KR20070032609A - 개선된 접착성을 갖는 수성 연마 패드 및 제조방법 - Google Patents

개선된 접착성을 갖는 수성 연마 패드 및 제조방법 Download PDFInfo

- Publication number

- KR20070032609A KR20070032609A KR1020060089922A KR20060089922A KR20070032609A KR 20070032609 A KR20070032609 A KR 20070032609A KR 1020060089922 A KR1020060089922 A KR 1020060089922A KR 20060089922 A KR20060089922 A KR 20060089922A KR 20070032609 A KR20070032609 A KR 20070032609A

- Authority

- KR

- South Korea

- Prior art keywords

- polishing pad

- polishing

- aqueous

- microspheres

- cellulose

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Withdrawn

Links

- 238000005498 polishing Methods 0.000 title claims abstract description 118

- 238000004519 manufacturing process Methods 0.000 title description 28

- 239000000758 substrate Substances 0.000 claims abstract description 46

- 229920000642 polymer Polymers 0.000 claims abstract description 36

- 239000000203 mixture Substances 0.000 claims abstract description 34

- 239000004005 microsphere Substances 0.000 claims abstract description 21

- 239000000126 substance Substances 0.000 claims abstract description 17

- 239000011159 matrix material Substances 0.000 claims abstract description 10

- 238000000034 method Methods 0.000 claims description 21

- 239000006185 dispersion Substances 0.000 claims description 18

- 239000012530 fluid Substances 0.000 claims description 18

- NIXOWILDQLNWCW-UHFFFAOYSA-N acrylic acid group Chemical group C(C=C)(=O)O NIXOWILDQLNWCW-UHFFFAOYSA-N 0.000 claims description 12

- JOYRKODLDBILNP-UHFFFAOYSA-N urethane group Chemical group NC(=O)OCC JOYRKODLDBILNP-UHFFFAOYSA-N 0.000 claims description 11

- 239000000945 filler Substances 0.000 claims description 9

- 239000012071 phase Substances 0.000 claims description 8

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Chemical compound C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 claims description 6

- 229920002635 polyurethane Polymers 0.000 claims description 6

- 239000004814 polyurethane Substances 0.000 claims description 6

- 239000007790 solid phase Substances 0.000 claims description 5

- 229920002125 Sokalan® Polymers 0.000 claims description 4

- 229920001577 copolymer Polymers 0.000 claims description 4

- 229920002134 Carboxymethyl cellulose Polymers 0.000 claims description 3

- 229920000858 Cyclodextrin Polymers 0.000 claims description 3

- 229920000663 Hydroxyethyl cellulose Polymers 0.000 claims description 3

- 239000004354 Hydroxyethyl cellulose Substances 0.000 claims description 3

- 229920002153 Hydroxypropyl cellulose Polymers 0.000 claims description 3

- 229920003171 Poly (ethylene oxide) Polymers 0.000 claims description 3

- 239000002202 Polyethylene glycol Substances 0.000 claims description 3

- 239000004372 Polyvinyl alcohol Substances 0.000 claims description 3

- 229920001328 Polyvinylidene chloride Polymers 0.000 claims description 3

- OFOBLEOULBTSOW-UHFFFAOYSA-N Propanedioic acid Natural products OC(=O)CC(O)=O OFOBLEOULBTSOW-UHFFFAOYSA-N 0.000 claims description 3

