KR20180132975A - 폐쇄 루프 제어 - Google Patents

폐쇄 루프 제어 Download PDFInfo

- Publication number

- KR20180132975A KR20180132975A KR1020187035066A KR20187035066A KR20180132975A KR 20180132975 A KR20180132975 A KR 20180132975A KR 1020187035066 A KR1020187035066 A KR 1020187035066A KR 20187035066 A KR20187035066 A KR 20187035066A KR 20180132975 A KR20180132975 A KR 20180132975A

- Authority

- KR

- South Korea

- Prior art keywords

- power

- cathode

- voltage

- deposition

- closed loop

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 238000000034 method Methods 0.000 claims abstract description 69

- 238000005137 deposition process Methods 0.000 claims abstract description 48

- 230000008569 process Effects 0.000 claims abstract description 38

- 230000001276 controlling effect Effects 0.000 claims abstract description 14

- 230000002596 correlated effect Effects 0.000 claims abstract description 3

- 238000000151 deposition Methods 0.000 claims description 67

- 230000008021 deposition Effects 0.000 claims description 63

- 239000007789 gas Substances 0.000 claims description 56

- 239000000758 substrate Substances 0.000 claims description 37

- 229910052760 oxygen Inorganic materials 0.000 claims description 27

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 claims description 26

- 239000001301 oxygen Substances 0.000 claims description 26

- 230000007704 transition Effects 0.000 claims description 18

- 238000012544 monitoring process Methods 0.000 claims description 6

- 230000010355 oscillation Effects 0.000 claims 2

- 238000000429 assembly Methods 0.000 abstract description 11

- 230000000712 assembly Effects 0.000 abstract description 11

- 230000000875 corresponding effect Effects 0.000 abstract description 3

- VYPSYNLAJGMNEJ-UHFFFAOYSA-N Silicium dioxide Chemical compound O=[Si]=O VYPSYNLAJGMNEJ-UHFFFAOYSA-N 0.000 description 9

- 229910052814 silicon oxide Inorganic materials 0.000 description 9

- 229910004298 SiO 2 Inorganic materials 0.000 description 8

- 239000011248 coating agent Substances 0.000 description 5

- 238000000576 coating method Methods 0.000 description 5

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 description 4

- 229910052751 metal Inorganic materials 0.000 description 4

- 239000002184 metal Substances 0.000 description 4

- 238000012986 modification Methods 0.000 description 3

- 230000004048 modification Effects 0.000 description 3

- 229910052757 nitrogen Inorganic materials 0.000 description 3

- 238000004806 packaging method and process Methods 0.000 description 3

- 229910018072 Al 2 O 3 Inorganic materials 0.000 description 2

- XKRFYHLGVUSROY-UHFFFAOYSA-N Argon Chemical compound [Ar] XKRFYHLGVUSROY-UHFFFAOYSA-N 0.000 description 2

- XUIMIQQOPSSXEZ-UHFFFAOYSA-N Silicon Chemical compound [Si] XUIMIQQOPSSXEZ-UHFFFAOYSA-N 0.000 description 2

- 229910006404 SnO 2 Inorganic materials 0.000 description 2

- 229910010413 TiO 2 Inorganic materials 0.000 description 2

- 230000001419 dependent effect Effects 0.000 description 2

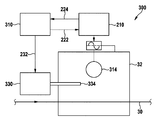

- 238000010586 diagram Methods 0.000 description 2

- 239000000463 material Substances 0.000 description 2

- 238000004886 process control Methods 0.000 description 2

- 229910052710 silicon Inorganic materials 0.000 description 2

- 239000010703 silicon Substances 0.000 description 2

- 239000006096 absorbing agent Substances 0.000 description 1

- 230000004075 alteration Effects 0.000 description 1

- 229910052786 argon Inorganic materials 0.000 description 1

- 230000008859 change Effects 0.000 description 1

- 238000005229 chemical vapour deposition Methods 0.000 description 1

- 238000007872 degassing Methods 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- 238000009434 installation Methods 0.000 description 1

- 238000001755 magnetron sputter deposition Methods 0.000 description 1

- TWNQGVIAIRXVLR-UHFFFAOYSA-N oxo(oxoalumanyloxy)alumane Chemical compound O=[Al]O[Al]=O TWNQGVIAIRXVLR-UHFFFAOYSA-N 0.000 description 1

- 238000005240 physical vapour deposition Methods 0.000 description 1

- 239000002985 plastic film Substances 0.000 description 1

- 229920006255 plastic film Polymers 0.000 description 1

- 238000005477 sputtering target Methods 0.000 description 1

- 238000001771 vacuum deposition Methods 0.000 description 1

- XLOMVQKBTHCTTD-UHFFFAOYSA-N zinc oxide Inorganic materials [Zn]=O XLOMVQKBTHCTTD-UHFFFAOYSA-N 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/0021—Reactive sputtering or evaporation

- C23C14/0036—Reactive sputtering

- C23C14/0042—Controlling partial pressure or flow rate of reactive or inert gases with feedback of measurements

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/0021—Reactive sputtering or evaporation

- C23C14/0036—Reactive sputtering

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/0021—Reactive sputtering or evaporation

- C23C14/0036—Reactive sputtering

- C23C14/0094—Reactive sputtering in transition mode

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/56—Apparatus specially adapted for continuous coating; Arrangements for maintaining the vacuum, e.g. vacuum locks

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/56—Apparatus specially adapted for continuous coating; Arrangements for maintaining the vacuum, e.g. vacuum locks

- C23C14/562—Apparatus specially adapted for continuous coating; Arrangements for maintaining the vacuum, e.g. vacuum locks for coating elongated substrates

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/32917—Plasma diagnostics

- H01J37/32935—Monitoring and controlling tubes by information coming from the object and/or discharge

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J37/00—Discharge tubes with provision for introducing objects or material to be exposed to the discharge, e.g. for the purpose of examination or processing thereof

- H01J37/32—Gas-filled discharge tubes

- H01J37/34—Gas-filled discharge tubes operating with cathodic sputtering

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01J—ELECTRIC DISCHARGE TUBES OR DISCHARGE LAMPS

- H01J2237/00—Discharge tubes exposing object to beam, e.g. for analysis treatment, etching, imaging

- H01J2237/32—Processing objects by plasma generation

- H01J2237/33—Processing objects by plasma generation characterised by the type of processing

- H01J2237/332—Coating

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Organic Chemistry (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Physics & Mathematics (AREA)

- Plasma & Fusion (AREA)

- Analytical Chemistry (AREA)

- Fluid Mechanics (AREA)

- Physical Vapour Deposition (AREA)

- Plasma Technology (AREA)

- Physical Or Chemical Processes And Apparatus (AREA)

- Chemical Vapour Deposition (AREA)

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/EP2011/071425 WO2013079108A1 (en) | 2011-11-30 | 2011-11-30 | Closed loop control |

Related Parent Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020147017890A Division KR20140097510A (ko) | 2011-11-30 | 2011-11-30 | 폐쇄 루프 제어 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20180132975A true KR20180132975A (ko) | 2018-12-12 |

Family

ID=45349469

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020147017890A Ceased KR20140097510A (ko) | 2011-11-30 | 2011-11-30 | 폐쇄 루프 제어 |

| KR1020187035066A Ceased KR20180132975A (ko) | 2011-11-30 | 2011-11-30 | 폐쇄 루프 제어 |

Family Applications Before (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020147017890A Ceased KR20140097510A (ko) | 2011-11-30 | 2011-11-30 | 폐쇄 루프 제어 |

Country Status (7)

| Country | Link |

|---|---|

| US (1) | US9758855B2 (enExample) |

| EP (1) | EP2785892B1 (enExample) |

| JP (1) | JP6305929B2 (enExample) |

| KR (2) | KR20140097510A (enExample) |

| CN (1) | CN103958723B (enExample) |

| TW (1) | TWI592510B (enExample) |

| WO (1) | WO2013079108A1 (enExample) |

Families Citing this family (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR101602517B1 (ko) | 2008-08-04 | 2016-03-10 | 에이지씨 플랫 글래스 노스 아메리카, 인코퍼레이티드 | Pecvd를 이용한 박막 코팅을 증착하기 위한 플라즈마 소스 및 방법 |

| CN107075663A (zh) * | 2014-09-01 | 2017-08-18 | 应用材料公司 | 用于在基板上沉积材料的组件和方法 |

| MY191327A (en) | 2014-12-05 | 2022-06-16 | Agc Flat Glass Na Inc | Plasma source utilizing a macro-particle reduction coating and method of using a plasma source utilizing a macro-particle reduction coating for deposition of thin film coatings and modification of surfaces |

| ES2883288T3 (es) | 2014-12-05 | 2021-12-07 | Agc Glass Europe Sa | Fuente de plasma de cátodo hueco |

| US9721765B2 (en) * | 2015-11-16 | 2017-08-01 | Agc Flat Glass North America, Inc. | Plasma device driven by multiple-phase alternating or pulsed electrical current |

| US10573499B2 (en) | 2015-12-18 | 2020-02-25 | Agc Flat Glass North America, Inc. | Method of extracting and accelerating ions |

| US10242846B2 (en) | 2015-12-18 | 2019-03-26 | Agc Flat Glass North America, Inc. | Hollow cathode ion source |

| DE102016116762B4 (de) * | 2016-09-07 | 2021-11-11 | Fraunhofer-Gesellschaft zur Förderung der angewandten Forschung e.V. | Verfahren zum Abscheiden einer Schicht mittels einer Magnetronsputtereinrichtung |

| WO2019094121A1 (en) | 2017-11-09 | 2019-05-16 | Applied Materials, Inc. | Ex-situ solid electrolyte interface modification using chalcogenides for lithium metal anode |

| US11631840B2 (en) | 2019-04-26 | 2023-04-18 | Applied Materials, Inc. | Surface protection of lithium metal anode |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE2821119C2 (de) | 1978-05-13 | 1983-08-25 | Leybold-Heraeus GmbH, 5000 Köln | Verfahren und Anordnung zur Regelung des Entladungsvorganges in einer Katodenzerstäubungsanlage |

| US4201645A (en) | 1978-06-26 | 1980-05-06 | Robert J. Ferran | Closed-loop sputtering system and method of operating same |

| DE4106513C2 (de) | 1991-03-01 | 2002-06-13 | Unaxis Deutschland Holding | Verfahren zur Regelung eines reaktiven Sputterprozesses und Vorrichtung zur Durchführung des Verfahrens |

| US6106676A (en) * | 1998-04-16 | 2000-08-22 | The Boc Group, Inc. | Method and apparatus for reactive sputtering employing two control loops |

| US6365010B1 (en) | 1998-11-06 | 2002-04-02 | Scivac | Sputtering apparatus and process for high rate coatings |

| US6537428B1 (en) * | 1999-09-02 | 2003-03-25 | Veeco Instruments, Inc. | Stable high rate reactive sputtering |

| JP3866615B2 (ja) * | 2002-05-29 | 2007-01-10 | 株式会社神戸製鋼所 | 反応性スパッタリング方法及び装置 |

| DE102004006131B4 (de) | 2004-02-07 | 2005-12-15 | Applied Films Gmbh & Co. Kg | Bandbeschichtungsanlage mit einer Vakuumkammer und einer Beschichtungswalze |

| JP2010229523A (ja) * | 2009-03-27 | 2010-10-14 | Bridgestone Corp | 導電性透明化合物薄膜の成膜方法および導電性透明化合物薄膜 |

| DE102009053756B4 (de) | 2009-06-26 | 2011-07-21 | VON ARDENNE Anlagentechnik GmbH, 01324 | Verfahren zur Beschichtung eines Substrates in einer Vakuumkammer mit mindestens einem rotierenden Magnetron |

-

2011

- 2011-11-30 JP JP2014543775A patent/JP6305929B2/ja active Active

- 2011-11-30 KR KR1020147017890A patent/KR20140097510A/ko not_active Ceased

- 2011-11-30 US US14/357,168 patent/US9758855B2/en not_active Expired - Fee Related

- 2011-11-30 CN CN201180075166.4A patent/CN103958723B/zh active Active

- 2011-11-30 EP EP11796945.1A patent/EP2785892B1/en not_active Revoked

- 2011-11-30 WO PCT/EP2011/071425 patent/WO2013079108A1/en not_active Ceased

- 2011-11-30 KR KR1020187035066A patent/KR20180132975A/ko not_active Ceased

-

2012

- 2012-11-29 TW TW101144735A patent/TWI592510B/zh active

Also Published As

| Publication number | Publication date |

|---|---|

| CN103958723A (zh) | 2014-07-30 |

| US9758855B2 (en) | 2017-09-12 |

| KR20140097510A (ko) | 2014-08-06 |

| JP2015500921A (ja) | 2015-01-08 |

| CN103958723B (zh) | 2017-04-05 |

| TWI592510B (zh) | 2017-07-21 |

| EP2785892B1 (en) | 2017-09-27 |

| US20150152542A1 (en) | 2015-06-04 |

| JP6305929B2 (ja) | 2018-04-04 |

| TW201329279A (zh) | 2013-07-16 |

| EP2785892A1 (en) | 2014-10-08 |

| WO2013079108A1 (en) | 2013-06-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9758855B2 (en) | Closed loop control | |

| US11680322B2 (en) | Method for forming a laminated film on a substrate | |

| CN214572199U (zh) | 一种高效快速电子束镀膜设备 | |

| JP2006249471A (ja) | 成膜方法 | |

| JP6596474B2 (ja) | 閉ループ制御 | |

| US8992742B2 (en) | Method for coating a substrate in a vacuum chamber having a rotating magnetron | |

| US6783640B2 (en) | Sputtering method and sputtering apparatus | |

| CN116334600A (zh) | 一种磁增强pecvd卷绕镀膜的生产装置和生产方法 | |

| CN215050676U (zh) | 一种多功能真空镀膜设备 | |

| KR102099601B1 (ko) | 프로세스 챔버로의 가스 공급을 제어하기 위한 방법, 프로세스 챔버로의 가스 공급을 제어하기 위한 제어기, 및 장치 | |

| Strümpfel et al. | Reactive dual magnetron sputtering of oxides for large area production of optical multilayers | |

| JP7572997B2 (ja) | 真空処理装置及び真空処理方法 | |

| CN107075663A (zh) | 用于在基板上沉积材料的组件和方法 | |

| CN111699277B (zh) | 沉积设备、涂覆柔性基板的方法和具有涂层的柔性基板 | |

| US6456483B1 (en) | Electrodes for electrolytic capacitors and production process thereof | |

| CN102443785B (zh) | 功能性薄膜的制造方法 | |

| JP2015074790A (ja) | プラズマ処理装置および処理方法 | |

| CN107916406B (zh) | 用于双极磁控溅射的方法和磁控装置 | |

| JP2005220445A (ja) | 巻き取り式蒸着装置及びcvd装置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A107 | Divisional application of patent | ||

| PA0104 | Divisional application for international application |

Comment text: Divisional Application for International Patent Patent event code: PA01041R01D Patent event date: 20181203 Application number text: 1020147017890 Filing date: 20140627 |

|

| PG1501 | Laying open of application | ||

| A201 | Request for examination | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20190102 Comment text: Request for Examination of Application |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20190305 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20200302 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20190305 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |