WO2013129409A1 - 遠心流体機械の吸気管構造 - Google Patents

遠心流体機械の吸気管構造 Download PDFInfo

- Publication number

- WO2013129409A1 WO2013129409A1 PCT/JP2013/054988 JP2013054988W WO2013129409A1 WO 2013129409 A1 WO2013129409 A1 WO 2013129409A1 JP 2013054988 W JP2013054988 W JP 2013054988W WO 2013129409 A1 WO2013129409 A1 WO 2013129409A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- intake pipe

- pipe structure

- transition portion

- impeller

- flow

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/40—Casings; Connections of working fluid

- F04D29/42—Casings; Connections of working fluid for radial or helico-centrifugal pumps

- F04D29/4206—Casings; Connections of working fluid for radial or helico-centrifugal pumps especially adapted for elastic fluid pumps

- F04D29/4213—Casings; Connections of working fluid for radial or helico-centrifugal pumps especially adapted for elastic fluid pumps suction ports

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M35/00—Combustion-air cleaners, air intakes, intake silencers, or induction systems specially adapted for, or arranged on, internal-combustion engines

- F02M35/10—Air intakes; Induction systems

- F02M35/10091—Air intakes; Induction systems characterised by details of intake ducts: shapes; connections; arrangements

- F02M35/10124—Ducts with special cross-sections, e.g. non-circular cross-section

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02M—SUPPLYING COMBUSTION ENGINES IN GENERAL WITH COMBUSTIBLE MIXTURES OR CONSTITUENTS THEREOF

- F02M35/00—Combustion-air cleaners, air intakes, intake silencers, or induction systems specially adapted for, or arranged on, internal-combustion engines

- F02M35/10—Air intakes; Induction systems

- F02M35/1015—Air intakes; Induction systems characterised by the engine type

- F02M35/10157—Supercharged engines

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D17/00—Radial-flow pumps, e.g. centrifugal pumps; Helico-centrifugal pumps

- F04D17/08—Centrifugal pumps

- F04D17/10—Centrifugal pumps for compressing or evacuating

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F04—POSITIVE - DISPLACEMENT MACHINES FOR LIQUIDS; PUMPS FOR LIQUIDS OR ELASTIC FLUIDS

- F04D—NON-POSITIVE-DISPLACEMENT PUMPS

- F04D29/00—Details, component parts, or accessories

- F04D29/40—Casings; Connections of working fluid

- F04D29/42—Casings; Connections of working fluid for radial or helico-centrifugal pumps

- F04D29/44—Fluid-guiding means, e.g. diffusers

- F04D29/441—Fluid-guiding means, e.g. diffusers especially adapted for elastic fluid pumps

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F02—COMBUSTION ENGINES; HOT-GAS OR COMBUSTION-PRODUCT ENGINE PLANTS

- F02B—INTERNAL-COMBUSTION PISTON ENGINES; COMBUSTION ENGINES IN GENERAL

- F02B39/00—Component parts, details, or accessories relating to, driven charging or scavenging pumps, not provided for in groups F02B33/00 - F02B37/00

- F02B39/16—Other safety measures for, or other control of, pumps

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2220/00—Application

- F05D2220/40—Application in turbochargers

-

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F05—INDEXING SCHEMES RELATING TO ENGINES OR PUMPS IN VARIOUS SUBCLASSES OF CLASSES F01-F04

- F05D—INDEXING SCHEME FOR ASPECTS RELATING TO NON-POSITIVE-DISPLACEMENT MACHINES OR ENGINES, GAS-TURBINES OR JET-PROPULSION PLANTS

- F05D2250/00—Geometry

- F05D2250/50—Inlet or outlet

- F05D2250/51—Inlet

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/10—Internal combustion engine [ICE] based vehicles

- Y02T10/12—Improving ICE efficiencies

Definitions

- the present invention relates to an intake pipe structure of a centrifugal compressor, a mixed flow compressor, a centrifugal blower, and a mixed flow blower (hereinafter collectively referred to as a centrifugal fluid machine) which is one of fluid machines.

- Turbochargers and turbo refrigerators mounted on vehicles and ships are equipped with an impeller rotating at high speed, and use a centrifugal compressor that pressurizes fluid using centrifugal force.

