KR20150112984A - 질화구리 미립자 및 그 제조 방법 - Google Patents

질화구리 미립자 및 그 제조 방법 Download PDFInfo

- Publication number

- KR20150112984A KR20150112984A KR1020157020804A KR20157020804A KR20150112984A KR 20150112984 A KR20150112984 A KR 20150112984A KR 1020157020804 A KR1020157020804 A KR 1020157020804A KR 20157020804 A KR20157020804 A KR 20157020804A KR 20150112984 A KR20150112984 A KR 20150112984A

- Authority

- KR

- South Korea

- Prior art keywords

- copper

- fine particles

- copper nitride

- compound

- nitride fine

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Ceased

Links

- 239000010949 copper Substances 0.000 title claims abstract description 193

- 229910052802 copper Inorganic materials 0.000 title claims abstract description 186

- -1 copper nitride Chemical class 0.000 title claims abstract description 176

- 238000004519 manufacturing process Methods 0.000 title claims abstract description 21

- 239000002245 particle Substances 0.000 title claims abstract description 14

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 claims abstract description 86

- 239000010419 fine particle Substances 0.000 claims abstract description 67

- IJGRMHOSHXDMSA-UHFFFAOYSA-N Atomic nitrogen Chemical compound N#N IJGRMHOSHXDMSA-UHFFFAOYSA-N 0.000 claims abstract description 55

- 239000011859 microparticle Substances 0.000 claims abstract description 36

- 229910052757 nitrogen Inorganic materials 0.000 claims abstract description 33

- 239000011164 primary particle Substances 0.000 claims abstract description 22

- 239000011163 secondary particle Substances 0.000 claims abstract description 22

- 238000000354 decomposition reaction Methods 0.000 claims abstract description 12

- 150000001875 compounds Chemical class 0.000 claims description 33

- 238000010438 heat treatment Methods 0.000 claims description 27

- 238000000034 method Methods 0.000 claims description 23

- QGZKDVFQNNGYKY-UHFFFAOYSA-N Ammonia Chemical compound N QGZKDVFQNNGYKY-UHFFFAOYSA-N 0.000 claims description 20

- 239000000463 material Substances 0.000 claims description 18

- 150000001879 copper Chemical class 0.000 claims description 17

- 239000000758 substrate Substances 0.000 claims description 16

- 239000003223 protective agent Substances 0.000 claims description 15

- 239000002904 solvent Substances 0.000 claims description 15

- 125000003178 carboxy group Chemical group [H]OC(*)=O 0.000 claims description 12

- 238000007639 printing Methods 0.000 claims description 12

- 239000013585 weight reducing agent Substances 0.000 claims description 11

- 238000009835 boiling Methods 0.000 claims description 10

- 238000004458 analytical method Methods 0.000 claims description 9

- 125000003277 amino group Chemical group 0.000 claims description 8

- 125000002887 hydroxy group Chemical group [H]O* 0.000 claims description 8

- XSQUKJJJFZCRTK-UHFFFAOYSA-N Urea Chemical compound NC(N)=O XSQUKJJJFZCRTK-UHFFFAOYSA-N 0.000 claims description 7

- 239000003960 organic solvent Substances 0.000 claims description 6

- 239000002612 dispersion medium Substances 0.000 claims description 5

- 239000004202 carbamide Substances 0.000 claims description 4

- 238000000634 powder X-ray diffraction Methods 0.000 claims description 4

- ALKZAGKDWUSJED-UHFFFAOYSA-N dinuclear copper ion Chemical compound [Cu].[Cu] ALKZAGKDWUSJED-UHFFFAOYSA-N 0.000 claims description 3

- 230000027455 binding Effects 0.000 claims description 2

- 238000002156 mixing Methods 0.000 claims description 2

- 238000011282 treatment Methods 0.000 abstract description 4

- MTHSVFCYNBDYFN-UHFFFAOYSA-N diethylene glycol Chemical compound OCCOCCO MTHSVFCYNBDYFN-UHFFFAOYSA-N 0.000 description 35

- 150000002430 hydrocarbons Chemical group 0.000 description 21

- 239000002244 precipitate Substances 0.000 description 21

- VLKZOEOYAKHREP-UHFFFAOYSA-N n-Hexane Chemical compound CCCCCC VLKZOEOYAKHREP-UHFFFAOYSA-N 0.000 description 20

- 229920006395 saturated elastomer Polymers 0.000 description 18

- 229930195734 saturated hydrocarbon Natural products 0.000 description 18

- 229930195735 unsaturated hydrocarbon Natural products 0.000 description 18

- 125000004432 carbon atom Chemical group C* 0.000 description 17

- 125000004122 cyclic group Chemical group 0.000 description 17

- 238000004627 transmission electron microscopy Methods 0.000 description 16

- KBPLFHHGFOOTCA-UHFFFAOYSA-N 1-Octanol Chemical compound CCCCCCCCO KBPLFHHGFOOTCA-UHFFFAOYSA-N 0.000 description 14

- 238000006243 chemical reaction Methods 0.000 description 12

- 239000000843 powder Substances 0.000 description 12

- 238000004455 differential thermal analysis Methods 0.000 description 11

- 238000007664 blowing Methods 0.000 description 10

- ARUVKPQLZAKDPS-UHFFFAOYSA-L copper(II) sulfate Chemical compound [Cu+2].[O-][S+2]([O-])([O-])[O-] ARUVKPQLZAKDPS-UHFFFAOYSA-L 0.000 description 10

- 238000005259 measurement Methods 0.000 description 10

- 238000001556 precipitation Methods 0.000 description 10

- 238000000197 pyrolysis Methods 0.000 description 10

- 229910000365 copper sulfate Inorganic materials 0.000 description 9

- OPQARKPSCNTWTJ-UHFFFAOYSA-L copper(ii) acetate Chemical compound [Cu+2].CC([O-])=O.CC([O-])=O OPQARKPSCNTWTJ-UHFFFAOYSA-L 0.000 description 9

- NLXLAEXVIDQMFP-UHFFFAOYSA-N Ammonia chloride Chemical compound [NH4+].[Cl-] NLXLAEXVIDQMFP-UHFFFAOYSA-N 0.000 description 8

- WIVXEZIMDUGYRW-UHFFFAOYSA-L copper(i) sulfate Chemical compound [Cu+].[Cu+].[O-]S([O-])(=O)=O WIVXEZIMDUGYRW-UHFFFAOYSA-L 0.000 description 8

- GSCLWPQCXDSGBU-UHFFFAOYSA-L copper;phthalate Chemical compound [Cu+2].[O-]C(=O)C1=CC=CC=C1C([O-])=O GSCLWPQCXDSGBU-UHFFFAOYSA-L 0.000 description 8

- 238000001228 spectrum Methods 0.000 description 7

- 239000013078 crystal Substances 0.000 description 6

- NAQMVNRVTILPCV-UHFFFAOYSA-N hexane-1,6-diamine Chemical compound NCCCCCCN NAQMVNRVTILPCV-UHFFFAOYSA-N 0.000 description 6

- 230000003647 oxidation Effects 0.000 description 6

- 238000007254 oxidation reaction Methods 0.000 description 6

- VNZQQAVATKSIBR-UHFFFAOYSA-L copper;octanoate Chemical compound [Cu+2].CCCCCCCC([O-])=O.CCCCCCCC([O-])=O VNZQQAVATKSIBR-UHFFFAOYSA-L 0.000 description 5

- 150000005846 sugar alcohols Polymers 0.000 description 5

- BMVXCPBXGZKUPN-UHFFFAOYSA-N 1-hexanamine Chemical compound CCCCCCN BMVXCPBXGZKUPN-UHFFFAOYSA-N 0.000 description 4

- USFZMSVCRYTOJT-UHFFFAOYSA-N Ammonium acetate Chemical compound N.CC(O)=O USFZMSVCRYTOJT-UHFFFAOYSA-N 0.000 description 4

- 239000005695 Ammonium acetate Substances 0.000 description 4

- QPLDLSVMHZLSFG-UHFFFAOYSA-N Copper oxide Chemical compound [Cu]=O QPLDLSVMHZLSFG-UHFFFAOYSA-N 0.000 description 4

- 239000005751 Copper oxide Substances 0.000 description 4

- QUSNBJAOOMFDIB-UHFFFAOYSA-N Ethylamine Chemical compound CCN QUSNBJAOOMFDIB-UHFFFAOYSA-N 0.000 description 4

- BAVYZALUXZFZLV-UHFFFAOYSA-N Methylamine Chemical compound NC BAVYZALUXZFZLV-UHFFFAOYSA-N 0.000 description 4

- PXIPVTKHYLBLMZ-UHFFFAOYSA-N Sodium azide Chemical compound [Na+].[N-]=[N+]=[N-] PXIPVTKHYLBLMZ-UHFFFAOYSA-N 0.000 description 4

- 229940043376 ammonium acetate Drugs 0.000 description 4

- 235000019257 ammonium acetate Nutrition 0.000 description 4

- 235000019270 ammonium chloride Nutrition 0.000 description 4

- 230000015572 biosynthetic process Effects 0.000 description 4

- HQABUPZFAYXKJW-UHFFFAOYSA-N butan-1-amine Chemical compound CCCCN HQABUPZFAYXKJW-UHFFFAOYSA-N 0.000 description 4

- 229910000431 copper oxide Inorganic materials 0.000 description 4

- KZTYYGOKRVBIMI-UHFFFAOYSA-N diphenyl sulfone Chemical compound C=1C=CC=CC=1S(=O)(=O)C1=CC=CC=C1 KZTYYGOKRVBIMI-UHFFFAOYSA-N 0.000 description 4

- FJDUDHYHRVPMJZ-UHFFFAOYSA-N nonan-1-amine Chemical compound CCCCCCCCCN FJDUDHYHRVPMJZ-UHFFFAOYSA-N 0.000 description 4

- ZWRUINPWMLAQRD-UHFFFAOYSA-N nonan-1-ol Chemical compound CCCCCCCCCO ZWRUINPWMLAQRD-UHFFFAOYSA-N 0.000 description 4

- WGYKZJWCGVVSQN-UHFFFAOYSA-N propylamine Chemical compound CCCN WGYKZJWCGVVSQN-UHFFFAOYSA-N 0.000 description 4

- 238000011179 visual inspection Methods 0.000 description 4

- 238000002441 X-ray diffraction Methods 0.000 description 3

- 150000004703 alkoxides Chemical class 0.000 description 3

- SWLVFNYSXGMGBS-UHFFFAOYSA-N ammonium bromide Chemical compound [NH4+].[Br-] SWLVFNYSXGMGBS-UHFFFAOYSA-N 0.000 description 3

- 239000011248 coating agent Substances 0.000 description 3

- 238000000576 coating method Methods 0.000 description 3

- 150000004699 copper complex Chemical class 0.000 description 3

- NBPFTDFXKORRKN-UHFFFAOYSA-L copper;pentanoate Chemical compound [Cu+2].CCCCC([O-])=O.CCCCC([O-])=O NBPFTDFXKORRKN-UHFFFAOYSA-L 0.000 description 3

- 150000004985 diamines Chemical class 0.000 description 3

- RTZKZFJDLAIYFH-UHFFFAOYSA-N ether Substances CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 3

- 239000003446 ligand Substances 0.000 description 3

- 229910052751 metal Inorganic materials 0.000 description 3

- 239000002184 metal Substances 0.000 description 3

- 230000009149 molecular binding Effects 0.000 description 3

- IOQPZZOEVPZRBK-UHFFFAOYSA-N octan-1-amine Chemical compound CCCCCCCCN IOQPZZOEVPZRBK-UHFFFAOYSA-N 0.000 description 3

- 239000012071 phase Substances 0.000 description 3

- 229920000642 polymer Polymers 0.000 description 3

- 229920000307 polymer substrate Polymers 0.000 description 3

- 239000000126 substance Substances 0.000 description 3

- 238000003786 synthesis reaction Methods 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 229910001868 water Inorganic materials 0.000 description 3

- CBCKQZAAMUWICA-UHFFFAOYSA-N 1,4-phenylenediamine Chemical compound NC1=CC=C(N)C=C1 CBCKQZAAMUWICA-UHFFFAOYSA-N 0.000 description 2

- BBMCTIGTTCKYKF-UHFFFAOYSA-N 1-heptanol Chemical compound CCCCCCCO BBMCTIGTTCKYKF-UHFFFAOYSA-N 0.000 description 2

- FEUISMYEFPANSS-UHFFFAOYSA-N 2-methylcyclohexan-1-amine Chemical compound CC1CCCCC1N FEUISMYEFPANSS-UHFFFAOYSA-N 0.000 description 2

- HXDOZKJGKXYMEW-UHFFFAOYSA-N 4-ethylphenol Chemical compound CCC1=CC=C(O)C=C1 HXDOZKJGKXYMEW-UHFFFAOYSA-N 0.000 description 2

- MQWCXKGKQLNYQG-UHFFFAOYSA-N 4-methylcyclohexan-1-ol Chemical compound CC1CCC(O)CC1 MQWCXKGKQLNYQG-UHFFFAOYSA-N 0.000 description 2

- ATRRKUHOCOJYRX-UHFFFAOYSA-N Ammonium bicarbonate Chemical compound [NH4+].OC([O-])=O ATRRKUHOCOJYRX-UHFFFAOYSA-N 0.000 description 2

- PAYRUJLWNCNPSJ-UHFFFAOYSA-N Aniline Chemical compound NC1=CC=CC=C1 PAYRUJLWNCNPSJ-UHFFFAOYSA-N 0.000 description 2

- 239000004475 Arginine Substances 0.000 description 2

- 239000005749 Copper compound Substances 0.000 description 2

- JPVYNHNXODAKFH-UHFFFAOYSA-N Cu2+ Chemical compound [Cu+2] JPVYNHNXODAKFH-UHFFFAOYSA-N 0.000 description 2

- WJYIASZWHGOTOU-UHFFFAOYSA-N Heptylamine Chemical compound CCCCCCCN WJYIASZWHGOTOU-UHFFFAOYSA-N 0.000 description 2

- AMQJEAYHLZJPGS-UHFFFAOYSA-N N-Pentanol Chemical compound CCCCCO AMQJEAYHLZJPGS-UHFFFAOYSA-N 0.000 description 2

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 description 2

- WCUXLLCKKVVCTQ-UHFFFAOYSA-M Potassium chloride Chemical compound [Cl-].[K+] WCUXLLCKKVVCTQ-UHFFFAOYSA-M 0.000 description 2

- 239000002253 acid Substances 0.000 description 2

- 150000001412 amines Chemical class 0.000 description 2

- 229940024606 amino acid Drugs 0.000 description 2

- 235000001014 amino acid Nutrition 0.000 description 2

- 150000001413 amino acids Chemical class 0.000 description 2

- 229910021529 ammonia Inorganic materials 0.000 description 2

- 239000001099 ammonium carbonate Substances 0.000 description 2

- ODKSFYDXXFIFQN-UHFFFAOYSA-N arginine Natural products OC(=O)C(N)CCCNC(N)=N ODKSFYDXXFIFQN-UHFFFAOYSA-N 0.000 description 2

- 150000004982 aromatic amines Chemical class 0.000 description 2

- 125000003118 aryl group Chemical group 0.000 description 2

- 239000004305 biphenyl Substances 0.000 description 2

- ODWXUNBKCRECNW-UHFFFAOYSA-M bromocopper(1+) Chemical compound Br[Cu+] ODWXUNBKCRECNW-UHFFFAOYSA-M 0.000 description 2

- VHRGRCVQAFMJIZ-UHFFFAOYSA-N cadaverine Chemical compound NCCCCCN VHRGRCVQAFMJIZ-UHFFFAOYSA-N 0.000 description 2

- BVKZGUZCCUSVTD-UHFFFAOYSA-N carbonic acid Chemical compound OC(O)=O BVKZGUZCCUSVTD-UHFFFAOYSA-N 0.000 description 2

- 150000001732 carboxylic acid derivatives Chemical class 0.000 description 2

- 150000001880 copper compounds Chemical class 0.000 description 2

- ORTQZVOHEJQUHG-UHFFFAOYSA-L copper(II) chloride Chemical compound Cl[Cu]Cl ORTQZVOHEJQUHG-UHFFFAOYSA-L 0.000 description 2

- XTVVROIMIGLXTD-UHFFFAOYSA-N copper(II) nitrate Chemical compound [Cu+2].[O-][N+]([O-])=O.[O-][N+]([O-])=O XTVVROIMIGLXTD-UHFFFAOYSA-N 0.000 description 2

- ZKXWKVVCCTZOLD-UHFFFAOYSA-N copper;4-hydroxypent-3-en-2-one Chemical compound [Cu].CC(O)=CC(C)=O.CC(O)=CC(C)=O ZKXWKVVCCTZOLD-UHFFFAOYSA-N 0.000 description 2

- PUHAKHQMSBQAKT-UHFFFAOYSA-L copper;butanoate Chemical compound [Cu+2].CCCC([O-])=O.CCCC([O-])=O PUHAKHQMSBQAKT-UHFFFAOYSA-L 0.000 description 2

- OBITVTZBIATBCL-UHFFFAOYSA-L copper;decanoate Chemical compound [Cu+2].CCCCCCCCCC([O-])=O.CCCCCCCCCC([O-])=O OBITVTZBIATBCL-UHFFFAOYSA-L 0.000 description 2

- HFDWIMBEIXDNQS-UHFFFAOYSA-L copper;diformate Chemical compound [Cu+2].[O-]C=O.[O-]C=O HFDWIMBEIXDNQS-UHFFFAOYSA-L 0.000 description 2

- JDPSPYBMORZJOD-UHFFFAOYSA-L copper;dodecanoate Chemical compound [Cu+2].CCCCCCCCCCCC([O-])=O.CCCCCCCCCCCC([O-])=O JDPSPYBMORZJOD-UHFFFAOYSA-L 0.000 description 2

- NQDSPXCXIOLFGI-UHFFFAOYSA-L copper;heptanoate Chemical compound [Cu+2].CCCCCCC([O-])=O.CCCCCCC([O-])=O NQDSPXCXIOLFGI-UHFFFAOYSA-L 0.000 description 2

- SMNMOEIFYRALNM-UHFFFAOYSA-L copper;hexanoate Chemical compound [Cu+2].CCCCCC([O-])=O.CCCCCC([O-])=O SMNMOEIFYRALNM-UHFFFAOYSA-L 0.000 description 2

- HZULDDWVCRWYCB-UHFFFAOYSA-L copper;nonanoate Chemical compound [Cu+2].CCCCCCCCC([O-])=O.CCCCCCCCC([O-])=O HZULDDWVCRWYCB-UHFFFAOYSA-L 0.000 description 2

- XCKXYAJAIPORLM-UHFFFAOYSA-L copper;undecanoate Chemical compound [Cu+2].CCCCCCCCCCC([O-])=O.CCCCCCCCCCC([O-])=O XCKXYAJAIPORLM-UHFFFAOYSA-L 0.000 description 2

- PFURGBBHAOXLIO-UHFFFAOYSA-N cyclohexane-1,2-diol Chemical compound OC1CCCCC1O PFURGBBHAOXLIO-UHFFFAOYSA-N 0.000 description 2

- PAFZNILMFXTMIY-UHFFFAOYSA-N cyclohexylamine Chemical compound NC1CCCCC1 PAFZNILMFXTMIY-UHFFFAOYSA-N 0.000 description 2

- SNRUBQQJIBEYMU-UHFFFAOYSA-N dodecane Chemical compound CCCCCCCCCCCC SNRUBQQJIBEYMU-UHFFFAOYSA-N 0.000 description 2

- 150000002148 esters Chemical class 0.000 description 2

- ZSIAUFGUXNUGDI-UHFFFAOYSA-N hexan-1-ol Chemical compound CCCCCCO ZSIAUFGUXNUGDI-UHFFFAOYSA-N 0.000 description 2

- 239000007791 liquid phase Substances 0.000 description 2

- 239000003607 modifier Substances 0.000 description 2

- 125000004433 nitrogen atom Chemical group N* 0.000 description 2

- 239000013110 organic ligand Substances 0.000 description 2

- 125000004430 oxygen atom Chemical group O* 0.000 description 2

- DPBLXKKOBLCELK-UHFFFAOYSA-N pentan-1-amine Chemical compound CCCCCN DPBLXKKOBLCELK-UHFFFAOYSA-N 0.000 description 2

- KIDHWZJUCRJVML-UHFFFAOYSA-N putrescine Chemical compound NCCCCN KIDHWZJUCRJVML-UHFFFAOYSA-N 0.000 description 2

- 239000002994 raw material Substances 0.000 description 2

- 238000012216 screening Methods 0.000 description 2

- 239000007787 solid Substances 0.000 description 2

- 150000004992 toluidines Chemical class 0.000 description 2

- XFNJVJPLKCPIBV-UHFFFAOYSA-N trimethylenediamine Chemical compound NCCCN XFNJVJPLKCPIBV-UHFFFAOYSA-N 0.000 description 2

- ZYECOAILUNWEAL-NUDFZHEQSA-N (4z)-4-[[2-methoxy-5-(phenylcarbamoyl)phenyl]hydrazinylidene]-n-(3-nitrophenyl)-3-oxonaphthalene-2-carboxamide Chemical compound COC1=CC=C(C(=O)NC=2C=CC=CC=2)C=C1N\N=C(C1=CC=CC=C1C=1)/C(=O)C=1C(=O)NC1=CC=CC([N+]([O-])=O)=C1 ZYECOAILUNWEAL-NUDFZHEQSA-N 0.000 description 1

- ORTVZLZNOYNASJ-UPHRSURJSA-N (z)-but-2-ene-1,4-diol Chemical compound OC\C=C/CO ORTVZLZNOYNASJ-UPHRSURJSA-N 0.000 description 1

- SHVRRGGZMBWAJT-ODZAUARKSA-N (z)-but-2-enedioic acid;copper Chemical compound [Cu].OC(=O)\C=C/C(O)=O SHVRRGGZMBWAJT-ODZAUARKSA-N 0.000 description 1

- QGLWBTPVKHMVHM-KTKRTIGZSA-N (z)-octadec-9-en-1-amine Chemical compound CCCCCCCC\C=C/CCCCCCCCN QGLWBTPVKHMVHM-KTKRTIGZSA-N 0.000 description 1

- WZCQRUWWHSTZEM-UHFFFAOYSA-N 1,3-phenylenediamine Chemical compound NC1=CC=CC(N)=C1 WZCQRUWWHSTZEM-UHFFFAOYSA-N 0.000 description 1

- QWOZZTWBWQMEPD-UHFFFAOYSA-N 1-(2-ethoxypropoxy)propan-2-ol Chemical compound CCOC(C)COCC(C)O QWOZZTWBWQMEPD-UHFFFAOYSA-N 0.000 description 1

- SMZOUWXMTYCWNB-UHFFFAOYSA-N 2-(2-methoxy-5-methylphenyl)ethanamine Chemical compound COC1=CC=C(C)C=C1CCN SMZOUWXMTYCWNB-UHFFFAOYSA-N 0.000 description 1

- SBASXUCJHJRPEV-UHFFFAOYSA-N 2-(2-methoxyethoxy)ethanol Chemical compound COCCOCCO SBASXUCJHJRPEV-UHFFFAOYSA-N 0.000 description 1

- PAWQVTBBRAZDMG-UHFFFAOYSA-N 2-(3-bromo-2-fluorophenyl)acetic acid Chemical compound OC(=O)CC1=CC=CC(Br)=C1F PAWQVTBBRAZDMG-UHFFFAOYSA-N 0.000 description 1

- NIXOWILDQLNWCW-UHFFFAOYSA-N 2-Propenoic acid Natural products OC(=O)C=C NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 description 1

- XZXYQEHISUMZAT-UHFFFAOYSA-N 2-[(2-hydroxy-5-methylphenyl)methyl]-4-methylphenol Chemical compound CC1=CC=C(O)C(CC=2C(=CC=C(C)C=2)O)=C1 XZXYQEHISUMZAT-UHFFFAOYSA-N 0.000 description 1

- KWIPUXXIFQQMKN-UHFFFAOYSA-N 2-azaniumyl-3-(4-cyanophenyl)propanoate Chemical compound OC(=O)C(N)CC1=CC=C(C#N)C=C1 KWIPUXXIFQQMKN-UHFFFAOYSA-N 0.000 description 1

- QTWJRLJHJPIABL-UHFFFAOYSA-N 2-methylphenol;3-methylphenol;4-methylphenol Chemical compound CC1=CC=C(O)C=C1.CC1=CC=CC(O)=C1.CC1=CC=CC=C1O QTWJRLJHJPIABL-UHFFFAOYSA-N 0.000 description 1

- NUIURNJTPRWVAP-UHFFFAOYSA-N 3,3'-Dimethylbenzidine Chemical group C1=C(N)C(C)=CC(C=2C=C(C)C(N)=CC=2)=C1 NUIURNJTPRWVAP-UHFFFAOYSA-N 0.000 description 1

- QCAHUFWKIQLBNB-UHFFFAOYSA-N 3-(3-methoxypropoxy)propan-1-ol Chemical compound COCCCOCCCO QCAHUFWKIQLBNB-UHFFFAOYSA-N 0.000 description 1

- ZBMISJGHVWNWTE-UHFFFAOYSA-N 3-(4-aminophenoxy)aniline Chemical compound C1=CC(N)=CC=C1OC1=CC=CC(N)=C1 ZBMISJGHVWNWTE-UHFFFAOYSA-N 0.000 description 1

- GDDNTTHUKVNJRA-UHFFFAOYSA-N 3-bromo-3,3-difluoroprop-1-ene Chemical compound FC(F)(Br)C=C GDDNTTHUKVNJRA-UHFFFAOYSA-N 0.000 description 1

- PMJNEQWWZRSFCE-UHFFFAOYSA-N 3-ethoxy-3-oxo-2-(thiophen-2-ylmethyl)propanoic acid Chemical compound CCOC(=O)C(C(O)=O)CC1=CC=CS1 PMJNEQWWZRSFCE-UHFFFAOYSA-N 0.000 description 1

- ICNFHJVPAJKPHW-UHFFFAOYSA-N 4,4'-Thiodianiline Chemical compound C1=CC(N)=CC=C1SC1=CC=C(N)C=C1 ICNFHJVPAJKPHW-UHFFFAOYSA-N 0.000 description 1

- YBRVSVVVWCFQMG-UHFFFAOYSA-N 4,4'-diaminodiphenylmethane Chemical compound C1=CC(N)=CC=C1CC1=CC=C(N)C=C1 YBRVSVVVWCFQMG-UHFFFAOYSA-N 0.000 description 1

- HLBLWEWZXPIGSM-UHFFFAOYSA-N 4-Aminophenyl ether Chemical compound C1=CC(N)=CC=C1OC1=CC=C(N)C=C1 HLBLWEWZXPIGSM-UHFFFAOYSA-N 0.000 description 1

- SJZRECIVHVDYJC-UHFFFAOYSA-N 4-hydroxybutyric acid Chemical compound OCCCC(O)=O SJZRECIVHVDYJC-UHFFFAOYSA-N 0.000 description 1

- QGZKDVFQNNGYKY-UHFFFAOYSA-O Ammonium Chemical compound [NH4+] QGZKDVFQNNGYKY-UHFFFAOYSA-O 0.000 description 1

- 229910000013 Ammonium bicarbonate Inorganic materials 0.000 description 1

- VHUUQVKOLVNVRT-UHFFFAOYSA-N Ammonium hydroxide Chemical compound [NH4+].[OH-] VHUUQVKOLVNVRT-UHFFFAOYSA-N 0.000 description 1

- 239000004254 Ammonium phosphate Substances 0.000 description 1

- DCXYFEDJOCDNAF-UHFFFAOYSA-N Asparagine Natural products OC(=O)C(N)CC(N)=O DCXYFEDJOCDNAF-UHFFFAOYSA-N 0.000 description 1

- BVEHSRXVCBOWCU-UHFFFAOYSA-L C(C#C)(=O)[O-].[Cu+2].C(C#C)(=O)[O-] Chemical compound C(C#C)(=O)[O-].[Cu+2].C(C#C)(=O)[O-] BVEHSRXVCBOWCU-UHFFFAOYSA-L 0.000 description 1

- WWZKQHOCKIZLMA-UHFFFAOYSA-N Caprylic acid Natural products CCCCCCCC(O)=O WWZKQHOCKIZLMA-UHFFFAOYSA-N 0.000 description 1

- UGFAIRIUMAVXCW-UHFFFAOYSA-N Carbon monoxide Chemical compound [O+]#[C-] UGFAIRIUMAVXCW-UHFFFAOYSA-N 0.000 description 1

- JJLJMEJHUUYSSY-UHFFFAOYSA-L Copper hydroxide Chemical compound [OH-].[OH-].[Cu+2] JJLJMEJHUUYSSY-UHFFFAOYSA-L 0.000 description 1

- 239000005750 Copper hydroxide Substances 0.000 description 1

- 239000005752 Copper oxychloride Substances 0.000 description 1

- 229910021594 Copper(II) fluoride Inorganic materials 0.000 description 1

- 229910016523 CuKa Inorganic materials 0.000 description 1

- PIICEJLVQHRZGT-UHFFFAOYSA-N Ethylenediamine Chemical compound NCCN PIICEJLVQHRZGT-UHFFFAOYSA-N 0.000 description 1

- CERQOIWHTDAKMF-UHFFFAOYSA-N Methacrylic acid Chemical compound CC(=C)C(O)=O CERQOIWHTDAKMF-UHFFFAOYSA-N 0.000 description 1

- OJGMBLNIHDZDGS-UHFFFAOYSA-N N-Ethylaniline Chemical class CCNC1=CC=CC=C1 OJGMBLNIHDZDGS-UHFFFAOYSA-N 0.000 description 1

- NUXQHXCLLXPADK-UHFFFAOYSA-N NC1=CC=C(C=C1)SC1=C(C(=O)C2=CC=CC=C2)C=CC=C1 Chemical compound NC1=CC=C(C=C1)SC1=C(C(=O)C2=CC=CC=C2)C=CC=C1 NUXQHXCLLXPADK-UHFFFAOYSA-N 0.000 description 1

- DPRDECGYTRQXHE-UHFFFAOYSA-L OC(C(=O)[O-])CC.[Cu+2].OC(C(=O)[O-])CC Chemical compound OC(C(=O)[O-])CC.[Cu+2].OC(C(=O)[O-])CC DPRDECGYTRQXHE-UHFFFAOYSA-L 0.000 description 1

- ZUFGEKLYOXYTJM-UHFFFAOYSA-L OC(CC(=O)[O-])C.[Cu+2].OC(CC(=O)[O-])C Chemical compound OC(CC(=O)[O-])C.[Cu+2].OC(CC(=O)[O-])C ZUFGEKLYOXYTJM-UHFFFAOYSA-L 0.000 description 1

- REYJJPSVUYRZGE-UHFFFAOYSA-N Octadecylamine Chemical compound CCCCCCCCCCCCCCCCCCN REYJJPSVUYRZGE-UHFFFAOYSA-N 0.000 description 1

- 240000007594 Oryza sativa Species 0.000 description 1

- 235000007164 Oryza sativa Nutrition 0.000 description 1

- ALQSHHUCVQOPAS-UHFFFAOYSA-N Pentane-1,5-diol Chemical compound OCCCCCO ALQSHHUCVQOPAS-UHFFFAOYSA-N 0.000 description 1

- 239000004642 Polyimide Substances 0.000 description 1

- 229920002675 Polyoxyl Polymers 0.000 description 1

- ZLMJMSJWJFRBEC-UHFFFAOYSA-N Potassium Chemical compound [K] ZLMJMSJWJFRBEC-UHFFFAOYSA-N 0.000 description 1

- 239000005700 Putrescine Substances 0.000 description 1

- MTCFGRXMJLQNBG-UHFFFAOYSA-N Serine Natural products OCC(N)C(O)=O MTCFGRXMJLQNBG-UHFFFAOYSA-N 0.000 description 1

- FOIXSVOLVBLSDH-UHFFFAOYSA-N Silver ion Chemical compound [Ag+] FOIXSVOLVBLSDH-UHFFFAOYSA-N 0.000 description 1

- AYFVYJQAPQTCCC-UHFFFAOYSA-N Threonine Natural products CC(O)C(N)C(O)=O AYFVYJQAPQTCCC-UHFFFAOYSA-N 0.000 description 1

- 239000004473 Threonine Substances 0.000 description 1

- YXFVVABEGXRONW-UHFFFAOYSA-N Toluene Chemical compound CC1=CC=CC=C1 YXFVVABEGXRONW-UHFFFAOYSA-N 0.000 description 1

- FNYLWPVRPXGIIP-UHFFFAOYSA-N Triamterene Chemical compound NC1=NC2=NC(N)=NC(N)=C2N=C1C1=CC=CC=C1 FNYLWPVRPXGIIP-UHFFFAOYSA-N 0.000 description 1

- QIVBCDIJIAJPQS-UHFFFAOYSA-N Tryptophan Natural products C1=CC=C2C(CC(N)C(O)=O)=CNC2=C1 QIVBCDIJIAJPQS-UHFFFAOYSA-N 0.000 description 1

- KZSNJWFQEVHDMF-UHFFFAOYSA-N Valine Natural products CC(C)C(N)C(O)=O KZSNJWFQEVHDMF-UHFFFAOYSA-N 0.000 description 1

- ITVSMRCGWRGLGH-UHFFFAOYSA-L [Cu+2].CCCCCCCCCCCCCCCCC([O-])=O.CCCCCCCCCCCCCCCCC([O-])=O Chemical compound [Cu+2].CCCCCCCCCCCCCCCCC([O-])=O.CCCCCCCCCCCCCCCCC([O-])=O ITVSMRCGWRGLGH-UHFFFAOYSA-L 0.000 description 1

- RAOSIAYCXKBGFE-UHFFFAOYSA-K [Cu+3].[O-]P([O-])([O-])=O Chemical compound [Cu+3].[O-]P([O-])([O-])=O RAOSIAYCXKBGFE-UHFFFAOYSA-K 0.000 description 1

- 235000004279 alanine Nutrition 0.000 description 1

- 125000001931 aliphatic group Chemical group 0.000 description 1

- 125000002947 alkylene group Chemical group 0.000 description 1

- OBETXYAYXDNJHR-UHFFFAOYSA-N alpha-ethylcaproic acid Natural products CCCCC(CC)C(O)=O OBETXYAYXDNJHR-UHFFFAOYSA-N 0.000 description 1

- PNEYBMLMFCGWSK-UHFFFAOYSA-N aluminium oxide Inorganic materials [O-2].[O-2].[O-2].[Al+3].[Al+3] PNEYBMLMFCGWSK-UHFFFAOYSA-N 0.000 description 1

- 150000001414 amino alcohols Chemical class 0.000 description 1

- 229940090948 ammonium benzoate Drugs 0.000 description 1

- 235000012538 ammonium bicarbonate Nutrition 0.000 description 1

- 235000012501 ammonium carbonate Nutrition 0.000 description 1

- KHPLPBHMTCTCHA-UHFFFAOYSA-N ammonium chlorate Chemical compound N.OCl(=O)=O KHPLPBHMTCTCHA-UHFFFAOYSA-N 0.000 description 1

- 239000000908 ammonium hydroxide Substances 0.000 description 1

- 235000011114 ammonium hydroxide Nutrition 0.000 description 1

- 229940107816 ammonium iodide Drugs 0.000 description 1

- 229910000148 ammonium phosphate Inorganic materials 0.000 description 1

- 235000019289 ammonium phosphates Nutrition 0.000 description 1

- 150000003863 ammonium salts Chemical class 0.000 description 1

- BFNBIHQBYMNNAN-UHFFFAOYSA-N ammonium sulfate Chemical compound N.N.OS(O)(=O)=O BFNBIHQBYMNNAN-UHFFFAOYSA-N 0.000 description 1

- 229910052921 ammonium sulfate Inorganic materials 0.000 description 1

- 235000011130 ammonium sulphate Nutrition 0.000 description 1

- SOIFLUNRINLCBN-UHFFFAOYSA-N ammonium thiocyanate Chemical compound [NH4+].[S-]C#N SOIFLUNRINLCBN-UHFFFAOYSA-N 0.000 description 1

- 150000001448 anilines Chemical class 0.000 description 1

- 229960001230 asparagine Drugs 0.000 description 1

- 235000009582 asparagine Nutrition 0.000 description 1

- QVGXLLKOCUKJST-UHFFFAOYSA-N atomic oxygen Chemical compound [O] QVGXLLKOCUKJST-UHFFFAOYSA-N 0.000 description 1

- ZRDJERPXCFOFCP-UHFFFAOYSA-N azane;iodic acid Chemical compound [NH4+].[O-]I(=O)=O ZRDJERPXCFOFCP-UHFFFAOYSA-N 0.000 description 1

- UAZDIGCOBKKMPU-UHFFFAOYSA-O azanium;azide Chemical compound [NH4+].[N-]=[N+]=[N-] UAZDIGCOBKKMPU-UHFFFAOYSA-O 0.000 description 1

- LDDQLRUQCUTJBB-UHFFFAOYSA-O azanium;hydrofluoride Chemical compound [NH4+].F LDDQLRUQCUTJBB-UHFFFAOYSA-O 0.000 description 1

- KCLGATRJYMEERW-UHFFFAOYSA-N benzene-1,3-dicarboxylic acid;copper Chemical compound [Cu].OC(=O)C1=CC=CC(C(O)=O)=C1 KCLGATRJYMEERW-UHFFFAOYSA-N 0.000 description 1

- YSVUPMYCAQOZGW-UHFFFAOYSA-N benzenesulfinic acid;hydrate Chemical compound O.OS(=O)C1=CC=CC=C1 YSVUPMYCAQOZGW-UHFFFAOYSA-N 0.000 description 1

- HFACYLZERDEVSX-UHFFFAOYSA-N benzidine Chemical group C1=CC(N)=CC=C1C1=CC=C(N)C=C1 HFACYLZERDEVSX-UHFFFAOYSA-N 0.000 description 1

- GHWVXCQZPNWFRO-UHFFFAOYSA-N butane-2,3-diamine Chemical compound CC(N)C(C)N GHWVXCQZPNWFRO-UHFFFAOYSA-N 0.000 description 1

- MGIWDIMSTXWOCO-UHFFFAOYSA-N butanedioic acid;copper Chemical compound [Cu].OC(=O)CCC(O)=O MGIWDIMSTXWOCO-UHFFFAOYSA-N 0.000 description 1

- 238000007707 calorimetry Methods 0.000 description 1

- 229910002091 carbon monoxide Inorganic materials 0.000 description 1

- 235000013339 cereals Nutrition 0.000 description 1

- HKMOPYJWSFRURD-UHFFFAOYSA-N chloro hypochlorite;copper Chemical compound [Cu].ClOCl HKMOPYJWSFRURD-UHFFFAOYSA-N 0.000 description 1

- 229940114081 cinnamate Drugs 0.000 description 1

- PMMYEEVYMWASQN-IMJSIDKUSA-N cis-4-Hydroxy-L-proline Chemical compound O[C@@H]1CN[C@H](C(O)=O)C1 PMMYEEVYMWASQN-IMJSIDKUSA-N 0.000 description 1

- 238000001246 colloidal dispersion Methods 0.000 description 1

- 238000004891 communication Methods 0.000 description 1

- 238000007796 conventional method Methods 0.000 description 1

- 229940116318 copper carbonate Drugs 0.000 description 1

- VVGDNYVYUZQYGR-UHFFFAOYSA-N copper dodecane Chemical compound [Cu].CCCCCCCCCCCC VVGDNYVYUZQYGR-UHFFFAOYSA-N 0.000 description 1

- 229910001956 copper hydroxide Inorganic materials 0.000 description 1

- 229910001431 copper ion Inorganic materials 0.000 description 1

- ZSISHHHXTSVFOF-UHFFFAOYSA-N copper(1+) cycloocta-1,3-diene Chemical compound C1=CC=CCCCC1.[Cu+] ZSISHHHXTSVFOF-UHFFFAOYSA-N 0.000 description 1

- OMZSGWSJDCOLKM-UHFFFAOYSA-N copper(II) sulfide Chemical compound [S-2].[Cu+2] OMZSGWSJDCOLKM-UHFFFAOYSA-N 0.000 description 1

- DOBRDRYODQBAMW-UHFFFAOYSA-N copper(i) cyanide Chemical compound [Cu+].N#[C-] DOBRDRYODQBAMW-UHFFFAOYSA-N 0.000 description 1

- GWFAVIIMQDUCRA-UHFFFAOYSA-L copper(ii) fluoride Chemical compound [F-].[F-].[Cu+2] GWFAVIIMQDUCRA-UHFFFAOYSA-L 0.000 description 1

- YRNNKGFMTBWUGL-UHFFFAOYSA-L copper(ii) perchlorate Chemical compound [Cu+2].[O-]Cl(=O)(=O)=O.[O-]Cl(=O)(=O)=O YRNNKGFMTBWUGL-UHFFFAOYSA-L 0.000 description 1

- SBTSVTLGWRLWOD-UHFFFAOYSA-L copper(ii) triflate Chemical compound [Cu+2].[O-]S(=O)(=O)C(F)(F)F.[O-]S(=O)(=O)C(F)(F)F SBTSVTLGWRLWOD-UHFFFAOYSA-L 0.000 description 1

- OGKRAMHEYIKPDE-UHFFFAOYSA-N copper;(1-carboxy-3-methylsulfanylpropyl)azanide Chemical compound [Cu+2].CSCCC([NH-])C(O)=O.CSCCC([NH-])C(O)=O OGKRAMHEYIKPDE-UHFFFAOYSA-N 0.000 description 1

- HALNNQZLOVPSEG-QXGOIDDHSA-L copper;(2s)-2-amino-3-phenylpropanoate Chemical compound [Cu+2].[O-]C(=O)[C@@H](N)CC1=CC=CC=C1.[O-]C(=O)[C@@H](N)CC1=CC=CC=C1 HALNNQZLOVPSEG-QXGOIDDHSA-L 0.000 description 1

- LHBCBDOIAVIYJI-DKWTVANSSA-L copper;(2s)-2-aminobutanedioate Chemical compound [Cu+2].[O-]C(=O)[C@@H](N)CC([O-])=O LHBCBDOIAVIYJI-DKWTVANSSA-L 0.000 description 1

- HIAAPJWEVOPQRI-DFWYDOINSA-L copper;(2s)-2-aminopentanedioate Chemical compound [Cu+2].[O-]C(=O)[C@@H](N)CCC([O-])=O HIAAPJWEVOPQRI-DFWYDOINSA-L 0.000 description 1

- SYHULLKZFALRDQ-SCGRZTRASA-L copper;(2s)-pyrrolidine-2-carboxylate Chemical compound [Cu+2].[O-]C(=O)[C@@H]1CCCN1.[O-]C(=O)[C@@H]1CCCN1 SYHULLKZFALRDQ-SCGRZTRASA-L 0.000 description 1

- HKHQECXDVWWYMU-WFGSYIHQSA-L copper;(2s,3s)-2-amino-3-methylpentanoate Chemical compound [Cu+2].CC[C@H](C)[C@H](N)C([O-])=O.CC[C@H](C)[C@H](N)C([O-])=O HKHQECXDVWWYMU-WFGSYIHQSA-L 0.000 description 1

- FXGNPUJCPZJYKO-TYYBGVCCSA-L copper;(e)-but-2-enedioate Chemical compound [Cu+2].[O-]C(=O)\C=C\C([O-])=O FXGNPUJCPZJYKO-TYYBGVCCSA-L 0.000 description 1

- SVOAENZIOKPANY-CVBJKYQLSA-L copper;(z)-octadec-9-enoate Chemical compound [Cu+2].CCCCCCCC\C=C/CCCCCCCC([O-])=O.CCCCCCCC\C=C/CCCCCCCC([O-])=O SVOAENZIOKPANY-CVBJKYQLSA-L 0.000 description 1

- RSJOBNMOMQFPKQ-UHFFFAOYSA-L copper;2,3-dihydroxybutanedioate Chemical compound [Cu+2].[O-]C(=O)C(O)C(O)C([O-])=O RSJOBNMOMQFPKQ-UHFFFAOYSA-L 0.000 description 1

- AWSWAKKAIQTOLD-UHFFFAOYSA-L copper;2,3-dihydroxypropanoate Chemical compound [Cu+2].OCC(O)C([O-])=O.OCC(O)C([O-])=O AWSWAKKAIQTOLD-UHFFFAOYSA-L 0.000 description 1

- VVYPIVJZLVJPGU-UHFFFAOYSA-L copper;2-aminoacetate Chemical compound [Cu+2].NCC([O-])=O.NCC([O-])=O VVYPIVJZLVJPGU-UHFFFAOYSA-L 0.000 description 1

- HXXRDHUDBAILGK-UHFFFAOYSA-L copper;2-hydroxyacetate Chemical compound [Cu+2].OCC([O-])=O.OCC([O-])=O HXXRDHUDBAILGK-UHFFFAOYSA-L 0.000 description 1

- DYROSKSLMAPFBZ-UHFFFAOYSA-L copper;2-hydroxypropanoate Chemical compound [Cu+2].CC(O)C([O-])=O.CC(O)C([O-])=O DYROSKSLMAPFBZ-UHFFFAOYSA-L 0.000 description 1

- VZWHXRLOECMQDD-UHFFFAOYSA-L copper;2-methylprop-2-enoate Chemical compound [Cu+2].CC(=C)C([O-])=O.CC(=C)C([O-])=O VZWHXRLOECMQDD-UHFFFAOYSA-L 0.000 description 1

- GEZOTWYUIKXWOA-UHFFFAOYSA-L copper;carbonate Chemical compound [Cu+2].[O-]C([O-])=O GEZOTWYUIKXWOA-UHFFFAOYSA-L 0.000 description 1

- LLVVIWYEOKVOFV-UHFFFAOYSA-L copper;diiodate Chemical compound [Cu+2].[O-]I(=O)=O.[O-]I(=O)=O LLVVIWYEOKVOFV-UHFFFAOYSA-L 0.000 description 1

- GBRBMTNGQBKBQE-UHFFFAOYSA-L copper;diiodide Chemical compound I[Cu]I GBRBMTNGQBKBQE-UHFFFAOYSA-L 0.000 description 1

- CRCKGIUJMFFISH-UHFFFAOYSA-N copper;ethanolate Chemical compound [Cu+2].CC[O-].CC[O-] CRCKGIUJMFFISH-UHFFFAOYSA-N 0.000 description 1

- GYPBUYJSHBFNEJ-UHFFFAOYSA-L copper;hexadecanoate Chemical compound [Cu+2].CCCCCCCCCCCCCCCC([O-])=O.CCCCCCCCCCCCCCCC([O-])=O GYPBUYJSHBFNEJ-UHFFFAOYSA-L 0.000 description 1

- ZCXLQZOQWCXFNN-UHFFFAOYSA-N copper;hexanedioic acid Chemical compound [Cu].OC(=O)CCCCC(O)=O ZCXLQZOQWCXFNN-UHFFFAOYSA-N 0.000 description 1

- COUNCWOLUGAQQG-UHFFFAOYSA-N copper;hydrogen peroxide Chemical compound [Cu].OO COUNCWOLUGAQQG-UHFFFAOYSA-N 0.000 description 1

- AYNQPTYHFBBKFC-UHFFFAOYSA-N copper;methanolate Chemical compound [Cu+2].[O-]C.[O-]C AYNQPTYHFBBKFC-UHFFFAOYSA-N 0.000 description 1

- ZOUQIAGHKFLHIA-UHFFFAOYSA-L copper;n,n-dimethylcarbamodithioate Chemical compound [Cu+2].CN(C)C([S-])=S.CN(C)C([S-])=S ZOUQIAGHKFLHIA-UHFFFAOYSA-L 0.000 description 1

- CAMXOLUXKJMDSB-UHFFFAOYSA-L copper;naphthalene-1-carboxylate Chemical compound [Cu+2].C1=CC=C2C(C(=O)[O-])=CC=CC2=C1.C1=CC=C2C(C(=O)[O-])=CC=CC2=C1 CAMXOLUXKJMDSB-UHFFFAOYSA-L 0.000 description 1

- QYCVHILLJSYYBD-UHFFFAOYSA-L copper;oxalate Chemical compound [Cu+2].[O-]C(=O)C([O-])=O QYCVHILLJSYYBD-UHFFFAOYSA-L 0.000 description 1

- LMCVMQNMDSVUFJ-UHFFFAOYSA-N copper;pentanedioic acid Chemical compound [Cu].OC(=O)CCCC(O)=O LMCVMQNMDSVUFJ-UHFFFAOYSA-N 0.000 description 1

- XPLSDXJBKRIVFZ-UHFFFAOYSA-L copper;prop-2-enoate Chemical compound [Cu+2].[O-]C(=O)C=C.[O-]C(=O)C=C XPLSDXJBKRIVFZ-UHFFFAOYSA-L 0.000 description 1

- BDHAOBSBMMJNGS-UHFFFAOYSA-N copper;propan-1-olate Chemical compound [Cu+2].CCC[O-].CCC[O-] BDHAOBSBMMJNGS-UHFFFAOYSA-N 0.000 description 1

- PJBGIAVUDLSOKX-UHFFFAOYSA-N copper;propanedioic acid Chemical compound [Cu].OC(=O)CC(O)=O PJBGIAVUDLSOKX-UHFFFAOYSA-N 0.000 description 1

- LZJJVTQGPPWQFS-UHFFFAOYSA-L copper;propanoate Chemical compound [Cu+2].CCC([O-])=O.CCC([O-])=O LZJJVTQGPPWQFS-UHFFFAOYSA-L 0.000 description 1

- ZISLUDLMVNEAHK-UHFFFAOYSA-L copper;terephthalate Chemical compound [Cu+2].[O-]C(=O)C1=CC=C(C([O-])=O)C=C1 ZISLUDLMVNEAHK-UHFFFAOYSA-L 0.000 description 1

- GOBQJWZGIQHYFF-UHFFFAOYSA-L copper;tetradecanoate Chemical compound [Cu+2].CCCCCCCCCCCCCC([O-])=O.CCCCCCCCCCCCCC([O-])=O GOBQJWZGIQHYFF-UHFFFAOYSA-L 0.000 description 1

- 239000011162 core material Substances 0.000 description 1

- 229930003836 cresol Natural products 0.000 description 1

- LDHQCZJRKDOVOX-NSCUHMNNSA-N crotonic acid Chemical compound C\C=C\C(O)=O LDHQCZJRKDOVOX-NSCUHMNNSA-N 0.000 description 1

- RLMGYIOTPQVQJR-UHFFFAOYSA-N cyclohexane-1,3-diol Chemical compound OC1CCCC(O)C1 RLMGYIOTPQVQJR-UHFFFAOYSA-N 0.000 description 1

- 150000003946 cyclohexylamines Chemical class 0.000 description 1

- VSSAZBXXNIABDN-UHFFFAOYSA-N cyclohexylmethanol Chemical compound OCC1CCCCC1 VSSAZBXXNIABDN-UHFFFAOYSA-N 0.000 description 1

- 235000018417 cysteine Nutrition 0.000 description 1

- XUJNEKJLAYXESH-UHFFFAOYSA-N cysteine Natural products SCC(N)C(O)=O XUJNEKJLAYXESH-UHFFFAOYSA-N 0.000 description 1

- 238000011161 development Methods 0.000 description 1

- 230000018109 developmental process Effects 0.000 description 1

- MNNHAPBLZZVQHP-UHFFFAOYSA-N diammonium hydrogen phosphate Chemical compound [NH4+].[NH4+].OP([O-])([O-])=O MNNHAPBLZZVQHP-UHFFFAOYSA-N 0.000 description 1

- XXJWXESWEXIICW-UHFFFAOYSA-N diethylene glycol monoethyl ether Chemical compound CCOCCOCCO XXJWXESWEXIICW-UHFFFAOYSA-N 0.000 description 1

- 229940075557 diethylene glycol monoethyl ether Drugs 0.000 description 1

- 229910001873 dinitrogen Inorganic materials 0.000 description 1

- SZXQTJUDPRGNJN-UHFFFAOYSA-N dipropylene glycol Chemical compound OCCCOCCCO SZXQTJUDPRGNJN-UHFFFAOYSA-N 0.000 description 1

- 239000002270 dispersing agent Substances 0.000 description 1

- 239000006185 dispersion Substances 0.000 description 1

- 238000004090 dissolution Methods 0.000 description 1

- 238000005516 engineering process Methods 0.000 description 1

- 238000004880 explosion Methods 0.000 description 1

- 238000011049 filling Methods 0.000 description 1

- 230000006870 function Effects 0.000 description 1

- ZDXPYRJPNDTMRX-UHFFFAOYSA-N glutamine Natural products OC(=O)C(N)CCC(N)=O ZDXPYRJPNDTMRX-UHFFFAOYSA-N 0.000 description 1

- UFULDTPDHIRNGS-UHFFFAOYSA-N hept-6-en-1-ol Chemical compound OCCCCCC=C UFULDTPDHIRNGS-UHFFFAOYSA-N 0.000 description 1

- PWSKHLMYTZNYKO-UHFFFAOYSA-N heptane-1,7-diamine Chemical compound NCCCCCCCN PWSKHLMYTZNYKO-UHFFFAOYSA-N 0.000 description 1

- UIZVMOZAXAMASY-UHFFFAOYSA-N hex-5-en-1-ol Chemical compound OCCCCC=C UIZVMOZAXAMASY-UHFFFAOYSA-N 0.000 description 1

- XXMIOPMDWAUFGU-UHFFFAOYSA-N hexane-1,6-diol Chemical compound OCCCCCCO XXMIOPMDWAUFGU-UHFFFAOYSA-N 0.000 description 1

- HNDVDQJCIGZPNO-UHFFFAOYSA-N histidine Natural products OC(=O)C(N)CC1=CN=CN1 HNDVDQJCIGZPNO-UHFFFAOYSA-N 0.000 description 1

- 239000001257 hydrogen Substances 0.000 description 1

- 229910052739 hydrogen Inorganic materials 0.000 description 1

- 238000010191 image analysis Methods 0.000 description 1

- 229910017053 inorganic salt Inorganic materials 0.000 description 1

- 150000002500 ions Chemical class 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 229940018564 m-phenylenediamine Drugs 0.000 description 1

- 238000001000 micrograph Methods 0.000 description 1

- 238000013508 migration Methods 0.000 description 1

- 230000005012 migration Effects 0.000 description 1

- ZETYUTMSJWMKNQ-UHFFFAOYSA-N n,n',n'-trimethylhexane-1,6-diamine Chemical compound CNCCCCCCN(C)C ZETYUTMSJWMKNQ-UHFFFAOYSA-N 0.000 description 1

- 239000002105 nanoparticle Substances 0.000 description 1

- GOGZBMRXLADNEV-UHFFFAOYSA-N naphthalene-2,6-diamine Chemical compound C1=C(N)C=CC2=CC(N)=CC=C21 GOGZBMRXLADNEV-UHFFFAOYSA-N 0.000 description 1

- 150000002823 nitrates Chemical class 0.000 description 1

- QJGQUHMNIGDVPM-UHFFFAOYSA-N nitrogen group Chemical group [N] QJGQUHMNIGDVPM-UHFFFAOYSA-N 0.000 description 1

- 125000005473 octanoic acid group Chemical group 0.000 description 1

- 239000001301 oxygen Substances 0.000 description 1

- 229910052760 oxygen Inorganic materials 0.000 description 1

- LQAVWYMTUMSFBE-UHFFFAOYSA-N pent-4-en-1-ol Chemical compound OCCCC=C LQAVWYMTUMSFBE-UHFFFAOYSA-N 0.000 description 1

- WLJVNTCWHIRURA-UHFFFAOYSA-M pimelate(1-) Chemical compound OC(=O)CCCCCC([O-])=O WLJVNTCWHIRURA-UHFFFAOYSA-M 0.000 description 1

- 229920000768 polyamine Polymers 0.000 description 1

- 229920001223 polyethylene glycol Polymers 0.000 description 1

- 229920000139 polyethylene terephthalate Polymers 0.000 description 1

- 239000005020 polyethylene terephthalate Substances 0.000 description 1

- 229920001721 polyimide Polymers 0.000 description 1

- 229920002451 polyvinyl alcohol Polymers 0.000 description 1

- 235000019422 polyvinyl alcohol Nutrition 0.000 description 1

- 229920000036 polyvinylpyrrolidone Polymers 0.000 description 1

- 235000013855 polyvinylpyrrolidone Nutrition 0.000 description 1

- 229910052700 potassium Inorganic materials 0.000 description 1

- 239000011591 potassium Substances 0.000 description 1

- 239000001103 potassium chloride Substances 0.000 description 1

- 235000011164 potassium chloride Nutrition 0.000 description 1

- 238000003825 pressing Methods 0.000 description 1

- 239000001294 propane Substances 0.000 description 1

- 239000012495 reaction gas Substances 0.000 description 1

- 230000007261 regionalization Effects 0.000 description 1

- 238000011160 research Methods 0.000 description 1

- 235000009566 rice Nutrition 0.000 description 1

- 229910052709 silver Inorganic materials 0.000 description 1

- 239000004332 silver Substances 0.000 description 1

- 238000003746 solid phase reaction Methods 0.000 description 1

- 239000012798 spherical particle Substances 0.000 description 1

- 238000005507 spraying Methods 0.000 description 1

- LITQZINTSYBKIU-UHFFFAOYSA-F tetracopper;hexahydroxide;sulfate Chemical compound [OH-].[OH-].[OH-].[OH-].[OH-].[OH-].[Cu+2].[Cu+2].[Cu+2].[Cu+2].[O-]S([O-])(=O)=O LITQZINTSYBKIU-UHFFFAOYSA-F 0.000 description 1

- 238000005979 thermal decomposition reaction Methods 0.000 description 1

- WBYWAXJHAXSJNI-VOTSOKGWSA-M trans-cinnamate Chemical compound [O-]C(=O)\C=C\C1=CC=CC=C1 WBYWAXJHAXSJNI-VOTSOKGWSA-M 0.000 description 1

- 229960001288 triamterene Drugs 0.000 description 1

- ZIBGPFATKBEMQZ-UHFFFAOYSA-N triethylene glycol Chemical compound OCCOCCOCCO ZIBGPFATKBEMQZ-UHFFFAOYSA-N 0.000 description 1

- AAAQKTZKLRYKHR-UHFFFAOYSA-N triphenylmethane Chemical compound C1=CC=CC=C1C(C=1C=CC=CC=1)C1=CC=CC=C1 AAAQKTZKLRYKHR-UHFFFAOYSA-N 0.000 description 1

- OUYCCCASQSFEME-UHFFFAOYSA-N tyrosine Natural products OC(=O)C(N)CC1=CC=C(O)C=C1 OUYCCCASQSFEME-UHFFFAOYSA-N 0.000 description 1

- 150000003672 ureas Chemical class 0.000 description 1

- 239000004474 valine Substances 0.000 description 1

- 230000008016 vaporization Effects 0.000 description 1

Images

Classifications

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B21/00—Nitrogen; Compounds thereof

- C01B21/06—Binary compounds of nitrogen with metals, with silicon, or with boron, or with carbon, i.e. nitrides; Compounds of nitrogen with more than one metal, silicon or boron

- C01B21/0615—Binary compounds of nitrogen with metals, with silicon, or with boron, or with carbon, i.e. nitrides; Compounds of nitrogen with more than one metal, silicon or boron with transition metals other than titanium, zirconium or hafnium

- C01B21/0625—Binary compounds of nitrogen with metals, with silicon, or with boron, or with carbon, i.e. nitrides; Compounds of nitrogen with more than one metal, silicon or boron with transition metals other than titanium, zirconium or hafnium with copper

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y30/00—Nanotechnology for materials or surface science, e.g. nanocomposites

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y40/00—Manufacture or treatment of nanostructures

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/22—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the deposition of inorganic material, other than metallic material

- C23C16/30—Deposition of compounds, mixtures or solid solutions, e.g. borides, carbides, nitrides

- C23C16/34—Nitrides

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C16/00—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes

- C23C16/44—Chemical coating by decomposition of gaseous compounds, without leaving reaction products of surface material in the coating, i.e. chemical vapour deposition [CVD] processes characterised by the method of coating

- C23C16/4417—Methods specially adapted for coating powder

-

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C24/00—Coating starting from inorganic powder

- C23C24/08—Coating starting from inorganic powder by application of heat or pressure and heat

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01P—INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS

- C01P2002/00—Crystal-structural characteristics

- C01P2002/70—Crystal-structural characteristics defined by measured X-ray, neutron or electron diffraction data

- C01P2002/72—Crystal-structural characteristics defined by measured X-ray, neutron or electron diffraction data by d-values or two theta-values, e.g. as X-ray diagram

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01P—INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS

- C01P2002/00—Crystal-structural characteristics

- C01P2002/80—Crystal-structural characteristics defined by measured data other than those specified in group C01P2002/70

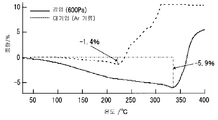

- C01P2002/88—Crystal-structural characteristics defined by measured data other than those specified in group C01P2002/70 by thermal analysis data, e.g. TGA, DTA, DSC

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01P—INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS

- C01P2004/00—Particle morphology

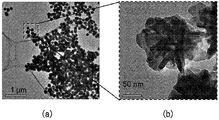

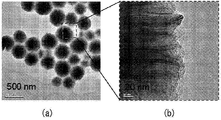

- C01P2004/01—Particle morphology depicted by an image

- C01P2004/04—Particle morphology depicted by an image obtained by TEM, STEM, STM or AFM

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01P—INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS

- C01P2004/00—Particle morphology

- C01P2004/30—Particle morphology extending in three dimensions

- C01P2004/32—Spheres

-

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01P—INDEXING SCHEME RELATING TO STRUCTURAL AND PHYSICAL ASPECTS OF SOLID INORGANIC COMPOUNDS

- C01P2004/00—Particle morphology

- C01P2004/60—Particles characterised by their size

- C01P2004/64—Nanometer sized, i.e. from 1-100 nanometer

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Organic Chemistry (AREA)

- Materials Engineering (AREA)

- Nanotechnology (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Crystallography & Structural Chemistry (AREA)

- Inorganic Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Manufacturing & Machinery (AREA)

- Composite Materials (AREA)

- Manufacture Of Metal Powder And Suspensions Thereof (AREA)

- Powder Metallurgy (AREA)

- Electrodes Of Semiconductors (AREA)

- Inks, Pencil-Leads, Or Crayons (AREA)

Applications Claiming Priority (5)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| JP2013017510 | 2013-01-31 | ||

| JPJP-P-2013-017510 | 2013-01-31 | ||

| JPJP-P-2013-225296 | 2013-10-30 | ||

| JP2013225296A JP6057379B2 (ja) | 2013-01-31 | 2013-10-30 | 窒化銅微粒子およびその製造方法 |

| PCT/JP2014/052321 WO2014119748A1 (ja) | 2013-01-31 | 2014-01-31 | 窒化銅微粒子およびその製造方法 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20150112984A true KR20150112984A (ko) | 2015-10-07 |

Family

ID=51262445

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020157020804A Ceased KR20150112984A (ko) | 2013-01-31 | 2014-01-31 | 질화구리 미립자 및 그 제조 방법 |

Country Status (4)

| Country | Link |

|---|---|

| JP (1) | JP6057379B2 (enExample) |

| KR (1) | KR20150112984A (enExample) |

| CN (1) | CN104981427A (enExample) |

| WO (1) | WO2014119748A1 (enExample) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20190049055A (ko) * | 2017-11-01 | 2019-05-09 | 전자부품연구원 | 전도체 패턴용 구리질화물 분말의 제조 방법 |

Families Citing this family (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2015147561A1 (ko) * | 2014-03-26 | 2015-10-01 | 전자부품연구원 | 전도체 패턴의 형성이 용이한 복합소재와 그 복합소재를 제조하는 방법 및 상기 복합소재에서 시드 소재인 구리질화물 및 그 구리질화물을 합성하는 방법 |

| JP6574553B2 (ja) * | 2014-06-26 | 2019-09-11 | 昭和電工株式会社 | 導電パターン形成用組成物および導電パターン形成方法 |

| CN110642304B (zh) * | 2019-10-09 | 2021-12-31 | 上海师范大学 | 一种超级电容器用三金属氮化物材料及其制备方法 |

| CN111450867A (zh) * | 2020-05-09 | 2020-07-28 | 青岛科技大学 | 用于电催化二氧化碳还原的Cu3N纳米催化剂的制备方法 |

| CN115057417B (zh) * | 2022-06-08 | 2023-09-12 | 安徽大学 | 一种氮化铜纳米片的制备及其在甲酸盐电合成中的应用 |

| CN116516280A (zh) * | 2023-04-27 | 2023-08-01 | 常州大学 | 一种高效节能的工件氮化方法 |

| CN116924697B (zh) * | 2023-07-31 | 2025-08-29 | 上海耀皮工程玻璃有限公司 | 一种Low-E镀膜玻璃调色层及其制备方法和用途 |

| CN119282131A (zh) * | 2024-11-18 | 2025-01-10 | 济源星翰新材料科技有限公司 | 一种微米铜粉的制备方法 |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2005122230A1 (ja) * | 2004-06-07 | 2005-12-22 | Kyushu Institute Of Technology | 銅表面の処理方法及び銅パターン配線形成方法、並びに該方法を用いて作成された半導体装置 |

| JP3870273B2 (ja) * | 2004-12-28 | 2007-01-17 | 国立大学法人九州工業大学 | 銅パターン配線形成方法及び該方法を用いて作成された半導体装置、並びにナノ銅金属粒子 |

| JP5778382B2 (ja) * | 2008-10-22 | 2015-09-16 | 東ソー株式会社 | 金属膜製造用組成物、金属膜の製造方法及び金属粉末の製造方法 |

| JP5243510B2 (ja) * | 2010-10-01 | 2013-07-24 | 富士フイルム株式会社 | 配線材料、配線の製造方法、及びナノ粒子分散液 |

-

2013

- 2013-10-30 JP JP2013225296A patent/JP6057379B2/ja not_active Expired - Fee Related

-

2014

- 2014-01-31 WO PCT/JP2014/052321 patent/WO2014119748A1/ja not_active Ceased

- 2014-01-31 KR KR1020157020804A patent/KR20150112984A/ko not_active Ceased

- 2014-01-31 CN CN201480006826.7A patent/CN104981427A/zh active Pending

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20190049055A (ko) * | 2017-11-01 | 2019-05-09 | 전자부품연구원 | 전도체 패턴용 구리질화물 분말의 제조 방법 |

Also Published As

| Publication number | Publication date |

|---|---|

| CN104981427A (zh) | 2015-10-14 |

| WO2014119748A1 (ja) | 2014-08-07 |

| JP6057379B2 (ja) | 2017-01-11 |

| JP2014166939A (ja) | 2014-09-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR20150112984A (ko) | 질화구리 미립자 및 그 제조 방법 | |

| JP7019197B2 (ja) | 導電性インク組成物 | |

| US20180168037A1 (en) | Method for producing silver nanoparticles, silver nanoparticles, and silver coating composition | |

| US9986638B2 (en) | Synthetic method of suppressing metal nano-particle from having oxidized film and method of manufacturing conductive metal thin film via solution-processed | |

| TWI665165B (zh) | 銀微粒子分散體、銀微粒子及其製造方法以及接合用組成物 | |

| JP5986636B2 (ja) | 銀ナノ粒子の製造方法、銀塗料組成物の製造方法および銀導電材料の製造方法 | |

| US10279393B2 (en) | Method of producing copper nano particle colloidal dispersions | |

| CN104540622B (zh) | 用于生产银纳米粒子的方法、银纳米粒子、涂覆的银纳米粒子、银涂覆组合物和银导电材料 | |

| JP5858374B2 (ja) | 被覆銅微粒子の製造方法 | |

| US20130334470A1 (en) | Coated metal fine particle and manufacturing method thereof | |

| JP2010064983A (ja) | ニッケル粒子の製造方法及びそれに適したニッケル錯体 | |

| CN104946022A (zh) | 一种高稳定性无颗粒型银基导电墨水及其制备方法 | |

| JP2009120940A (ja) | 金属ナノ粒子の製造方法 | |

| TWI686447B (zh) | 轉印印刷用導電性墨水 | |

| JP4168371B2 (ja) | 金属コロイドオルガノゾル及びその製造方法 | |

| Chen et al. | Facile synthesis of silver malonate conductive MOD ink for screen printing | |

| JP6531456B2 (ja) | 導電性インク組成物 | |

| Lee et al. | Large-scale synthesis of polymer-stabilized silver nanoparticles | |

| JP7573378B2 (ja) | ニッケルナノ粒子凝集体、その製造方法及びニッケルナノ粒子複合基板 | |

| TW201500564A (zh) | 銀粒子之製造方法 | |

| JP6099160B2 (ja) | 複合化合物、及び懸濁液 | |

| KR20160090861A (ko) | 은 나노입자의 분산물 | |

| Kim et al. | Preparation of highly stabilized silver nanopowders by the thermal reduction and their properties | |

| JP2018021246A (ja) | 金属ナノ粒子の製造方法 | |

| TWI757412B (zh) | 銀奈米粒子的製造方法 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0105 | International application |

Patent event date: 20150730 Patent event code: PA01051R01D Comment text: International Patent Application |

|

| PG1501 | Laying open of application | ||

| A201 | Request for examination | ||

| PA0201 | Request for examination |

Patent event code: PA02012R01D Patent event date: 20181016 Comment text: Request for Examination of Application |

|

| E902 | Notification of reason for refusal | ||

| PE0902 | Notice of grounds for rejection |

Comment text: Notification of reason for refusal Patent event date: 20200507 Patent event code: PE09021S01D |

|

| E601 | Decision to refuse application | ||

| PE0601 | Decision on rejection of patent |

Patent event date: 20200814 Comment text: Decision to Refuse Application Patent event code: PE06012S01D Patent event date: 20200507 Comment text: Notification of reason for refusal Patent event code: PE06011S01I |