe having an outer diameter of 66.6 mm, an inner diameter of 60.2 mm, and a height of 53 mm is disposed at a measurement location excluding the crease in the subject pet absorbent sheet 100.

- 40 cc of 0.9% physiological saline is dropped into the center of the polyvinyl chloride pipe from 6 mm above the pet absorbent sheet 100 using a 40 cc / 6 second burette in 6 seconds.

- the diffusion length of the physiological saline in the predetermined first direction of the physiological saline and the diffusion length in the second direction intersecting with the first direction are determined. Measure each.

- the first direction is defined as the MD direction (Machine Direction) as the feeding direction in the manufacturing apparatus when manufacturing the pet absorbent sheet 100

- the second direction is the MD direction.

- the liquid diffusion area (cm2) is calculated using the following calculation formula for the measured first direction diffusion length and second direction diffusion length. [(First direction diffusion length / 2) ⁇ (second direction diffusion length / 2) ⁇ 3.14]

- the comparative sample was about 40 seconds, while the present sample was about 33 seconds.

- the comparative sample was about 217 square centimeters, whereas the present sample was about 178 square centimeters.

- the second example relates to a change in the arrangement of the absorbent body 150 in the pet absorbent sheet 100 according to the first example described above, and the configuration of other members is the same as that of the first example.

- the absorption layer 270 of the absorber 250 as the absorption layer 270 of the absorber 250, the pulp layer 271 which comprises an absorption 1st layer, and the super absorbent polymer layer 272 which is provided in the said pulp layer 271 and comprises an absorption 2nd layer, Have In other words, the superabsorbent polymer layer 272 that is the second absorption layer is sandwiched by the pulp layer 271 that is the first absorption layer.

- the absorbent body 150 is formed by joining the front and back surfaces of the pulp layer 271 in FIG. 7 to the front-side tissue layer 261 and the back-side tissue layer 263 via the hot melt adhesive 180, respectively.

- the pet absorbent sheet 100 is an example of a configuration corresponding to the “pet absorbent sheet” in the present invention.

- the top sheet 110 is an example of a configuration corresponding to the “top sheet” in the present invention.

- the back sheet 130 is an example of a configuration corresponding to the “back sheet” in the present invention.

- the absorber 150 is an example of a configuration corresponding to the “absorber” in the present invention.

- the main absorption region 151 is an example of a configuration corresponding to the “main absorption region” in the present invention.

- the surface-side tissue layer 161 is an example of a configuration corresponding to the “surface-side covering sheet” in the present invention.

- the back side tissue layer 163 is an example of a configuration corresponding to the “back side covering sheet” in the present invention.

- the absorption layer 170 is an example of a configuration corresponding to the “absorption layer” in the present invention.

- the pulp layer 171 is an example of a configuration corresponding to “pulp material” or “absorption first layer” in the present invention.

- the superabsorbent polymer layer 172 is an example of a configuration corresponding to the “absorbing second layer” in the present invention.

- the hot melt adhesive 180 is an example of a configuration corresponding to the “adhesive” or “heat-welding adhesive” in the present invention.

- the laminate 190 is an example of a configuration corresponding to the “laminate” in the present invention.

- the pressurizing unit 195 is an example of a configuration corresponding to the “pressurizing unit” in the present invention.

- the pressure roller 197 is an example of a configuration corresponding to the “pressure roller” in the present invention.

- the top sheet is configured to receive pet excrement in a state where the back sheet is placed at a placement location;

- the said absorber is a non-embossing area

- An absorbent sheet for pets characterized in that it is set to be uniform.

- the absorbent sheet for pets according to aspect 1 The absorbent sheet for pets, wherein the absorbent layer is bonded to at least one of the front surface side coating sheet and the back surface side coating sheet through an adhesive throughout.

- the absorbent sheet for pets according to aspect 1 or 2 The absorbent sheet for pets, wherein the absorbent layer has an absorbent first layer having hydrophilic fibers and an absorbent second layer having a hydrophilic resin.

- the absorbent sheet for pets according to aspect 3 The absorption second layer is disposed between the surface-side covering sheet and the first layer, The pet absorbent sheet, wherein at least the surface-side covering sheet and the second absorbent layer are joined together through the adhesive.

- the absorptive second layer is composed of a highly water-absorbing polymer.

- the top sheet is configured to receive pet excrement in a state where the back sheet is placed at a placement location;

- the absorber is a pet formed by a front surface side covering sheet facing the front surface sheet, a back surface side covering sheet facing the back surface sheet, and an absorbent layer disposed between the front surface side covering sheet and the back surface side covering sheet.

- a method of manufacturing an absorbent sheet for use A non-embossing region is obtained by feeding and pressurizing a laminate in which the front surface side coating sheet, the back surface side coating sheet, and the absorption layer are superposed on each other to a pressurizing portion having a pressurizing surface having no unevenness.

- the manufacturing method of the absorptive sheet for pets characterized by forming the absorber which has this.

- the said pressurization part is comprised by the pressurization roller which has the curved-surface pressurization surface which does not have an uneven

- a method for producing an absorbent sheet for pets according to aspect 9 or 10 The thickness of the laminate after being fed to the pressurizing unit and being pressurized is fixed at a predetermined thickness smaller than that of the laminate before being fed to the pressurizing unit.

- a method for producing an absorbent sheet for pets. A method for producing an absorbent sheet for pets.

- Absorbent sheet for pets 110 ... surface sheet (surface sheet) 130 .. back sheet (back sheet) 150 ... Absorber (absorber) 151 ... main absorption region (main absorption region) 161 ... surface side tissue layer (surface side covering sheet) 163 ... back side tissue layer (back side covering sheet) 170 ... absorption layer (absorption layer) 171 ... Pulp layer (pulp material, absorption first layer) 172 ... super absorbent polymer layer (absorption second layer) 180 ... hot melt adhesive (heat-weldable adhesive) 190 ... Laminated body (laminated body) 195: Pressurizing part (pressurizing part) 197 ... Pressure roller (Pressure roller) 199 ... Cutter C ... Pressure clearance (Pressure clearance) F ... Placement surface W ... Excrement

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Environmental Sciences (AREA)

- Zoology (AREA)

- Animal Husbandry (AREA)

- Biodiversity & Conservation Biology (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Housing For Livestock And Birds (AREA)

Priority Applications (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP13813810.2A EP2870869A4 (en) | 2012-07-06 | 2013-06-20 | ABSORBENT FOIL FOR PETS AND METHOD FOR PRODUCING A SUCTIONAL FOIL FOR PETS |

| AU2013284681A AU2013284681B2 (en) | 2012-07-06 | 2013-06-20 | Absorbent sheet for pets and production method for absorbent sheet for pets |

| US14/413,041 US9661826B2 (en) | 2012-07-06 | 2013-06-20 | Absorbent sheet for pets and production method for absorbent sheet for pets |

| IN796DEN2015 IN2015DN00796A (enExample) | 2012-07-06 | 2013-06-20 | |

| CN201380035996.3A CN104411159A (zh) | 2012-07-06 | 2013-06-20 | 宠物用吸收性片以及宠物用吸收性片的制造方法 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012153045A JP6008623B2 (ja) | 2012-07-06 | 2012-07-06 | ペット用吸収性シート |

| JP2012-153045 | 2012-07-06 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2014007073A1 true WO2014007073A1 (ja) | 2014-01-09 |

Family

ID=49881832

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2013/067011 Ceased WO2014007073A1 (ja) | 2012-07-06 | 2013-06-20 | ペット用吸収性シートおよびペット用吸収性シートの製造方法 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US9661826B2 (enExample) |

| EP (1) | EP2870869A4 (enExample) |

| JP (1) | JP6008623B2 (enExample) |

| CN (1) | CN104411159A (enExample) |

| AU (1) | AU2013284681B2 (enExample) |

| IN (1) | IN2015DN00796A (enExample) |

| WO (1) | WO2014007073A1 (enExample) |

Families Citing this family (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6008623B2 (ja) * | 2012-07-06 | 2016-10-19 | ユニ・チャーム株式会社 | ペット用吸収性シート |

| JP6008622B2 (ja) * | 2012-07-06 | 2016-10-19 | ユニ・チャーム株式会社 | ペット用吸収性シート |

| NL2009780C2 (nl) * | 2012-11-09 | 2014-05-12 | Uniq Ag | Legnest met uitdrijfsysteem. |

| JP6359427B2 (ja) * | 2014-11-19 | 2018-07-18 | ユニ・チャーム株式会社 | ペット用吸収性シート |

| JP5728123B1 (ja) * | 2014-11-19 | 2015-06-03 | ユニ・チャーム株式会社 | ペット用吸収性シート |

| CN204317221U (zh) * | 2014-11-26 | 2015-05-13 | 江苏中恒宠物用品股份有限公司 | 一种防侧漏宠物尿垫 |

| CN204259607U (zh) * | 2014-11-26 | 2015-04-15 | 江苏中恒宠物用品股份有限公司 | 快速吸收防侧漏宠物尿垫 |

| JP5998305B1 (ja) * | 2016-05-13 | 2016-09-28 | ユニ・チャーム株式会社 | ペット用ベッド |

| JP6494563B2 (ja) * | 2016-05-13 | 2019-04-03 | ユニ・チャーム株式会社 | ペット用介護用品 |

| PT3573452T (pt) | 2017-01-27 | 2021-10-06 | Ctb Inc | Ninho de postura com sistema de expulsão de piso de acionamento de cremalheira |

| JP6726135B2 (ja) * | 2017-06-15 | 2020-07-22 | ユニ・チャーム株式会社 | ペット用吸収性シート |

| US20190124881A1 (en) * | 2017-10-31 | 2019-05-02 | Pettrix LLC | Pet bed liner |

| WO2021183263A1 (en) | 2020-03-13 | 2021-09-16 | Carbon, Inc. | Additively manufactured products having a matte surface finish |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005198598A (ja) * | 2004-01-16 | 2005-07-28 | Unicharm Petcare Corp | ペット用吸収シート |

| JP2006238744A (ja) * | 2005-03-01 | 2006-09-14 | Unicharm Petcare Corp | ペット用排泄物吸収シート |

| JP2008043243A (ja) * | 2006-08-14 | 2008-02-28 | Sanotec Co Ltd | ペット用吸収シート |

| JP2011205979A (ja) | 2010-03-30 | 2011-10-20 | Mitsubishi Rayon Co Ltd | 組換えタンパク質の生産方法 |

| JP2011205984A (ja) * | 2010-03-30 | 2011-10-20 | Unicharm Corp | 動物用排泄物処理シート及びその製造方法 |

Family Cites Families (23)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4774907A (en) * | 1984-01-26 | 1988-10-04 | Patrick Yananton | Nonwoven screen for odorless animal litter unit |

| JP2965467B2 (ja) * | 1994-08-23 | 1999-10-18 | ユニ・ハートス株式会社 | 愛玩動物用の排尿処理シート |

| HU2762U (en) * | 2002-12-20 | 2004-06-28 | Procter & Gamble | Disposable absorbent article |

| JP3676787B2 (ja) * | 2003-06-20 | 2005-07-27 | ユニ・チャームペットケア株式会社 | 動物用トイレ砂及びこれを用いた動物用トイレ |

| JP4395333B2 (ja) * | 2003-06-20 | 2010-01-06 | ユニ・チャームペットケア株式会社 | ペットのトイレ用吸液シート |

| US7314663B2 (en) * | 2003-09-29 | 2008-01-01 | The Procter + Gamble Company | Embossed multi-ply fibrous structure product and process for making same |

| JP4227031B2 (ja) * | 2004-01-16 | 2009-02-18 | ユニ・チャームペットケア株式会社 | ペット用吸収シート |

| JP4652847B2 (ja) * | 2005-03-01 | 2011-03-16 | ユニ・チャーム株式会社 | ペット用排泄物吸収シートの製造方法 |

| ATE525993T1 (de) * | 2006-04-07 | 2011-10-15 | Procter & Gamble | Hygiene produkt für frauen mit wellenförmiger struktur |

| EP2090157A1 (en) * | 2006-12-27 | 2009-08-19 | Kao Corporation | Pet sheet |

| JP5186141B2 (ja) * | 2007-06-29 | 2013-04-17 | ユニ・チャーム株式会社 | 動物用排泄物処理シート |

| JP4996997B2 (ja) * | 2007-06-29 | 2012-08-08 | ユニ・チャーム株式会社 | 動物用排泄物処理シート |

| JP5185738B2 (ja) * | 2008-08-29 | 2013-04-17 | ユニ・チャーム株式会社 | 愛玩動物用の排泄物処理シート |

| ES2529218T3 (es) * | 2009-03-31 | 2015-02-18 | Sumitomo Seika Chemicals Co., Ltd. | Lámina absorbente de agua |

| US20110232578A1 (en) * | 2010-03-24 | 2011-09-29 | Duke Robert T | Absorbent Pad Containing Corrugate |

| JP5581093B2 (ja) | 2010-03-30 | 2014-08-27 | 大王製紙株式会社 | ペット用吸収性シート |

| EP2399557B2 (en) | 2010-06-25 | 2017-03-29 | The Procter and Gamble Company | Disposable diaper with reduced bulk |

| JP6095265B2 (ja) * | 2011-12-21 | 2017-03-15 | ユニ・チャーム株式会社 | ペット用シート |

| JP5952663B2 (ja) * | 2012-07-06 | 2016-07-13 | ユニ・チャーム株式会社 | ペットシートおよびペットシート包装体パッケージ |