- this centrifugal compressor requires a wide operating range, when the flow rate of the fluid introduced to the centrifugal compressor decreases, the discharge pressure pulsates to cause surging in which the operating state becomes unstable, which results in an operation limit. . Therefore, in order to secure a wide operating range in a centrifugal compressor, it is necessary to reduce the critical flow rate at which surging occurs.

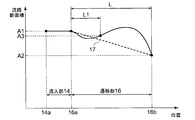

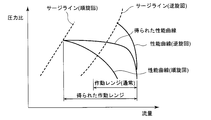

- FIG. 13 (a) is a graph showing a change in the performance characteristic of the compressor when the fluid introduced to the impeller is swirled in the forward direction when the rotation speed is fixed.

- FIG. 13 (a) when the fluid guided to the impeller is turned forward, the surge line moves to the left side of the graph, and the critical flow rate at which surging occurs decreases.

- the maximum flow rate is also reduced, so the operating range itself can not be expanded.

- FIG. 13 (b) is a graph showing a change in performance characteristics of the compressor when the fluid led to the impeller is reversely swirled when the rotation speed is fixed.

- the performance curve moves to the upper right side of the graph, and the pressure ratio is improved.

- the surge line is also moved to the right of the graph, and the operating range itself is narrowed.

- Patent Document 1 in a centrifugal compressor of a turbocharger for an automobile, a variable mechanism including an air deflection vane is operated by an actuator or the like to reversely swirl the fluid guided to the impeller at a large flow rate and at a small flow rate.

- a pre-turn generator is disclosed that can be turned forward.

- the pressure ratio is improved by guiding the reverse swirl flow at the large flow rate, and the forward swirl flow is introduced at the small flow rate. Can avoid surging.

- the maximum flow rate of the operating range is not reduced, a wide operating range can be secured.

- Patent No. 4446661 gazette

- the pre-swing generator described in Patent Document 1 described above is a mechanical pre-swing generator that operates a variable mechanism by an actuator or the like, and there is a problem in that the size and cost of the apparatus are increased.

- turbochargers for automobiles there is a strong demand for downsizing and cost reduction of the apparatus, and it is not practical to adopt mechanical means.

- the present invention is an invention made in view of such a problem of the prior art, and reverses the flow of the fluid conducted to the impeller at a large flow rate by devising the shape of the intake pipe without using mechanical means. It is an object of the present invention to provide an intake pipe structure of a centrifugal fluid machine which can be swirled to improve a pressure ratio and forward swirl at a small flow rate to avoid surging and secure a wide operation range.

- the intake pipe structure of the centrifugal fluid machine according to the present invention is a centrifugal fluid machine having an impeller mounted on a rotary shaft and a housing for housing the impeller, substantially in a direction orthogonal to the axial direction of the rotary shaft.

- An intake pipe structure for guiding a flowing fluid to a rotation center of an impeller housed in the housing through a suction pipe portion of the housing protruding in the axial direction of the rotation shaft,

- the inflow portion extending in a direction substantially orthogonal to the axial direction of the rotation shaft; and a transition portion connecting the inflow portion and the suction pipe portion of the housing,

- There is a virtual plane which is orthogonal to the axial direction of the rotation axis and passes through the flow passage cross section of the inflow portion, and the intersection with the axial line of the rotation axis is located inside the transition portion It is characterized in that it is configured to

- the intake pipe structure of the centrifugal fluid machine of the present invention is an intake pipe structure for guiding a fluid flowing in a direction substantially orthogonal to the axial direction of the rotation shaft to the rotation center of the impeller, as described above And an imaginary plane configured to be orthogonal to the axial direction of the rotation axis and pass through the flow passage cross section of the inflow portion, and the intersection point with the axial direction line of the rotation axis is located inside the transition portion It is configured.

- the intake pipe structure of the present invention thus configured has a shape that is sharply bent in front of the suction pipe portion of the housing.

- the flow (main flow) of the fluid from the inflow portion to the suction pipe portion of the housing through the transition portion is rapidly changed in front of the suction pipe portion to cause disturbance in the main flow.

- the pressure ratio is high when the flow rate is small, the fluid to which the swirling flow is given by the impeller flows back to the upstream of the impeller, and the reverse flow flows into the transition part, and the flow is disturbed to the mainstream It produces a swirling flow.

