JP6836595B2 - 予め接着されたワイヤ要素を含む織布又は編布を含むタイヤ用に意図された組立体 - Google Patents

予め接着されたワイヤ要素を含む織布又は編布を含むタイヤ用に意図された組立体 Download PDFInfo

- Publication number

- JP6836595B2 JP6836595B2 JP2018531218A JP2018531218A JP6836595B2 JP 6836595 B2 JP6836595 B2 JP 6836595B2 JP 2018531218 A JP2018531218 A JP 2018531218A JP 2018531218 A JP2018531218 A JP 2018531218A JP 6836595 B2 JP6836595 B2 JP 6836595B2

- Authority

- JP

- Japan

- Prior art keywords

- thread

- woven

- tire

- elements

- coated

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000004744 fabric Substances 0.000 title claims description 89

- 239000000203 mixture Substances 0.000 claims description 96

- 239000002759 woven fabric Substances 0.000 claims description 96

- 239000000853 adhesive Substances 0.000 claims description 68

- 230000001070 adhesive effect Effects 0.000 claims description 68

- 229920000642 polymer Polymers 0.000 claims description 40

- 238000000034 method Methods 0.000 claims description 25

- 238000004519 manufacturing process Methods 0.000 claims description 17

- 239000004753 textile Substances 0.000 claims description 12

- 235000009508 confectionery Nutrition 0.000 claims description 4

- 239000010410 layer Substances 0.000 description 49

- 229920001971 elastomer Polymers 0.000 description 28

- 239000000806 elastomer Substances 0.000 description 25

- -1 for example Polymers 0.000 description 19

- 229920002725 thermoplastic elastomer Polymers 0.000 description 16

- 229920000139 polyethylene terephthalate Polymers 0.000 description 13

- 239000005020 polyethylene terephthalate Substances 0.000 description 13

- 229920003244 diene elastomer Polymers 0.000 description 10

- 239000000835 fiber Substances 0.000 description 10

- 238000010438 heat treatment Methods 0.000 description 10

- 229920001577 copolymer Polymers 0.000 description 9

- 238000004804 winding Methods 0.000 description 9

- RRHGJUQNOFWUDK-UHFFFAOYSA-N Isoprene Natural products CC(=C)C=C RRHGJUQNOFWUDK-UHFFFAOYSA-N 0.000 description 8

- 239000000463 material Substances 0.000 description 8

- 239000002184 metal Substances 0.000 description 8

- 229910052751 metal Inorganic materials 0.000 description 8

- 229920001169 thermoplastic Polymers 0.000 description 8

- 230000015572 biosynthetic process Effects 0.000 description 7

- 230000008859 change Effects 0.000 description 7

- 239000011248 coating agent Substances 0.000 description 7

- 238000000576 coating method Methods 0.000 description 7

- WSFSSNUMVMOOMR-UHFFFAOYSA-N Formaldehyde Chemical compound O=C WSFSSNUMVMOOMR-UHFFFAOYSA-N 0.000 description 6

- 244000043261 Hevea brasiliensis Species 0.000 description 6

- 239000004952 Polyamide Substances 0.000 description 6

- 229920003052 natural elastomer Polymers 0.000 description 6

- 229920001194 natural rubber Polymers 0.000 description 6

- 229920002647 polyamide Polymers 0.000 description 6

- 229920001707 polybutylene terephthalate Polymers 0.000 description 6

- 229920000728 polyester Polymers 0.000 description 6

- 230000003014 reinforcing effect Effects 0.000 description 6

- KAKZBPTYRLMSJV-UHFFFAOYSA-N vinyl-ethylene Natural products C=CC=C KAKZBPTYRLMSJV-UHFFFAOYSA-N 0.000 description 6

- PPBRXRYQALVLMV-UHFFFAOYSA-N Styrene Natural products C=CC1=CC=CC=C1 PPBRXRYQALVLMV-UHFFFAOYSA-N 0.000 description 5

- 239000004760 aramid Substances 0.000 description 4

- 229920003235 aromatic polyamide Polymers 0.000 description 4

- 230000008901 benefit Effects 0.000 description 4

- 230000000052 comparative effect Effects 0.000 description 4

- 230000007423 decrease Effects 0.000 description 4

- 238000009826 distribution Methods 0.000 description 4

- 238000005516 engineering process Methods 0.000 description 4

- 239000003822 epoxy resin Substances 0.000 description 4

- 230000014509 gene expression Effects 0.000 description 4

- 238000005470 impregnation Methods 0.000 description 4

- 239000012948 isocyanate Substances 0.000 description 4

- 229920000647 polyepoxide Polymers 0.000 description 4

- GHMLBKRAJCXXBS-UHFFFAOYSA-N resorcinol Chemical compound OC1=CC=CC(O)=C1 GHMLBKRAJCXXBS-UHFFFAOYSA-N 0.000 description 4

- 239000004953 Aliphatic polyamide Substances 0.000 description 3

- 239000004677 Nylon Substances 0.000 description 3

- 239000005062 Polybutadiene Substances 0.000 description 3

- 229920003231 aliphatic polyamide Polymers 0.000 description 3

- 230000000712 assembly Effects 0.000 description 3

- 238000000429 assembly Methods 0.000 description 3

- 230000006835 compression Effects 0.000 description 3

- 238000007906 compression Methods 0.000 description 3

- 238000000265 homogenisation Methods 0.000 description 3

- 230000006872 improvement Effects 0.000 description 3

- 229920001778 nylon Polymers 0.000 description 3

- 229920003207 poly(ethylene-2,6-naphthalate) Polymers 0.000 description 3

- 238000005096 rolling process Methods 0.000 description 3

- 239000005060 rubber Substances 0.000 description 3

- 239000004416 thermosoftening plastic Substances 0.000 description 3

- 238000004073 vulcanization Methods 0.000 description 3

- RTZKZFJDLAIYFH-UHFFFAOYSA-N Diethyl ether Chemical compound CCOCC RTZKZFJDLAIYFH-UHFFFAOYSA-N 0.000 description 2

- 239000004372 Polyvinyl alcohol Substances 0.000 description 2

- 230000009471 action Effects 0.000 description 2

- 229920001400 block copolymer Polymers 0.000 description 2

- 239000011203 carbon fibre reinforced carbon Substances 0.000 description 2

- 229920002678 cellulose Polymers 0.000 description 2

- 239000001913 cellulose Substances 0.000 description 2

- 239000000470 constituent Substances 0.000 description 2

- 238000005520 cutting process Methods 0.000 description 2

- 230000000694 effects Effects 0.000 description 2

- 239000013536 elastomeric material Substances 0.000 description 2

- JBKVHLHDHHXQEQ-UHFFFAOYSA-N epsilon-caprolactam Chemical compound O=C1CCCCCN1 JBKVHLHDHHXQEQ-UHFFFAOYSA-N 0.000 description 2

- 150000002513 isocyanates Chemical class 0.000 description 2

- 229920000126 latex Polymers 0.000 description 2

- 150000002739 metals Chemical class 0.000 description 2

- 239000002557 mineral fiber Substances 0.000 description 2

- 239000000178 monomer Substances 0.000 description 2

- 230000036961 partial effect Effects 0.000 description 2

- 229920002857 polybutadiene Polymers 0.000 description 2

- 229920001470 polyketone Polymers 0.000 description 2

- 229920002451 polyvinyl alcohol Polymers 0.000 description 2

- 230000002787 reinforcement Effects 0.000 description 2

- 229920006395 saturated elastomer Polymers 0.000 description 2

- 229920003051 synthetic elastomer Polymers 0.000 description 2

- XLYOFNOQVPJJNP-UHFFFAOYSA-N water Substances O XLYOFNOQVPJJNP-UHFFFAOYSA-N 0.000 description 2

- 238000003466 welding Methods 0.000 description 2

- VSKJLJHPAFKHBX-UHFFFAOYSA-N 2-methylbuta-1,3-diene;styrene Chemical compound CC(=C)C=C.C=CC1=CC=CC=C1.C=CC1=CC=CC=C1 VSKJLJHPAFKHBX-UHFFFAOYSA-N 0.000 description 1

- VGGSQFUCUMXWEO-UHFFFAOYSA-N Ethene Chemical compound C=C VGGSQFUCUMXWEO-UHFFFAOYSA-N 0.000 description 1

- 239000005977 Ethylene Substances 0.000 description 1

- 239000000654 additive Substances 0.000 description 1

- 238000004026 adhesive bonding Methods 0.000 description 1

- 239000012790 adhesive layer Substances 0.000 description 1

- 230000002411 adverse Effects 0.000 description 1

- 239000011324 bead Substances 0.000 description 1

- 239000006229 carbon black Substances 0.000 description 1

- 230000001143 conditioned effect Effects 0.000 description 1

- 230000008021 deposition Effects 0.000 description 1

- 150000001993 dienes Chemical class 0.000 description 1

- 238000001035 drying Methods 0.000 description 1

- 238000010894 electron beam technology Methods 0.000 description 1

- 239000000446 fuel Substances 0.000 description 1

- 230000009477 glass transition Effects 0.000 description 1

- LNEPOXFFQSENCJ-UHFFFAOYSA-N haloperidol Chemical compound C1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1 LNEPOXFFQSENCJ-UHFFFAOYSA-N 0.000 description 1

- 239000004816 latex Substances 0.000 description 1

- 230000000670 limiting effect Effects 0.000 description 1

- 238000005457 optimization Methods 0.000 description 1

- 230000008520 organization Effects 0.000 description 1

- 238000009832 plasma treatment Methods 0.000 description 1

- 239000011112 polyethylene naphthalate Substances 0.000 description 1

- 229920000223 polyglycerol Polymers 0.000 description 1

- 229920001195 polyisoprene Polymers 0.000 description 1

- 230000001681 protective effect Effects 0.000 description 1

- 230000005855 radiation Effects 0.000 description 1

- 230000002829 reductive effect Effects 0.000 description 1

- 239000012763 reinforcing filler Substances 0.000 description 1

- 230000002441 reversible effect Effects 0.000 description 1

- 238000000926 separation method Methods 0.000 description 1

- 239000003351 stiffener Substances 0.000 description 1

- 229920006132 styrene block copolymer Polymers 0.000 description 1

- 125000003011 styrenyl group Chemical group [H]\C(*)=C(/[H])C1=C([H])C([H])=C([H])C([H])=C1[H] 0.000 description 1

- 125000000383 tetramethylene group Chemical group [H]C([H])([*:1])C([H])([H])C([H])([H])C([H])([H])[*:2] 0.000 description 1

- 238000009941 weaving Methods 0.000 description 1

Images

Classifications

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

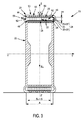

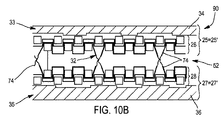

- B60C9/00—Reinforcements or ply arrangement of pneumatic tyres

- B60C9/02—Carcasses

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/02—Solid tyres ; Moulds therefor

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/06—Pneumatic tyres or parts thereof (e.g. produced by casting, moulding, compression moulding, injection moulding, centrifugal casting)

- B29D30/08—Building tyres

- B29D30/20—Building tyres by the flat-tyre method, i.e. building on cylindrical drums

- B29D30/24—Drums

- B29D30/242—Drums for manufacturing substantially cylindrical tyre components without cores or beads, e.g. treads or belts

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B29—WORKING OF PLASTICS; WORKING OF SUBSTANCES IN A PLASTIC STATE IN GENERAL

- B29D—PRODUCING PARTICULAR ARTICLES FROM PLASTICS OR FROM SUBSTANCES IN A PLASTIC STATE

- B29D30/00—Producing pneumatic or solid tyres or parts thereof

- B29D30/06—Pneumatic tyres or parts thereof (e.g. produced by casting, moulding, compression moulding, injection moulding, centrifugal casting)

- B29D30/38—Textile inserts, e.g. cord or canvas layers, for tyres; Treatment of inserts prior to building the tyre

- B29D30/40—Chemical pretreatment of textile inserts before building the tyre

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

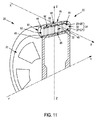

- B60C7/00—Non-inflatable or solid tyres

- B60C7/10—Non-inflatable or solid tyres characterised by means for increasing resiliency

- B60C7/14—Non-inflatable or solid tyres characterised by means for increasing resiliency using springs

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60C—VEHICLE TYRES; TYRE INFLATION; TYRE CHANGING; CONNECTING VALVES TO INFLATABLE ELASTIC BODIES IN GENERAL; DEVICES OR ARRANGEMENTS RELATED TO TYRES

- B60C7/00—Non-inflatable or solid tyres

- B60C7/10—Non-inflatable or solid tyres characterised by means for increasing resiliency

- B60C7/14—Non-inflatable or solid tyres characterised by means for increasing resiliency using springs

- B60C7/146—Non-inflatable or solid tyres characterised by means for increasing resiliency using springs extending substantially radially, e.g. like spokes

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Manufacturing & Machinery (AREA)

- Tires In General (AREA)

- Tyre Moulding (AREA)

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| FR1562630A FR3045463B1 (fr) | 2015-12-17 | 2015-12-17 | Assemblage pour pneumatique comprenant des tissu(s) ou tricot(s) comprenant des elements filaires pre-encolles |

| FR1562630 | 2015-12-17 | ||

| PCT/FR2016/053450 WO2017103491A1 (fr) | 2015-12-17 | 2016-12-15 | Assemblage pour pneumatique comprenant des tissu(s) ou tricot(s) comprenant des éléments filaires pré-encollés |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2019502571A JP2019502571A (ja) | 2019-01-31 |

| JP2019502571A5 JP2019502571A5 (enExample) | 2019-11-21 |

| JP6836595B2 true JP6836595B2 (ja) | 2021-03-03 |

Family

ID=55752425

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2018531218A Active JP6836595B2 (ja) | 2015-12-17 | 2016-12-15 | 予め接着されたワイヤ要素を含む織布又は編布を含むタイヤ用に意図された組立体 |

Country Status (6)

| Country | Link |

|---|---|

| US (1) | US11148379B2 (enExample) |

| EP (1) | EP3390115B1 (enExample) |

| JP (1) | JP6836595B2 (enExample) |

| CN (1) | CN108367639B (enExample) |

| FR (1) | FR3045463B1 (enExample) |

| WO (1) | WO2017103491A1 (enExample) |

Families Citing this family (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| FR3045462B1 (fr) | 2015-12-17 | 2017-12-29 | Michelin & Cie | Ensemble pour pneumatique comprenant des tissu(s) ou tricot(s) impregnes et un moyen de maintien sacrificiel |

| US11318790B2 (en) * | 2016-04-13 | 2022-05-03 | The Goodyear Tire & Robber Company | Shear band and non-pneumatic tire |

| FR3061675A1 (fr) | 2017-01-12 | 2018-07-13 | Compagnie Generale Des Etablissements Michelin | Assemblage comprenant une structure rompable et une structure porteuse |

| FR3061674A1 (fr) | 2017-01-12 | 2018-07-13 | Compagnie Generale Des Etablissements Michelin | Assemblage comprenant un tissu partiellement rompable et une structure porteuse |

| US10308134B2 (en) * | 2017-03-02 | 2019-06-04 | The Goodyear Tire & Rubber Company | Spherical wheel/tire assembly |

| FR3067980A1 (fr) * | 2017-06-23 | 2018-12-28 | Compagnie Generale Des Etablissements Michelin | Dispositif de type pneumatique pour vehicule |

| FR3067981A1 (fr) * | 2017-06-23 | 2018-12-28 | Compagnie Generale Des Etablissements Michelin | Dispositif de type pneumatique pour vehicule |

| CN111246993B (zh) * | 2017-10-18 | 2021-12-24 | 米其林集团总公司 | 用于轮胎的包括三维纺织物或编织物以及固定元件的组件 |

| EP3697629B1 (fr) * | 2017-10-18 | 2021-12-01 | Compagnie Générale des Etablissements Michelin | Assemblage |

| KR102739357B1 (ko) * | 2017-11-17 | 2024-12-05 | 주식회사 쿠라레 | 자전거 타이어용의 보강 부재 및 자전거 타이어 |

| FR3088238B3 (fr) * | 2018-11-09 | 2020-10-23 | Michelin & Cie | Procede de fabrication d'un pneumatique |

| WO2020094979A1 (fr) * | 2018-11-09 | 2020-05-14 | Compagnie Generale Des Etablissements Michelin | Dispositif de type pneumatique à éléments filaires souples pour véhicule |

| FR3090498A3 (fr) | 2018-12-24 | 2020-06-26 | Michelin & Cie | Assemblage pour un pneumatique, pneumatique et procédés de fabrication associés |

| FR3090497B3 (fr) | 2018-12-24 | 2020-12-04 | Michelin & Cie | Assemblage pour un pneumatique, pneumatique et procédés de fabrication associés |

| FR3103733B1 (fr) * | 2019-11-29 | 2022-08-19 | Michelin & Cie | Assemblage comprenant une structure porteuse adaptable |

| FR3103732B1 (fr) * | 2019-11-29 | 2023-03-31 | Michelin & Cie | Assemblage comprenant une structure porteuse adaptable |

| US20210170795A1 (en) * | 2019-12-10 | 2021-06-10 | The Goodyear Tire & Rubber Company | Shear band |

| EP4084964A4 (en) | 2019-12-30 | 2024-01-17 | Bridgestone Americas Tire Operations, LLC | Bump stop for non-pneumatic tire |

| US20210300120A1 (en) * | 2020-03-30 | 2021-09-30 | The Goodyear Tire & Rubber Company | Shear band |

| FR3112311B1 (fr) * | 2020-07-08 | 2022-06-24 | Michelin & Cie | Pneumatique pour véhicule de tourisme |

Family Cites Families (35)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US1426763A (en) * | 1919-10-20 | 1922-08-22 | O'bannon Maurice | Tire |

| US2506861A (en) * | 1947-11-28 | 1950-05-09 | Harry E Drennan | Cushion tire |

| US2502101A (en) * | 1949-03-02 | 1950-03-28 | Woonsocket Falls Mill | Fabric and method of making same |

| US3606921A (en) * | 1969-06-23 | 1971-09-21 | Caterpillar Tractor Co | Belted oval pneumatic tube-tire |

| US3979536A (en) | 1971-07-08 | 1976-09-07 | Uniroyal Inc. | Zero degree belted tires, and high "soft stretch" belt-forming tapes therefor |

| US4157107A (en) * | 1978-04-03 | 1979-06-05 | General Motors Corporation | Run-flat tire having integral internal support means |

| US4235270A (en) | 1978-06-30 | 1980-11-25 | The Goodyear Tire & Rubber Company | Tire with supporting and cushioning walls |

| JPS5940641B2 (ja) * | 1978-10-12 | 1984-10-02 | ザ グツドイア− タイヤ アンド ラバ− コンパニ− | 自動車用管状タイヤ |

