JP6769986B2 - 熱可塑性ポリマーをベースとした金属導電性ホットメルトペースト - Google Patents

熱可塑性ポリマーをベースとした金属導電性ホットメルトペースト Download PDFInfo

- Publication number

- JP6769986B2 JP6769986B2 JP2017549240A JP2017549240A JP6769986B2 JP 6769986 B2 JP6769986 B2 JP 6769986B2 JP 2017549240 A JP2017549240 A JP 2017549240A JP 2017549240 A JP2017549240 A JP 2017549240A JP 6769986 B2 JP6769986 B2 JP 6769986B2

- Authority

- JP

- Japan

- Prior art keywords

- hot melt

- polymer

- resin

- parts

- weight

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000012943 hotmelt Substances 0.000 title claims description 68

- 229910052751 metal Inorganic materials 0.000 title description 27

- 239000002184 metal Substances 0.000 title description 27

- 229920001169 thermoplastic Polymers 0.000 title description 2

- 229920000642 polymer Polymers 0.000 claims description 119

- 239000000203 mixture Substances 0.000 claims description 19

- 239000002904 solvent Substances 0.000 claims description 17

- 238000000034 method Methods 0.000 claims description 13

- BQCADISMDOOEFD-UHFFFAOYSA-N Silver Chemical compound [Ag] BQCADISMDOOEFD-UHFFFAOYSA-N 0.000 claims description 12

- 239000003990 capacitor Substances 0.000 claims description 11

- 239000000155 melt Substances 0.000 claims description 11

- 239000004645 polyester resin Substances 0.000 claims description 9

- 229920001225 polyester resin Polymers 0.000 claims description 9

- 239000003822 epoxy resin Substances 0.000 claims description 8

- 239000013034 phenoxy resin Substances 0.000 claims description 8

- 229920006287 phenoxy resin Polymers 0.000 claims description 8

- 229920000647 polyepoxide Polymers 0.000 claims description 8

- 239000004925 Acrylic resin Substances 0.000 claims description 6

- 229920000178 Acrylic resin Polymers 0.000 claims description 6

- 229920000877 Melamine resin Polymers 0.000 claims description 6

- 239000004640 Melamine resin Substances 0.000 claims description 6

- 239000012461 cellulose resin Substances 0.000 claims description 6

- 238000004519 manufacturing process Methods 0.000 claims description 6

- 229920003986 novolac Polymers 0.000 claims description 6

- 229920002037 poly(vinyl butyral) polymer Polymers 0.000 claims description 6

- 229920006122 polyamide resin Polymers 0.000 claims description 6

- 229920001721 polyimide Polymers 0.000 claims description 6

- 239000009719 polyimide resin Substances 0.000 claims description 6

- 229920005990 polystyrene resin Polymers 0.000 claims description 6

- 229920005749 polyurethane resin Polymers 0.000 claims description 6

- 229920002451 polyvinyl alcohol Polymers 0.000 claims description 6

- 229920005989 resin Polymers 0.000 claims description 6

- 239000011347 resin Substances 0.000 claims description 6

- 239000004065 semiconductor Substances 0.000 claims description 6

- 229920002050 silicone resin Polymers 0.000 claims description 6

- 238000001035 drying Methods 0.000 claims description 5

- 235000019422 polyvinyl alcohol Nutrition 0.000 claims 1

- 229910000679 solder Inorganic materials 0.000 description 36

- 239000000843 powder Substances 0.000 description 33

- 239000000758 substrate Substances 0.000 description 16

- 239000011135 tin Substances 0.000 description 13

- 229910052718 tin Inorganic materials 0.000 description 11

- PXHVJJICTQNCMI-UHFFFAOYSA-N Nickel Chemical compound [Ni] PXHVJJICTQNCMI-UHFFFAOYSA-N 0.000 description 9

- 230000004907 flux Effects 0.000 description 9

- 239000000919 ceramic Substances 0.000 description 8

- 230000000052 comparative effect Effects 0.000 description 8

- 239000002245 particle Substances 0.000 description 8

- 229920001187 thermosetting polymer Polymers 0.000 description 8

- 239000010949 copper Substances 0.000 description 7

- 229910052797 bismuth Inorganic materials 0.000 description 6

- 239000011521 glass Substances 0.000 description 6

- 229910052709 silver Inorganic materials 0.000 description 6

- 239000004332 silver Substances 0.000 description 6

- 239000004372 Polyvinyl alcohol Substances 0.000 description 5

- 229910052802 copper Inorganic materials 0.000 description 5

- 239000011701 zinc Substances 0.000 description 5

- RYGMFSIKBFXOCR-UHFFFAOYSA-N Copper Chemical compound [Cu] RYGMFSIKBFXOCR-UHFFFAOYSA-N 0.000 description 4

- KDLHZDBZIXYQEI-UHFFFAOYSA-N Palladium Chemical compound [Pd] KDLHZDBZIXYQEI-UHFFFAOYSA-N 0.000 description 4

- 230000009477 glass transition Effects 0.000 description 4

- 238000002844 melting Methods 0.000 description 4

- 230000008018 melting Effects 0.000 description 4

- 229910052759 nickel Inorganic materials 0.000 description 4

- BASFCYQUMIYNBI-UHFFFAOYSA-N platinum Chemical compound [Pt] BASFCYQUMIYNBI-UHFFFAOYSA-N 0.000 description 4

- 239000004634 thermosetting polymer Substances 0.000 description 4

- LYCAIKOWRPUZTN-UHFFFAOYSA-N Ethylene glycol Chemical compound OCCO LYCAIKOWRPUZTN-UHFFFAOYSA-N 0.000 description 3

- ATJFFYVFTNAWJD-UHFFFAOYSA-N Tin Chemical compound [Sn] ATJFFYVFTNAWJD-UHFFFAOYSA-N 0.000 description 3

- HCHKCACWOHOZIP-UHFFFAOYSA-N Zinc Chemical compound [Zn] HCHKCACWOHOZIP-UHFFFAOYSA-N 0.000 description 3

- 239000000654 additive Substances 0.000 description 3

- 229910052782 aluminium Inorganic materials 0.000 description 3

- JCXGWMGPZLAOME-UHFFFAOYSA-N bismuth atom Chemical compound [Bi] JCXGWMGPZLAOME-UHFFFAOYSA-N 0.000 description 3

- 238000007598 dipping method Methods 0.000 description 3

- 230000005484 gravity Effects 0.000 description 3

- 238000010438 heat treatment Methods 0.000 description 3

- 229910052738 indium Inorganic materials 0.000 description 3

- 239000002923 metal particle Substances 0.000 description 3

- 238000007650 screen-printing Methods 0.000 description 3

- 238000005476 soldering Methods 0.000 description 3

- 229910052725 zinc Inorganic materials 0.000 description 3

- KZVBBTZJMSWGTK-UHFFFAOYSA-N 1-[2-(2-butoxyethoxy)ethoxy]butane Chemical compound CCCCOCCOCCOCCCC KZVBBTZJMSWGTK-UHFFFAOYSA-N 0.000 description 2

- 239000004593 Epoxy Substances 0.000 description 2

- GYHNNYVSQQEPJS-UHFFFAOYSA-N Gallium Chemical compound [Ga] GYHNNYVSQQEPJS-UHFFFAOYSA-N 0.000 description 2

- XAGFODPZIPBFFR-UHFFFAOYSA-N aluminium Chemical compound [Al] XAGFODPZIPBFFR-UHFFFAOYSA-N 0.000 description 2

- 229910052733 gallium Inorganic materials 0.000 description 2

- PCHJSUWPFVWCPO-UHFFFAOYSA-N gold Chemical compound [Au] PCHJSUWPFVWCPO-UHFFFAOYSA-N 0.000 description 2

- 229910052737 gold Inorganic materials 0.000 description 2

- 239000010931 gold Substances 0.000 description 2

- APFVFJFRJDLVQX-UHFFFAOYSA-N indium atom Chemical compound [In] APFVFJFRJDLVQX-UHFFFAOYSA-N 0.000 description 2

- 229910052763 palladium Inorganic materials 0.000 description 2

- 229920001568 phenolic resin Polymers 0.000 description 2

- 239000005011 phenolic resin Substances 0.000 description 2

- 229910052697 platinum Inorganic materials 0.000 description 2

- 229920000728 polyester Polymers 0.000 description 2

- 229910052703 rhodium Inorganic materials 0.000 description 2

- 239000010948 rhodium Substances 0.000 description 2

- MHOVAHRLVXNVSD-UHFFFAOYSA-N rhodium atom Chemical compound [Rh] MHOVAHRLVXNVSD-UHFFFAOYSA-N 0.000 description 2

- 239000000126 substance Substances 0.000 description 2

- DAFHKNAQFPVRKR-UHFFFAOYSA-N (3-hydroxy-2,2,4-trimethylpentyl) 2-methylpropanoate Chemical compound CC(C)C(O)C(C)(C)COC(=O)C(C)C DAFHKNAQFPVRKR-UHFFFAOYSA-N 0.000 description 1

- OAYXUHPQHDHDDZ-UHFFFAOYSA-N 2-(2-butoxyethoxy)ethanol Chemical compound CCCCOCCOCCO OAYXUHPQHDHDDZ-UHFFFAOYSA-N 0.000 description 1

- FPZWZCWUIYYYBU-UHFFFAOYSA-N 2-(2-ethoxyethoxy)ethyl acetate Chemical compound CCOCCOCCOC(C)=O FPZWZCWUIYYYBU-UHFFFAOYSA-N 0.000 description 1

- POAOYUHQDCAZBD-UHFFFAOYSA-N 2-butoxyethanol Chemical compound CCCCOCCO POAOYUHQDCAZBD-UHFFFAOYSA-N 0.000 description 1

- KXGFMDJXCMQABM-UHFFFAOYSA-N 2-methoxy-6-methylphenol Chemical compound [CH]OC1=CC=CC([CH])=C1O KXGFMDJXCMQABM-UHFFFAOYSA-N 0.000 description 1

- 239000004971 Cross linker Substances 0.000 description 1

- ISWSIDIOOBJBQZ-UHFFFAOYSA-N Phenol Chemical compound OC1=CC=CC=C1 ISWSIDIOOBJBQZ-UHFFFAOYSA-N 0.000 description 1

- IJMMLESAAHRIPW-UHFFFAOYSA-N acetic acid;1-phenoxypropan-2-ol Chemical compound CC(O)=O.CC(O)COC1=CC=CC=C1 IJMMLESAAHRIPW-UHFFFAOYSA-N 0.000 description 1

- 229910045601 alloy Inorganic materials 0.000 description 1

- 239000000956 alloy Substances 0.000 description 1

- WUOACPNHFRMFPN-UHFFFAOYSA-N alpha-terpineol Chemical compound CC1=CCC(C(C)(C)O)CC1 WUOACPNHFRMFPN-UHFFFAOYSA-N 0.000 description 1

- 238000009835 boiling Methods 0.000 description 1

- 238000001816 cooling Methods 0.000 description 1

- 239000003431 cross linking reagent Substances 0.000 description 1

- SQIFACVGCPWBQZ-UHFFFAOYSA-N delta-terpineol Natural products CC(C)(O)C1CCC(=C)CC1 SQIFACVGCPWBQZ-UHFFFAOYSA-N 0.000 description 1

- 239000002270 dispersing agent Substances 0.000 description 1

- 238000009826 distribution Methods 0.000 description 1

- 238000001704 evaporation Methods 0.000 description 1

- 238000010304 firing Methods 0.000 description 1

- 239000011888 foil Substances 0.000 description 1

- LNEPOXFFQSENCJ-UHFFFAOYSA-N haloperidol Chemical compound C1CC(O)(C=2C=CC(Cl)=CC=2)CCN1CCCC(=O)C1=CC=C(F)C=C1 LNEPOXFFQSENCJ-UHFFFAOYSA-N 0.000 description 1

- -1 inductor Substances 0.000 description 1

- 239000003112 inhibitor Substances 0.000 description 1

- 229910052745 lead Inorganic materials 0.000 description 1

- 239000007788 liquid Substances 0.000 description 1

- 229910001092 metal group alloy Inorganic materials 0.000 description 1

- 239000003960 organic solvent Substances 0.000 description 1

- 230000003647 oxidation Effects 0.000 description 1

- 238000007254 oxidation reaction Methods 0.000 description 1

- 239000004014 plasticizer Substances 0.000 description 1

- 239000004848 polyfunctional curative Substances 0.000 description 1

- 229920006254 polymer film Polymers 0.000 description 1

- 238000007639 printing Methods 0.000 description 1

- 238000000790 scattering method Methods 0.000 description 1

- 239000003381 stabilizer Substances 0.000 description 1

- 239000004094 surface-active agent Substances 0.000 description 1

- 229940116411 terpineol Drugs 0.000 description 1

- 239000004416 thermosoftening plastic Substances 0.000 description 1

- 238000010023 transfer printing Methods 0.000 description 1

Images

Classifications

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L24/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L24/31—Structure, shape, material or disposition of the layer connectors after the connecting process

- H01L24/32—Structure, shape, material or disposition of the layer connectors after the connecting process of an individual layer connector

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G4/00—Fixed capacitors; Processes of their manufacture

- H01G4/30—Stacked capacitors

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D3/00—Pretreatment of surfaces to which liquids or other fluent materials are to be applied; After-treatment of applied coatings, e.g. intermediate treating of an applied coating preparatory to subsequent applications of liquids or other fluent materials

- B05D3/007—After-treatment

-

- B—PERFORMING OPERATIONS; TRANSPORTING

- B05—SPRAYING OR ATOMISING IN GENERAL; APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D—PROCESSES FOR APPLYING FLUENT MATERIALS TO SURFACES, IN GENERAL

- B05D7/00—Processes, other than flocking, specially adapted for applying liquids or other fluent materials to particular surfaces or for applying particular liquids or other fluent materials

- B05D7/14—Processes, other than flocking, specially adapted for applying liquids or other fluent materials to particular surfaces or for applying particular liquids or other fluent materials to metal, e.g. car bodies

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01C—RESISTORS

- H01C1/00—Details

- H01C1/14—Terminals or tapping points or electrodes specially adapted for resistors; Arrangements of terminals or tapping points or electrodes on resistors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01F—MAGNETS; INDUCTANCES; TRANSFORMERS; SELECTION OF MATERIALS FOR THEIR MAGNETIC PROPERTIES

- H01F27/00—Details of transformers or inductances, in general

- H01F27/28—Coils; Windings; Conductive connections

- H01F27/29—Terminals; Tapping arrangements for signal inductances

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G2/00—Details of capacitors not covered by a single one of groups H01G4/00-H01G11/00

- H01G2/02—Mountings

- H01G2/06—Mountings specially adapted for mounting on a printed-circuit support

- H01G2/065—Mountings specially adapted for mounting on a printed-circuit support for surface mounting, e.g. chip capacitors

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G4/00—Fixed capacitors; Processes of their manufacture

- H01G4/002—Details

- H01G4/228—Terminals

- H01G4/232—Terminals electrically connecting two or more layers of a stacked or rolled capacitor

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G4/00—Fixed capacitors; Processes of their manufacture

- H01G4/002—Details

- H01G4/228—Terminals

- H01G4/232—Terminals electrically connecting two or more layers of a stacked or rolled capacitor

- H01G4/2325—Terminals electrically connecting two or more layers of a stacked or rolled capacitor characterised by the material of the terminals

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01G—CAPACITORS; CAPACITORS, RECTIFIERS, DETECTORS, SWITCHING DEVICES, LIGHT-SENSITIVE OR TEMPERATURE-SENSITIVE DEVICES OF THE ELECTROLYTIC TYPE

- H01G4/00—Fixed capacitors; Processes of their manufacture

- H01G4/002—Details

- H01G4/228—Terminals

- H01G4/248—Terminals the terminals embracing or surrounding the capacitive element, e.g. caps

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L24/00—Arrangements for connecting or disconnecting semiconductor or solid-state bodies; Methods or apparatus related thereto

- H01L24/80—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected

- H01L24/83—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected using a layer connector

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/01—Means for bonding being attached to, or being formed on, the surface to be connected, e.g. chip-to-package, die-attach, "first-level" interconnects; Manufacturing methods related thereto

- H01L2224/26—Layer connectors, e.g. plate connectors, solder or adhesive layers; Manufacturing methods related thereto

- H01L2224/31—Structure, shape, material or disposition of the layer connectors after the connecting process

- H01L2224/32—Structure, shape, material or disposition of the layer connectors after the connecting process of an individual layer connector

- H01L2224/321—Disposition

- H01L2224/32151—Disposition the layer connector connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive

- H01L2224/32221—Disposition the layer connector connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked

- H01L2224/32225—Disposition the layer connector connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked the item being non-metallic, e.g. insulating substrate with or without metallisation

- H01L2224/3223—Disposition the layer connector connecting between a semiconductor or solid-state body and an item not being a semiconductor or solid-state body, e.g. chip-to-substrate, chip-to-passive the body and the item being stacked the item being non-metallic, e.g. insulating substrate with or without metallisation the layer connector connecting to a pin of the item

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2224/00—Indexing scheme for arrangements for connecting or disconnecting semiconductor or solid-state bodies and methods related thereto as covered by H01L24/00

- H01L2224/80—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected

- H01L2224/83—Methods for connecting semiconductor or other solid state bodies using means for bonding being attached to, or being formed on, the surface to be connected using a layer connector

- H01L2224/838—Bonding techniques

- H01L2224/8385—Bonding techniques using a polymer adhesive, e.g. an adhesive based on silicone, epoxy, polyimide, polyester

- H01L2224/83851—Bonding techniques using a polymer adhesive, e.g. an adhesive based on silicone, epoxy, polyimide, polyester being an anisotropic conductive adhesive

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01013—Aluminum [Al]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01028—Nickel [Ni]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01029—Copper [Cu]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/0103—Zinc [Zn]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01031—Gallium [Ga]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01045—Rhodium [Rh]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01046—Palladium [Pd]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01047—Silver [Ag]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01049—Indium [In]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/0105—Tin [Sn]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01079—Gold [Au]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/01—Chemical elements

- H01L2924/01083—Bismuth [Bi]

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/013—Alloys

- H01L2924/014—Solder alloys

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/10—Details of semiconductor or other solid state devices to be connected

- H01L2924/11—Device type

- H01L2924/12—Passive devices, e.g. 2 terminal devices

- H01L2924/1205—Capacitor

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/10—Details of semiconductor or other solid state devices to be connected

- H01L2924/11—Device type

- H01L2924/12—Passive devices, e.g. 2 terminal devices

- H01L2924/1206—Inductor

-

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01L—SEMICONDUCTOR DEVICES NOT COVERED BY CLASS H10

- H01L2924/00—Indexing scheme for arrangements or methods for connecting or disconnecting semiconductor or solid-state bodies as covered by H01L24/00

- H01L2924/10—Details of semiconductor or other solid state devices to be connected

- H01L2924/11—Device type

- H01L2924/12—Passive devices, e.g. 2 terminal devices

- H01L2924/1207—Resistor

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Manufacturing & Machinery (AREA)

- Computer Hardware Design (AREA)

- Life Sciences & Earth Sciences (AREA)

- Wood Science & Technology (AREA)

- Conductive Materials (AREA)

- Compositions Of Macromolecular Compounds (AREA)

- Electric Connection Of Electric Components To Printed Circuits (AREA)

- Non-Insulated Conductors (AREA)

Description

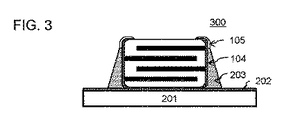

キャパシタとしての電気部品100を図1に示す。電気部品100は、端子電極104およびその端子電極上に形成されたホットメルトポリマー層105を備える。端子電極は、回路などの外部導電性要素と電気的および物理的に接合された電極と定義される。図1中のキャパシタは、本体101および本体101の両側での端子電極104ならびに両端子電極上のホットメルトポリマー層105を備える。

金属粉末は、ある実施形態において、銀、銅、金、パラジウム、白金、ロジウム、ニッケル、アルミニウム、ガリウム、インジウム、スズ、亜鉛、ビスマス、およびそれらの混合物からなる群から選択され得る。金属粉末は、別の実施形態において、銀、ニッケル、スズ、亜鉛、ビスマス、およびそれらの混合物からなる群から選択され得る。金属粉末は、別の実施形態において、銀であり得る。

ホットメルトポリマー層は、金属粉末がその中に分散するポリマーを含む。ポリマーは、リフロー中に溶融する。ポリマーのメルトマスフローレート(MFR)は、120〜200℃および0.3〜8kgfで0.5〜20g/10分である。ポリマーのMFRは、120〜200℃および0.3〜8kgfで、別の実施形態において0.8〜15g/10分、別の実施形態において1.0〜10g/10分であり得る。このようなポリマーは、高温で流動化する。MFRは、溶融ポリマーの流れの容易さの尺度である。それは、ある温度について重力重量を介して印加された圧力によって、特定の直径および長さの毛細管を通って10分で流れる、グラム単位でのポリマーの質量と定義される。MFRは、ある実施形態において、JIS7210に従って測定され得る。

溶媒は、ポリマーを溶解させるために使用され得る。溶媒は、端子電極上のホットメルトポリマーペーストを完全に乾燥させる間に蒸発する。

ポリマーペーストは、融剤をさらに含み得る。融剤は、はんだ付け対象の表面上の、酸化などの阻害因子を除去することによって、端子電極のはんだ付け性を増加させ得る。ポリマーペーストは、ある実施形態において0.1〜3重量部、別の実施形態において0.4〜2重量部、別の実施形態において0.5〜1.2重量部の融剤を含む。融剤は、リフロー後にホットメルトポリマー層に残存する。

添加剤、例えば、界面活性剤、分散剤、安定剤および可塑剤は、ペーストの所望の特性に基づいて、ポリマーペーストに添加することができる。

以下に、本発明の好ましい態様を示す。

[1] 端子電極と、前記端子電極上に形成されたホットメルトポリマー層とを備える電気部品であって、前記ホットメルトポリマー層は、(i)100重量部の金属粉末、および(ii)1〜30重量部のポリマーを含み、前記ポリマーのメルトマスフローレート(MFR)は、120〜200℃および0.3〜8kgfで0.5〜20g/10分である、電気部品。

[2] 前記金属粉末が、薄片、球状、団塊状、またはそれらの混合である粒子を含む、[1]に記載の電気部品。

[3] 前記金属粉末が、0.5〜20μmの直径(D50)を有する粒子を含む、[1]に記載の電気部品。

[4] 前記金属粉末が、銀、銅、金、パラジウム、白金、ロジウム、ニッケル、アルミニウム、ガリウム、インジウム、スズ、亜鉛、ビスマス、およびそれらの混合物からなる群から選択される、[1]に記載の電気部品。

[5] 前記ポリマーのガラス転移点が、−25〜180℃である、[1]に記載の電気部品。

[6] 前記ポリマーの分子量が、500〜100,000である、[1]に記載の電気部品。

[7] 前記ホットメルトポリマー層が、0.1〜3重量部の融剤をさらに含む、[1]に記載の電気部品。

[8] 前記ポリマーが、ポリエステル樹脂、フェノキシ樹脂、ノボラック樹脂、エポキシ樹脂、アクリル樹脂、メラミン樹脂、ポリイミド樹脂、ポリアミド樹脂、ポリスチレン樹脂、ブチラール樹脂、セルロース樹脂、ポリビニルアルコール、ポリウレタン樹脂、シリコーン樹脂、およびそれらの混合物からなる群から選択される、[1]に記載の電気部品。

[9] 前記電気部品が、抵抗器、キャパシタ、インダクタ、または半導体チップである、[1]に記載の電気部品。

[10] 電気部品を製造する方法であって、

本体を備える電気部品を提供する工程であって、少なくとも1種の端子電極が前記本体の上に形成される、工程と;

ホットメルトポリマーペーストを前記端子電極に適用する工程であって、前記ホットメルトポリマーペーストは、(i)100重量部の金属粉末、(ii)1〜30重量部のポリマーおよび(iii)溶媒を含み、前記ポリマーのメルトマスフローレートは、120〜200℃および0.3〜8kgfで0.5〜15g/10分である、工程と;

前記適用されたホットメルトポリマーペーストを乾燥させる工程と

を含む方法。

[11] 前記金属粉末が、薄片、球状、団塊状またはそれらの混合である、[10]に記載の方法。

[12] 前記ポリマーが、ポリエステル樹脂、フェノキシ樹脂、ノボラック樹脂、エポキシ樹脂、アクリル樹脂、メラミン樹脂、ポリイミド樹脂、ポリアミド樹脂、ポリスチレン樹脂、ブチラール樹脂、セルロース樹脂、ポリビニルアルコール、ポリウレタン樹脂、シリコーン樹脂、およびそれらの混合物からなる群から選択される、[10]に記載の方法。

[13] 前記ホットメルトポリマーペーストが、0.1〜3重量部の融剤をさらに含む、[10]に記載の方法。

[14] 乾燥温度が、50〜200℃である、[10]に記載の方法。

[15] 前記電気部品が、抵抗器、キャパシタ、インダクタ、または半導体チップである、[10]に記載の方法。

[16] 端子電極と、前記端子電極上に形成されたホットメルトポリマー層とを備える電気部品であって、前記ホットメルトポリマー層は、(i)100重量部の金属粉末および(ii)1〜30重量部のポリマーを含み、前記ポリマーは、ポリエステル樹脂、フェノキシ樹脂、ノボラック樹脂、エポキシ樹脂、アクリル樹脂、メラミン樹脂、ポリイミド樹脂、ポリアミド樹脂、ポリスチレン樹脂、ブチラール樹脂、セルロース樹脂、ポリビニルアルコール、ポリウレタン樹脂、シリコーン樹脂、およびそれらの混合物からなる群から選択される、電気部品。

ホットメルトポリマーペーストを、以下のとおり調製した。

ホットメルトポリマーペースト組成物を調べた。

− フェノキシ樹脂:

MFR 1.17g/10分(190℃および1.2kgfで);

Tg 92℃;

Mw 52,000。

− ポリエステル樹脂A:

MFR 6.59g/10分(130℃および5kgfで);

Tg 36℃;

Mw 16000。

− ポリエステル樹脂B:

MFR8.68g/10分(190℃および1.2kgfで);

Tg 65℃;

Mw 16000。

− エポキシ樹脂:

MFR 2.72g/10分(130℃および5kgfで);

Tg 65℃;

Mw 7000。

− フェノール樹脂:

熱硬化性ポリマー。

Claims (3)

- 端子電極と、前記端子電極上に形成されたホットメルトポリマー層とを備える電気部品であって、前記電気部品は、抵抗器、キャパシタ、インダクタまたは半導体チップであり、前記ホットメルトポリマー層は、(i)100重量部の銀粉末、および(ii)1〜30重量部のポリマーを含み、前記ポリマーのメルトマスフローレート(MFR)は、120〜200℃および0.3〜8kgfで0.5〜20g/10分である、電気部品。

- 抵抗器、キャパシタ、インダクタまたは半導体チップである電気部品を製造する方法であって、

本体を備える電気部品を提供する工程であって、少なくとも1種の端子電極が前記本体の上に形成される、工程と;

ホットメルトポリマーペーストを前記端子電極に適用する工程であって、前記ホットメルトポリマーペーストは、(i)100重量部の銀粉末、(ii)1〜30重量部のポリマーおよび(iii)溶媒を含み、前記ポリマーのメルトマスフローレートは、120〜200℃および0.3〜8kgfで0.5〜15g/10分である、工程と;

前記適用されたホットメルトポリマーペーストを乾燥させる工程と

を含む方法。 - 端子電極と、前記端子電極上に形成されたホットメルトポリマー層とを備える電気部品であって、前記電気部品は、抵抗器、キャパシタ、インダクタまたは半導体チップであり、前記ホットメルトポリマー層は、(i)100重量部の銀粉末および(ii)1〜30重量部のポリマーを含み、前記ポリマーは、ポリエステル樹脂、フェノキシ樹脂、ノボラック樹脂、エポキシ樹脂、アクリル樹脂、メラミン樹脂、ポリイミド樹脂、ポリアミド樹脂、ポリスチレン樹脂、ブチラール樹脂、セルロース樹脂、ポリビニルアルコール、ポリウレタン樹脂、シリコーン樹脂、およびそれらの混合物からなる群から選択される、電気部品。

Applications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US14/660,203 US20160276303A1 (en) | 2015-03-17 | 2015-03-17 | Electronic component |

| US14/660,203 | 2015-03-17 | ||

| PCT/US2016/022633 WO2016149361A1 (en) | 2015-03-17 | 2016-03-16 | Metallic conductive hot melt paste based on thermoplastic polymer |

Publications (3)

| Publication Number | Publication Date |

|---|---|

| JP2018516755A JP2018516755A (ja) | 2018-06-28 |

| JP2018516755A5 JP2018516755A5 (ja) | 2019-04-18 |

| JP6769986B2 true JP6769986B2 (ja) | 2020-10-14 |

Family

ID=55755669

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| JP2017549240A Active JP6769986B2 (ja) | 2015-03-17 | 2016-03-16 | 熱可塑性ポリマーをベースとした金属導電性ホットメルトペースト |

Country Status (4)

| Country | Link |

|---|---|

| US (2) | US20160276303A1 (ja) |

| JP (1) | JP6769986B2 (ja) |

| CN (1) | CN107533988B (ja) |

| WO (1) | WO2016149361A1 (ja) |

Families Citing this family (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109096975A (zh) * | 2018-07-12 | 2018-12-28 | 常州聚和新材料股份有限公司 | 一种导电性热熔胶粘合剂 |

| US10910340B1 (en) | 2019-10-14 | 2021-02-02 | Heraeus Deutschland GmbH & Co. KG | Silver sintering preparation and the use thereof for the connecting of electronic components |

| US11310950B2 (en) * | 2019-10-22 | 2022-04-19 | International Business Machines Corporation | Liquid metal infiltration rework of electronic assembly |

| WO2021084981A1 (ja) * | 2019-10-29 | 2021-05-06 | パナソニックIpマネジメント株式会社 | ペースト組成物、誘電体組成物、キャパシタ、及び誘電体組成物を製造する方法 |

| WO2022073647A2 (en) * | 2020-10-07 | 2022-04-14 | Alpha Assembly Solutions Inc. | Composition for use in the manufacture of an in-mould electronic (ime) component |

Family Cites Families (18)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5062896A (en) * | 1990-03-30 | 1991-11-05 | International Business Machines Corporation | Solder/polymer composite paste and method |

| US5354918A (en) * | 1992-07-17 | 1994-10-11 | Shin-Etsu Chemical Co., Ltd. | Highly pure monoalkylphosphine |

| JPH08186049A (ja) | 1994-12-28 | 1996-07-16 | Du Pont Kk | 多層コンデンサー用端子電極組成物 |

| JPH09260822A (ja) * | 1996-03-18 | 1997-10-03 | Teikoku Tsushin Kogyo Co Ltd | 基板への半田による電子部品接続固定構造 |

| US6238599B1 (en) * | 1997-06-18 | 2001-05-29 | International Business Machines Corporation | High conductivity, high strength, lead-free, low cost, electrically conducting materials and applications |

| JP3911345B2 (ja) * | 1998-06-18 | 2007-05-09 | Tdk株式会社 | 有機質正特性サーミスタ |

| US6299801B1 (en) * | 1998-11-02 | 2001-10-09 | Tdk Corporation | Organic positive temperature coefficient thermistor |

| JP2001055517A (ja) * | 1999-08-20 | 2001-02-27 | Matsushita Electric Works Ltd | 導電性樹脂組成物およびその製造方法 |

| US6853074B2 (en) * | 1999-12-27 | 2005-02-08 | Matsushita Electric Industrial Co., Ltd. | Electronic part, an electronic part mounting element and a process for manufacturing such the articles |

| US6814795B2 (en) * | 2001-11-27 | 2004-11-09 | Ferro Corporation | Hot melt conductor paste composition |

| JP4389148B2 (ja) * | 2002-05-17 | 2009-12-24 | 日立化成工業株式会社 | 導電ペースト |

| JP3723549B2 (ja) * | 2003-01-30 | 2005-12-07 | 荒川化学工業株式会社 | ハンダ付け用フラックス組成物、クリームハンダ組成物および電子部品 |

| JP4093188B2 (ja) * | 2003-05-27 | 2008-06-04 | 株式会社村田製作所 | 積層セラミック電子部品とその実装構造および実装方法 |

| JP2005120301A (ja) * | 2003-10-20 | 2005-05-12 | Hitachi Chem Co Ltd | 導電性塗料 |

| US8518303B2 (en) * | 2005-03-16 | 2013-08-27 | Hitachi Chemical Company, Ltd. | Adhesive composition, circuit connecting material, connection structure of circuit member, and semiconductor device |

| JP2007069259A (ja) * | 2005-09-09 | 2007-03-22 | Uchihashi Estec Co Ltd | ヤニ入りはんだ |

| JP2007091959A (ja) * | 2005-09-30 | 2007-04-12 | Sumitomo Electric Ind Ltd | 異方導電性接着剤 |

| FR2942673B1 (fr) * | 2009-02-27 | 2011-04-01 | Nexans | Cable electrique a haute tension |

-

2015

- 2015-03-17 US US14/660,203 patent/US20160276303A1/en not_active Abandoned

-

2016

- 2016-03-16 JP JP2017549240A patent/JP6769986B2/ja active Active

- 2016-03-16 WO PCT/US2016/022633 patent/WO2016149361A1/en active Application Filing

- 2016-03-16 CN CN201680022381.0A patent/CN107533988B/zh active Active

-

2017

- 2017-07-12 US US15/647,789 patent/US10186494B2/en active Active

Also Published As

| Publication number | Publication date |

|---|---|

| US20160276303A1 (en) | 2016-09-22 |

| CN107533988A (zh) | 2018-01-02 |

| JP2018516755A (ja) | 2018-06-28 |

| US20170309591A1 (en) | 2017-10-26 |

| US10186494B2 (en) | 2019-01-22 |

| WO2016149361A1 (en) | 2016-09-22 |

| CN107533988B (zh) | 2021-08-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP6769986B2 (ja) | 熱可塑性ポリマーをベースとした金属導電性ホットメルトペースト | |

| CN102084435B (zh) | 金属糊料和油墨 | |

| JP5342453B2 (ja) | 導電性ペーストおよびこれを用いた電気電子機器 | |

| JP5323996B2 (ja) | 加熱接合用材料、加熱接合用コーティング材料、及びコーティング物 | |

| JP6959706B2 (ja) | 電気部品 | |

| KR101293914B1 (ko) | 도전성 잉크 및 이를 이용한 전자소자 | |

| KR102302357B1 (ko) | 도전성 페이스트, 적층 세라믹 부품, 프린트 배선판 및 전자 장치 | |

| US9661756B1 (en) | Nano-copper pillar interconnects and methods thereof | |

| JPWO2014002893A1 (ja) | 異方性導電シート、および、それを用いた電極接合方法 | |

| US20160143145A1 (en) | Electrical device | |

| JP4227482B2 (ja) | 部品内蔵モジュールの製造方法 | |

| WO2014133124A1 (ja) | 導電性微粒子、異方性導電材料、及び、導電接続構造体 | |

| JPH1135904A (ja) | 導電性組成物およびそれを用いた電子機器 | |

| US20160322163A1 (en) | Terminal electrode of electronic component | |

| JP6737506B2 (ja) | 導電性ペースト、チップ電子部品及びその製造方法 | |

| JP4097310B2 (ja) | 多層回路基板の製造方法 | |

| JP3798979B2 (ja) | 導電ペースト及びその使用 | |

| JP5526818B2 (ja) | プリント配線板 | |

| JP2007027173A (ja) | 電子部品実装構造体 | |

| JP2010272502A (ja) | 導電性微粒子、異方性導電材料、及び、接続構造体 | |

| JP3034238B2 (ja) | ビアホール導体用導電性ペースト組成物 | |

| JP2014131026A (ja) | 印刷回路基板及び印刷回路基板の表面処理方法 | |

| JP2009111181A (ja) | 電子部品の表面実装方法 | |

| JP3516983B2 (ja) | プリント基板の製造方法並びに表面実装部品の実装方法 | |

| JP2004249359A (ja) | ハンダペースト及び導電接続構造体 |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20190308 |

|

| A621 | Written request for application examination |

Free format text: JAPANESE INTERMEDIATE CODE: A621 Effective date: 20190308 |

|

| A977 | Report on retrieval |

Free format text: JAPANESE INTERMEDIATE CODE: A971007 Effective date: 20191224 |

|

| A131 | Notification of reasons for refusal |

Free format text: JAPANESE INTERMEDIATE CODE: A131 Effective date: 20200204 |

|

| A521 | Request for written amendment filed |

Free format text: JAPANESE INTERMEDIATE CODE: A523 Effective date: 20200415 |

|

| TRDD | Decision of grant or rejection written | ||

| A01 | Written decision to grant a patent or to grant a registration (utility model) |

Free format text: JAPANESE INTERMEDIATE CODE: A01 Effective date: 20200901 |

|

| A61 | First payment of annual fees (during grant procedure) |

Free format text: JAPANESE INTERMEDIATE CODE: A61 Effective date: 20200924 |

|

| R150 | Certificate of patent or registration of utility model |

Ref document number: 6769986 Country of ref document: JP Free format text: JAPANESE INTERMEDIATE CODE: R150 |

|

| S111 | Request for change of ownership or part of ownership |

Free format text: JAPANESE INTERMEDIATE CODE: R313113 |

|

| R350 | Written notification of registration of transfer |

Free format text: JAPANESE INTERMEDIATE CODE: R350 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |

|

| R250 | Receipt of annual fees |

Free format text: JAPANESE INTERMEDIATE CODE: R250 |