JP5260547B2 - 混入装置中での流体出発物質の前混合を伴なって触媒床で2つの流体出発物質の間で反応を実施するための反応器 - Google Patents

混入装置中での流体出発物質の前混合を伴なって触媒床で2つの流体出発物質の間で反応を実施するための反応器 Download PDFInfo

- Publication number

- JP5260547B2 JP5260547B2 JP2009542012A JP2009542012A JP5260547B2 JP 5260547 B2 JP5260547 B2 JP 5260547B2 JP 2009542012 A JP2009542012 A JP 2009542012A JP 2009542012 A JP2009542012 A JP 2009542012A JP 5260547 B2 JP5260547 B2 JP 5260547B2

- Authority

- JP

- Japan

- Prior art keywords

- reactor

- tube

- fluid starting

- tubes

- finned

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Expired - Fee Related

Links

- 239000012530 fluid Substances 0.000 title claims description 88

- 239000007858 starting material Substances 0.000 title claims description 69

- 239000003054 catalyst Substances 0.000 title claims description 44

- 238000006243 chemical reaction Methods 0.000 title claims description 12

- 238000011144 upstream manufacturing Methods 0.000 claims description 23

- 239000000203 mixture Substances 0.000 claims description 17

- 239000007789 gas Substances 0.000 claims description 16

- 239000000463 material Substances 0.000 claims description 9

- 239000012495 reaction gas Substances 0.000 claims description 5

- 239000011541 reaction mixture Substances 0.000 claims description 5

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims description 4

- 238000000034 method Methods 0.000 claims description 4

- 239000001301 oxygen Substances 0.000 claims description 4

- 229910052760 oxygen Inorganic materials 0.000 claims description 4

- 230000003647 oxidation Effects 0.000 claims description 3

- 238000007254 oxidation reaction Methods 0.000 claims description 3

- 239000000376 reactant Substances 0.000 claims description 3

- 238000010438 heat treatment Methods 0.000 claims description 2

- 239000011343 solid material Substances 0.000 claims 2

- CURLTUGMZLYLDI-UHFFFAOYSA-N Carbon dioxide Chemical compound O=C=O CURLTUGMZLYLDI-UHFFFAOYSA-N 0.000 description 10

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 6

- 229910002092 carbon dioxide Inorganic materials 0.000 description 5

- 239000001569 carbon dioxide Substances 0.000 description 5

- 238000010586 diagram Methods 0.000 description 4

- 238000005259 measurement Methods 0.000 description 4

- 230000003068 static effect Effects 0.000 description 4

- 239000007788 liquid Substances 0.000 description 3

- 229910052757 nitrogen Inorganic materials 0.000 description 3

- 239000007787 solid Substances 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 238000012360 testing method Methods 0.000 description 3

- ATUOYWHBWRKTHZ-UHFFFAOYSA-N Propane Chemical compound CCC ATUOYWHBWRKTHZ-UHFFFAOYSA-N 0.000 description 2

- 238000010521 absorption reaction Methods 0.000 description 2

- 238000012993 chemical processing Methods 0.000 description 2

- 238000004891 communication Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000002245 particle Substances 0.000 description 2

- OKTJSMMVPCPJKN-UHFFFAOYSA-N Carbon Chemical compound [C] OKTJSMMVPCPJKN-UHFFFAOYSA-N 0.000 description 1

- 229910000831 Steel Inorganic materials 0.000 description 1

- 230000004308 accommodation Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 239000001273 butane Substances 0.000 description 1

- 229910052799 carbon Inorganic materials 0.000 description 1

- 238000003763 carbonization Methods 0.000 description 1

- 238000004523 catalytic cracking Methods 0.000 description 1

- 239000000470 constituent Substances 0.000 description 1

- 238000005520 cutting process Methods 0.000 description 1

- 238000006477 desulfuration reaction Methods 0.000 description 1

- 230000023556 desulfurization Effects 0.000 description 1

- 238000004821 distillation Methods 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 239000004744 fabric Substances 0.000 description 1