- the pressure ratio is low, and the flow velocity of the main stream flowing through the transition part is also high, so that a swirling flow due to the reverse flow does not occur.

- the shape of the intake pipe structure in a front view when the rotation center of the impeller is viewed from the front is in the direction opposite to the rotation direction of the impeller from the inflow portion side toward the transition portion side bent. That is, when the impeller is rotating in the clockwise direction in front view, it is bent to the left from the inflow side to the transition portion side, and when the impeller is rotating in the counterclockwise direction. Is bent to the right from the inflow side to the transition side.

- the intake pipe structure As described above, if the intake pipe structure is bent in the direction opposite to the rotational direction of the impeller, the main flow through the intake pipe structure becomes a swirling flow in reverse rotation with respect to the rotational direction of the impeller at a large flow rate. Since it flows into the impeller, the pressure ratio can be improved. On the other hand, when the flow rate is small, the influence of the above-described backflow is stronger, and the fluid guided to the impeller remains in the forward swirling flow. Therefore, according to such an intake pipe structure of the present invention, when the flow rate is large, the fluid conducted to the impeller is reversely swirled to improve the pressure ratio, and when the flow rate is small, the fluid conducted to the impeller is forward swirled. It is possible to avoid surging. In addition, a wide operating range can be secured without reducing the maximum flow rate of the operating range.

- the entire length of the transition portion is L

- the flow passage cross-sectional area of one end of the transition portion connected to the inflow portion is A1

- the flow passage cross-sectional area of the other end of the transition portion connected to the suction pipe portion Where at least a partial section of the transition portion satisfies the relationship of the following formula (1), where A2 is a channel cross-sectional area of the transition portion at a position separated by a distance L1 from one end of the transition portion as A3. It is desirable to be configured.

- a large section of the flow passage cross section is formed between one end and the other end of the transition portion, so that the backflow easily reaches the upstream side of the transition portion at a small flow rate. A stronger forward swirling flow can be generated with respect to the main flow.

- the flow passage cross-section of a partial section of the transition portion is formed in a non-circular shape, it is easier for the backflow to reach the upstream side of the transition portion at a small flow rate. It is preferable because a swirl flow in the direction is generated.

- the intake pipe structure of the centrifugal fluid machine of the present invention thus configured can be particularly suitably used as a centrifugal compressor of an automotive turbocharger.

- the fluid guided to the impeller is reversely rotated at a large flow rate to improve the pressure ratio, and the fluid guided to the impeller is forwardly rotated at a small flow rate, without using mechanical means. It is possible to provide an intake pipe structure of a centrifugal fluid machine that can avoid surging and secure a wide operating range.

- FIG. 5 is a view showing velocity vector distribution of fluid in the x-x cross section of FIG. 4 (a). It is a schematic diagram showing the flow of the fluid in the intake pipe structure of the present invention. It is the graph which showed the flow-path cross-sectional area of the intake pipe structure of this invention. It is a schematic diagram for demonstrating the flow-path cross section in the transition part of the intake pipe structure of this invention. It is the figure which showed each cross section of the intake pipe structure of this invention. It is the figure which showed each cross section of the intake pipe structure of a comparative example.

- FIG. 16 is a graph showing a change in performance characteristics of the compressor when the fluid introduced to the impeller is reversely swirled in the case where FIG. 10 is a graph showing a change in performance characteristics of the compressor when the fluid introduced to the impeller is forwardly rotated at low flow rate and the fluid introduced to the impeller is reversely rotated at high flow rate.

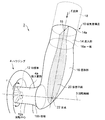

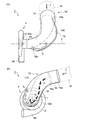

- FIG. 1 is a schematic view showing a centrifugal compressor of an automotive turbocharger to which an intake pipe structure of the present invention is applied, as one embodiment of the present invention.

- the automotive turbocharger 1 includes a compressor housing 4 (housing) containing a compressor rotor (impeller), a bearing housing 5 containing a rotation shaft, and a turbine rotor.

- the turbine housing 6 is provided.

- the compressor rotor and the turbine rotor are mounted coaxially with respect to the rotation axis, and the exhaust gas flowing into the turbine housing 6 rotates the turbine rotor, whereby the coaxially mounted compressor rotor also rotates. Is configured as.

- a suction pipe portion 4a is provided in the axial direction of the rotation shaft so as to protrude from the front surface of the compressor housing 4 (the surface viewed from the A direction in FIG. 1).

- an intake pipe structure 10 of the present invention is connected to the intake pipe portion 4a, and the intake pipe structure 10 extends in a direction substantially orthogonal to the rotation axis 3 (axial line of the rotation axis).

- An intake passage 18 is connected.

- an exhaust pipe 8 is connected to the scroll portion 4 b extended in the circumferential direction of the compressor housing 4.

- the centrifugal compressor 2 of the present embodiment is composed of the compressor housing 4, an exhaust pipe 8 and an intake pipe structure 10. Then, as the compressor rotor rotates, a fluid f such as air flowing through the intake passage 18 flows through the intake pipe structure 10, and the front surface of the compressor rotor accommodated in the compressor housing 4 via the intake pipe portion 4a. It is introduced to the

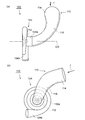

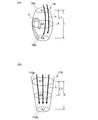

- FIG. 2A is a view showing an intake pipe structure of the present invention, in which (a) is a side view of a rotational axis viewed from the side, and (b) is a front view of a compressor rotor viewed from the front.

- FIG. 2B is a perspective view showing the intake pipe structure of the present invention.

- Arrows f1 and f2 in FIG. 2A indicate the flow directions of the main flow f1 and the reverse flow f2 at a small flow rate

- a two-dot chain line 110 in FIG. 2A indicates the shape of the intake pipe structure 110 in the comparative example. It is a line.

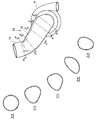

- FIG. 3A is a view showing an intake pipe structure in a comparative example, in which (a) is a side view in which the rotation axis is viewed from the side, and (b) is a front view in which the impeller is viewed from the front.

- FIG. 3B is a perspective view showing the intake pipe structure of the present invention.

- the intake pipe structure 110 of the comparative example the loss of the fluid f flowing in the direction substantially orthogonal to the rotation axis 103 is as small as possible based on the general design concept to the conventional intake pipe structure, and the compressor is The present inventors designed an intake pipe structure that can be conducted to the rotation center 112 a of the rotor 112.

- the compressor rotor 12 housed in the compressor housing 4 is housed so as to rotate clockwise in a front view about the rotation center 12a. There is.

- the inflow portion 14 extends straight in a direction substantially orthogonal to the rotation axis 3, and the flow passage cross section does not change.

- substantially orthogonal means that the crossing angle between the extending direction of the inflow portion 14 and the rotation axis 3 forms an angle close to a substantially right angle, specifically, a case where it is in the range of 75 degrees to 105 degrees. It shall be.

- one end 16 a is oriented substantially horizontally to the rotation axis 3, and the other end 16 b is oriented perpendicularly to the rotation axis 3.

- the flow passage cross section is formed such that the flow passage cross section in the middle is enlarged as described later.

- the intake pipe structure 10 of the present invention has a shape bulging out on both sides inside and outside of the curved portion in side view in side view It has become. Moreover, in front view, it has the shape which bulged inside the curved part in front view.

- the intake pipe structure 10 of the present invention is orthogonal to the rotation axis 3 and passes through the flow passage cross section of the inflow portion 14, and the intersection 22 with the rotation axis 3 is inside the transition portion 16.

- the imaginary plane 20 of FIG. 2B passes through the center 15 at the upstream end 14 a of the inlet 14.

- the intake pipe structure 110 of the comparative example as shown in FIG. 3B, it passes through the inflow cross section of the inflow portion 114 orthogonal to the rotation axis 103 and the intersection 122 with the rotation axis 103 is a transition portion

- the intersection point 122 with the rotation axis 103 is located outside the transition portion 116.

- the intake pipe structure 10 of the present invention configured as described above has a shape in which the transition portion 16 is sharply bent in front of the intake pipe portion 4 a.

- the flow of the fluid (main stream f1) flowing from the intake passage 18 and flowing from the inflow portion 14 through the transition portion 16 to the suction pipe 4a of the compressor housing 4 is The air changes rapidly in front of the suction pipe 4a, and turbulence occurs in the main flow f1.

- the pressure ratio is high when the flow rate is small as shown in FIG. 4A, the fluid flowing into the compressor housing 4 collides with the surface of the compressor rotor 12 to generate a swirling flow (backflow f2).

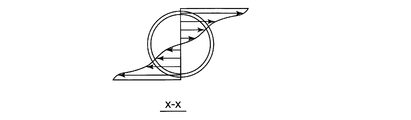

- FIG. 5 shows the velocity vector distribution of the fluid in the x-x cross section of FIG. 4 (a).

- the pressure ratio is low, and the flow velocity of the main flow f1 flowing through the transition section 16 is also fast, so that the swirl flow due to the backflow f2 does not occur.

- the main flow f 1 is conducted straight toward the rotation center 12 of the compressor rotor 12. That is, in the intake pipe structure 10 of the present invention, a forward swirl flow is generated in the fluid conducted to the compressor housing 4 only when the flow rate is small.

- the shape of the intake pipe structure 10 in a front view is a compressor from the inflow portion 14 side to the other end 16b side of the transition portion 16

- the rotor 12 is curved in the direction opposite to the rotational direction r, that is, in the counterclockwise direction.

- the intake pipe structure 10 is bent in the direction opposite to the rotation direction of the compressor rotor 12, as shown schematically in FIG. 6, the intake air at the large flow rate shown in FIG.

- the main flow f 1 flowing through the pipe structure 10 flows into the compressor rotor 12 as a swirl flow reversely rotating with respect to the rotational direction r of the compressor rotor 12.

- the influence of the above-described backflow f2 is stronger, so the fluid f1 conducted to the compressor rotor 12 remains a swirling flow in the forward direction.

- the fluid guided to the compressor rotor 12 is reversely rotated at a large flow rate, and the fluid guided to the compressor rotor 12 is forwardly rotated at a small flow rate.

- An intake pipe structure 10 capable of securing a range can be provided.

- the swirling flow reverse to the rotational direction r of the compressor rotor 112 is the compressor rotor at both large flow and small flow. It flows into 112. Therefore, although the pressure ratio can be improved when the flow rate is large, surging tends to occur when the flow rate is small, and a wide operating range can not be ensured.

- FIG. 7 is a graph showing the flow passage cross-sectional area at each position of the intake pipe structure 10.

- L is the total length of the transition portion 16

- A1 is the flow passage cross-sectional area of one end 16a of the transition portion 16

- A2 is the flow passage cross-sectional area of the other end 16b of the transition portion 16

- A3 is the transition portion It is a flow passage cross-sectional area of the transition portion 16 at a position separated by a distance L1 from one end 16a of 16.

- the flow passage cross-sectional area A3 at a position separated from the one end 16a of the transition portion 16 by the distance L1 is formed larger than the cross-sectional area indicated by the dotted line 7 in the drawing. That is, as schematically shown in FIG. 8A, the transition portion 16 of the present invention has a barrel-shaped bulging shape in which the cross section of the flow passage between one end 16a and the other end 16b is enlarged. .

- the transition portion 116 of the comparative example as schematically shown in FIG. 8B, the flow passage cross-sectional area A1 of the one end 116a is the largest, and the flow is toward the other end 116b.

- the road cross-sectional area is uniformly reduced.

- a section in which the flow channel cross section is enlarged is formed between the one end 16a and the other end 16b, as schematically shown in FIG. 8A.

- the backflow f2 can easily reach the upstream side of the transition portion 16. As a result, a stronger forward swirl flow can be generated by the main flow f1.

- the flow passage cross section of the transition portion 16 is formed in a non-circular shape.

- the intake pipe structure 110 of the comparative example as shown in FIG. 10, not only the inflow portion 114 but also the flow passage cross section of the transition portion 116 is formed in a circular shape.

- the flow passage cross section of the transition portion 16 is formed in a non-circular shape, it flows in the transition portion 16 as compared with the case where the flow passage cross section of the transition portion 116 is formed in a circular shape as in the comparative example.

- the loss of fluid increases, and the mainstream f1 is easily disturbed by that amount. Therefore, at low flow rates, the backflow f2 can more easily reach the upstream side of the transition portion 16, and a strong forward swirl flow can be generated by the main flow f1.

- a non-circular channel cross section may not be formed in the entire section of the transition portion 16, and may be formed in at least a partial section of the transition portion 16.

- the backflow f2 easily reaches the upstream of the transition portion 16 and is stronger than the main flow f1. It is effective in generating a forward swirl flow.

- the intake pipe structure 10 of the present invention improves the compression ratio by reversing the fluid conducted to the compressor rotor 12 at a large flow rate by devising the shape of the intake pipe and the like without using mechanical means. Surging is avoided by forwardly swirling the fluid conducted to the compressor rotor 12 when the flow rate is small, and a wide operating range can be secured.

- Such an intake pipe structure 10 according to the present invention can be particularly suitably used in a turbocharger for a motor vehicle where there is a strong demand for downsizing and cost reduction of the device.

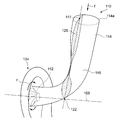

- FIG. 11A is a view showing an intake pipe structure according to another embodiment of the present invention, in which (a) is a side view of the rotational axis viewed from the side, and (b) is a front view of the compressor rotor.

- FIG. 11B is a perspective view showing an intake pipe structure according to another embodiment of the present invention. Arrows f1 and f2 in FIG. 11A indicate the flow directions of the main flow f1 and the back flow f2 at a small flow rate.

- the intake pipe structure of this another embodiment basically has the same configuration as that of the above-described embodiment, and the same configuration is denoted with the same reference numeral, and the detailed description thereof will be omitted.

- the intake pipe structure 10 of this another embodiment passes through the flow passage cross section of the inflow portion 14 at a right angle with the rotation axis 3 as shown in FIG. 11B.

- the imaginary plane 20 of FIG. 11B passes through the center 15 at the upstream end 14 a of the inflow portion 14.

- the difference is that the curved portion in the side view largely bulges out more than the embodiment described above, and as shown in FIG. 11A (a), at the small flow rate, the outer side in the side view

- the backflow f2 flows into the bulging portion.

- the backflow f2 flows into the outside of the curved portion in the front view, and the main flow f1 flows in the inside of the curved portion in the front view It is supposed to flow.

- the fluid introduced to the compressor rotor 12 is reversely swirled at a large flow rate to improve the compression ratio, as in the above-described embodiment.

- forward swirling of the fluid introduced to the compressor rotor 12 can avoid surging and secure a wide operating range.

- the flow passage cross section of the transition portion 16 satisfies the relationship of the above equation (1) at least in the section on the other end 16b side.

- the backflow f2 can easily reach at least the section satisfying the above equation (1) when the flow rate is small, so that the swirl flow stronger in the forward direction by the main flow f1 as in the embodiment described above. Can be generated.

- centrifugal-fluid machines such as a centrifugal compressor and a centrifugal blower

- an inlet pipe structure in centrifugal compressors such as a turbocharger mounted in a vehicle or a ship, and a turbo refrigerator.

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Structures Of Non-Positive Displacement Pumps (AREA)

- Supercharger (AREA)

Priority Applications (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US14/379,691 US9790957B2 (en) | 2012-02-29 | 2013-02-26 | Air intake duct structure for centrifugal fluid machine |

| EP13754588.5A EP2821652B1 (en) | 2012-02-29 | 2013-02-26 | Centrifugal fluid machine with air intake pipe structure |

| CN201380011346.5A CN104169588B (zh) | 2012-02-29 | 2013-02-26 | 离心流体机械的吸气管结构 |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2012-044103 | 2012-02-29 | ||

| JP2012044103A JP5787790B2 (ja) | 2012-02-29 | 2012-02-29 | 遠心流体機械の吸気管構造 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2013129409A1 true WO2013129409A1 (ja) | 2013-09-06 |

Family

ID=49082606

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2013/054988 Ceased WO2013129409A1 (ja) | 2012-02-29 | 2013-02-26 | 遠心流体機械の吸気管構造 |

Country Status (5)

| Country | Link |

|---|---|

| US (1) | US9790957B2 (enExample) |

| EP (1) | EP2821652B1 (enExample) |

| JP (1) | JP5787790B2 (enExample) |

| CN (1) | CN104169588B (enExample) |

| WO (1) | WO2013129409A1 (enExample) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016001181A1 (de) * | 2014-07-03 | 2016-01-07 | Siemens Aktiengesellschaft | Strömungsumlenkung bei einer strömungsmaschine |

| CN111212972A (zh) * | 2017-10-13 | 2020-05-29 | 五十铃自动车株式会社 | 进气导管 |

Families Citing this family (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2014010650A1 (ja) | 2012-07-11 | 2014-01-16 | 川崎重工業株式会社 | 鞍乗型車両の吸気ダクト |

| CN104903593B (zh) | 2013-02-21 | 2017-05-17 | 三菱重工业株式会社 | 流体机械及具备它的流体机械系统 |

| FR3023877B1 (fr) * | 2014-07-16 | 2019-04-19 | Alstom Transport Technologies | Dispositif de ventilation a encombrement axial reduit |

| JP6172758B2 (ja) * | 2014-12-11 | 2017-08-02 | 三菱重工業株式会社 | 回転機械の片吸込み式吸気装置 |

| JP6446705B2 (ja) * | 2015-01-09 | 2019-01-09 | 三菱重工業株式会社 | エンジンシステム |

| JP6762724B2 (ja) * | 2016-01-22 | 2020-09-30 | 三菱重工コンプレッサ株式会社 | 被動形流体機械の配管 |

| US11022355B2 (en) * | 2017-03-24 | 2021-06-01 | Johnson Controls Technology Company | Converging suction line for compressor |

| KR101988228B1 (ko) * | 2018-11-28 | 2019-06-12 | (주)대주기계 | 고속 고효율 터보 공기압축기의 공기유입 연결관 |

| EP3936710B1 (en) * | 2020-07-06 | 2023-04-12 | ANSALDO ENERGIA S.p.A. | Air intake for a stationary gas turbine engine |

| CN112523998A (zh) * | 2020-11-18 | 2021-03-19 | 安徽科海压缩机制造有限公司 | 一种新型压缩机的进气结构 |

| CN115076137A (zh) * | 2022-07-19 | 2022-09-20 | 威海克莱特菲尔风机股份有限公司 | 海上风电冷却系统用高效低噪离心风机 |

| CN115419616B (zh) * | 2022-09-05 | 2025-10-24 | 江森自控空调冷冻设备(无锡)有限公司 | 离心压缩机的吸气管 |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60190942U (ja) * | 1984-05-29 | 1985-12-18 | 日野自動車株式会社 | タ−ボチヤ−ジヤ− |

| JP2007154895A (ja) * | 2005-12-08 | 2007-06-21 | General Electric Co <Ge> | 圧縮機入口のための流れ方向転換器 |

| JP2010065681A (ja) * | 2008-09-10 | 2010-03-25 | Borgwarner Inc | 受動的予旋回の逆方向回転のためのターボチャージャ連結 |

| US20100221107A1 (en) * | 2007-10-19 | 2010-09-02 | Borgwarner Inc. | Duct for changing direction of flow, particularly for turbocharger compressor inlet |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1887873A (en) | 1930-02-03 | 1932-11-15 | B F Sturtevant Co | Centrifugal fan |

| US1991660A (en) | 1932-07-14 | 1935-02-19 | Collins Thomas Bosanko | Control of fans, blowers, and pumps |

| US6520738B2 (en) * | 2001-03-15 | 2003-02-18 | Honeywell International, Inc. | Plenum entry bulk swirl generator |

| EP1420146A1 (en) | 2002-11-13 | 2004-05-19 | Borg Warner Inc. | Prewhirl generator for radial compressor |

| US6994518B2 (en) | 2002-11-13 | 2006-02-07 | Borgwarner Inc. | Pre-whirl generator for radial compressor |

| US7093589B2 (en) * | 2004-01-08 | 2006-08-22 | Visteon Global Technologies, Inc. | Apparatus for increasing induction air flow rate to a turbocharger |

| ITTO20050558A1 (it) * | 2005-08-05 | 2007-02-06 | Fiat Ricerche | Motocompressore a piu' stadi per la compressione di fluidi, ad esempio per autoveicoli |

| US7556009B2 (en) * | 2007-09-07 | 2009-07-07 | Advanced Flow Engineering, Inc. | Air intake manifold for coupling the output of a compressor to the air intake of an internal combustion engine |

| CN201334927Y (zh) | 2008-12-10 | 2009-10-28 | 山东美晨科技股份有限公司 | 车用涡轮增压器进气管 |

| JP5193093B2 (ja) | 2009-02-27 | 2013-05-08 | 三菱重工業株式会社 | 可変容量型排気ターボ過給機 |

-

2012

- 2012-02-29 JP JP2012044103A patent/JP5787790B2/ja not_active Expired - Fee Related

-

2013

- 2013-02-26 WO PCT/JP2013/054988 patent/WO2013129409A1/ja not_active Ceased

- 2013-02-26 CN CN201380011346.5A patent/CN104169588B/zh not_active Expired - Fee Related

- 2013-02-26 EP EP13754588.5A patent/EP2821652B1/en active Active

- 2013-02-26 US US14/379,691 patent/US9790957B2/en not_active Expired - Fee Related

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS60190942U (ja) * | 1984-05-29 | 1985-12-18 | 日野自動車株式会社 | タ−ボチヤ−ジヤ− |

| JP2007154895A (ja) * | 2005-12-08 | 2007-06-21 | General Electric Co <Ge> | 圧縮機入口のための流れ方向転換器 |

| US20100221107A1 (en) * | 2007-10-19 | 2010-09-02 | Borgwarner Inc. | Duct for changing direction of flow, particularly for turbocharger compressor inlet |

| JP2010065681A (ja) * | 2008-09-10 | 2010-03-25 | Borgwarner Inc | 受動的予旋回の逆方向回転のためのターボチャージャ連結 |

Non-Patent Citations (1)

| Title |

|---|

| See also references of EP2821652A4 * |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2016001181A1 (de) * | 2014-07-03 | 2016-01-07 | Siemens Aktiengesellschaft | Strömungsumlenkung bei einer strömungsmaschine |

| CN111212972A (zh) * | 2017-10-13 | 2020-05-29 | 五十铃自动车株式会社 | 进气导管 |

| CN111212972B (zh) * | 2017-10-13 | 2022-07-12 | 五十铃自动车株式会社 | 进气导管 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2821652A1 (en) | 2015-01-07 |

| US20150050136A1 (en) | 2015-02-19 |

| CN104169588B (zh) | 2016-11-16 |

| EP2821652B1 (en) | 2022-08-31 |

| JP2013181414A (ja) | 2013-09-12 |

| EP2821652A4 (en) | 2015-10-28 |

| CN104169588A (zh) | 2014-11-26 |

| JP5787790B2 (ja) | 2015-09-30 |

| US9790957B2 (en) | 2017-10-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5787790B2 (ja) | 遠心流体機械の吸気管構造 | |

| JP5221985B2 (ja) | 遠心圧縮機 | |

| JP6470853B2 (ja) | 遠心圧縮機及びターボチャージャ | |

| JP2007239538A (ja) | 遠心式送風機 | |

| WO2016035329A1 (ja) | ターボチャージャの排気タービン | |

| JP2008208753A (ja) | 遠心圧縮機 | |

| JPWO2020012648A1 (ja) | 遠心圧縮機及びターボチャージャ | |

| JPWO2018131167A1 (ja) | タービンホイール、タービン及びターボチャージャ | |

| JP2007127108A (ja) | 排気ターボ過給機のコンプレッサ | |

| JP2016053352A (ja) | ターボチャージャの排気タービン | |

| JP6638159B2 (ja) | 圧縮機スクロール、および、遠心圧縮機 | |

| US11209015B2 (en) | Centrifugal compressor | |

| JP6077100B2 (ja) | 流体機械及びこれを備えた流体機械システム | |

| JP6620440B2 (ja) | 遠心圧縮機 | |

| JP6949227B2 (ja) | 遠心圧縮機及びターボチャージャ | |

| JPWO2019097730A1 (ja) | 遠心圧縮機及びこの遠心圧縮機を備えたターボチャージャ | |

| CN117242265A (zh) | 风扇、尤其是径流式风扇或斜流式风扇 | |

| KR100669917B1 (ko) | 팬과 쉬라우드의 조립체 | |

| JPWO2018179112A1 (ja) | コンプレッサのスクロール形状及び過給機 | |

| JP7515025B2 (ja) | 遠心圧縮機及びターボチャージャ | |

| JP2016053353A (ja) | ターボチャージャの排気タービン | |

| WO2021124466A1 (ja) | コンプレッサおよび該コンプレッサを備えるターボチャージャ | |

| JP2012215073A (ja) | ターボチャージャ |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 13754588 Country of ref document: EP Kind code of ref document: A1 |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 14379691 Country of ref document: US Ref document number: 2013754588 Country of ref document: EP |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |