KR20180098338A - 원형 부재의 내주 길이 측정 장치 - Google Patents

원형 부재의 내주 길이 측정 장치 Download PDFInfo

- Publication number

- KR20180098338A KR20180098338A KR1020187021217A KR20187021217A KR20180098338A KR 20180098338 A KR20180098338 A KR 20180098338A KR 1020187021217 A KR1020187021217 A KR 1020187021217A KR 20187021217 A KR20187021217 A KR 20187021217A KR 20180098338 A KR20180098338 A KR 20180098338A

- Authority

- KR

- South Korea

- Prior art keywords

- dimensional sensor

- circular member

- inner circumferential

- distance

- tooth

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B11/00—Measuring arrangements characterised by the use of optical techniques

- G01B11/08—Measuring arrangements characterised by the use of optical techniques for measuring diameters

- G01B11/12—Measuring arrangements characterised by the use of optical techniques for measuring diameters internal diameters

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B11/00—Measuring arrangements characterised by the use of optical techniques

- G01B11/02—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness

- G01B11/04—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness specially adapted for measuring length or width of objects while moving

- G01B11/043—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness specially adapted for measuring length or width of objects while moving for measuring length

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B11/00—Measuring arrangements characterised by the use of optical techniques

- G01B11/02—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B11/00—Measuring arrangements characterised by the use of optical techniques

- G01B11/02—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness

- G01B11/026—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness by measuring distance between sensor and object

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B11/00—Measuring arrangements characterised by the use of optical techniques

- G01B11/24—Measuring arrangements characterised by the use of optical techniques for measuring contours or curvatures

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B11/00—Measuring arrangements characterised by the use of optical techniques

- G01B11/24—Measuring arrangements characterised by the use of optical techniques for measuring contours or curvatures

- G01B11/255—Measuring arrangements characterised by the use of optical techniques for measuring contours or curvatures for measuring radius of curvature

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B21/00—Measuring arrangements or details thereof, where the measuring technique is not covered by the other groups of this subclass, unspecified or not relevant

- G01B21/02—Measuring arrangements or details thereof, where the measuring technique is not covered by the other groups of this subclass, unspecified or not relevant for measuring length, width, or thickness

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B21/00—Measuring arrangements or details thereof, where the measuring technique is not covered by the other groups of this subclass, unspecified or not relevant

- G01B21/10—Measuring arrangements or details thereof, where the measuring technique is not covered by the other groups of this subclass, unspecified or not relevant for measuring diameters

- G01B21/14—Measuring arrangements or details thereof, where the measuring technique is not covered by the other groups of this subclass, unspecified or not relevant for measuring diameters internal diameters

-

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B21/00—Measuring arrangements or details thereof, where the measuring technique is not covered by the other groups of this subclass, unspecified or not relevant

- G01B21/20—Measuring arrangements or details thereof, where the measuring technique is not covered by the other groups of this subclass, unspecified or not relevant for measuring contours or curvatures, e.g. determining profile

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Length Measuring Devices With Unspecified Measuring Means (AREA)

- Length Measuring Devices By Optical Means (AREA)

Abstract

Description

도 2는 도 1의 측정 장치를 측면시(側面視)로 예시하는 설명도이다.

도 3은 도 2의 측정 장치의 치대를 기립시킨 상태를 측면시로 예시하는 설명도이다.

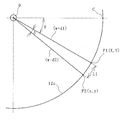

도 4는 2차원 센서에 의해 원형 부재의 내주면까지의 이격 거리를 측정하고 있는 공정을 평면시로 예시하는 설명도이다.

도 5는 도 4의 공정을 측면시로 예시하는 설명도이다.

도 6은 내주 길이의 산출 방법을 예시하는 설명도이다.

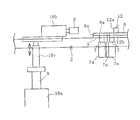

도 7은 측정 장치의 다른 실시형태에 있어서의 2차원 센서의 주변을 측면시로 예시하는 설명도이다.

2: 프레임

2a: 베이스 프레임

2b: 가동 프레임

3: 기복 기구

4: 치대

5: 분할체

6: 볼록상 지지부

6a: 저반사면

7: 돌출부

7a: 출몰 기구

8: 차원 센서

9: 회전축

10a: 회전 구동 기구

10b: 수평 이동 기구

10c: 상하 이동 기구

11: 연산부

12: 원형 부재

12a: 내주면

12b: 하면

Claims (3)

- 원형 부재가 재치되는 치대와, 이 치대에 대해 이동 가능하게 설치되어 있는 2차원 센서와, 이 2차원 센서를 회전시키는 회전 구동 기구와, 상기 2차원 센서에 의한 측정 데이터가 입력되는 연산부를 구비하고,

상기 치대에 무구속 상태로 평치된 원형 부재의 내주면에 대향하여 상기 2차원 센서가 소정의 측정 위치에 배치되고, 상기 원형 부재의 내측의 소정 위치를 중심으로 하여 상기 2차원 센서를 상기 회전 구동 기구에 의해 회전시킴으로써, 상기 2차원 센서로부터 상기 내주면까지 이격 거리가 상기 원형 부재의 전체 둘레의 범위에서 상기 원형 부재에 비접촉으로 측정되고, 측정된 상기 이격 거리와, 평면시의 상기 소정 위치와 상기 2차원 센서와의 거리에 기초하여, 상기 연산부에 의해 상기 원형 부재의 내주 길이가 산출되는 구성으로 한 것을 특징으로 하는 원형 부재의 내주 길이 측정 장치. - 제1항에 있어서,

상기 2차원 센서를 수평 방향으로 이동시키는 수평 이동 기구를 갖고, 이 수평 이동 기구에 의해 상기 2차원 센서가 평면시로 상기 측정 위치에 위치 결정되는 구성으로 한 원형 부재의 내주 길이 측정 장치. - 제1항 또는 제2항에 있어서,

상기 2차원 센서를 상하 방향으로 이동시키는 상하 이동 기구를 갖고, 이 상하 이동 기구에 의해 상기 2차원 센서가 상기 내주면과 대향하는 위치에 위치 결정되는 구성으로 한 내주 길이 측정 장치.

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JPJP-P-2016-052614 | 2016-03-16 | ||

| JP2016052614A JP6206527B2 (ja) | 2016-03-16 | 2016-03-16 | 円形部材の内周長測定装置 |

| PCT/JP2017/005615 WO2017159193A1 (ja) | 2016-03-16 | 2017-02-16 | 円形部材の内周長測定装置 |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| KR20180098338A true KR20180098338A (ko) | 2018-09-03 |

| KR102067776B1 KR102067776B1 (ko) | 2020-02-11 |

Family

ID=59850217

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020187021217A Active KR102067776B1 (ko) | 2016-03-16 | 2017-02-16 | 원형 부재의 내주 길이 측정 장치 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US10775154B2 (ko) |

| EP (1) | EP3431922B1 (ko) |

| JP (1) | JP6206527B2 (ko) |

| KR (1) | KR102067776B1 (ko) |

| CN (1) | CN108603753B (ko) |

| WO (1) | WO2017159193A1 (ko) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP6146505B1 (ja) * | 2016-03-16 | 2017-06-14 | 横浜ゴム株式会社 | 円形部材の内周長測定装置 |

| JP6233434B2 (ja) * | 2016-03-16 | 2017-11-22 | 横浜ゴム株式会社 | 円形部材の内周長測定方法 |

| US10845192B2 (en) * | 2017-09-13 | 2020-11-24 | Shawn Thomas Lause | Machine tool test fixture |

| CN109341622B (zh) * | 2018-12-06 | 2020-10-02 | 燕山大学 | 接触式特种车辆支承滚轮高度检测仪 |

Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH01195309A (ja) * | 1988-01-29 | 1989-08-07 | Sumitomo Rubber Ind Ltd | 円筒体測定装置 |

| JP2005140726A (ja) * | 2003-11-10 | 2005-06-02 | Omron Corp | 薄膜測定方法及び薄膜測定装置 |

| JP2012150013A (ja) | 2011-01-19 | 2012-08-09 | Sumitomo Rubber Ind Ltd | ビードコアの内周長測定装置 |

Family Cites Families (22)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH061128A (ja) | 1992-06-23 | 1994-01-11 | Yokohama Rubber Co Ltd:The | タイヤビード部の内周長計測機 |

| JP2759055B2 (ja) * | 1994-08-22 | 1998-05-28 | 川崎製鉄株式会社 | ペイオフリールの自動減速制御方法 |

| US6289600B1 (en) * | 1999-11-02 | 2001-09-18 | United States Pipe & Foundry Company | Non-contact measuring device |

| US7251580B2 (en) * | 2003-10-20 | 2007-07-31 | Mitutoyo Corporation | Method for measuring curved surface of workpiece, program and medium thereof |

| GB0605796D0 (en) | 2006-03-23 | 2006-05-03 | Renishaw Plc | Apparatus and method of measuring workpieces |

| JP5120625B2 (ja) * | 2008-03-07 | 2013-01-16 | アイシン精機株式会社 | 内面測定装置 |

| JP2010048731A (ja) * | 2008-08-25 | 2010-03-04 | Toyota Motor Corp | 断面形状の測定装置と測定方法 |

| JP5269698B2 (ja) * | 2009-06-10 | 2013-08-21 | 株式会社ミツトヨ | 真円度測定装置 |

| KR101118957B1 (ko) * | 2009-12-29 | 2012-03-05 | 주식회사 성우하이텍 | 도어 샌딩용 테이블 지그 |

| CN202432959U (zh) * | 2011-12-26 | 2012-09-12 | 宝山钢铁股份有限公司 | 多功能圆盘剪刀片检测台架 |

| JP2013134176A (ja) * | 2011-12-27 | 2013-07-08 | Sharp Corp | 撮像装置および撮像方法 |

| JP2013186009A (ja) * | 2012-03-08 | 2013-09-19 | Toyota Motor Corp | 形状測定装置の校正方法 |

| JP6169339B2 (ja) | 2012-10-04 | 2017-07-26 | 株式会社日立製作所 | 形状計測方法及び装置 |

| CN102980558A (zh) * | 2012-12-07 | 2013-03-20 | 辽宁工程技术大学 | 基于极坐标积分的矿用智能巷道断面测量装置及方法 |

| CN102997851B (zh) * | 2012-12-11 | 2015-08-05 | 三一重工股份有限公司 | 螺旋筒的圆周测量方法及圆周测量装置 |

| CN104180763A (zh) * | 2013-05-24 | 2014-12-03 | 南开大学 | 大直径圆环类零件内外径非接触式测量装置 |

| CN103278100B (zh) * | 2013-06-19 | 2016-06-22 | 天津大学 | 一种基于非接触式传感器组合的孔径测量方法 |

| CN105452802B (zh) * | 2013-07-19 | 2019-02-01 | 株式会社尼康 | 形状测定装置、构造物制造系统、形状测定方法、构造物制造方法、形状测定程序、以及记录介质 |

| CN203615897U (zh) * | 2013-09-23 | 2014-05-28 | 北京石油化工学院 | 基于位移传感器的管道内径测量装置 |

| CN204325905U (zh) * | 2014-10-28 | 2015-05-13 | 中铁二院工程集团有限责任公司 | 用于多向测力球型钢支座的测力弹性体 |

| JP6146505B1 (ja) * | 2016-03-16 | 2017-06-14 | 横浜ゴム株式会社 | 円形部材の内周長測定装置 |

| JP6233434B2 (ja) * | 2016-03-16 | 2017-11-22 | 横浜ゴム株式会社 | 円形部材の内周長測定方法 |

-

2016

- 2016-03-16 JP JP2016052614A patent/JP6206527B2/ja active Active

-

2017

- 2017-02-16 CN CN201780010562.6A patent/CN108603753B/zh active Active

- 2017-02-16 WO PCT/JP2017/005615 patent/WO2017159193A1/ja not_active Ceased

- 2017-02-16 EP EP17766200.4A patent/EP3431922B1/en active Active

- 2017-02-16 KR KR1020187021217A patent/KR102067776B1/ko active Active

- 2017-02-16 US US16/085,561 patent/US10775154B2/en active Active

Patent Citations (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH01195309A (ja) * | 1988-01-29 | 1989-08-07 | Sumitomo Rubber Ind Ltd | 円筒体測定装置 |

| JP2005140726A (ja) * | 2003-11-10 | 2005-06-02 | Omron Corp | 薄膜測定方法及び薄膜測定装置 |

| JP2012150013A (ja) | 2011-01-19 | 2012-08-09 | Sumitomo Rubber Ind Ltd | ビードコアの内周長測定装置 |

Non-Patent Citations (1)

| Title |

|---|

| 일본 공개특허공보 제(평)6-1128호 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN108603753B (zh) | 2020-08-04 |

| JP2017166982A (ja) | 2017-09-21 |

| EP3431922A4 (en) | 2019-09-25 |

| EP3431922A1 (en) | 2019-01-23 |

| JP6206527B2 (ja) | 2017-10-04 |

| US20190154433A1 (en) | 2019-05-23 |

| CN108603753A (zh) | 2018-09-28 |

| KR102067776B1 (ko) | 2020-02-11 |

| EP3431922B1 (en) | 2022-03-02 |

| WO2017159193A1 (ja) | 2017-09-21 |

| US10775154B2 (en) | 2020-09-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN106415197B (zh) | 修正环形旋转体的表面形状数据的方法和检查环形旋转体的外观的装置 | |

| JP5946424B2 (ja) | タイヤ試験機 | |

| KR20180098338A (ko) | 원형 부재의 내주 길이 측정 장치 | |

| KR20180097706A (ko) | 원형 부재의 내주 길이 측정 방법 | |

| CN102139608A (zh) | 通过非接触感测确定轮胎几何尺寸的设备和方法 | |

| CN105415990A (zh) | 用于装配和移除轮胎的机器和用于操作机器的方法 | |

| JP6420639B2 (ja) | トレッド形状測定方法 | |

| CA2909373A1 (en) | Uniformity testing system and methodology for utilizing the same | |

| KR20180097705A (ko) | 원형 부재의 내주 길이 측정 장치 | |

| CN103250024B (zh) | 用于在修车车间机器或类似物上检测车轮的形状和/或尺寸的方法 | |

| KR20150088924A (ko) | 대형 베어링의 진원도 측정 시스템 | |

| JP6265864B2 (ja) | タイヤ試験装置 | |

| JP6735254B2 (ja) | タイヤの動負荷半径の算出装置及び算出方法 | |

| US20200300617A1 (en) | Measuring device and measuring method for a grooved axially symmetric body | |

| WO2023171396A1 (ja) | 表面形状計測装置 | |

| CN117387543A (zh) | 一种轮辋外轮缘高度的检测装置及检测方法 | |

| US20200263975A1 (en) | Shape Measuring Device for Hose Connector Fitting | |

| TWM616494U (zh) | 非接觸式環形物件真圓度量測裝置 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A201 | Request for examination | ||

| PA0105 | International application |

St.27 status event code: A-0-1-A10-A15-nap-PA0105 |

|

| PA0201 | Request for examination |

St.27 status event code: A-1-2-D10-D11-exm-PA0201 |

|

| PG1501 | Laying open of application |

St.27 status event code: A-1-1-Q10-Q12-nap-PG1501 |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

St.27 status event code: A-1-2-D10-D21-exm-PE0902 |

|

| P11-X000 | Amendment of application requested |

St.27 status event code: A-2-2-P10-P11-nap-X000 |

|

| P13-X000 | Application amended |

St.27 status event code: A-2-2-P10-P13-nap-X000 |

|

| E701 | Decision to grant or registration of patent right | ||

| PE0701 | Decision of registration |

St.27 status event code: A-1-2-D10-D22-exm-PE0701 |

|

| GRNT | Written decision to grant | ||

| PR0701 | Registration of establishment |

St.27 status event code: A-2-4-F10-F11-exm-PR0701 |

|

| PR1002 | Payment of registration fee |

St.27 status event code: A-2-2-U10-U12-oth-PR1002 Fee payment year number: 1 |

|

| PG1601 | Publication of registration |

St.27 status event code: A-4-4-Q10-Q13-nap-PG1601 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 4 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 5 |

|

| R18-X000 | Changes to party contact information recorded |

St.27 status event code: A-5-5-R10-R18-oth-X000 |

|

| PR1001 | Payment of annual fee |

St.27 status event code: A-4-4-U10-U11-oth-PR1001 Fee payment year number: 6 |