RU2074052C1 - Промежуточное устройство для литья под низким давлением металлических сплавов с высокой точкой плавления и установка, использующая это устройство - Google Patents

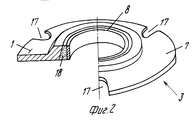

Промежуточное устройство для литья под низким давлением металлических сплавов с высокой точкой плавления и установка, использующая это устройство Download PDFInfo

- Publication number

- RU2074052C1 RU2074052C1 SU915001378A SU5001378A RU2074052C1 RU 2074052 C1 RU2074052 C1 RU 2074052C1 SU 915001378 A SU915001378 A SU 915001378A SU 5001378 A SU5001378 A SU 5001378A RU 2074052 C1 RU2074052 C1 RU 2074052C1

- Authority

- RU

- Russia

- Prior art keywords

- sleeve

- casting

- mold

- metal

- intermediate device

- Prior art date

Links

- 238000002844 melting Methods 0.000 title claims description 7

- 230000008018 melting Effects 0.000 title claims description 7

- 229910001092 metal group alloy Inorganic materials 0.000 title claims description 5

- 238000004512 die casting Methods 0.000 title abstract 2

- 238000005266 casting Methods 0.000 claims abstract description 37

- 239000002184 metal Substances 0.000 claims abstract description 18

- 229910052751 metal Inorganic materials 0.000 claims abstract description 18

- 239000011819 refractory material Substances 0.000 claims abstract description 10

- 229910000831 Steel Inorganic materials 0.000 claims description 6

- 239000010959 steel Substances 0.000 claims description 6

- 229910001018 Cast iron Inorganic materials 0.000 claims description 5

- 238000009434 installation Methods 0.000 claims description 5

- 229910000601 superalloy Inorganic materials 0.000 claims description 5

- UAMZXLIURMNTHD-UHFFFAOYSA-N dialuminum;magnesium;oxygen(2-) Chemical compound [O-2].[O-2].[O-2].[O-2].[Mg+2].[Al+3].[Al+3] UAMZXLIURMNTHD-UHFFFAOYSA-N 0.000 claims description 2

- 239000000463 material Substances 0.000 claims description 2

- 238000005058 metal casting Methods 0.000 claims 2

- 230000015572 biosynthetic process Effects 0.000 claims 1

- 230000003993 interaction Effects 0.000 claims 1

- 238000000034 method Methods 0.000 abstract description 5

- 239000000126 substance Substances 0.000 abstract 1

- 230000035939 shock Effects 0.000 description 7

- 229910001338 liquidmetal Inorganic materials 0.000 description 5

- 229940125773 compound 10 Drugs 0.000 description 3

- 238000001816 cooling Methods 0.000 description 3

- ZLVXBBHTMQJRSX-VMGNSXQWSA-N jdtic Chemical compound C1([C@]2(C)CCN(C[C@@H]2C)C[C@H](C(C)C)NC(=O)[C@@H]2NCC3=CC(O)=CC=C3C2)=CC=CC(O)=C1 ZLVXBBHTMQJRSX-VMGNSXQWSA-N 0.000 description 3

- 229910045601 alloy Inorganic materials 0.000 description 2

- 239000000956 alloy Substances 0.000 description 2

- 239000002893 slag Substances 0.000 description 2

- 206010011878 Deafness Diseases 0.000 description 1

- 229910001060 Gray iron Inorganic materials 0.000 description 1

- 229910001296 Malleable iron Inorganic materials 0.000 description 1

- 238000003723 Smelting Methods 0.000 description 1

- 238000004140 cleaning Methods 0.000 description 1

- 239000011248 coating agent Substances 0.000 description 1

- 238000000576 coating method Methods 0.000 description 1

- -1 described Chemical compound 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 239000000203 mixture Substances 0.000 description 1

- 238000007711 solidification Methods 0.000 description 1

- 230000008023 solidification Effects 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B22—CASTING; POWDER METALLURGY

- B22D—CASTING OF METALS; CASTING OF OTHER SUBSTANCES BY THE SAME PROCESSES OR DEVICES

- B22D18/00—Pressure casting; Vacuum casting

- B22D18/04—Low pressure casting, i.e. making use of pressures up to a few bars to fill the mould

Landscapes

- Mechanical Engineering (AREA)

- Engineering & Computer Science (AREA)

- Furnace Housings, Linings, Walls, And Ceilings (AREA)

- Manufacture Of Alloys Or Alloy Compounds (AREA)

- Casting Or Compression Moulding Of Plastics Or The Like (AREA)

- Molds, Cores, And Manufacturing Methods Thereof (AREA)

- Moulds For Moulding Plastics Or The Like (AREA)

- Superconductors And Manufacturing Methods Therefor (AREA)

- Disintegrating Or Milling (AREA)

- Crushing And Grinding (AREA)

- Ceramic Products (AREA)

- Moulding By Coating Moulds (AREA)

- Injection Moulding Of Plastics Or The Like (AREA)

- Treatment Of Steel In Its Molten State (AREA)

- Casting Support Devices, Ladles, And Melt Control Thereby (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR9010798 | 1990-08-27 | ||

| FR9010798A FR2666036A1 (fr) | 1990-08-27 | 1990-08-27 | Dispositif intermediaire pour la coulee de pieces moulees. |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| RU2074052C1 true RU2074052C1 (ru) | 1997-02-27 |

Family

ID=9399949

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| SU915001378A RU2074052C1 (ru) | 1990-08-27 | 1991-08-23 | Промежуточное устройство для литья под низким давлением металлических сплавов с высокой точкой плавления и установка, использующая это устройство |

Country Status (18)

| Country | Link |

|---|---|

| US (1) | US5184665A (enExample) |

| EP (1) | EP0477119B1 (enExample) |

| JP (1) | JP2611067B2 (enExample) |

| AT (1) | ATE125739T1 (enExample) |

| BR (1) | BR9103668A (enExample) |

| CA (1) | CA2049816C (enExample) |

| CZ (1) | CZ290725B6 (enExample) |

| DE (1) | DE69111729T2 (enExample) |

| DK (1) | DK0477119T3 (enExample) |

| ES (1) | ES2069512T3 (enExample) |

| FI (1) | FI96100C (enExample) |

| FR (1) | FR2666036A1 (enExample) |

| GR (1) | GR3017024T3 (enExample) |

| HU (1) | HU208930B (enExample) |

| MX (1) | MX9100815A (enExample) |

| NO (1) | NO179035C (enExample) |

| PL (1) | PL169288B1 (enExample) |

| RU (1) | RU2074052C1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2330891C2 (ru) * | 2006-09-19 | 2008-08-10 | Открытое акционерное общество "Оскольский электрометаллургический комбинат" | Сортовой прокат круглый из низкоуглеродистой высокопластичной стали для холодной объемной штамповки |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP3420263B2 (ja) * | 1992-09-02 | 2003-06-23 | 黒崎播磨株式会社 | 連続鋳造用ノズルの支持構造 |

| US6431785B1 (en) | 2000-06-05 | 2002-08-13 | Wec Co. | Direct pin quick coupler |

| DE102005009669A1 (de) * | 2005-02-28 | 2006-08-31 | Bühler Druckguss AG | Giesskammer |

| CN107096903B (zh) * | 2017-04-26 | 2019-10-22 | 哈尔滨工业大学 | 反重力铸造升液管定位机构 |

| CN108918314B (zh) * | 2018-08-17 | 2021-03-16 | 西南交通大学 | 一种能够模拟沙粒及高温复杂环境的冲击磨损试验装置 |

Family Cites Families (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US2852822A (en) * | 1955-08-12 | 1958-09-23 | Griffin Wheel Co | Vacuum seal for pressure pouring apparatus |

| BE557897A (enExample) * | 1957-06-03 | 1957-06-15 | ||

| DE1156942B (de) * | 1962-06-12 | 1963-11-07 | Alcan Aluminiumwerke | Steigrohr fuer den Anschluss der Kokillen beim Niederdruckgiessverfahren |

| FR2289279A1 (fr) * | 1974-11-04 | 1976-05-28 | Activite Atom Avance | Installation de coulee rapide basse pression |

| US4133370A (en) * | 1974-12-24 | 1979-01-09 | Pont-A-Mousson S.A. | Method and apparatus for low-pressure casting in a sand mould |

| FR2378591A1 (fr) * | 1977-01-28 | 1978-08-25 | Buscher Kg | Conduit elevateur pour la coulee de metaux sous la pression d'un gaz |

| FR2532866B1 (fr) * | 1982-09-13 | 1985-06-07 | Pont A Mousson | Chenal de coulee chauffe par induction |

| FR2534167B1 (fr) * | 1982-10-11 | 1985-06-07 | Pont A Mousson | Procede de fabrication en fonderie de pieces moulees en alliages metalliques oxydables |

| FR2556996B1 (fr) * | 1983-12-26 | 1988-03-11 | Pont A Mousson | Procede d'alimentation de moules de fonderie en alliages metalliques sous pression differentielle controlee |

| FR2559407B1 (fr) * | 1984-02-15 | 1986-09-05 | Pont A Mousson | Procede de moulage en fonderie et moule pour la coulee de precision sous basse pression, avec modele gazeifiable et moule en sable sans liant |

| JPS623859A (ja) * | 1985-06-28 | 1987-01-09 | Toyota Motor Corp | スト−クと金型間のシ−ル方法 |

-

1990

- 1990-08-27 FR FR9010798A patent/FR2666036A1/fr active Granted

-

1991

- 1991-08-02 HU HU912587A patent/HU208930B/hu not_active IP Right Cessation

- 1991-08-14 EP EP91470021A patent/EP0477119B1/fr not_active Expired - Lifetime

- 1991-08-14 DE DE69111729T patent/DE69111729T2/de not_active Expired - Lifetime

- 1991-08-14 AT AT91470021T patent/ATE125739T1/de not_active IP Right Cessation

- 1991-08-14 DK DK91470021.6T patent/DK0477119T3/da active

- 1991-08-14 ES ES91470021T patent/ES2069512T3/es not_active Expired - Lifetime

- 1991-08-23 PL PL91291507A patent/PL169288B1/pl not_active IP Right Cessation

- 1991-08-23 RU SU915001378A patent/RU2074052C1/ru not_active IP Right Cessation

- 1991-08-23 NO NO913306A patent/NO179035C/no unknown

- 1991-08-23 FI FI913994A patent/FI96100C/fi not_active IP Right Cessation

- 1991-08-26 CA CA002049816A patent/CA2049816C/fr not_active Expired - Lifetime

- 1991-08-26 BR BR919103668A patent/BR9103668A/pt not_active IP Right Cessation

- 1991-08-26 MX MX9100815A patent/MX9100815A/es not_active IP Right Cessation

- 1991-08-27 CZ CS19912637A patent/CZ290725B6/cs not_active IP Right Cessation

- 1991-08-27 US US07/750,352 patent/US5184665A/en not_active Expired - Lifetime

- 1991-08-27 JP JP3240545A patent/JP2611067B2/ja not_active Expired - Lifetime

-

1995

- 1995-08-03 GR GR950401875T patent/GR3017024T3/el unknown

Non-Patent Citations (1)

| Title |

|---|

| Патент Франции N 1187724, кл. B 22 D 17/06. Патент Германии N 1156942, кл. B 22 D 27/14, 1963. Европейский патент N 152754, кл. B 22 C 9/04, 1985. * |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| RU2330891C2 (ru) * | 2006-09-19 | 2008-08-10 | Открытое акционерное общество "Оскольский электрометаллургический комбинат" | Сортовой прокат круглый из низкоуглеродистой высокопластичной стали для холодной объемной штамповки |

Also Published As

| Publication number | Publication date |

|---|---|

| NO179035C (no) | 1996-07-24 |

| HU912587D0 (en) | 1992-01-28 |

| MX9100815A (es) | 1992-04-01 |

| JPH0732123A (ja) | 1995-02-03 |

| ES2069512T3 (es) | 1995-11-16 |

| NO913306D0 (no) | 1991-08-23 |

| HUT60944A (en) | 1992-11-30 |

| US5184665A (en) | 1993-02-09 |

| FI913994A0 (fi) | 1991-08-23 |

| CA2049816C (fr) | 1996-09-10 |

| NO179035B (no) | 1996-04-15 |

| EP0477119B1 (fr) | 1995-08-02 |

| ES2069512T1 (es) | 1995-05-16 |

| DE69111729T2 (de) | 1996-01-18 |

| JP2611067B2 (ja) | 1997-05-21 |

| FI96100B (fi) | 1996-01-31 |

| PL291507A1 (en) | 1992-04-06 |

| BR9103668A (pt) | 1992-05-19 |

| HU208930B (en) | 1994-02-28 |

| GR3017024T3 (en) | 1995-11-30 |

| FR2666036B1 (enExample) | 1994-12-16 |

| CA2049816A1 (fr) | 1992-02-28 |

| CZ290725B6 (cs) | 2002-10-16 |

| NO913306L (no) | 1992-02-28 |

| FI96100C (fi) | 1996-05-10 |

| FR2666036A1 (fr) | 1992-02-28 |

| ATE125739T1 (de) | 1995-08-15 |

| CS263791A3 (en) | 1992-03-18 |

| EP0477119A1 (fr) | 1992-03-25 |

| DK0477119T3 (da) | 1995-12-27 |

| DE69111729D1 (de) | 1995-09-07 |

| PL169288B1 (pl) | 1996-06-28 |

| FI913994L (fi) | 1992-02-28 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US3396961A (en) | Precast taphole assembly | |

| RU2074052C1 (ru) | Промежуточное устройство для литья под низким давлением металлических сплавов с высокой точкой плавления и установка, использующая это устройство | |

| CA1297144C (en) | Gas scavenging apparatus for metallurgical vessels | |

| KR960015339B1 (ko) | 저압력 주조장치 | |

| CA2242078C (en) | Pouring tube structure and assembly | |

| JPS5841142B2 (ja) | 溶融金属の流れを制御する摺動ゲ−ト閉鎖機構 | |

| RU2180279C2 (ru) | Устройство для продувки металла газами в ковше и защитный клапан для этого устройства | |

| US3918624A (en) | Method and device for fixing an insert to a mold stool | |

| US3534949A (en) | Steel degassing vessels | |

| US3329201A (en) | Pouring tube for pressure pouring apparatus | |

| US2894739A (en) | Ladle relining method | |

| JP3171494B2 (ja) | タンディッシュ羽口レンガの交換方法及び装置 | |

| US6768766B1 (en) | Precast one piece upper castable ring for induction furnaces | |

| JPS62500844A (ja) | 溶融金属用レ−ドルの改良 | |

| FI68370B (fi) | Apparat och metod foer kontinuerlig gjutning av metallstraengar vid hoega hastigheter med anvaendning av vibrerande formaggregat | |

| GB2122532A (en) | Manufacture of gas-permeable plugs | |

| US3017676A (en) | Apparatus for providing gas-free liquid metal to a casting mould for the continuous casting of metal | |

| JPH0788627A (ja) | 鋳型注入管 | |

| RU2146183C1 (ru) | Отливка блока цилиндров двигателя внутреннего сгорания и способ ее получения | |

| RU2284243C2 (ru) | Способ изготовления желоба для транспортировки жидкого металла | |

| RU2043831C1 (ru) | Сталеразливочный комплект | |

| JPS585918Y2 (ja) | ライニング補修用仕切装置 | |

| RU2090306C1 (ru) | Способ изготовления пористой металлической формы | |

| SU904876A1 (ru) | Кристаллизатор дл установок непрерывного лить намораживанием | |

| SU1156841A1 (ru) | Металлопровод дл лить под низким давлением |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| MM4A | The patent is invalid due to non-payment of fees |

Effective date: 20060824 |