| JPS5963203A (ja) * | 1982-09-02 | 1984-04-10 | ソシエテ・デ・デベロップメント・テクノロジック・エス・ア− | 空気圧不要タイヤ用インサ−トチユ−ブ |

| US5407701A (en) * | 1993-05-14 | 1995-04-18 | The Goodyear Tire & Rubber Company | Cords for pneumatic tires and process for making them |

| KR960007209A (ko) * | 1994-08-31 | 1996-03-22 | 마사아키 니시 | 타이어 조립체용 림 |

| JPH1076807A (ja) * | 1996-09-03 | 1998-03-24 | Tetsuji Matsumori | ワイヤーにより横剛性を強化したタイヤ |

| US6983776B2 (en) * | 1999-12-10 | 2006-01-10 | Michelin Recherche Et Technique S.A. | Structurally supported resilient tire with bias ply carcass |

| JP4614622B2 (ja) * | 2001-04-16 | 2011-01-19 | ミシュラン ルシェルシュ エ テクニーク ソシエテ アノニム | バイアスプライカーカスを有する構造的に支持された弾性タイヤ |

| US7013939B2 (en) | 2001-08-24 | 2006-03-21 | Michelin Recherche Et Technique S.A. | Compliant wheel |

| DE60131469T2 (de) * | 2001-08-24 | 2008-09-18 | Société de Technologie Michelin | Nicht- pneumatischer reifen |

| CN100528613C (zh) * | 2003-02-04 | 2009-08-19 | 米其林技术公司 | 轮胎安全支撑的润滑剂组合物和使用及其轮胎和安装组件 |

| US20060033231A1 (en) * | 2004-08-10 | 2006-02-16 | Reuter Rene F | Monofilament reinforced rubber component and method of producing |

| US20080115871A1 (en) * | 2006-11-16 | 2008-05-22 | Paul Harry Sandstrom | Tire having a sidewall component containing a dispersion of adhesive coated short carbon fiber reinforcement |

| FR2921013B1 (fr) | 2007-09-14 | 2009-11-27 | Soc Tech Michelin | Roue elastique non pneumatique. |

| FR2922159B1 (fr) | 2007-10-15 | 2011-04-29 | Michelin Soc Tech | Pneumatique a virole et a structure porteuse |

| CN101214780A (zh) * | 2008-01-16 | 2008-07-09 | 李日出 | 一种轮胎爆裂、漏气后车辆、飞机不会失控的轮子 |

| JP5225743B2 (ja) * | 2008-04-30 | 2013-07-03 | 東洋ゴム工業株式会社 | 非空気圧タイヤ |

| CN101318450A (zh) * | 2008-05-14 | 2008-12-10 | 王明江 | 网架式免充气空心轮胎 |

| JP5314621B2 (ja) * | 2010-03-02 | 2013-10-16 | 東洋ゴム工業株式会社 | 非空気圧タイヤ |

| WO2012098130A1 (en) * | 2011-01-17 | 2012-07-26 | Vds Weaving Nv | A tridimensional woven fabric, an integrated permeate channel membrane comprising said fabric and uses thereof |

| FR2978770B1 (fr) | 2011-08-04 | 2013-09-27 | Michelin Soc Tech | Composition adhesive aqueuse a base de polyaldehyde et phloroglucinol |

| FR2978771B1 (fr) | 2011-08-04 | 2013-09-27 | Michelin Soc Tech | Composition adhesive aqueuse a base de polyaldehyde et 2,2', 4,4'-tetrahydroxydiphenyl sulfide |

| FR2978769B1 (fr) | 2011-08-04 | 2013-09-27 | Michelin Soc Tech | Composition adhesive aqueuse a base de polyaldehyde et de polyphenol |

| WO2014103841A1 (ja) * | 2012-12-25 | 2014-07-03 | 横浜ゴム株式会社 | タイヤ/ホイール組立体及びトレッドリング |

| FR3008707B1 (fr) | 2013-07-16 | 2017-11-10 | Michelin & Cie | Composition adhesive aqueuse a base d'aldehyde biosource et de polyphenol |

| US9849734B2 (en) * | 2014-10-31 | 2017-12-26 | The Goodyear Tire & Rubber Company | Pneumatic tire with a three dimensional component |

| FR3038543B1 (fr) * | 2015-07-06 | 2017-07-21 | Michelin & Cie | Dispositif de type pneumatique pour vehicule |

| FR3045462B1 (fr) | 2015-12-17 | 2017-12-29 | Michelin & Cie | Ensemble pour pneumatique comprenant des tissu(s) ou tricot(s) impregnes et un moyen de maintien sacrificiel |

| US20180154694A1 (en) * | 2016-12-01 | 2018-06-07 | The Goodyear Tire & Rubber Company | Lightweight tire assembly |

-

2015

- 2015-12-17 FR FR1562630A patent/FR3045463B1/fr not_active Expired - Fee Related

-

2016

- 2016-12-15 US US15/780,367 patent/US11148379B2/en active Active

- 2016-12-15 WO PCT/FR2016/053450 patent/WO2017103491A1/fr not_active Ceased

- 2016-12-15 CN CN201680072790.1A patent/CN108367639B/zh active Active

- 2016-12-15 JP JP2018531218A patent/JP6836595B2/ja active Active

- 2016-12-15 EP EP16825850.7A patent/EP3390115B1/fr active Active

Also Published As

| Publication number | Publication date |

|---|---|

| EP3390115B1 (fr) | 2020-02-26 |

| EP3390115A1 (fr) | 2018-10-24 |

| US11148379B2 (en) | 2021-10-19 |

| JP2019502571A (ja) | 2019-01-31 |

| FR3045463A1 (fr) | 2017-06-23 |

| US20180361791A1 (en) | 2018-12-20 |

| FR3045463B1 (fr) | 2017-12-29 |

| WO2017103491A1 (fr) | 2017-06-22 |

| CN108367639A (zh) | 2018-08-03 |

| CN108367639B (zh) | 2020-10-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6836595B2 (ja) | 予め接着されたワイヤ要素を含む織布又は編布を含むタイヤ用に意図された組立体 | |

| JP6890590B2 (ja) | 含浸された織布又は編布及び犠牲保持手段を含むタイヤ用組立体 | |

| JP7488972B2 (ja) | 破断可能な構造体と支持構造体とを含むタイヤアセンブリ | |

| CN110300655B (zh) | 包括可部分断裂的织物以及支撑结构的组件 | |

| US10766307B2 (en) | Tire-type device for a vehicle | |

| JP5236181B2 (ja) | 強化ラジアル航空機用タイヤ | |

| KR101970365B1 (ko) | 공기압 타이어용 아코디언 구조의 나선형 오버레이 | |

| CN107223089B (zh) | 用于车辆的轮胎型设备 | |

| EP2810791B1 (en) | Pneumatic tire and hybrid cord for such a pneumatic tire | |

| JP2018508403A (ja) | 車両用のタイヤ型装置 | |

| KR20100129697A (ko) | 오버레이 보강부를 갖는 공기 타이어 | |

| KR20120036290A (ko) | 편직물 플립퍼를 갖는 공기압 타이어 | |

| US20230066575A1 (en) | Shear band | |

| JP6051155B2 (ja) | タイヤ | |

| CN114746255B (zh) | 包括适应性支撑结构的组件 | |

| KR20230158501A (ko) | 내구성 있는 강성화 구조를 포함하고 적절한 평탄화를 허용하는 타이어 | |

| CN114746260B (zh) | 包括适应性支撑结构的组件 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20191010 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20191010 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20200625 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20201001 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20201222 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20210107 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20210205 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6836595 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |