RU2456067C2 - Реактор для проведения реакции между двумя текучими исходными веществами в катализаторном слое с предварительным смешиванием текучих исходных веществ в устройстве для смешивания - Google Patents

Реактор для проведения реакции между двумя текучими исходными веществами в катализаторном слое с предварительным смешиванием текучих исходных веществ в устройстве для смешивания Download PDFInfo

- Publication number

- RU2456067C2 RU2456067C2 RU2009127502/05A RU2009127502A RU2456067C2 RU 2456067 C2 RU2456067 C2 RU 2456067C2 RU 2009127502/05 A RU2009127502/05 A RU 2009127502/05A RU 2009127502 A RU2009127502 A RU 2009127502A RU 2456067 C2 RU2456067 C2 RU 2456067C2

- Authority

- RU

- Russia

- Prior art keywords

- pipes

- perforated metal

- metal sheet

- reactor according

- ribs

- Prior art date

Links

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/30—Injector mixers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/008—Details of the reactor or of the particulate material; Processes to increase or to retard the rate of reaction

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/30—Injector mixers

- B01F25/31—Injector mixers in conduits or tubes through which the main component flows

- B01F25/313—Injector mixers in conduits or tubes through which the main component flows wherein additional components are introduced in the centre of the conduit

- B01F25/3132—Injector mixers in conduits or tubes through which the main component flows wherein additional components are introduced in the centre of the conduit by using two or more injector devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/30—Injector mixers

- B01F25/31—Injector mixers in conduits or tubes through which the main component flows

- B01F25/313—Injector mixers in conduits or tubes through which the main component flows wherein additional components are introduced in the centre of the conduit

- B01F25/3132—Injector mixers in conduits or tubes through which the main component flows wherein additional components are introduced in the centre of the conduit by using two or more injector devices

- B01F25/31322—Injector mixers in conduits or tubes through which the main component flows wherein additional components are introduced in the centre of the conduit by using two or more injector devices used simultaneously

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/008—Details of the reactor or of the particulate material; Processes to increase or to retard the rate of reaction

- B01J8/0085—Details of the reactor or of the particulate material; Processes to increase or to retard the rate of reaction promoting uninterrupted fluid flow, e.g. by filtering out particles in front of the catalyst layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

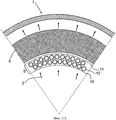

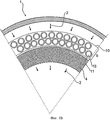

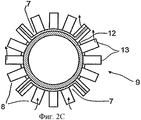

- B01J8/0207—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid flow within the bed being predominantly horizontal

- B01J8/0214—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid flow within the bed being predominantly horizontal in a cylindrical annular shaped bed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

- B01J8/0278—Feeding reactive fluids

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

- B01J8/04—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

- B01J8/04—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds

- B01J8/0446—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds the flow within the beds being predominantly vertical

- B01J8/0449—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds the flow within the beds being predominantly vertical in two or more cylindrical beds

- B01J8/0453—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds the flow within the beds being predominantly vertical in two or more cylindrical beds the beds being superimposed one above the other

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

- B01J8/04—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds

- B01J8/0492—Feeding reactive fluids

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2208/00—Processes carried out in the presence of solid particles; Reactors therefor

- B01J2208/00796—Details of the reactor or of the particulate material

- B01J2208/00823—Mixing elements

- B01J2208/00831—Stationary elements

- B01J2208/00849—Stationary elements outside the bed, e.g. baffles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2208/00—Processes carried out in the presence of solid particles; Reactors therefor

- B01J2208/00796—Details of the reactor or of the particulate material

- B01J2208/00884—Means for supporting the bed of particles, e.g. grids, bars, perforated plates

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2219/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

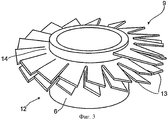

- B01J2219/19—Details relating to the geometry of the reactor

- B01J2219/194—Details relating to the geometry of the reactor round

- B01J2219/1941—Details relating to the geometry of the reactor round circular or disk-shaped

- B01J2219/1946—Details relating to the geometry of the reactor round circular or disk-shaped conical

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8593—Systems

- Y10T137/87571—Multiple inlet with single outlet

- Y10T137/87652—With means to promote mixing or combining of plural fluids

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Devices And Processes Conducted In The Presence Of Fluids And Solid Particles (AREA)

- Physical Or Chemical Processes And Apparatus (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

Applications Claiming Priority (4)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102006060507.1 | 2006-12-19 | ||

| DE200610060507 DE102006060507A1 (de) | 2006-12-19 | 2006-12-19 | Reaktor zur Durchführung einer Reaktion zwischen zwei fluiden Edukten an einem Katalysatorbett mit Vorvermischen der fluiden Edukte in einer Einmischvorrichtung |

| US87094506P | 2006-12-20 | 2006-12-20 | |

| US60/870,945 | 2006-12-20 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| RU2009127502A RU2009127502A (ru) | 2011-01-27 |

| RU2456067C2 true RU2456067C2 (ru) | 2012-07-20 |

Family

ID=39431505

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| RU2009127502/05A RU2456067C2 (ru) | 2006-12-19 | 2007-12-14 | Реактор для проведения реакции между двумя текучими исходными веществами в катализаторном слое с предварительным смешиванием текучих исходных веществ в устройстве для смешивания |

Country Status (13)

| Country | Link |

|---|---|

| US (1) | US7854906B2 (fr) |

| EP (2) | EP2104553B1 (fr) |

| JP (1) | JP5260547B2 (fr) |

| KR (1) | KR101424028B1 (fr) |

| CN (1) | CN101600494B (fr) |

| BR (1) | BRPI0720412A2 (fr) |

| DE (1) | DE102006060507A1 (fr) |

| MY (1) | MY149683A (fr) |

| RU (1) | RU2456067C2 (fr) |

| SG (1) | SG153458A1 (fr) |

| TW (1) | TWI430842B (fr) |

| WO (1) | WO2008074737A1 (fr) |

| ZA (1) | ZA200904965B (fr) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7704293B2 (en) * | 2007-10-23 | 2010-04-27 | Institute Of Nuclear Energy Research | Turbulence device used for air filtration system |

| TW200936245A (en) * | 2007-10-30 | 2009-09-01 | Basf Se | Horizontal reactor for reacting a fluid feed stream with a fluid oxidant stream in the presence of a solid catalyst |

| EP2165755A1 (fr) * | 2008-09-23 | 2010-03-24 | Methanol Casale S.A. | Échangeur thermique avec éléments agencés de manière radiale pour des réacteurs chimiques isothermes |

| US9308121B2 (en) * | 2011-02-07 | 2016-04-12 | Roger Clemente | Helical air distribution system |

| EP2703076B1 (fr) * | 2012-08-29 | 2016-04-27 | Wolfgang Gerlinger | Réacteur pourvu d'une ou plusieurs conduites d'entrée de fluide et d'un dispositif de distribution desdits fluides |

| CN105623733B (zh) * | 2014-10-27 | 2017-03-01 | 中国石油化工股份有限公司 | 一种石油烃的吸附脱硫方法 |

| US10478794B1 (en) | 2019-02-26 | 2019-11-19 | Chevron Phillips Chemical Company Lp | Bi-modal radial flow reactor |

| PL429466A1 (pl) * | 2019-04-01 | 2020-10-05 | Marek Mania | Filtr szczelinowy samooczyszczający się |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2350644A (en) * | 1942-10-28 | 1944-06-06 | Socony Vacuum Oil Co Inc | Apparatus for catalytic conversion |

| US2417393A (en) * | 1942-11-04 | 1947-03-11 | Socony Vacuum Oil Co Inc | Apparatus for hydrocarbon reaction |

| US5462719A (en) * | 1994-06-08 | 1995-10-31 | Atlantic Richfield Company | Method and apparatus for mixing and distributing fluids in a reactor |

| US5885442A (en) * | 1994-09-02 | 1999-03-23 | Michael Grigorjewitsch Lapunow | Process for producing petrol of high octane number by catalytic reforming and a reactor for carrying out this process |

| RU30289U1 (ru) * | 2003-03-27 | 2003-06-27 | Общество с ограниченной ответственностью Научно-производственная компания "Кедр - 89" | Реактор для каталитических процессов |

| RU2234975C2 (ru) * | 1998-07-09 | 2004-08-27 | Стоун энд Вебстэ, Инк. | Проточный реактор с радиальным потоком и способ обработки жидкого потока реагентов |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2276307A (en) * | 1938-04-18 | 1942-03-17 | Houdry Process Corp | Catalytic converter |

| US3214247A (en) | 1963-02-25 | 1965-10-26 | Universal Oil Prod Co | Fluid distributing means for packed chambers |

| FR2019968B1 (fr) | 1968-10-04 | 1974-11-15 | Escoa Corp | |

| GB1328302A (en) * | 1970-06-25 | 1973-08-30 | Escoa Fintube Corp | Segmented finned tube and its method of manufacture |

| JPS5932178B2 (ja) * | 1981-11-06 | 1984-08-07 | 永岡金網株式会社 | 多孔管内包式スクリ−ン筒 |

| JPS5959242A (ja) * | 1982-09-28 | 1984-04-05 | Toyo Eng Corp | 反応方法およびそのための反応器 |

| JP3858132B2 (ja) * | 1999-03-29 | 2006-12-13 | 日立造船株式会社 | 排ガス脱硝システムのアンモニア注入装置 |

| US6772830B1 (en) * | 1999-07-21 | 2004-08-10 | Stone & Webster, Inc. | Enhanced crossflow heat transfer |

| EP1080780B1 (fr) * | 1999-08-31 | 2007-08-01 | Nippon Shokubai Co., Ltd. | Réacteur pour l'oxydation catalytique en phase gazeuse |

| US7316804B2 (en) * | 2001-08-02 | 2008-01-08 | Ineos Usa Llc | Flow reactors for chemical conversions with heterogeneous catalysts |

| DE10359744A1 (de) * | 2003-12-19 | 2005-07-14 | Uhde Gmbh | Verfahren und Vorrichtung zum Eindüsen von Sauerstoff in einen Synthesereaktor |

| DE102004024957A1 (de) | 2004-05-22 | 2005-12-22 | Uhde Gmbh | Verfahren und Vorrichtung zum Eindüsen von Sauerstoff in ein einen Synthesereaktor durchströmendes Reaktionsgas |

| DE102006060509A1 (de) * | 2006-12-19 | 2008-06-26 | Basf Se | Reaktor zur Durchführung einer kontinuierlichen Oxidehydrierung sowie Verfahren |

-

2006

- 2006-12-19 DE DE200610060507 patent/DE102006060507A1/de not_active Withdrawn

-

2007

- 2007-12-14 BR BRPI0720412-4A2A patent/BRPI0720412A2/pt not_active IP Right Cessation

- 2007-12-14 RU RU2009127502/05A patent/RU2456067C2/ru not_active IP Right Cessation

- 2007-12-14 SG SG200904205A patent/SG153458A1/en unknown

- 2007-12-14 MY MYPI20092537A patent/MY149683A/en unknown

- 2007-12-14 KR KR1020097014950A patent/KR101424028B1/ko not_active IP Right Cessation

- 2007-12-14 EP EP20070848103 patent/EP2104553B1/fr not_active Not-in-force

- 2007-12-14 CN CN2007800510248A patent/CN101600494B/zh not_active Expired - Fee Related

- 2007-12-14 WO PCT/EP2007/063951 patent/WO2008074737A1/fr active Application Filing

- 2007-12-14 EP EP12175556.5A patent/EP2517784B1/fr not_active Not-in-force

- 2007-12-14 JP JP2009542012A patent/JP5260547B2/ja not_active Expired - Fee Related

- 2007-12-18 US US11/959,008 patent/US7854906B2/en not_active Expired - Fee Related

- 2007-12-19 TW TW96148759A patent/TWI430842B/zh not_active IP Right Cessation

-

2009

- 2009-07-16 ZA ZA200904965A patent/ZA200904965B/xx unknown

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2350644A (en) * | 1942-10-28 | 1944-06-06 | Socony Vacuum Oil Co Inc | Apparatus for catalytic conversion |

| US2417393A (en) * | 1942-11-04 | 1947-03-11 | Socony Vacuum Oil Co Inc | Apparatus for hydrocarbon reaction |

| US5462719A (en) * | 1994-06-08 | 1995-10-31 | Atlantic Richfield Company | Method and apparatus for mixing and distributing fluids in a reactor |

| US5885442A (en) * | 1994-09-02 | 1999-03-23 | Michael Grigorjewitsch Lapunow | Process for producing petrol of high octane number by catalytic reforming and a reactor for carrying out this process |

| RU2234975C2 (ru) * | 1998-07-09 | 2004-08-27 | Стоун энд Вебстэ, Инк. | Проточный реактор с радиальным потоком и способ обработки жидкого потока реагентов |

| RU30289U1 (ru) * | 2003-03-27 | 2003-06-27 | Общество с ограниченной ответственностью Научно-производственная компания "Кедр - 89" | Реактор для каталитических процессов |

Also Published As

| Publication number | Publication date |

|---|---|

| DE102006060507A1 (de) | 2008-06-26 |

| TW200909058A (en) | 2009-03-01 |

| EP2104553B1 (fr) | 2014-03-26 |

| CN101600494B (zh) | 2013-01-30 |

| KR20090091234A (ko) | 2009-08-26 |

| EP2517784A2 (fr) | 2012-10-31 |

| KR101424028B1 (ko) | 2014-07-28 |

| MY149683A (en) | 2013-09-30 |

| JP2010513005A (ja) | 2010-04-30 |

| EP2517784B1 (fr) | 2018-03-07 |

| ZA200904965B (en) | 2010-09-29 |

| CN101600494A (zh) | 2009-12-09 |

| US20080145285A1 (en) | 2008-06-19 |

| US7854906B2 (en) | 2010-12-21 |

| TWI430842B (zh) | 2014-03-21 |

| BRPI0720412A2 (pt) | 2013-12-31 |

| RU2009127502A (ru) | 2011-01-27 |

| EP2517784A3 (fr) | 2013-05-15 |

| SG153458A1 (en) | 2009-07-29 |

| JP5260547B2 (ja) | 2013-08-14 |

| EP2104553A1 (fr) | 2009-09-30 |

| WO2008074737A1 (fr) | 2008-06-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| RU2456067C2 (ru) | Реактор для проведения реакции между двумя текучими исходными веществами в катализаторном слое с предварительным смешиванием текучих исходных веществ в устройстве для смешивания | |

| US8061890B2 (en) | Static mixer | |

| US7837856B2 (en) | Reactor for carrying out a continuous oxydehydrogenation and process | |

| JP6245787B2 (ja) | モジュール式リアクタ | |

| US8303164B2 (en) | Low-pressure-drop mixing device and use thereof in the mixing of two gases/vapours | |

| WO2009109379A1 (fr) | Réacteur catalytique | |

| KR20140087053A (ko) | 튜브 모듈 | |

| GB2273888A (en) | Packed contact vessel | |

| JP2023073343A (ja) | 改善されたミキサー・ダクトおよびそれを使用するプロセス | |

| US20050095185A1 (en) | Catalytic reactor, corresponding reaction installation and method | |

| CN101842152A (zh) | 在存在固体催化剂时使流体供给流与流体氧化剂流发生反应的水平式反应器 | |

| US6657079B1 (en) | Method for mixing gases and apparatus therefor | |

| CN105582857B (zh) | 一种气液固三相反应器及其应用方法 | |

| JP2010513005A5 (fr) | ||

| MXPA01004118A (es) | Mezclador estatico con capas perfiladas. | |

| JP2021536351A (ja) | 構造化充填物 | |

| US20070212268A1 (en) | Laboratory-scale hydrogenation cartridge reactor for hydrogenating an inflowing multi-component fluid composition | |

| US20150071835A1 (en) | Non-adiabatic catalytic reactor | |

| DE102006006379B4 (de) | Verwendung einer Vorrichtung zur gleichmäßigen Verteilung von Stoffen | |

| RU2776384C2 (ru) | Реактор с радиальным потоком | |

| FI88115C (fi) | Statisk blandare | |

| JP5272998B2 (ja) | プレート反応器における充填物の充填方法 | |

| US20150166339A1 (en) | Reformer tube and apparatus and also process for producing a synthesis gas |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| MM4A | The patent is invalid due to non-payment of fees |

Effective date: 20181215 |