- 229920002472 Starch Polymers 0.000 claims description 3

- 239000002518 antifoaming agent Substances 0.000 claims description 3

- 239000001768 carboxy methyl cellulose Substances 0.000 claims description 3

- 235000010948 carboxy methyl cellulose Nutrition 0.000 claims description 3

- 239000008112 carboxymethyl-cellulose Substances 0.000 claims description 3

- 239000001913 cellulose Substances 0.000 claims description 3

- 229920002678 cellulose Polymers 0.000 claims description 3

- 235000010980 cellulose Nutrition 0.000 claims description 3

- 235000019447 hydroxyethyl cellulose Nutrition 0.000 claims description 3

- 239000001863 hydroxypropyl cellulose Substances 0.000 claims description 3

- 235000010977 hydroxypropyl cellulose Nutrition 0.000 claims description 3

- 239000011976 maleic acid Substances 0.000 claims description 3

- 229920000609 methyl cellulose Polymers 0.000 claims description 3

- 239000001923 methylcellulose Substances 0.000 claims description 3

- 235000010981 methylcellulose Nutrition 0.000 claims description 3

- 239000001814 pectin Substances 0.000 claims description 3

- 229920001277 pectin Polymers 0.000 claims description 3

- 235000010987 pectin Nutrition 0.000 claims description 3

- 229920002401 polyacrylamide Polymers 0.000 claims description 3

- 239000004584 polyacrylic acid Substances 0.000 claims description 3

- 229920002239 polyacrylonitrile Polymers 0.000 claims description 3

- 229920001223 polyethylene glycol Polymers 0.000 claims description 3

- 229920002451 polyvinyl alcohol Polymers 0.000 claims description 3

- 235000019422 polyvinyl alcohol Nutrition 0.000 claims description 3

- 229920000036 polyvinylpyrrolidone Polymers 0.000 claims description 3

- 239000001267 polyvinylpyrrolidone Substances 0.000 claims description 3

- 235000013855 polyvinylpyrrolidone Nutrition 0.000 claims description 3

- HFHDHCJBZVLPGP-UHFFFAOYSA-N schardinger α-dextrin Chemical compound O1C(C(C2O)O)C(CO)OC2OC(C(C2O)O)C(CO)OC2OC(C(C2O)O)C(CO)OC2OC(C(O)C2O)C(CO)OC2OC(C(C2O)O)C(CO)OC2OC2C(O)C(O)C1OC2CO HFHDHCJBZVLPGP-UHFFFAOYSA-N 0.000 claims description 3

- 239000008107 starch Substances 0.000 claims description 3

- 235000019698 starch Nutrition 0.000 claims description 3

- VZCYOOQTPOCHFL-UHFFFAOYSA-N trans-butenedioic acid Natural products OC(=O)C=CC(O)=O VZCYOOQTPOCHFL-UHFFFAOYSA-N 0.000 claims description 3

- 238000000465 moulding Methods 0.000 claims description 2

- 239000006254 rheological additive Substances 0.000 claims description 2

- 239000003795 chemical substances by application Substances 0.000 claims 1

- 230000007547 defect Effects 0.000 abstract description 12

- 235000012431 wafers Nutrition 0.000 description 14

- 239000007789 gas Substances 0.000 description 9

- 239000002245 particle Substances 0.000 description 9

- 239000000463 material Substances 0.000 description 8

- 230000032258 transport Effects 0.000 description 8

- 238000005266 casting Methods 0.000 description 7

- 239000004065 semiconductor Substances 0.000 description 7

- 230000008569 process Effects 0.000 description 6

- 239000003989 dielectric material Substances 0.000 description 4

- 229920002959 polymer blend Polymers 0.000 description 4

- ZMXDDKWLCZADIW-UHFFFAOYSA-N N,N-Dimethylformamide Chemical compound CN(C)C=O ZMXDDKWLCZADIW-UHFFFAOYSA-N 0.000 description 3

- 239000004820 Pressure-sensitive adhesive Substances 0.000 description 3

- 238000005054 agglomeration Methods 0.000 description 3

- 230000002776 aggregation Effects 0.000 description 3

- 230000032798 delamination Effects 0.000 description 3

- 239000012528 membrane Substances 0.000 description 3

- 239000003960 organic solvent Substances 0.000 description 3

- 239000011148 porous material Substances 0.000 description 3

- 239000002904 solvent Substances 0.000 description 3

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 3

- 239000004604 Blowing Agent Substances 0.000 description 2

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 2

- 239000000853 adhesive Substances 0.000 description 2

- 230000001070 adhesive effect Effects 0.000 description 2

- 238000005229 chemical vapour deposition Methods 0.000 description 2

- 230000003750 conditioning effect Effects 0.000 description 2

- 239000004020 conductor Substances 0.000 description 2

- 229910052802 copper Inorganic materials 0.000 description 2

- 239000010949 copper Substances 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 238000000151 deposition Methods 0.000 description 2

- 239000012776 electronic material Substances 0.000 description 2

- 239000012467 final product Substances 0.000 description 2

- 238000003801 milling Methods 0.000 description 2

- 238000005240 physical vapour deposition Methods 0.000 description 2

- 238000000623 plasma-assisted chemical vapour deposition Methods 0.000 description 2

- 238000007517 polishing process Methods 0.000 description 2

- 239000000047 product Substances 0.000 description 2

- 239000002002 slurry Substances 0.000 description 2

- 238000003860 storage Methods 0.000 description 2

- DAFHKNAQFPVRKR-UHFFFAOYSA-N (3-hydroxy-2,2,4-trimethylpentyl) 2-methylpropanoate Chemical compound CC(C)C(O)C(C)(C)COC(=O)C(C)C DAFHKNAQFPVRKR-UHFFFAOYSA-N 0.000 description 1

- 101100412856 Mus musculus Rhod gene Proteins 0.000 description 1

- 239000004677 Nylon Substances 0.000 description 1

- 230000009471 action Effects 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 230000015572 biosynthetic process Effects 0.000 description 1

- 230000000903 blocking effect Effects 0.000 description 1

- 238000006243 chemical reaction Methods 0.000 description 1

- 230000000052 comparative effect Effects 0.000 description 1

- 238000000748 compression moulding Methods 0.000 description 1

- 238000004132 cross linking Methods 0.000 description 1

- 239000013078 crystal Substances 0.000 description 1

- 230000007812 deficiency Effects 0.000 description 1

- 239000013530 defoamer Substances 0.000 description 1

- -1 ester alcohols Chemical class 0.000 description 1

- 239000000835 fiber Substances 0.000 description 1

- 238000007730 finishing process Methods 0.000 description 1

- 239000008394 flocculating agent Substances 0.000 description 1

- 238000005189 flocculation Methods 0.000 description 1

- 238000005187 foaming Methods 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 238000010438 heat treatment Methods 0.000 description 1

- KTUFNOKKBVMGRW-UHFFFAOYSA-N imatinib Chemical compound C1CN(C)CCN1CC1=CC=C(C(=O)NC=2C=C(NC=3N=C(C=CN=3)C=3C=NC=CC=3)C(C)=CC=2)C=C1 KTUFNOKKBVMGRW-UHFFFAOYSA-N 0.000 description 1

- 238000011065 in-situ storage Methods 0.000 description 1

- 238000007373 indentation Methods 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 238000001465 metallisation Methods 0.000 description 1

- 229920001778 nylon Polymers 0.000 description 1

- 230000003287 optical effect Effects 0.000 description 1

- 238000007747 plating Methods 0.000 description 1

- 229920000728 polyester Polymers 0.000 description 1

- 239000005033 polyvinylidene chloride Substances 0.000 description 1

- 239000002994 raw material Substances 0.000 description 1

- 230000009467 reduction Effects 0.000 description 1

- 150000003839 salts Chemical class 0.000 description 1

- 239000007787 solid Substances 0.000 description 1

- 238000004544 sputter deposition Methods 0.000 description 1

- 229910001220 stainless steel Inorganic materials 0.000 description 1

- 239000010935 stainless steel Substances 0.000 description 1

- 235000000346 sugar Nutrition 0.000 description 1

- 150000008163 sugars Chemical class 0.000 description 1

- 230000008961 swelling Effects 0.000 description 1

- 239000002562 thickening agent Substances 0.000 description 1

- 238000012876 topography Methods 0.000 description 1

- WFKWXMTUELFFGS-UHFFFAOYSA-N tungsten Chemical compound [W] WFKWXMTUELFFGS-UHFFFAOYSA-N 0.000 description 1

- 229910052721 tungsten Inorganic materials 0.000 description 1

- 239000010937 tungsten Substances 0.000 description 1

- 229920003169 water-soluble polymer Polymers 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24D—TOOLS FOR GRINDING, BUFFING OR SHARPENING

- B24D11/00—Constructional features of flexible abrasive materials; Special features in the manufacture of such materials

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B24—GRINDING; POLISHING

- B24B—MACHINES, DEVICES, OR PROCESSES FOR GRINDING OR POLISHING; DRESSING OR CONDITIONING OF ABRADING SURFACES; FEEDING OF GRINDING, POLISHING, OR LAPPING AGENTS

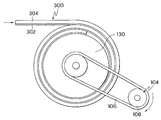

- B24B37/00—Lapping machines or devices; Accessories

- B24B37/11—Lapping tools

- B24B37/20—Lapping pads for working plane surfaces

- B24B37/24—Lapping pads for working plane surfaces characterised by the composition or properties of the pad materials

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L75/00—Compositions of polyureas or polyurethanes; Compositions of derivatives of such polymers

- C08L75/04—Polyurethanes

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L21/00—Processes or apparatus adapted for the manufacture or treatment of semiconductor or solid state devices or of parts thereof

- H01L21/02—Manufacture or treatment of semiconductor devices or of parts thereof

- H01L21/04—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer

- H01L21/18—Manufacture or treatment of semiconductor devices or of parts thereof the devices having potential barriers, e.g. a PN junction, depletion layer or carrier concentration layer the devices having semiconductor bodies comprising elements of Group IV of the Periodic Table or AIIIBV compounds with or without impurities, e.g. doping materials

- H01L21/30—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26

- H01L21/302—Treatment of semiconductor bodies using processes or apparatus not provided for in groups H01L21/20 - H01L21/26 to change their surface-physical characteristics or shape, e.g. etching, polishing, cutting

- H01L21/304—Mechanical treatment, e.g. grinding, polishing, cutting

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K7/00—Use of ingredients characterised by shape

- C08K7/22—Expanded, porous or hollow particles

-

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08L—COMPOSITIONS OF MACROMOLECULAR COMPOUNDS

- C08L33/00—Compositions of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and only one being terminated by only one carboxyl radical, or of salts, anhydrides, esters, amides, imides or nitriles thereof; Compositions of derivatives of such polymers

- C08L33/04—Homopolymers or copolymers of esters

- C08L33/06—Homopolymers or copolymers of esters of esters containing only carbon, hydrogen and oxygen, which oxygen atoms are present only as part of the carboxyl radical

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Mechanical Engineering (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- General Physics & Mathematics (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Power Engineering (AREA)

- Finish Polishing, Edge Sharpening, And Grinding By Specific Grinding Devices (AREA)

- Mechanical Treatment Of Semiconductor (AREA)

- Manufacture Of Macromolecular Shaped Articles (AREA)

- Compositions Of Macromolecular Compounds (AREA)

Applications Claiming Priority (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US71848905P | 2005-09-19 | 2005-09-19 | |

| US60/718,489 | 2005-09-19 |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| KR20070032609A true KR20070032609A (ko) | 2007-03-22 |

Family

ID=37776011

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| KR1020060089922A Withdrawn KR20070032609A (ko) | 2005-09-19 | 2006-09-18 | 개선된 접착성을 갖는 수성 연마 패드 및 제조방법 |

Country Status (7)

| Country | Link |

|---|---|

| US (2) | US20070066195A1 (enExample) |

| JP (1) | JP2007088464A (enExample) |

| KR (1) | KR20070032609A (enExample) |

| CN (1) | CN1935461A (enExample) |

| DE (1) | DE102006042674A1 (enExample) |

| FR (1) | FR2890882A1 (enExample) |

| TW (1) | TW200720017A (enExample) |

Families Citing this family (26)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US7655117B2 (en) | 2005-04-06 | 2010-02-02 | Leviton Manufacturing Co., Inc. | Continuous plating system and method with mask registration |

| US7744732B2 (en) * | 2005-04-06 | 2010-06-29 | Leviton Manufacturing Company, Inc. | Continuous plating system and method with mask registration |

| CN102672630B (zh) | 2006-04-19 | 2015-03-18 | 东洋橡胶工业株式会社 | 抛光垫的制造方法 |

| US7311590B1 (en) * | 2007-01-31 | 2007-12-25 | Rohm And Haas Electronic Materials Cmp Holdings, Inc. | Polishing pad with grooves to retain slurry on the pad texture |

| JP4943233B2 (ja) * | 2007-05-31 | 2012-05-30 | 東洋ゴム工業株式会社 | 研磨パッドの製造方法 |

| US7635290B2 (en) * | 2007-08-15 | 2009-12-22 | Rohm And Haas Electronic Materials Cmp Holdings, Inc. | Interpenetrating network for chemical mechanical polishing |

| US8182655B2 (en) * | 2007-09-05 | 2012-05-22 | Leviton Manufacturing Co., Inc. | Plating systems and methods |

| TW200927896A (en) * | 2007-12-28 | 2009-07-01 | Iv Technologies Co Ltd | Polishing pad and polishing method |

| TWI360459B (en) * | 2008-04-11 | 2012-03-21 | Bestac Advanced Material Co Ltd | A polishing pad having groove structure for avoidi |

| US8177603B2 (en) * | 2008-04-29 | 2012-05-15 | Semiquest, Inc. | Polishing pad composition |

| US8303375B2 (en) | 2009-01-12 | 2012-11-06 | Novaplanar Technology, Inc. | Polishing pads for chemical mechanical planarization and/or other polishing methods |

| KR20100096459A (ko) * | 2009-02-24 | 2010-09-02 | 삼성전자주식회사 | 화학적 기계적 연마장치 |

| US10022842B2 (en) | 2012-04-02 | 2018-07-17 | Thomas West, Inc. | Method and systems to control optical transmissivity of a polish pad material |

| US11090778B2 (en) | 2012-04-02 | 2021-08-17 | Thomas West, Inc. | Methods and systems for centrifugal casting of polymer polish pads and polishing pads made by the methods |

| US10722997B2 (en) * | 2012-04-02 | 2020-07-28 | Thomas West, Inc. | Multilayer polishing pads made by the methods for centrifugal casting of polymer polish pads |

| US9073172B2 (en) * | 2012-05-11 | 2015-07-07 | Rohm And Haas Electronic Materials Cmp Holdings, Inc. | Alkaline-earth metal oxide-polymeric polishing pad |

| US8888877B2 (en) * | 2012-05-11 | 2014-11-18 | Rohm And Haas Electronic Materials Cmp Holdings, Inc. | Forming alkaline-earth metal oxide polishing pad |

| US9108293B2 (en) * | 2012-07-30 | 2015-08-18 | Rohm And Haas Electronic Materials Cmp Holdings, Inc. | Method for chemical mechanical polishing layer pretexturing |

| US9522454B2 (en) * | 2012-12-17 | 2016-12-20 | Seagate Technology Llc | Method of patterning a lapping plate, and patterned lapping plates |

| TWI518176B (zh) * | 2015-01-12 | 2016-01-21 | 三芳化學工業股份有限公司 | 拋光墊及其製造方法 |

| CN107717762A (zh) * | 2017-10-26 | 2018-02-23 | 东莞金太阳研磨股份有限公司 | 一种磨具用的聚酯薄膜基材的处理工艺 |

| CN112423935B (zh) * | 2018-06-29 | 2023-07-21 | 圣戈班磨料磨具有限公司 | 磨料制品及其形成方法 |

| TWI850338B (zh) * | 2019-02-28 | 2024-08-01 | 美商應用材料股份有限公司 | 拋光墊、化學機械拋光系統、及控制拋光墊的背襯層的剛度的方法 |

| US11667061B2 (en) * | 2020-04-18 | 2023-06-06 | Rohm And Haas Electronic Materials Cmp Holdings, Inc. | Method of forming leveraged poromeric polishing pad |

| CN112318363B (zh) * | 2020-11-06 | 2022-03-11 | 万华化学集团电子材料有限公司 | 一种化学机械抛光垫的抛光层及其制备方法 |

| CN113442056B (zh) * | 2021-07-15 | 2022-12-02 | 湖北鼎汇微电子材料有限公司 | 一种抛光垫及其制备方法、半导体器件的制造方法 |

Family Cites Families (27)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US3862074A (en) * | 1971-11-30 | 1975-01-21 | Environmental Enterprises Inc | Aqueous polymeric compositions of nonionic urethane polymer and acrylic polymer |

| JPH0726080B2 (ja) * | 1987-11-30 | 1995-03-22 | サンスター技研株式会社 | 高防錆性付与構造用接着剤 |

| DE4127605A1 (de) * | 1991-08-21 | 1993-02-25 | Hoechst Ag | Haertbare ueberzugsmassen |

| US6379794B1 (en) * | 1992-06-17 | 2002-04-30 | Ppg Industries Ohio, Inc. | Acrylic impregnant for fibers |

| US6069080A (en) * | 1992-08-19 | 2000-05-30 | Rodel Holdings, Inc. | Fixed abrasive polishing system for the manufacture of semiconductor devices, memory disks and the like |

| MY114512A (en) * | 1992-08-19 | 2002-11-30 | Rodel Inc | Polymeric substrate with polymeric microelements |

| US5643669A (en) * | 1996-02-08 | 1997-07-01 | Minnesota Mining And Manufacturing Company | Curable water-based coating compositions and cured products thereof |

| US5692950A (en) * | 1996-08-08 | 1997-12-02 | Minnesota Mining And Manufacturing Company | Abrasive construction for semiconductor wafer modification |

| US6169043B1 (en) * | 1998-06-17 | 2001-01-02 | Milliken & Company | Polyurethane/polyacrylate dispersion coating for airbag fabrics |

| US6354915B1 (en) * | 1999-01-21 | 2002-03-12 | Rodel Holdings Inc. | Polishing pads and methods relating thereto |

| JP4450337B2 (ja) * | 1999-02-22 | 2010-04-14 | 大日本印刷株式会社 | 化粧シート |

| JP2003516872A (ja) * | 1999-12-14 | 2003-05-20 | ロデール ホールディングス インコーポレイテッド | 高分子又は高分子複合材研磨パッドの製造方法 |

| GB0005612D0 (en) * | 2000-03-09 | 2000-05-03 | Avecia Bv | Aqueous polymer compositions |

| WO2001091975A1 (en) * | 2000-05-31 | 2001-12-06 | Jsr Corporation | Abrasive material |

| US7112121B2 (en) * | 2000-08-30 | 2006-09-26 | Micron Technology, Inc. | Methods and apparatus for electrical, mechanical and/or chemical removal of conductive material from a microelectronic substrate |

| AU2001291143A1 (en) * | 2000-10-06 | 2002-04-22 | Cabot Microelectronics Corporation | Polishing pad comprising a filled translucent region |

| US20020098784A1 (en) * | 2001-01-19 | 2002-07-25 | Saket Chadda | Abrasive free polishing in copper damascene applications |

| US20030104770A1 (en) * | 2001-04-30 | 2003-06-05 | Arch Specialty Chemicals, Inc. | Chemical mechanical polishing slurry composition for polishing conductive and non-conductive layers on semiconductor wafers |

| US6811470B2 (en) * | 2001-07-16 | 2004-11-02 | Applied Materials Inc. | Methods and compositions for chemical mechanical polishing shallow trench isolation substrates |

| US6805722B2 (en) * | 2002-10-01 | 2004-10-19 | 3M Innovative Properties Company | Apparatus and method for forming a spiral wound abrasive article, and the resulting article |

| US20040224259A1 (en) * | 2002-12-12 | 2004-11-11 | Shipley Company, L.L.C. | Functionalized polymer |

| US7066801B2 (en) * | 2003-02-21 | 2006-06-27 | Dow Global Technologies, Inc. | Method of manufacturing a fixed abrasive material |

| US6910951B2 (en) * | 2003-02-24 | 2005-06-28 | Dow Global Technologies, Inc. | Materials and methods for chemical-mechanical planarization |

| US6918821B2 (en) * | 2003-11-12 | 2005-07-19 | Dow Global Technologies, Inc. | Materials and methods for low pressure chemical-mechanical planarization |

| US7222011B2 (en) * | 2004-07-23 | 2007-05-22 | General Motors Corporation | Engine and driveline torque transfer device control |

| KR20060099398A (ko) | 2005-03-08 | 2006-09-19 | 롬 앤드 하스 일렉트로닉 머티리얼스 씨엠피 홀딩스 인코포레이티드 | 수계 연마 패드 및 제조 방법 |

| US20080063856A1 (en) | 2006-09-11 | 2008-03-13 | Duong Chau H | Water-based polishing pads having improved contact area |

-

2006

- 2006-08-11 TW TW095129494A patent/TW200720017A/zh unknown

- 2006-08-14 US US11/504,415 patent/US20070066195A1/en not_active Abandoned

- 2006-09-07 CN CNA2006101517951A patent/CN1935461A/zh active Pending

- 2006-09-12 DE DE102006042674A patent/DE102006042674A1/de not_active Withdrawn

- 2006-09-18 KR KR1020060089922A patent/KR20070032609A/ko not_active Withdrawn

- 2006-09-19 FR FR0653809A patent/FR2890882A1/fr not_active Withdrawn

- 2006-09-19 JP JP2006252243A patent/JP2007088464A/ja active Pending

-

2008

- 2008-04-23 US US12/055,621 patent/US8272922B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| TW200720017A (en) | 2007-06-01 |

| US20080188163A1 (en) | 2008-08-07 |

| US20070066195A1 (en) | 2007-03-22 |

| DE102006042674A1 (de) | 2007-03-22 |

| CN1935461A (zh) | 2007-03-28 |

| JP2007088464A (ja) | 2007-04-05 |

| US8272922B2 (en) | 2012-09-25 |

| FR2890882A1 (fr) | 2007-03-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8272922B2 (en) | Method of polishing a substrate | |

| US7186166B2 (en) | Fiber embedded polishing pad | |

| US6986705B2 (en) | Polishing pad and method of making same | |

| US6626740B2 (en) | Self-leveling pads and methods relating thereto | |

| EP1509364B1 (en) | Microporous polishing pad | |

| US6998166B2 (en) | Polishing pad with oriented pore structure | |

| KR100770852B1 (ko) | 화학 기계적 평탄화용 그루브형 연마 패드 | |

| KR102195526B1 (ko) | 연성이고 컨디셔닝가능한 화학 기계적 창 연마 패드 | |

| KR20010076351A (ko) | 기판 연마 장치 | |

| US20060202384A1 (en) | Water-based polishing pads and methods of manufacture | |

| US20070141312A1 (en) | Multilayered polishing pads having improved defectivity and methods of manufacture | |

| JP2006253691A5 (enExample) | ||

| US20080063856A1 (en) | Water-based polishing pads having improved contact area | |

| JP7088647B2 (ja) | 研磨パッド及び研磨パッドの製造方法 | |

| KR20010055971A (ko) | 연마 패드 | |

| KR101175337B1 (ko) | 다공성 시트의 제조방법 및 이에 의해 제조된 다공성 시트 | |

| KR20250066273A (ko) | 슬러리 유동성이 개선된 연마패드 및 이를 이용한 반도체 소자의 제조방법 | |

| WO2025050490A1 (zh) | 抛光垫及半导体器件的制造方法 | |

| KR20230092626A (ko) | 균일하게 분포된 액상 포어를 포함하는 연마 패드 및 이의 제조방법 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PA0109 | Patent application |

Patent event code: PA01091R01D Comment text: Patent Application Patent event date: 20060918 |

|

| PG1501 | Laying open of application | ||

| PC1203 | Withdrawal of no request for examination | ||

| WITN | Application deemed withdrawn, e.g. because no request for examination was filed or no examination fee was paid |