WO2012165397A1 - 遊離塩素を除去する工程を設けたパーム油の製造方法 - Google Patents

遊離塩素を除去する工程を設けたパーム油の製造方法 Download PDFInfo

- Publication number

- WO2012165397A1 WO2012165397A1 PCT/JP2012/063691 JP2012063691W WO2012165397A1 WO 2012165397 A1 WO2012165397 A1 WO 2012165397A1 JP 2012063691 W JP2012063691 W JP 2012063691W WO 2012165397 A1 WO2012165397 A1 WO 2012165397A1

- Authority

- WO

- WIPO (PCT)

- Prior art keywords

- free chlorine

- palm

- oil

- crude oil

- water

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11B—PRODUCING, e.g. BY PRESSING RAW MATERIALS OR BY EXTRACTION FROM WASTE MATERIALS, REFINING OR PRESERVING FATS, FATTY SUBSTANCES, e.g. LANOLIN, FATTY OILS OR WAXES; ESSENTIAL OILS; PERFUMES

- C11B1/00—Production of fats or fatty oils from raw materials

- C11B1/06—Production of fats or fatty oils from raw materials by pressing

-

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23D—EDIBLE OILS OR FATS, e.g. MARGARINES, SHORTENINGS OR COOKING OILS

- A23D9/00—Other edible oils or fats, e.g. shortenings or cooking oils

- A23D9/02—Other edible oils or fats, e.g. shortenings or cooking oils characterised by the production or working-up

-

- C—CHEMISTRY; METALLURGY

- C11—ANIMAL OR VEGETABLE OILS, FATS, FATTY SUBSTANCES OR WAXES; FATTY ACIDS THEREFROM; DETERGENTS; CANDLES

- C11B—PRODUCING, e.g. BY PRESSING RAW MATERIALS OR BY EXTRACTION FROM WASTE MATERIALS, REFINING OR PRESERVING FATS, FATTY SUBSTANCES, e.g. LANOLIN, FATTY OILS OR WAXES; ESSENTIAL OILS; PERFUMES

- C11B3/00—Refining fats or fatty oils

Definitions

- the present invention relates to a method for producing palm crude oil provided with a step of removing free chlorine.

- palm crude oil having a free chlorine content of 2 ppm or less obtained by the production method, and refinement in which the content of 3-monochloropropane-1,2-diol fatty acid ester obtained by refining the palm crude oil is 1 mg / kg or less Concerning palm oil.

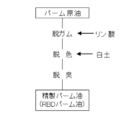

- Palm oil is mainly produced in Malaysia and Indonesia, and the manufacturing process consists of an oil extraction process for extracting oil from the mesocarp of the palm fruit bunch and a purification process for purification.

- purification methods There are two types of purification methods: physical purification and chemical purification.

- physical purification is possible because the purification process can be simplified, the yield is good, and the quality of the fatty acid obtained is good. Law has become mainstream.

- Physically refined RBD (Refined Bleached Deodorized) oil is exported, and imported countries such as Japan often use it after decoloring and deodorizing again.

- the flow of the oil extraction process and the refining process (physical refining method) is shown in FIGS.

- Non-Patent Document 2 discloses a study of removing 3-monochloropropane-1,2-diol fatty acid esters from fats and oils.

- An object of the present invention is to provide a method for producing palm oil that can suppress the production of 3-monochloropropane-1,2-diol fatty acid ester at low cost.

- palm oil more specifically, palm crude oil having a free chlorine content of 2 ppm or less, and a content of 3-monochloropropane-1,2-diol fatty acid ester obtained by refining the palm crude oil is 1 mg / kg. It is an object to provide the following refined palm oil.

- the gist of the present invention is a method for producing palm crude oil from which free chlorine described in the following (1) to (5) is removed.

- Free chlorine is removed by providing a step for removing free chlorine from the compressed oil after pressing in the oil pressing step and / or from palm crude oil before refining treatment in the refining step.

- the step of removing free chlorine is the step of removing free chlorine, which is a factor that produces 3-monochloropropane-1,2-diol fatty acid ester, and the free chlorine described in (1) above is removed.

- a method for producing palm crude oil is a method for producing palm crude oil.

- this invention makes the summary the palm crude oil described in the following (6).

- Palm crude oil having a free chlorine content of 2 ppm or less by the production method according to any one of (1) to (5) above.

- this invention makes the summary the refined palm oil described in the following (7).

- (7) Refined palm oil having a content of 3-monochloropropane-1,2-diol fatty acid ester of 1 mg / kg or less obtained by refining the palm crude oil according to (6) above.

- the method for producing palm crude oil of the present invention is a compressed oil after squeezing in the oil squeezing process at the time of palm crude oil production and / or before a refining process in the refining process at the time of producing refined palm oil.

- a process for removing free chlorine is provided for palm crude oil.

- the process of removing free chlorine for compressed oil is provided after pressing in the oil pressing process during the production of palm crude oil, preferably after water washing (clarification treatment) for the purpose of removing fibers and the like. It is before refinement

- the removal of free chlorine in the step of removing free chlorine of the present invention is preferably to reduce the amount of free chlorine to such an extent that the production of 3-monochloropropane-1,2-diol fatty acid ester can be sufficiently suppressed.

- the purpose of removing free chlorine is to remove free chlorine which is a substance that produces 3-monochloropropane-1,2-diol fatty acid ester. Accordingly, it can be said that palm crude oil from which free chlorine has been removed, preferably palm crude oil having a free chlorine content of 2 ppm or less, is palm crude oil in which the production of 3-monochloropropane-1,2-diol fatty acid ester is suppressed.

- the refined palm oil obtained by refining the crude palm oil becomes a refined palm oil having a content of 3-monochloropropane-1,2-diol fatty acid ester of 1 mg / kg or less.

- the step of removing free chlorine is a step of washing with water once or more.

- the water used for washing to remove free chlorine is preferably water that does not contain chlorine ions, such as pure water, ultrapure water, distilled water, or ion-exchanged water, or water from which chlorine ions have been removed. Further, water having a temperature of 20 ° C. to 80 ° C. is used in an amount of 5 to 100% by weight based on the oil.

- free chlorine cannot be removed sufficiently by a single water wash (clarification treatment) for the purpose of removing the current fiber.

- the step of removing free chlorine according to the present invention that is, washing with water containing no chlorine at 80 ° C. once or more, preferably twice or more, thereby producing 3-monochloropropane-1,2-diol fatty acid ester. Free chlorine, which is a generation factor, could be removed.

- Comparative Example 1 (conventional): 3.3 mg / kg

- Example 1 one water wash to remove free chlorine

- Example 2 (twice with water to remove free chlorine): 0.5 mg / kg

- 3-monochloropropane-1,2-diol fatty acid ester in refined palm oil even when washing with tap water (free chlorine amount 15 mg / L) is performed twice.

- free chlorine amount 15 mg / L is performed twice.

- Palm oil was obtained by using the compressed oil obtained after the squeezing in FIG. 1 and then washed with water for the purpose of removing fibers and the like after squeezing (clarification treatment). The amount of free chlorine in the obtained palm crude oil was 5.2 ppm. This palm crude oil was subjected to physical refining treatment (FIG. 2) under the following conditions to obtain refined palm oil (RBD palm oil). The content of 3-monochloropropane-1,2-diol fatty acid ester in the refined palm oil was 3.3 mg / kg.

- ⁇ Physical purification treatment> Degumming treatment: 0.1% by weight of 75% phosphoric acid solution was added to palm crude oil and stirred at 40 ° C. for 15 minutes.

- Decoloring treatment 2% by weight of activated clay was added to palm crude oil, stirred at 105 ° C. under reduced pressure for 20 minutes, and filtered.

- Deodorization treatment Deodorization was performed by blowing 2.5% by weight of steam at 250 ° C. for 60 minutes under vacuum.

- Example 1 As shown in FIG. 3, 20 wt. Of pure water (80 ° C.) with respect to the pressed oil is obtained by pressing water (80 ° C.) once with water washing (clarification treatment) for the purpose of removing fibers and the like after pressing. % was added and stirred, and the water layer was removed by centrifugal separation and washed once with water, and then dried to obtain palm crude oil. The amount of free chlorine in the obtained palm crude oil was 1.6 ppm. As in Comparative Example 1, physical purification treatment (degumming treatment, decolorization treatment, deodorization treatment) was performed to obtain purified palm oil (RBD palm oil). The content of 3-monochloropropane-1,2-diol fatty acid ester in the refined palm oil was 0.9 mg / kg.

- Example 2 As shown in FIG. 3, 20 wt. Of pure water (80 ° C.) with respect to the pressed oil is obtained by pressing water (80 ° C.) once with water washing (clarification treatment) for the purpose of removing fibers and the like after pressing. %, And the process of removing the aqueous layer by centrifugation and washing with water was repeated twice, and then dried to obtain palm crude oil. The amount of free chlorine in the obtained palm crude oil was 0.4 ppm. As in Comparative Example 1, physical purification treatment (degumming treatment, decolorization treatment, deodorization treatment) was performed to obtain purified palm oil (RBD palm oil). The content of 3-monochloropropane-1,2-diol fatty acid ester in the refined palm oil was 0.5 mg / kg.

- Example 3 The palm crude oil obtained in Comparative Example 1 was heated to 80 ° C., and as shown in FIG. 4, pure water (80 ° C.) was added to the palm crude oil by 20% by weight and stirred, and the aqueous layer was separated by centrifugation. The process of removing and washing with water was repeated twice to obtain palm crude oil.

- the obtained palm crude oil had a free chlorine content of 0.4 ppm, and it was confirmed that the quality was equivalent to the palm crude oil obtained in Example 2. Thereafter, the same results as in Example 2 were obtained when physical purification treatment (degumming treatment, decolorization treatment, deodorization treatment) was performed, and the content of 3-monochloropropane-1,2-diol fatty acid ester was 0.5 mg. / Kg.

- Palm crude oil obtained in the same manner as in Comparative Example 1 was heated to 80 ° C., and as shown in FIG. 4, tap water (free chlorine amount 15 mg / L, 80 ° C.) was added at 20% by weight to palm crude oil. Then, the process of removing the water layer by centrifugation and washing with water was repeated twice to obtain palm crude oil. The amount of free chlorine in the obtained palm crude oil was 0.8 ppm.

- physical purification treatment (degumming treatment, decolorization treatment, deodorization treatment) was performed to obtain purified palm oil (RBD palm oil).

- the content of 3-monochloropropane-1,2-diol fatty acid ester in the refined palm oil was 0.7 mg / kg.

- Example 4 The results of Example 4 are shown in Table 2.

- the method for producing palm crude oil according to the present invention does not generate soda oil cake, has a good yield, and retains the characteristics of a physical refining method for obtaining a high-quality fatty acid, and 3-monochloropropane-1,2-diol fatty acid. Formation of ester can be suppressed. Moreover, it can be manufactured at low cost because it uses only alkaline water, adsorbents such as silica gel and activated carbon, and enzymes, and only water. The present invention can be expected to contribute to providing a refined palm oil that suppresses the formation of 3-monochloropropane-1,2-diol fatty acid ester.

Landscapes

- Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Wood Science & Technology (AREA)

- Organic Chemistry (AREA)

- Food Science & Technology (AREA)

- Polymers & Plastics (AREA)

- Microbiology (AREA)

- Fats And Perfumes (AREA)

- Edible Oils And Fats (AREA)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| EP12793855.3A EP2716746A1 (en) | 2011-06-01 | 2012-05-29 | Method for producing palm oil comprising step of removing free chlorine |

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2011-123352 | 2011-06-01 | ||

| JP2011123352A JP2011174091A (ja) | 2011-06-01 | 2011-06-01 | 遊離塩素を除去する工程を設けたパーム油の製造方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| WO2012165397A1 true WO2012165397A1 (ja) | 2012-12-06 |

Family

ID=44687216

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| PCT/JP2012/063691 Ceased WO2012165397A1 (ja) | 2011-06-01 | 2012-05-29 | 遊離塩素を除去する工程を設けたパーム油の製造方法 |

Country Status (3)

| Country | Link |

|---|---|

| EP (1) | EP2716746A1 (enExample) |

| JP (1) | JP2011174091A (enExample) |

| WO (1) | WO2012165397A1 (enExample) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2015020236A1 (en) * | 2013-08-09 | 2015-02-12 | Kao Corporation | Fat or oil composition |

| WO2017035403A1 (en) | 2015-08-25 | 2017-03-02 | Dsm Ip Assets B.V. | Refined oil compositions and methods for making |

| WO2018156013A1 (en) | 2017-02-21 | 2018-08-30 | Sime Darby Plantation Berhad | Process for producing refined palm fruit oil |

| WO2019027315A2 (en) | 2017-08-04 | 2019-02-07 | Sime Darby Plantation Intellectual Property Sdn Bhd | PROCESS FOR PRODUCING REFINED PALM OIL HAVING REDUCED 3-MCPD CONTENT |

| CN111819270A (zh) * | 2018-03-14 | 2020-10-23 | 雀巢产品有限公司 | 三酰基甘油酯油的机械纯化 |

| CN113242901A (zh) * | 2018-12-19 | 2021-08-10 | 雀巢产品有限公司 | 防止三酰基甘油酯油中mcpde的形成 |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101207413B1 (ko) * | 2011-06-09 | 2012-12-04 | 씨제이제일제당 (주) | 3-클로로-1,2-프로판디올 생성물질이 저감된 식용유지 및 그 제조방법 |

| JP2014009292A (ja) * | 2012-06-29 | 2014-01-20 | Taiyo Yushi Kk | 3−クロロプロパン−1,2−ジオール脂肪酸エステルの量を低減させた油脂組成物の製造方法 |

| JP6451447B2 (ja) * | 2015-03-27 | 2019-01-16 | 不二製油株式会社 | モノクロロプロパンジオール生成物質含有量を低減させた精製パーム油の製造方法 |

| MY190874A (en) | 2017-03-30 | 2022-05-13 | Sime Darby Plantation Berhad | Process for producing a refined vegetable oil |

| MY186195A (en) * | 2018-06-01 | 2021-06-30 | Sime Darby Plantation Intellectual Property Sdn Bhd | Process for producing crude palm fruit oil |

| US20220333036A1 (en) * | 2019-09-13 | 2022-10-20 | Societe Des Produits Nestle S.A. | Prevention of mcpd formation in triacylglyceride oils |

| CN114845556A (zh) | 2019-12-25 | 2022-08-02 | 不二制油集团控股株式会社 | 降低了缩水甘油及缩水甘油脂肪酸酯含量的食用油脂及其制造方法 |

| JP6919755B2 (ja) * | 2019-12-25 | 2021-08-18 | 不二製油株式会社 | グリシドール及びグリシドール脂肪酸エステル含有量を低減させた食用油脂及びその製造方法 |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS53114805A (en) * | 1977-02-24 | 1978-10-06 | Nisshin Oil Mills Ltd:The | Production of palm oil |

| JPH041296A (ja) * | 1990-04-19 | 1992-01-06 | Nisshin Oil Mills Ltd:The | 植物油の脱ロウ法 |

| JP2006028466A (ja) * | 2004-07-16 | 2006-02-02 | Tsukishima Shokuhin Kogyo Kk | 油脂の精製方法 |

| WO2010050449A1 (ja) * | 2008-10-28 | 2010-05-06 | 日清オイリオグループ株式会社 | パーム油、脱臭留出物及びそれらの製造方法 |

| WO2010126136A1 (ja) | 2009-04-30 | 2010-11-04 | 不二製油株式会社 | グリセリド油脂中のクロロプロパノール類及びその形成物質の生成を抑制する方法 |

| WO2011040539A1 (ja) | 2009-09-30 | 2011-04-07 | 不二製油株式会社 | グリセリド油脂中のクロロプロパノール類及びその形成物質、グリシドール脂肪酸エステルを低減する方法 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102008060059A1 (de) * | 2008-12-02 | 2010-06-10 | Süd-Chemie AG | Verfahren zur Reduzierung des 3-MCPD-Gehalts in raffinierten Pflanzenölen |

| SG177423A1 (en) * | 2009-06-30 | 2012-02-28 | Sime Darby Malaysia Berhad | Process for removing unwanted propanol components from unused triglyceride oil |

| CN102843914B (zh) * | 2010-05-07 | 2016-01-20 | 株式会社艾迪科 | 食用油脂的精制方法 |

| JP5561481B2 (ja) * | 2010-12-10 | 2014-07-30 | Jfeエンジニアリング株式会社 | アブラヤシ空果房の前処理方法及び燃焼・熱回収方法 |

-

2011

- 2011-06-01 JP JP2011123352A patent/JP2011174091A/ja active Pending

-

2012

- 2012-05-29 WO PCT/JP2012/063691 patent/WO2012165397A1/ja not_active Ceased

- 2012-05-29 EP EP12793855.3A patent/EP2716746A1/en not_active Withdrawn

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS53114805A (en) * | 1977-02-24 | 1978-10-06 | Nisshin Oil Mills Ltd:The | Production of palm oil |

| JPH041296A (ja) * | 1990-04-19 | 1992-01-06 | Nisshin Oil Mills Ltd:The | 植物油の脱ロウ法 |

| JP2006028466A (ja) * | 2004-07-16 | 2006-02-02 | Tsukishima Shokuhin Kogyo Kk | 油脂の精製方法 |

| WO2010050449A1 (ja) * | 2008-10-28 | 2010-05-06 | 日清オイリオグループ株式会社 | パーム油、脱臭留出物及びそれらの製造方法 |

| WO2010126136A1 (ja) | 2009-04-30 | 2010-11-04 | 不二製油株式会社 | グリセリド油脂中のクロロプロパノール類及びその形成物質の生成を抑制する方法 |

| WO2011040539A1 (ja) | 2009-09-30 | 2011-04-07 | 不二製油株式会社 | グリセリド油脂中のクロロプロパノール類及びその形成物質、グリシドール脂肪酸エステルを低減する方法 |

Non-Patent Citations (5)

| Title |

|---|

| "Summary report of a workshop held", February 2009, INTERNATIONAL LIFE SCIENCES INSTITUTE, article "ILSI Europe Report Series: 3-MCPD esters in food products" |

| EUR J LIPID SCI TECHNOL, vol. 112, no. 5, 2010, pages 552 - 556 |

| FOOD ADDIT CONTAM, vol. 23, no. 12, 2006, pages 1290 - 1298 |

| LWT FOOD SCI TECHNOL, vol. 42, no. 10, 2009, pages 1751 - 1754 |

| YOSHIRO ABE, YUSHI YURYO HANDBOOK, 25 May 1988 (1988-05-25), pages 257 - 260, XP008142372 * |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2015020236A1 (en) * | 2013-08-09 | 2015-02-12 | Kao Corporation | Fat or oil composition |

| JP2015034259A (ja) * | 2013-08-09 | 2015-02-19 | 花王株式会社 | 油脂組成物 |

| WO2017035403A1 (en) | 2015-08-25 | 2017-03-02 | Dsm Ip Assets B.V. | Refined oil compositions and methods for making |

| US11672258B2 (en) | 2015-08-25 | 2023-06-13 | Dsm Ip Assets B.V. | Refined oil compositions and methods for making |

| WO2018156013A1 (en) | 2017-02-21 | 2018-08-30 | Sime Darby Plantation Berhad | Process for producing refined palm fruit oil |

| WO2019027315A2 (en) | 2017-08-04 | 2019-02-07 | Sime Darby Plantation Intellectual Property Sdn Bhd | PROCESS FOR PRODUCING REFINED PALM OIL HAVING REDUCED 3-MCPD CONTENT |

| CN111819270A (zh) * | 2018-03-14 | 2020-10-23 | 雀巢产品有限公司 | 三酰基甘油酯油的机械纯化 |

| CN111819270B (zh) * | 2018-03-14 | 2024-03-15 | 雀巢产品有限公司 | 三酰基甘油酯油的机械纯化 |

| CN113242901A (zh) * | 2018-12-19 | 2021-08-10 | 雀巢产品有限公司 | 防止三酰基甘油酯油中mcpde的形成 |

Also Published As

| Publication number | Publication date |

|---|---|

| EP2716746A1 (en) | 2014-04-09 |

| JP2011174091A (ja) | 2011-09-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| WO2012165397A1 (ja) | 遊離塩素を除去する工程を設けたパーム油の製造方法 | |

| WO2010126136A1 (ja) | グリセリド油脂中のクロロプロパノール類及びその形成物質の生成を抑制する方法 | |

| EP2449070B1 (en) | Process for removing unwanted propanol components from unused triglyceride oil | |

| EP3058054A1 (en) | Mitigation of 2-mcpd, 3-mcpd, esters therof and glycidyl esters in vegetable oil | |

| CN104159454A (zh) | 处理植物油的方法 | |

| WO2014081279A1 (en) | An improved palm oil refining process | |

| JP5216942B1 (ja) | 精製グリセリド組成物及び該精製グリセリド組成物の製造方法 | |

| WO2011055732A1 (ja) | グリセリド油脂中のクロロプロパノール類及びその形成物質を低減する方法 | |

| WO2010050449A1 (ja) | パーム油、脱臭留出物及びそれらの製造方法 | |

| JP2014501808A (ja) | 精製された植物油を製造する方法 | |

| WO2014034154A1 (ja) | 精製油脂の製造方法 | |

| JP6385634B2 (ja) | 油脂の製造方法 | |

| JP6451447B2 (ja) | モノクロロプロパンジオール生成物質含有量を低減させた精製パーム油の製造方法 | |

| WO2013163112A1 (en) | Improved fractionation processes | |

| WO2011034091A1 (ja) | 精製油脂の製造方法 | |

| CN113563970B (zh) | 一种降低精炼食用植物油油烟量的生产工艺 | |

| WO2015146248A1 (ja) | 精製パーム系油脂の製造方法 | |

| JP6013746B2 (ja) | 精製食用油脂の製造法 | |

| JP6396399B2 (ja) | 飽和炭化水素含有量が低減されたパーム油 | |

| JP6639149B2 (ja) | 精製油脂の製造方法 | |

| JP6219147B2 (ja) | 精製魚油の製造方法 | |

| JP4365260B2 (ja) | なたね香味油の製造法 | |

| CN106336941A (zh) | 一种化妆品用茶叶籽油的制备方法 | |

| JP6857017B2 (ja) | 油脂組成物 | |

| JP5535461B2 (ja) | 油脂の製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| 121 | Ep: the epo has been informed by wipo that ep was designated in this application |

Ref document number: 12793855 Country of ref document: EP Kind code of ref document: A1 |

|

| NENP | Non-entry into the national phase |

Ref country code: DE |

|

| WWE | Wipo information: entry into national phase |

Ref document number: 2012793855 Country of ref document: EP |