- 239000002638 heterogeneous catalyst Substances 0.000 description 1

- 229930195733 hydrocarbon Natural products 0.000 description 1

- 150000002430 hydrocarbons Chemical class 0.000 description 1

- 238000004519 manufacturing process Methods 0.000 description 1

- 239000002184 metal Substances 0.000 description 1

- IJDNQMDRQITEOD-UHFFFAOYSA-N n-butane Chemical compound CCCC IJDNQMDRQITEOD-UHFFFAOYSA-N 0.000 description 1

- OFBQJSOFQDEBGM-UHFFFAOYSA-N n-pentane Natural products CCCCC OFBQJSOFQDEBGM-UHFFFAOYSA-N 0.000 description 1

- 238000012856 packing Methods 0.000 description 1

- 239000001294 propane Substances 0.000 description 1

- 239000010959 steel Substances 0.000 description 1

- 238000003466 welding Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/008—Details of the reactor or of the particulate material; Processes to increase or to retard the rate of reaction

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/30—Injector mixers

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/30—Injector mixers

- B01F25/31—Injector mixers in conduits or tubes through which the main component flows

- B01F25/313—Injector mixers in conduits or tubes through which the main component flows wherein additional components are introduced in the centre of the conduit

- B01F25/3132—Injector mixers in conduits or tubes through which the main component flows wherein additional components are introduced in the centre of the conduit by using two or more injector devices

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01F—MIXING, e.g. DISSOLVING, EMULSIFYING OR DISPERSING

- B01F25/00—Flow mixers; Mixers for falling materials, e.g. solid particles

- B01F25/30—Injector mixers

- B01F25/31—Injector mixers in conduits or tubes through which the main component flows

- B01F25/313—Injector mixers in conduits or tubes through which the main component flows wherein additional components are introduced in the centre of the conduit

- B01F25/3132—Injector mixers in conduits or tubes through which the main component flows wherein additional components are introduced in the centre of the conduit by using two or more injector devices

- B01F25/31322—Injector mixers in conduits or tubes through which the main component flows wherein additional components are introduced in the centre of the conduit by using two or more injector devices used simultaneously

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/008—Details of the reactor or of the particulate material; Processes to increase or to retard the rate of reaction

- B01J8/0085—Details of the reactor or of the particulate material; Processes to increase or to retard the rate of reaction promoting uninterrupted fluid flow, e.g. by filtering out particles in front of the catalyst layer

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

- B01J8/0207—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid flow within the bed being predominantly horizontal

- B01J8/0214—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid flow within the bed being predominantly horizontal in a cylindrical annular shaped bed

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

- B01J8/0278—Feeding reactive fluids

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

- B01J8/04—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

- B01J8/04—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds

- B01J8/0446—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds the flow within the beds being predominantly vertical

- B01J8/0449—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds the flow within the beds being predominantly vertical in two or more cylindrical beds

- B01J8/0453—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds the flow within the beds being predominantly vertical in two or more cylindrical beds the beds being superimposed one above the other

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J8/00—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes

- B01J8/02—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds

- B01J8/04—Chemical or physical processes in general, conducted in the presence of fluids and solid particles; Apparatus for such processes with stationary particles, e.g. in fixed beds the fluid passing successively through two or more beds

- B01J8/0492—Feeding reactive fluids

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2208/00—Processes carried out in the presence of solid particles; Reactors therefor

- B01J2208/00796—Details of the reactor or of the particulate material

- B01J2208/00823—Mixing elements

- B01J2208/00831—Stationary elements

- B01J2208/00849—Stationary elements outside the bed, e.g. baffles

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2208/00—Processes carried out in the presence of solid particles; Reactors therefor

- B01J2208/00796—Details of the reactor or of the particulate material

- B01J2208/00884—Means for supporting the bed of particles, e.g. grids, bars, perforated plates

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J2219/00—Chemical, physical or physico-chemical processes in general; Their relevant apparatus

- B01J2219/19—Details relating to the geometry of the reactor

- B01J2219/194—Details relating to the geometry of the reactor round

- B01J2219/1941—Details relating to the geometry of the reactor round circular or disk-shaped

- B01J2219/1946—Details relating to the geometry of the reactor round circular or disk-shaped conical

-

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y10—TECHNICAL SUBJECTS COVERED BY FORMER USPC

- Y10T—TECHNICAL SUBJECTS COVERED BY FORMER US CLASSIFICATION

- Y10T137/00—Fluid handling

- Y10T137/8593—Systems

- Y10T137/87571—Multiple inlet with single outlet

- Y10T137/87652—With means to promote mixing or combining of plural fluids

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Fluid Mechanics (AREA)

- Devices And Processes Conducted In The Presence Of Fluids And Solid Particles (AREA)

- Physical Or Chemical Processes And Apparatus (AREA)

- Organic Low-Molecular-Weight Compounds And Preparation Thereof (AREA)

Description

第1の流体出発物質流のための漏出断面積を1/2〜1/10に狭隘化する、2つまたは3つの連続配置された一連の管の外側に乱流発生装置を備えた、2つまたは3つの連続配置された一連の管、この場合前記管の内部空間には、第2の流体出発物質流が導通され、この第2の流体出発物質流は、前記管中の開口を介して第1の流体出発物質流中に噴入され、ならびに

前記管を上流の穿孔薄板および

前記管を下流の穿孔薄板

から形成されていることによって特徴付けられる、2つの流体出発物質の間での反応を、触媒床上で流体出発物質の前混合を伴なって触媒床への供給前に150ms未満の遅延時間で混入装置中で実施するための反応器によって解決される。

2つまたは3つの連続配置された一連の管の外側に乱流発生装置を備えた、2つまたは3つの連続配置された一連の管ならびに

前記管を上流の穿孔薄板および

前記管を下流の穿孔薄板。

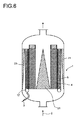

しばしば円筒状の反応器の長手方向の軸線の方向に反応混合物の貫流を有する軸方向の流れの装置の場合には、単数の触媒床または複数の触媒床は、水平方向に反応器の横断面に沿って配置されている。相応して、混入装置の一部分を形成するフィン付き管の列は、本質的に触媒床に対して平行に反応器の横断面の平面内に配置されていなければならない。

第1の流体出発物質流のための漏出断面積を1/2〜1/10に狭隘化する、2つまたは3つの連続配置された一連の管の外側に乱流発生装置を備えた、2つまたは3つの連続配置された一連の管、この場合前記管の内部空間には、第2の流体または他の流体が導通され、この第2の流体または他の流体は、前記管中の開口を介して第1の流体出発物質流中に噴入され、ならびに

前記管の上流の穿孔薄板および

前記管の下流の穿孔薄板

から形成されている、2つまたはそれ以上の流体のための静的混合装置である。

Claims (21)

- 流体出発物質(2、3)の前混合を触媒床(4)への供給前に150ms未満の遅延時間にて混入装置(5)中で実施後、2つの流体出発物質(2、3)の間での反応を、触媒床(4)上で実施するための反応器(1)において、混入装置(5)が本質的に第1の流体出発物質流(2)の流入方向に対して横方向に配置されている次の要素:

第1の流体出発物質流(2)のための漏出断面積を1/2〜1/10に狭隘化する、2つまたは3つの連続配置された一連の管(6)の外側に乱流発生装置を備えた、2つまたは3つの連続配置された一連の管(6)、この場合前記管(6)の内部空間には、第2の流体出発物質流(3)が導通され、この第2の流体出発物質流(3)は、前記管(6)中の開口(7)を介して第1の流体出発物質流(2)中に噴入され、ならびに

前記管(6)の上流の穿孔薄板(10)および

前記管(6)の下流の穿孔薄板(11)

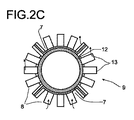

から形成されていることを特徴とする、2つの流体出発物質(2、3)の間での反応を実施するための上記反応器(1)。 - 外側に乱流発生装置を備えた管(6)は、フィン付き管(12)であり、この場合乱流発生器は、フィン(9)として構成されており、管(6)中の開口(7)は、フィン(9)間のフィンピッチ(8)中に開口している、請求項1記載の反応器(1)。

- フィン付き管(12)が、長手方向のストリップからなるフィン(9)を備えた、円筒状の外周を有する管(6)から形成され、前記フィンがこの管の外周上に螺旋状にストリップ長手縁部に沿って溶接され、および切り込みを入れてフィン基部(14)の切欠を備え、セグメント(13)を形成している、請求項1または2に記載の反応器(1)。

- セグメント(13)が、フィン基部(14)に対して角度をもってねじ曲げられている、請求項3記載の反応器(1)。

- フィン付き管(12)が、管(6)の長さ1m当たり100〜300回のフィン(9)の折り返し点を有する、請求項1から4までのいずれか1項に記載の反応器(1)。

- 管(12)が25〜150mmの範囲内、有利に20〜50mmの範囲内の外径を有する、請求項1から5までのいずれか1項に記載の反応器(1)。

- フィン(9)の高さと管(12)の外径との比が1/10〜1/2の範囲内にある、請求項1から6までのいずれか1項に記載の反応器(1)。

- フィン(9)が0.3〜1.5mmの範囲内の厚さを有し、セグメント(13)が3〜12mmの範囲内、有利に4〜8mmの範囲内の幅を有する、請求項1から7までのいずれか1項に記載の反応器(1)。

- フィン付き管(6)の第2の列の管がフィン付き管(6)の第1の列の管の間の間隙に配置されている、請求項1から8までのいずれか1項に記載の反応器(1)。

- フィン付き管(6)の3つの列を有し、該フィン付き管(6)の第3の列の管は、フィン付き管(6)の第2の列の管の間の間隙に配置されている、請求項9記載の反応器(1)。

- 熱媒体がフィン付き管(6)の第2の列を貫流する、請求項1から10までのいずれか1項に記載の反応器(1)。

- 熱媒体がフィン付き管(6)の第2の列とフィン付き管(6)の第3の列を貫流する、請求項1から10までのいずれか1項に記載の反応器(1)。

- フィン付き管(6)の第2の列が、任意の断面積の中実材料から形成されている、請求項11または12に記載の反応器(1)。

- フィン付き管(6)の第2の列とフィン付き管(6)の第3の列が、任意の断面積の中実材料から形成されている、請求項11または12に記載の反応器(1)。

- 上流の穿孔薄板(10)中の開口(15)の直径が、2つの重なり合って続く折り返し点間のフィンの内法スパンの半分よりも短い、請求項1から14までのいずれか1項に記載の反応器(1)。

- 混入装置(5)への第1の流体出発物質流(2)の流入方向に対して垂直方向に全横断面積に対する穿孔薄板中の開口(15)の自由面積の総和として定義された上流の穿孔薄板(10)中の開口比が0.5以下、有利に0.3以下である、請求項1から15までのいずれか1項に記載の反応器(1)。

- 穿孔薄板厚と穿孔薄板(10、11)中の開口(15、16)の直径との比が0.75〜2.0の範囲内にある、請求項1から16までのいずれか1項に記載の反応器(1)。

- 下流の穿孔薄板(11)中の開口(16)の直径が上流の穿孔薄板(10)中の開口(15)の直径より大きいかまたはこの直径に等しい、請求項1から17までのいずれか1項に記載の反応器(1)。

- 下流の穿孔薄板(11)から触媒床(4)中への反応混合物の入口までの距離が下流の穿孔薄板(11)中の開口(16)の直径の5〜20倍に相当する、請求項1から18までのいずれか1項に記載の反応器(1)。

- 高められた温度で耐酸化性および場合によっては耐炭化性である材料が管(6)および穿孔薄板(10、11)のための材料として使用されている、請求項1から19までのいずれか1項に記載の反応器(1)。

- 請求項1から20までのいずれか1項に記載の反応器(1)中の触媒床(4)上で2つの流体出発物質(2、3)間の化学反応を実施するための方法において、殊にオキシ脱水素化を実施するために、第1の流体出発物質流(2)が反応ガス混合物であり、第2の流体出発物質流(3)が酸素含有ガス流であることを特徴とする、請求項1から20までのいずれか1項に記載の反応器(1)中の触媒床(4)上で2つの流体出発物質(2、3)間の化学反応を実施するための方法。

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| DE102006060507.1 | 2006-12-19 | ||

| DE200610060507 DE102006060507A1 (de) | 2006-12-19 | 2006-12-19 | Reaktor zur Durchführung einer Reaktion zwischen zwei fluiden Edukten an einem Katalysatorbett mit Vorvermischen der fluiden Edukte in einer Einmischvorrichtung |

| US87094506P | 2006-12-20 | 2006-12-20 | |

| US60/870,945 | 2006-12-20 | ||

| PCT/EP2007/063951 WO2008074737A1 (de) | 2006-12-19 | 2007-12-14 | Reaktor zur durchführung einer reaktion zwischen zwei fluiden edukten an einem katalysatorbett mit vorvermischen der fluiden edukte in einer einmischvorrichtung |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2010513005A JP2010513005A (ja) | 2010-04-30 |

| JP2010513005A5 JP2010513005A5 (ja) | 2012-08-09 |

| JP5260547B2 true JP5260547B2 (ja) | 2013-08-14 |

Family

ID=39431505

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2009542012A Expired - Fee Related JP5260547B2 (ja) | 2006-12-19 | 2007-12-14 | 混入装置中での流体出発物質の前混合を伴なって触媒床で2つの流体出発物質の間で反応を実施するための反応器 |

Country Status (13)

| Country | Link |

|---|---|

| US (1) | US7854906B2 (ja) |

| EP (2) | EP2517784B1 (ja) |

| JP (1) | JP5260547B2 (ja) |

| KR (1) | KR101424028B1 (ja) |

| CN (1) | CN101600494B (ja) |

| BR (1) | BRPI0720412A2 (ja) |

| DE (1) | DE102006060507A1 (ja) |

| MY (1) | MY149683A (ja) |

| RU (1) | RU2456067C2 (ja) |

| SG (1) | SG153458A1 (ja) |

| TW (1) | TWI430842B (ja) |

| WO (1) | WO2008074737A1 (ja) |

| ZA (1) | ZA200904965B (ja) |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7704293B2 (en) * | 2007-10-23 | 2010-04-27 | Institute Of Nuclear Energy Research | Turbulence device used for air filtration system |

| TW200936245A (en) * | 2007-10-30 | 2009-09-01 | Basf Se | Horizontal reactor for reacting a fluid feed stream with a fluid oxidant stream in the presence of a solid catalyst |

| EP2165755A1 (en) * | 2008-09-23 | 2010-03-24 | Methanol Casale S.A. | Heat exchanger with radially arranged elements for isothermal chemical reactors |

| US9308121B2 (en) * | 2011-02-07 | 2016-04-12 | Roger Clemente | Helical air distribution system |

| EP2703076B1 (de) * | 2012-08-29 | 2016-04-27 | Wolfgang Gerlinger | Reaktor mit einer oder mehreren zuführleitungen und einer gleichverteilungseinrichtung für einen oder mehrere fluidströme |

| CN105623733B (zh) * | 2014-10-27 | 2017-03-01 | 中国石油化工股份有限公司 | 一种石油烃的吸附脱硫方法 |

| US10478794B1 (en) | 2019-02-26 | 2019-11-19 | Chevron Phillips Chemical Company Lp | Bi-modal radial flow reactor |

| PL245339B1 (pl) * | 2019-04-01 | 2024-07-01 | Marek Mania | Rura szczelinowa spiralna do filtrów samooczyszczających się, ciśnieniowych oraz filtr szczelinowy samooczyszczający się ciśnieniowy z taką rurą szczelinową |

Family Cites Families (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2276307A (en) * | 1938-04-18 | 1942-03-17 | Houdry Process Corp | Catalytic converter |

| US2350644A (en) * | 1942-10-28 | 1944-06-06 | Socony Vacuum Oil Co Inc | Apparatus for catalytic conversion |

| US2417393A (en) * | 1942-11-04 | 1947-03-11 | Socony Vacuum Oil Co Inc | Apparatus for hydrocarbon reaction |

| US3214247A (en) | 1963-02-25 | 1965-10-26 | Universal Oil Prod Co | Fluid distributing means for packed chambers |

| FR2019968B1 (ja) | 1968-10-04 | 1974-11-15 | Escoa Corp | |

| GB1328302A (en) * | 1970-06-25 | 1973-08-30 | Escoa Fintube Corp | Segmented finned tube and its method of manufacture |

| JPS5932178B2 (ja) * | 1981-11-06 | 1984-08-07 | 永岡金網株式会社 | 多孔管内包式スクリ−ン筒 |

| JPS5959242A (ja) * | 1982-09-28 | 1984-04-05 | Toyo Eng Corp | 反応方法およびそのための反応器 |

| US5462719A (en) * | 1994-06-08 | 1995-10-31 | Atlantic Richfield Company | Method and apparatus for mixing and distributing fluids in a reactor |

| AU7693594A (en) * | 1994-09-02 | 1996-03-27 | Walerie Iwanowitsch Abramow | Catalytic reforming process and reactor |

| EP1100616A4 (en) * | 1998-07-09 | 2002-02-06 | Washington Group Int | CENTRIFUGAL REACTOR |

| JP3858132B2 (ja) * | 1999-03-29 | 2006-12-13 | 日立造船株式会社 | 排ガス脱硝システムのアンモニア注入装置 |

| US6772830B1 (en) * | 1999-07-21 | 2004-08-10 | Stone & Webster, Inc. | Enhanced crossflow heat transfer |

| EP1080780B1 (en) * | 1999-08-31 | 2007-08-01 | Nippon Shokubai Co., Ltd. | Reactor for catalytic gas phase oxidation |

| US7316804B2 (en) * | 2001-08-02 | 2008-01-08 | Ineos Usa Llc | Flow reactors for chemical conversions with heterogeneous catalysts |

| RU30289U1 (ru) * | 2003-03-27 | 2003-06-27 | Общество с ограниченной ответственностью Научно-производственная компания "Кедр - 89" | Реактор для каталитических процессов |

| DE10359744A1 (de) * | 2003-12-19 | 2005-07-14 | Uhde Gmbh | Verfahren und Vorrichtung zum Eindüsen von Sauerstoff in einen Synthesereaktor |

| DE102004024957A1 (de) * | 2004-05-22 | 2005-12-22 | Uhde Gmbh | Verfahren und Vorrichtung zum Eindüsen von Sauerstoff in ein einen Synthesereaktor durchströmendes Reaktionsgas |

| DE102006060509A1 (de) * | 2006-12-19 | 2008-06-26 | Basf Se | Reaktor zur Durchführung einer kontinuierlichen Oxidehydrierung sowie Verfahren |

-

2006

- 2006-12-19 DE DE200610060507 patent/DE102006060507A1/de not_active Withdrawn

-

2007

- 2007-12-14 RU RU2009127502/05A patent/RU2456067C2/ru not_active IP Right Cessation

- 2007-12-14 CN CN2007800510248A patent/CN101600494B/zh not_active Expired - Fee Related

- 2007-12-14 KR KR1020097014950A patent/KR101424028B1/ko not_active IP Right Cessation

- 2007-12-14 WO PCT/EP2007/063951 patent/WO2008074737A1/de active Application Filing

- 2007-12-14 SG SG200904205A patent/SG153458A1/en unknown

- 2007-12-14 MY MYPI20092537A patent/MY149683A/en unknown

- 2007-12-14 BR BRPI0720412-4A2A patent/BRPI0720412A2/pt not_active IP Right Cessation

- 2007-12-14 EP EP12175556.5A patent/EP2517784B1/de not_active Not-in-force

- 2007-12-14 EP EP20070848103 patent/EP2104553B1/de not_active Not-in-force

- 2007-12-14 JP JP2009542012A patent/JP5260547B2/ja not_active Expired - Fee Related

- 2007-12-18 US US11/959,008 patent/US7854906B2/en not_active Expired - Fee Related

- 2007-12-19 TW TW96148759A patent/TWI430842B/zh not_active IP Right Cessation

-

2009

- 2009-07-16 ZA ZA200904965A patent/ZA200904965B/xx unknown

Also Published As

| Publication number | Publication date |

|---|---|

| EP2517784A2 (de) | 2012-10-31 |

| EP2517784A3 (de) | 2013-05-15 |

| EP2104553B1 (de) | 2014-03-26 |

| CN101600494A (zh) | 2009-12-09 |

| RU2009127502A (ru) | 2011-01-27 |

| EP2104553A1 (de) | 2009-09-30 |

| JP2010513005A (ja) | 2010-04-30 |

| TWI430842B (zh) | 2014-03-21 |

| KR101424028B1 (ko) | 2014-07-28 |

| MY149683A (en) | 2013-09-30 |

| DE102006060507A1 (de) | 2008-06-26 |

| SG153458A1 (en) | 2009-07-29 |

| US20080145285A1 (en) | 2008-06-19 |

| EP2517784B1 (de) | 2018-03-07 |

| TW200909058A (en) | 2009-03-01 |

| CN101600494B (zh) | 2013-01-30 |

| BRPI0720412A2 (pt) | 2013-12-31 |

| WO2008074737A1 (de) | 2008-06-26 |

| US7854906B2 (en) | 2010-12-21 |

| RU2456067C2 (ru) | 2012-07-20 |

| KR20090091234A (ko) | 2009-08-26 |

| ZA200904965B (en) | 2010-09-29 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP5260547B2 (ja) | 混入装置中での流体出発物質の前混合を伴なって触媒床で2つの流体出発物質の間で反応を実施するための反応器 | |

| KR101395994B1 (ko) | 연속적 옥시탈수소화를 수행하기 위한 반응기 및 그 방법 | |

| US8178075B2 (en) | Tubular reactor with jet impingement heat transfer | |

| US3645701A (en) | Reformer furnace | |

| EP2249954B1 (en) | Catalytic reactor | |

| US7871579B2 (en) | Tubular reactor with expandable insert | |

| RU2654041C2 (ru) | Устройство предварительного смешивания, реактор с неподвижным слоем и радиальным потоком и реакционная система для окислительной дегидрогенизации бутилена | |

| JPH01139137A (ja) | 不均一触媒化学プロセスの実施法 | |

| JP4386621B2 (ja) | 積層物に基づく管型反応器 | |

| JP2010513005A5 (ja) | ||

| WO2003031050A1 (en) | Heat exchange reactor | |

| US10005079B2 (en) | Catalyst having a helical outer shape, improving hydrodynamics in reactors | |

| CN106999885A (zh) | 反应器和其使用方法 | |

| KR20070086049A (ko) | 촉매 변환 반응을 위한 반응기 | |

| US20150071835A1 (en) | Non-adiabatic catalytic reactor | |

| RU2796425C1 (ru) | Реактор синтез-газа и способ получения синтез-газа в таком реакторе | |

| US3977090A (en) | Fixed-bed vapor/solids contacting device | |

| Bracco et al. | Computed and measured emissions from the catalytic combustion of propane/air mixtures | |

| UA58417C2 (en) | Reactor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20101213 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20101213 |

|

| RD04 | Notification of resignation of power of attorney |

Free format text: JAPANESE INTERMEDIATE CODE: A7424 Effective date: 20101228 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20120126 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20120224 |

|

| A601 | Written request for extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A601 Effective date: 20120524 |

|

| A602 | Written permission of extension of time |

Free format text: JAPANESE INTERMEDIATE CODE: A602 Effective date: 20120531 |

|

| A524 | Written submission of copy of amendment under article 19 pct |

Free format text: JAPANESE INTERMEDIATE CODE: A524 Effective date: 20120621 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20130327 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20130425 |

|

| FPAY | Renewal fee payment (event date is renewal date of database) |

Free format text: PAYMENT UNTIL: 20160502 Year of fee payment: 3 |

|

| R150 | Certificate of patent or registration of utility model |

Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| LAPS | Cancellation because of no payment of annual fees |