| JP6008623B2 (ja) * | 2012-07-06 | 2016-10-19 | ユニ・チャーム株式会社 | ペット用吸収性シート |

| JP6008624B2 (ja) * | 2012-07-06 | 2016-10-19 | ユニ・チャーム株式会社 | ペット用シート |

| JP6008622B2 (ja) * | 2012-07-06 | 2016-10-19 | ユニ・チャーム株式会社 | ペット用吸収性シート |

| JP6008625B2 (ja) * | 2012-07-06 | 2016-10-19 | ユニ・チャーム株式会社 | ペット用シート |

-

2012

- 2012-07-06 JP JP2012153045A patent/JP6008623B2/ja active Active

-

2013

- 2013-06-20 IN IN796DEN2015 patent/IN2015DN00796A/en unknown

- 2013-06-20 EP EP13813810.2A patent/EP2870869A4/en not_active Withdrawn

- 2013-06-20 US US14/413,041 patent/US9661826B2/en active Active

- 2013-06-20 WO PCT/JP2013/067011 patent/WO2014007073A1/ja not_active Ceased

- 2013-06-20 AU AU2013284681A patent/AU2013284681B2/en not_active Ceased

- 2013-06-20 CN CN201380035996.3A patent/CN104411159A/zh active Pending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2005198598A (ja) * | 2004-01-16 | 2005-07-28 | Unicharm Petcare Corp | ペット用吸収シート |

| JP2006238744A (ja) * | 2005-03-01 | 2006-09-14 | Unicharm Petcare Corp | ペット用排泄物吸収シート |

| JP2008043243A (ja) * | 2006-08-14 | 2008-02-28 | Sanotec Co Ltd | ペット用吸収シート |

| JP2011205979A (ja) | 2010-03-30 | 2011-10-20 | Mitsubishi Rayon Co Ltd | 組換えタンパク質の生産方法 |

| JP2011205984A (ja) * | 2010-03-30 | 2011-10-20 | Unicharm Corp | 動物用排泄物処理シート及びその製造方法 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP2870869A4 * |

Also Published As

| Publication number | Publication date |

|---|---|

| AU2013284681A1 (en) | 2015-02-26 |

| JP6008623B2 (ja) | 2016-10-19 |

| EP2870869A4 (en) | 2016-03-09 |

| US20150201579A1 (en) | 2015-07-23 |

| JP2014014302A (ja) | 2014-01-30 |

| CN104411159A (zh) | 2015-03-11 |

| IN2015DN00796A (enExample) | 2015-07-03 |

| US9661826B2 (en) | 2017-05-30 |

| AU2013284681B2 (en) | 2017-11-09 |

| EP2870869A1 (en) | 2015-05-13 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6008623B2 (ja) | ペット用吸収性シート | |

| JP3571044B2 (ja) | 層状吸収構造体 | |

| JP5328273B2 (ja) | 体液吸収性物品 | |

| JP5517290B2 (ja) | 吸収性物品 | |

| CN110290698A (zh) | 动物用排泄物处理片 | |

| JP5318747B2 (ja) | 吸収性物品 | |

| JP6008622B2 (ja) | ペット用吸収性シート | |

| CN104010490A (zh) | 宠物用片 | |

| JP2016174741A (ja) | 吸収性物品 | |

| JP5926904B2 (ja) | 吸収性物品 | |

| JP5581093B2 (ja) | ペット用吸収性シート | |

| TWI709392B (zh) | 失禁墊及失禁墊收納物 | |

| JP6694706B2 (ja) | 吸収性物品 | |

| JP2017104255A (ja) | 吸収性物品 | |

| CN1254274A (zh) | 包括颗粒材料的独立分层结构及其制造方法 | |

| JP6241909B2 (ja) | ペット用吸収性シート | |

| JP6707336B2 (ja) | 吸収性物品 | |

| JP7291004B2 (ja) | 吸収性物品 | |

| JP5995313B2 (ja) | 吸収性物品 | |

| WO2017098819A1 (ja) | 吸収性物品 | |

| JP4859508B2 (ja) | 吸収性物品 | |

| JP3960960B2 (ja) | 吸収性製品及び吸収性製品の製造装置 | |

| JP3242336U (ja) | 吸収性物品 | |

| TWI900748B (zh) | 吸收性物品 | |

| JP7190852B2 (ja) | 吸収性物品 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 13813810 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 14413041 Country of ref document: US |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| REEP | Request for entry into the european phase |

Ref document number: 2013813810 Country of ref document: EP |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2013813810 Country of ref document: EP |

|

| ENP | Entry into the national phase |

Ref document number: 2013284681 Country of ref document: AU Date of ref document: 20130620 Kind code of ref document: A |